Understanding the intricate elements that make up a popular lawn maintenance machine is crucial for effective operation and maintenance. These components work in harmony to ensure optimal performance, contributing to the longevity and efficiency of the equipment.

In this section, we will explore the various sections and functionalities of this particular model, focusing on its design and how each part interacts with the others. By breaking down the construction, users can better appreciate the machine’s capabilities and troubleshoot issues more effectively.

Whether you’re a seasoned operator or a newcomer, gaining insight into the essential components enhances your overall experience. This knowledge empowers you to make informed decisions regarding repairs and upgrades, ensuring your machine remains in peak condition.

Understanding John Deere L111 Parts

Gaining insight into the components of your mowing machine can significantly enhance its performance and longevity. Each element plays a crucial role, and knowing their functions helps in effective maintenance and repair. This knowledge ensures your equipment operates smoothly and efficiently.

Key Components Overview

Familiarizing yourself with the essential parts allows for better troubleshooting and upgrades. Below are some vital elements to consider:

| Component | Function |

|---|---|

| Engine | Powers the entire machine for optimal performance. |

| Deck | Houses the cutting blades, influencing cutting height and quality. |

| Transmission | Controls movement and speed for a smooth operation. |

| Wheels | Provide stability and maneuverability on various terrains. |

Importance of Regular Maintenance

Routine inspection and care of each part can prevent unexpected failures and extend the lifespan of your machinery. Understanding these components and their upkeep leads to the ultimate performance and efficiency of your outdoor equipment.

Overview of L111 Specifications

This section provides a comprehensive look at the key characteristics and features of the model, highlighting its functionality and design elements. Understanding these specifications is crucial for users seeking to optimize performance and maintenance.

- Engine Type: The unit is equipped with a reliable powertrain, designed for efficiency.

- Cutting Width: Offers a generous cutting width to enhance productivity during lawn care tasks.

- Transmission: Features a smooth transmission system for ease of operation.

- Fuel Capacity: Equipped with a sizeable fuel tank, allowing for extended use without frequent refueling.

These attributes collectively contribute to the machine’s overall effectiveness, ensuring it meets the demands of various users.

Common Issues with L111 Components

In the realm of outdoor machinery, certain elements often present challenges that can impact overall performance. Understanding these frequent problems is crucial for maintenance and longevity. Below, we explore some prevalent issues associated with various components.

| Component | Common Issue | Potential Solution |

|---|---|---|

| Engine | Hard starting | Check the spark plug and fuel line. |

| Blade | Uneven cutting | Sharpen or replace the blade. |

| Transmission | Slipping gears | Inspect the fluid levels and belts. |

| Battery | Frequent discharges | Test the battery and check connections. |

How to Identify Parts for L111

Understanding the components of your machine is essential for effective maintenance and repair. This guide will help you recognize various elements crucial for optimal performance. By familiarizing yourself with these aspects, you can ensure longevity and reliability.

Utilizing Manufacturer Resources

Consulting official resources is a valuable step. Manuals often include detailed information and illustrations, aiding in the identification of each component. Accessing the manufacturer’s website can also provide you with specific details that enhance your knowledge.

Engaging with Online Communities

Participating in forums and discussion groups can offer insights from experienced users. Sharing information about your machine with others can help you pinpoint parts and learn from real-world experiences. This collaborative approach often leads to a deeper understanding of your equipment.

Benefits of Using Original Parts

Utilizing authentic components for machinery offers numerous advantages that enhance both performance and longevity. These elements are meticulously designed to fit seamlessly, ensuring optimal functionality and reliability.

Quality Assurance: Original components are manufactured under strict quality control standards. This guarantees that each piece meets the required specifications, providing peace of mind regarding durability and effectiveness.

Enhanced Performance: Authentic parts are engineered to work together harmoniously. This synergy improves overall machine efficiency, reducing the likelihood of malfunctions or unexpected breakdowns.

Long-Term Savings: While genuine components may have a higher initial cost, they often lead to significant savings in the long run. Their durability and reliability can minimize repair costs and extend the lifespan of the equipment.

Warranty Protection: Many manufacturers offer warranties on their genuine components. Using these items can help maintain warranty coverage for the machinery, providing additional financial protection against potential issues.

Better Resale Value: Equipment maintained with authentic parts typically retains a higher resale value. Buyers are often willing to pay more for well-maintained machinery, knowing it has been serviced with quality components.

Maintenance Tips for L111 Owners

Proper upkeep of your equipment is essential for ensuring longevity and optimal performance. Regular attention to various components not only enhances efficiency but also prevents costly repairs in the future.

Start by routinely checking the oil levels and changing the oil according to the manufacturer’s recommendations. Clean or replace air filters to maintain airflow and engine performance. Additionally, inspect the blades frequently; sharpening or replacing them will ensure a clean cut and promote healthy growth of your lawn.

Don’t overlook the battery; keeping it charged and free from corrosion will extend its life. Ensure the wheels and tires are properly inflated to facilitate smooth operation. Finally, store your machine in a dry place during off-seasons to protect it from environmental damage.

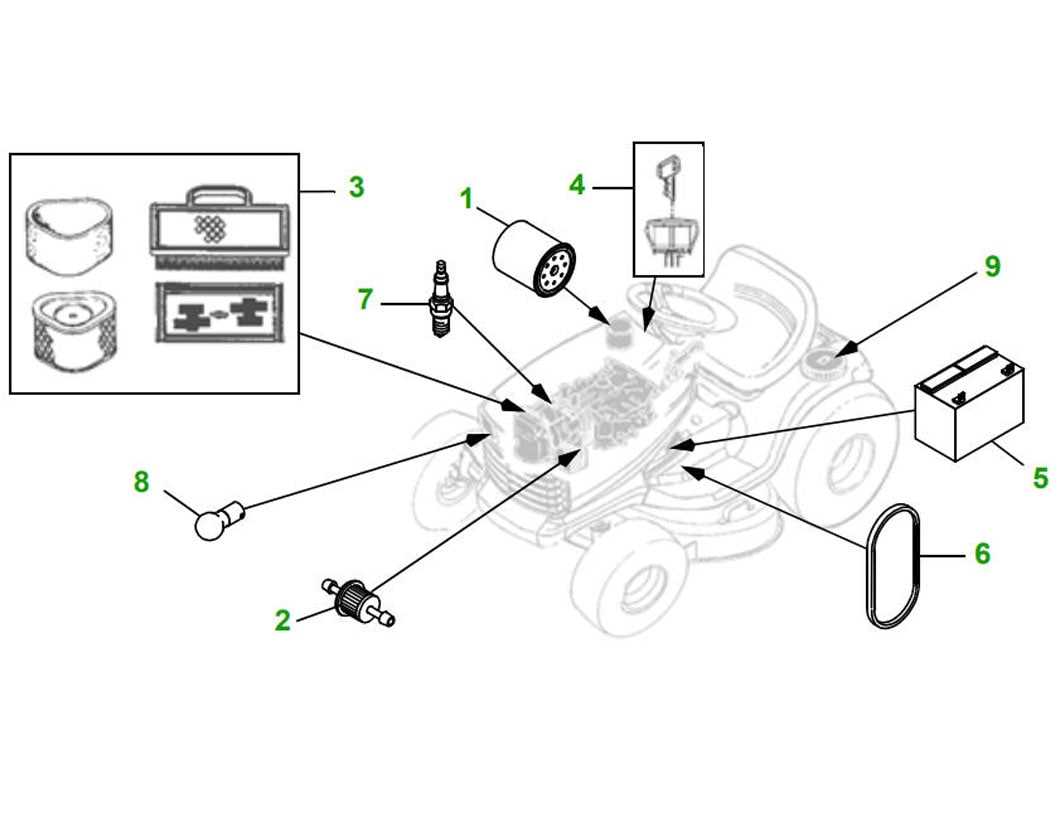

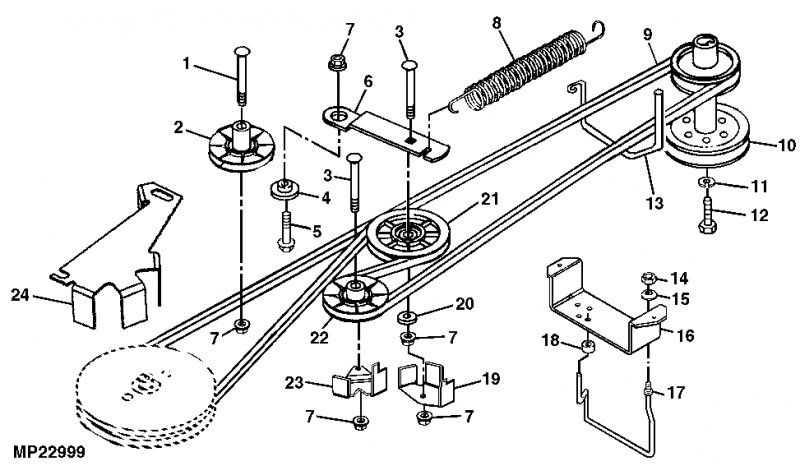

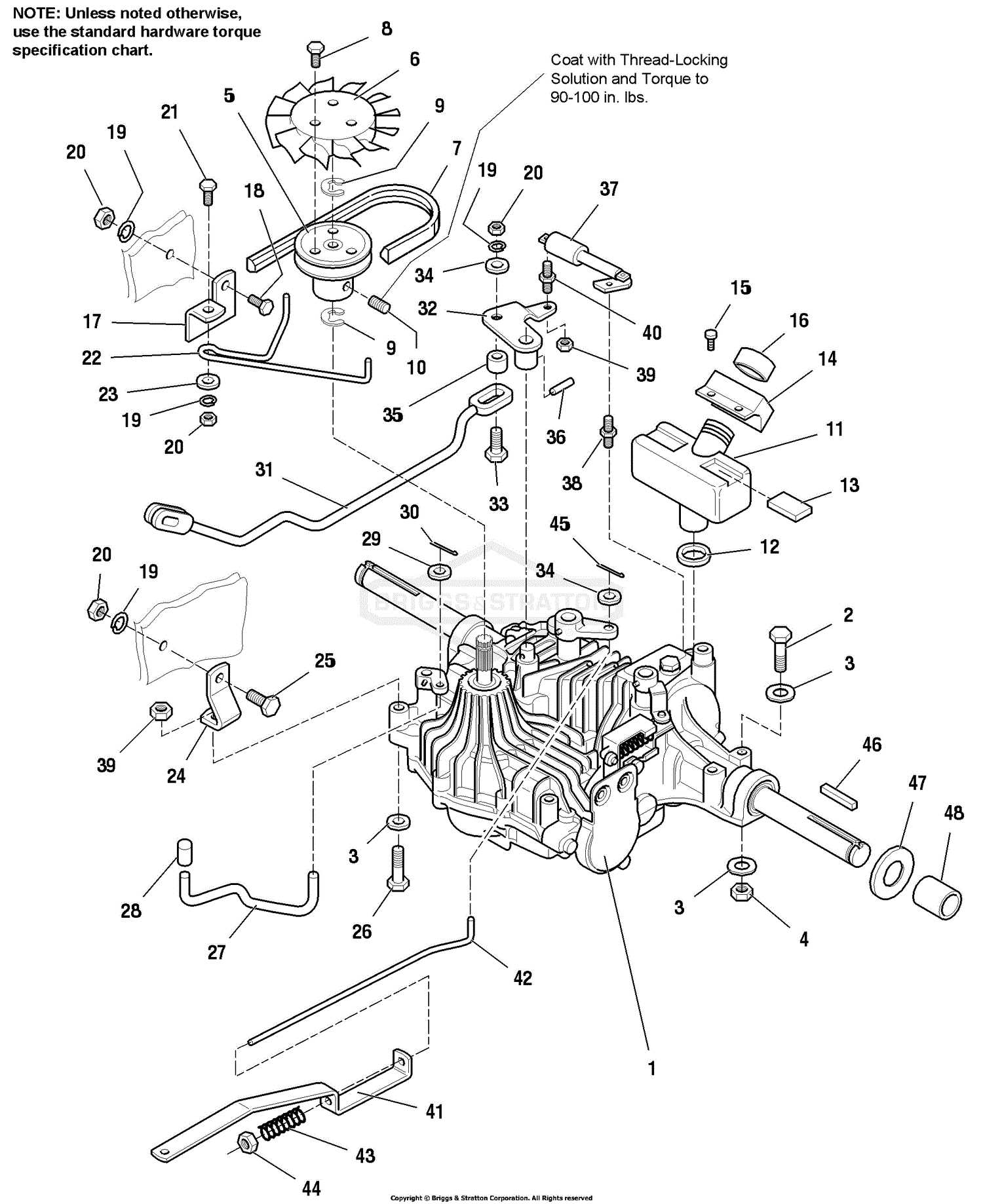

Exploring the Parts Diagram

This section delves into the intricacies of a specific machine’s assembly, providing a visual representation of its components. Understanding the layout and function of each element is essential for effective maintenance and repair. By familiarizing oneself with this visual guide, users can enhance their operational efficiency and ensure longevity of their equipment.

Understanding Component Relationships

The illustration serves as a vital tool for grasping how various pieces interconnect. Each segment plays a crucial role in the overall functionality, and recognizing their relationships can simplify troubleshooting and replacement processes.

Key Components Overview

Below is a table highlighting some of the critical elements within the visual guide, along with their functions:

| Component | Description |

|---|---|

| Engine | Powers the machine and drives its operations. |

| Deck | Forms the base structure, supporting various attachments. |

| Wheels | Facilitate movement across different terrains. |

| Blade | Responsible for cutting grass or other materials. |

| Transmission | Transfers power from the engine to the wheels. |

Utilizing this visual representation empowers users to effectively maintain and operate their machinery, leading to improved performance and reduced downtime.

Where to Buy Replacement Parts

Finding suitable components for your equipment is essential for maintaining its performance and longevity. Several options are available for sourcing these crucial items, each offering unique advantages. Whether you prefer shopping online or visiting a local store, the right choice depends on your specific needs and preferences.

Here are some popular avenues to explore:

- Online Retailers: Websites specializing in machinery components often provide a vast selection and competitive pricing. Look for reputable platforms that offer customer reviews.

- Manufacturer’s Website: Many brands have official online stores where you can find original items designed specifically for your equipment.

- Local Dealers: Visiting nearby distributors can be beneficial, allowing you to receive personalized service and immediate assistance.

- Aftermarket Suppliers: These vendors offer alternative options that may be more affordable while still ensuring compatibility with your machinery.

- Salvage Yards: For those seeking cost-effective solutions, salvage yards can provide used items that are still in good condition.

Before making a purchase, always verify the compatibility of the components with your model. This will help ensure optimal performance and avoid potential issues down the line.

Essential Tools for Repairs

When tackling maintenance tasks, having the right equipment is crucial for efficiency and success. A well-stocked toolkit not only facilitates smoother repairs but also ensures that you can handle any unexpected issues that may arise during the process. Understanding which tools are essential can save time and enhance overall performance.

Basic Hand Tools

Every toolkit should include a variety of hand tools such as wrenches, screwdrivers, and pliers. These versatile items are fundamental for loosening or tightening components and making precise adjustments. Investing in high-quality hand tools can lead to a more enjoyable and effective repair experience.

Power Tools

For more complex tasks, power tools like drills and impact wrenches can significantly speed up the process. These tools offer enhanced power and efficiency, allowing for quicker completion of repairs. Choosing the right power tools can elevate your repair capabilities to the next level.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues encountered with your equipment. By following a systematic method, you can ensure that repairs are efficient and effective, ultimately prolonging the life of your machinery.

Step 1: Diagnosis

Begin by identifying the symptoms your equipment is displaying. Listen for unusual sounds, check for leaks, and observe any performance issues. Documenting these observations will aid in pinpointing the root cause.

Step 2: Gather Tools and Supplies

Before starting any repair, collect all necessary tools and materials. Having everything at hand will streamline the process and reduce downtime. Ensure that you have safety gear, such as gloves and goggles, for protection.

Step 3: Disassembly

Carefully disassemble the components related to the issue. Follow the order of removal to avoid losing parts or causing further damage. Take photos during disassembly to assist with reassembly later.

Step 4: Inspection

Once disassembled, inspect each part for wear and tear. Look for cracks, rust, or any other signs of damage. It may be necessary to replace certain components if they are beyond repair.

Step 5: Repair or Replace

Decide whether to repair the damaged parts or replace them entirely. If opting for repair, use appropriate techniques and tools to restore functionality. For replacement, ensure that new parts match the specifications required.

Step 6: Reassembly

Begin reassembling the equipment in the reverse order of disassembly. Refer to the photos taken earlier to ensure accuracy. Tighten all bolts and connections securely to prevent future issues.

Step 7: Testing

After reassembly, conduct a thorough test of the machinery. Monitor for any irregularities and verify that all functions operate as intended. Make adjustments if necessary.

Step 8: Maintenance

Implement a regular maintenance schedule to prevent future breakdowns. Cleaning, lubricating, and inspecting your equipment regularly will help maintain optimal performance and longevity.

Upgrading Your L111: Options

Enhancing the performance and functionality of your equipment can significantly improve your gardening or landscaping tasks. Various upgrades are available to boost efficiency, comfort, and durability. Exploring these options can help you tailor your machine to better meet your specific needs.

Performance Enhancements

- Engine Upgrades: Consider a more powerful engine for improved speed and efficiency.

- Transmission Modifications: Upgrading to a more advanced transmission can enhance handling and control.

- Blade Options: Switching to high-performance blades can increase cutting efficiency and reduce maintenance time.

Comfort and Usability

- Seat Replacement: Upgrading to a more comfortable seat can reduce fatigue during long hours of operation.

- Steering Wheel Additions: Adding ergonomic steering wheel grips can enhance control and comfort.

- Attachment Accessories: Investing in various attachments can expand the functionality of your equipment for different tasks.

Frequently Asked Questions About L111

This section aims to address common inquiries regarding a popular model of garden machinery, providing clarity and insights for users seeking information on maintenance and functionality.

What maintenance is required for optimal performance?

Regular upkeep, including oil changes, filter replacements, and blade sharpening, is essential to ensure longevity and efficiency.

Where can I find replacement components?

Replacement elements can typically be sourced from authorized dealers, online marketplaces, or specialized retailers offering a wide selection.

How do I troubleshoot common issues?

Identifying problems often involves checking fuel levels, battery conditions, and inspecting belts and cables for wear or damage.

What are the specifications of this model?

Specifications can vary, but typical features include engine size, cutting width, and transmission type, all of which influence performance.

Can I upgrade or customize my equipment?

Yes, numerous aftermarket enhancements are available, allowing users to tailor their machinery to better suit specific needs and preferences.