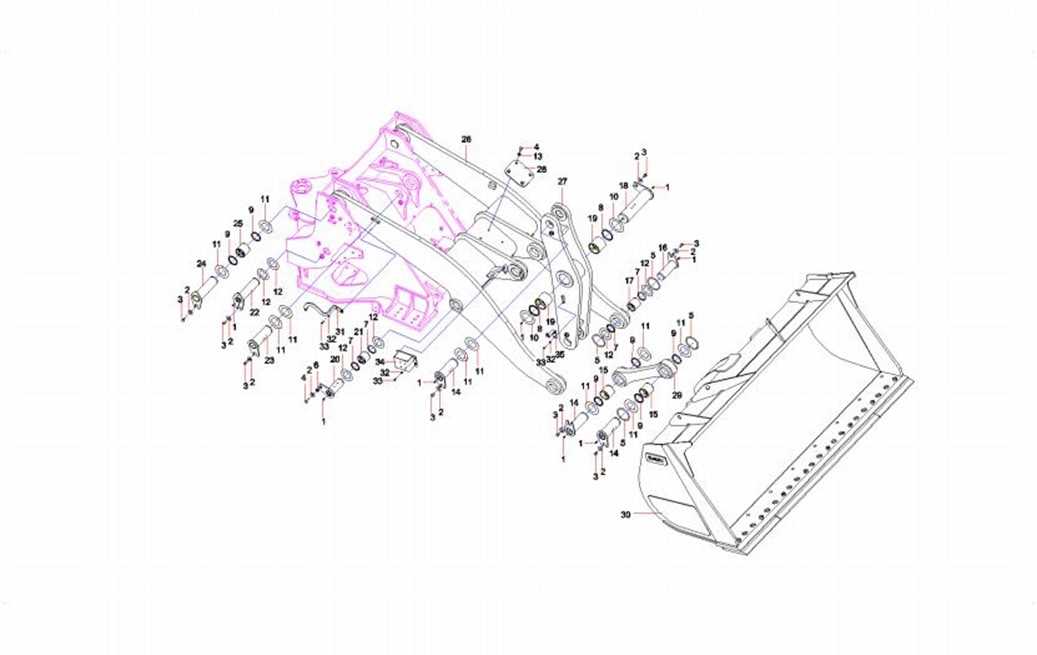

In the realm of agricultural and construction equipment, comprehending the intricate assembly of vital components is essential for efficient operation and maintenance. This section aims to explore the various elements that contribute to the functionality of a specific model, enabling users to enhance their familiarity with each part’s role and importance.

As we delve deeper, you will find a visual representation that simplifies the complexity of these mechanical structures. Each segment is carefully detailed, highlighting connections and interactions that are pivotal for seamless performance. By grasping this information, operators can ensure their machinery remains in optimal condition, ultimately prolonging its lifespan.

Whether you are a seasoned professional or a newcomer, understanding these components will provide you with the ultimate advantage in troubleshooting and repairs. With this knowledge, you can approach maintenance tasks with confidence, ensuring that your equipment operates efficiently and effectively.

Understanding John Deere H240 Loaders

Exploring the functionalities and features of compact machinery is essential for both efficiency and productivity. These versatile implements serve a critical role in various agricultural and construction tasks, enhancing the overall workflow. Familiarity with their components and capabilities can significantly impact operational success.

Key Features

- Enhanced lifting capabilities

- Versatile attachment options

- Efficient hydraulic systems

- User-friendly controls

Applications

- Material handling in construction sites

- Loading and unloading agricultural products

- Landscaping and maintenance tasks

- Site preparation and grading activities

Understanding these elements contributes to maximizing the efficiency and longevity of the equipment, ensuring that operators can tackle a wide range of tasks effectively.

Importance of Loader Parts Diagrams

Understanding the components of heavy machinery is crucial for effective maintenance and repair. Visual representations of these elements provide a clear roadmap, enabling operators and technicians to identify specific sections and their functions easily.

Enhanced Maintenance Efficiency

Comprehending machinery layouts allows for quicker diagnosis of issues, leading to more efficient repairs. This ultimately reduces downtime and enhances productivity on the job site.

Informed Decision-Making

With detailed visuals, users can make informed choices regarding upgrades or replacements. This knowledge fosters confidence in handling machinery and ensures optimal performance.

Key Components of H240 Loaders

Understanding the essential elements of these versatile machinery units is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring functionality, efficiency, and longevity. Here, we will explore the main features that contribute to the effectiveness of these powerful machines.

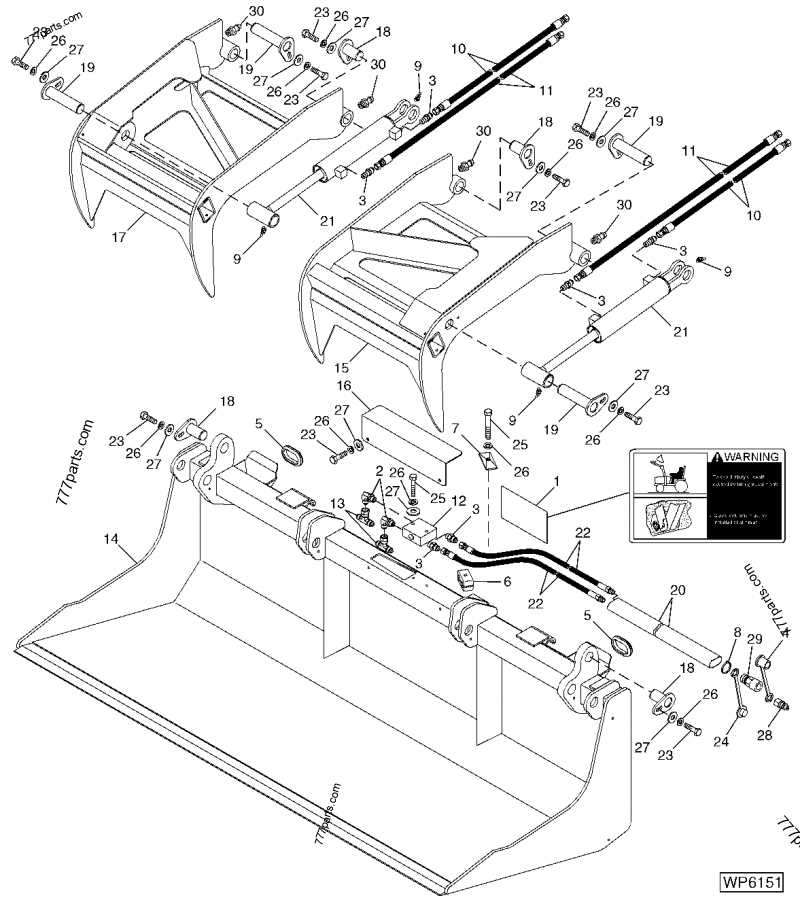

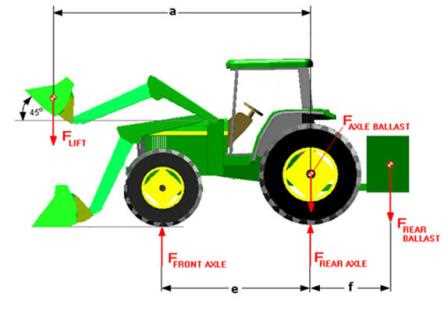

1. Hydraulic System: The hydraulic mechanism is at the heart of performance, allowing for powerful lifting and precise control. This system utilizes fluid pressure to operate various attachments, ensuring seamless operations in diverse environments.

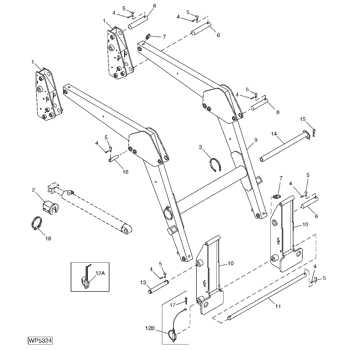

2. Frame Structure: A robust frame serves as the backbone of the unit, providing stability and support during heavy lifting tasks. Its design must balance strength and weight to enhance maneuverability without sacrificing durability.

3. Attachment Interface: The ability to quickly switch attachments is essential for versatility. The connection point must be engineered for easy engagement and disengagement, allowing operators to adapt to various tasks efficiently.

4. Engine: The power source drives all operations, and selecting the right engine is critical. It must deliver the necessary horsepower while maintaining fuel efficiency, contributing to the overall productivity of the equipment.

5. Tires: The choice of tires affects traction, stability, and ground protection. Quality tires ensure optimal performance across different terrains, enhancing safety and operational effectiveness.

Each of these components is designed to work in harmony, ensuring that operators can tackle a wide range of jobs with confidence and ease.

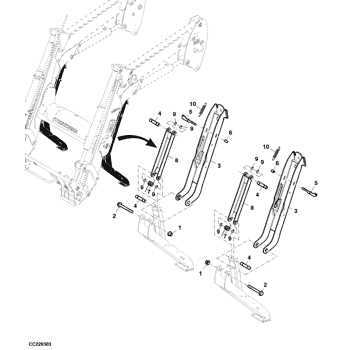

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations provide a clear view of how various elements interact and are organized within a system. Familiarity with these visuals can enhance your ability to identify necessary components and streamline the replacement process.

Begin by observing the overall layout, which typically categorizes sections into groups or clusters. Each area corresponds to specific functionalities, allowing you to locate parts quickly. Pay attention to labels and numbers that correspond to individual elements, as these will guide you in cross-referencing with lists or catalogs for procurement.

Next, note the lines and connections that indicate how pieces fit together. Understanding these relationships is crucial for ensuring that replacements are installed correctly. Additionally, different shading or color coding may highlight various materials or versions of components, which is important for selecting the right items.

Finally, practice interpreting these visuals with real-world examples to build confidence. Familiarity will make it easier to navigate complex assemblies and ensure you have everything needed for successful repairs. A clear comprehension of these illustrations is a valuable skill for any technician or DIY enthusiast.

Common Issues with H240 Loaders

Operating heavy machinery can lead to various challenges that users may encounter over time. Understanding these issues is essential for maintaining efficiency and prolonging the lifespan of the equipment. Regular inspections and prompt repairs can significantly reduce downtime and enhance overall performance.

Hydraulic Problems: One frequent concern is the malfunction of the hydraulic system. Leaks or low fluid levels can result in decreased lifting capacity and slower response times.

Electrical Failures: Electrical components may experience issues such as faulty wiring or blown fuses, leading to operational failures or erratic behavior of the machinery.

Wear and Tear: Over time, components may suffer from wear, particularly in high-use areas. Regular maintenance is crucial to prevent more extensive damage and ensure smooth functionality.

Attachment Compatibility: Users often face challenges with attaching and detaching implements. Ensuring proper alignment and compatibility can prevent unnecessary wear and operational delays.

Addressing these common challenges through routine checks and maintenance can enhance the reliability and performance of the equipment.

Finding Replacement Parts Online

In the digital age, sourcing components for machinery has never been easier. Online platforms offer a vast selection of options, enabling users to quickly locate what they need without the hassle of traditional shopping methods.

Steps to Locate Components

- Identify the specific item you require.

- Use search engines to explore various websites dedicated to machinery supplies.

- Check for reputable vendors and read customer reviews.

Tips for Successful Purchasing

- Compare prices across different platforms.

- Ensure compatibility with your equipment.

- Look for warranties or return policies.

Maintenance Tips for H240 Loaders

Proper upkeep is essential for ensuring the longevity and efficiency of your equipment. Regular maintenance not only enhances performance but also prevents costly repairs down the line. Here are some key practices to follow.

Regular Inspections

- Check fluid levels frequently, including oil and hydraulic fluids.

- Inspect for any signs of wear or damage to components.

- Ensure all connections and fittings are secure and leak-free.

Scheduled Servicing

- Follow the manufacturer’s recommended service intervals.

- Replace filters and fluids as needed to maintain optimal performance.

- Grease moving parts regularly to reduce friction and wear.

Benefits of Using Genuine Parts

Opting for authentic components in machinery maintenance ensures optimal performance and longevity. Genuine items are designed to fit perfectly and work harmoniously with the equipment, minimizing the risk of malfunction and enhancing overall efficiency.

Quality Assurance

Original components undergo rigorous testing and quality control, guaranteeing reliability. This leads to better operational stability, reducing the likelihood of breakdowns and costly repairs. Using authentic products means investing in the durability of the machinery.

Warranty Protection

Utilizing original components often keeps warranties intact. Many manufacturers require the use of certified items to uphold warranty agreements. This protection provides peace of mind, ensuring that any issues that arise will be addressed without additional costs.

DIY Repairs for Loader Components

Maintaining and repairing equipment can be both fulfilling and cost-effective. By understanding the various elements that make up your machinery, you can tackle issues head-on and enhance its longevity. Whether it’s a minor fix or a more complex restoration, having the right knowledge can make all the difference.

Assessing the Issue: Start by carefully examining the equipment to identify the problem. Look for signs of wear or damage that might affect performance.

Gathering Tools: Ensure you have the necessary tools at hand. Common items may include wrenches, pliers, and screwdrivers tailored for your specific task.

Step-by-Step Approach: Break down the repair process into manageable steps. This method not only simplifies the task but also minimizes the risk of overlooking important details.

Testing Your Work: After completing the repairs, conduct a thorough test to ensure everything functions correctly. This final check is crucial for confirming that the issue has been resolved.

Engaging in DIY repairs not only saves money but also deepens your understanding of the machinery you operate.

Upgrades and Modifications for H240

Enhancing the performance and functionality of equipment can significantly improve efficiency and usability. This section explores various enhancements that can be implemented to elevate the capabilities of your machinery, ensuring it meets the demands of various tasks.

Power Enhancements: Increasing the engine’s power output can provide greater lifting capacity and faster operation. Upgrading the air intake system and exhaust can facilitate better airflow, leading to improved engine performance.

Attachment Compatibility: Modifying existing connections or integrating new attachments can broaden the versatility of your machinery. This allows for the use of specialized tools, such as grapples or forks, making it adaptable for various projects.

Hydraulic System Improvements: Enhancing the hydraulic system can lead to faster response times and increased lifting capabilities. Consider upgrading hydraulic hoses and fittings to ensure they can handle higher pressures effectively.

Comfort and Ergonomics: Improving the operator’s experience is crucial for productivity. Upgrading the seat, adding ergonomic controls, or installing better visibility options can greatly enhance comfort during long hours of operation.

Safety Features: Adding or upgrading safety mechanisms, such as roll-over protection systems and improved lighting, can ensure safer operation in various conditions, protecting both the operator and the equipment.

These enhancements not only improve the machine’s performance but also extend its lifespan and make it more enjoyable to operate. Careful planning and execution of these modifications can lead to a more efficient and effective work experience.

Resources for Loader Owners

For individuals managing heavy machinery, having access to reliable resources is essential for maintenance, repairs, and optimal performance. A wealth of information is available to assist operators in understanding their equipment better and ensuring longevity through proper care.

- Online Manuals: Most manufacturers provide comprehensive manuals on their websites, detailing operational procedures and maintenance guidelines.

- Community Forums: Engaging in online communities can connect users with experienced operators who share insights, troubleshooting tips, and personal experiences.

- Videos and Tutorials: Platforms like YouTube host countless videos demonstrating maintenance techniques and repair processes, making it easier to visualize steps.

- Local Dealerships: Authorized dealers often have knowledgeable staff who can provide expert advice and specific recommendations for servicing machinery.

- Parts Suppliers: Numerous online and local suppliers offer a range of components, making it easier to find what is needed for any repair or upgrade.

Utilizing these resources can greatly enhance the ownership experience, ensuring that equipment remains efficient and reliable for years to come.