When maintaining outdoor machinery, understanding the layout and functionality of its individual components is essential for smooth operation and long-lasting performance. By exploring the different elements of your equipment, you can better identify any potential issues and ensure that replacements or repairs are conducted efficiently.

Knowing the specific features of various mechanical parts can help extend the lifespan of your equipment, ensuring it runs at peak performance. Each component plays a crucial role in the overall functionality, so a detailed exploration of these elements can make all the difference when it comes to troubleshooting or routine upkeep.

Having a clear understanding of your machine’s structure will not only help you perform regular maintenance with ease but will also enable you to make informed decisions about replacements, adjustments, and potential

Understanding the Components of a Popular Lawn Tractor

The efficient operation of any lawn tractor relies on a variety of essential elements working together. Each component plays a crucial role in maintaining the machine’s performance, from its engine to the smallest fittings. Knowing how these pieces function not only helps in daily operation but also in identifying potential issues and ensuring proper maintenance.

Key Engine and Transmission Features

The engine and transmission systems are the core of any lawn tractor. The engine provides the necessary power, while the transmission ensures smooth movement and control. Regular maintenance of these elements is important for ensuring long-term reliability and peak efficiency during use.

Additional Mechanisms to Consider

Beyond the engine and transmission, other important mechanisms include the cutting deck, steering system, and electrical wiring. These are critical for effective grass cutting, maneuvering, and powering the tractor’s various systems

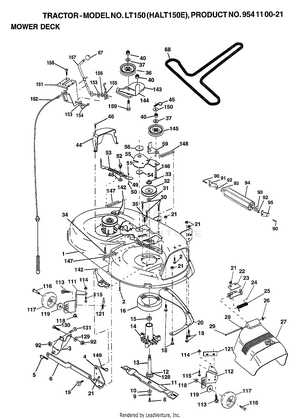

Key Components of the LT150 Mower

The efficient operation of any lawn equipment relies on a combination of essential mechanical and structural elements. Understanding these core components helps in ensuring proper maintenance, smooth performance, and longevity of the machine. Each part plays a pivotal role in achieving a seamless mowing experience.

Engine and Transmission

At the heart of the mower lies its engine, providing the necessary power for cutting and maneuvering. The transmission system, in turn, ensures that the power is smoothly delivered to the wheels, offering variable speed control and a consistent mowing experience.

Cutting Deck and Blades

The cutting deck houses the blades responsible for trimming grass. This part is designed for efficient grass cutting, with the sharp blades ensuring a clean and even cut. Regular maintenance of the deck and blades is crucial for optimal mowing performance.

Engine Layout and Specifications Overview

The engine layout provides a clear understanding of how components are arranged and connected, ensuring efficient performance and easy maintenance. This section outlines the key structural elements and core features of the engine, offering insights into its configuration and functionality without delving into technical specifics.

Component Arrangement

The engine’s design follows a logical structure, where key components such as the cylinder block, pistons, and fuel system are organized for optimal performance. The arrangement ensures that power is delivered smoothly and consistently, while accessibility for routine inspections is maintained.

Key Performance Metrics

Several important specifications define the engine’s performance, including power output, displacement, and torque. These parameters are critical for understanding the engine’s capability under various operating conditions, helping users gauge its reliability and efficiency in different applications.

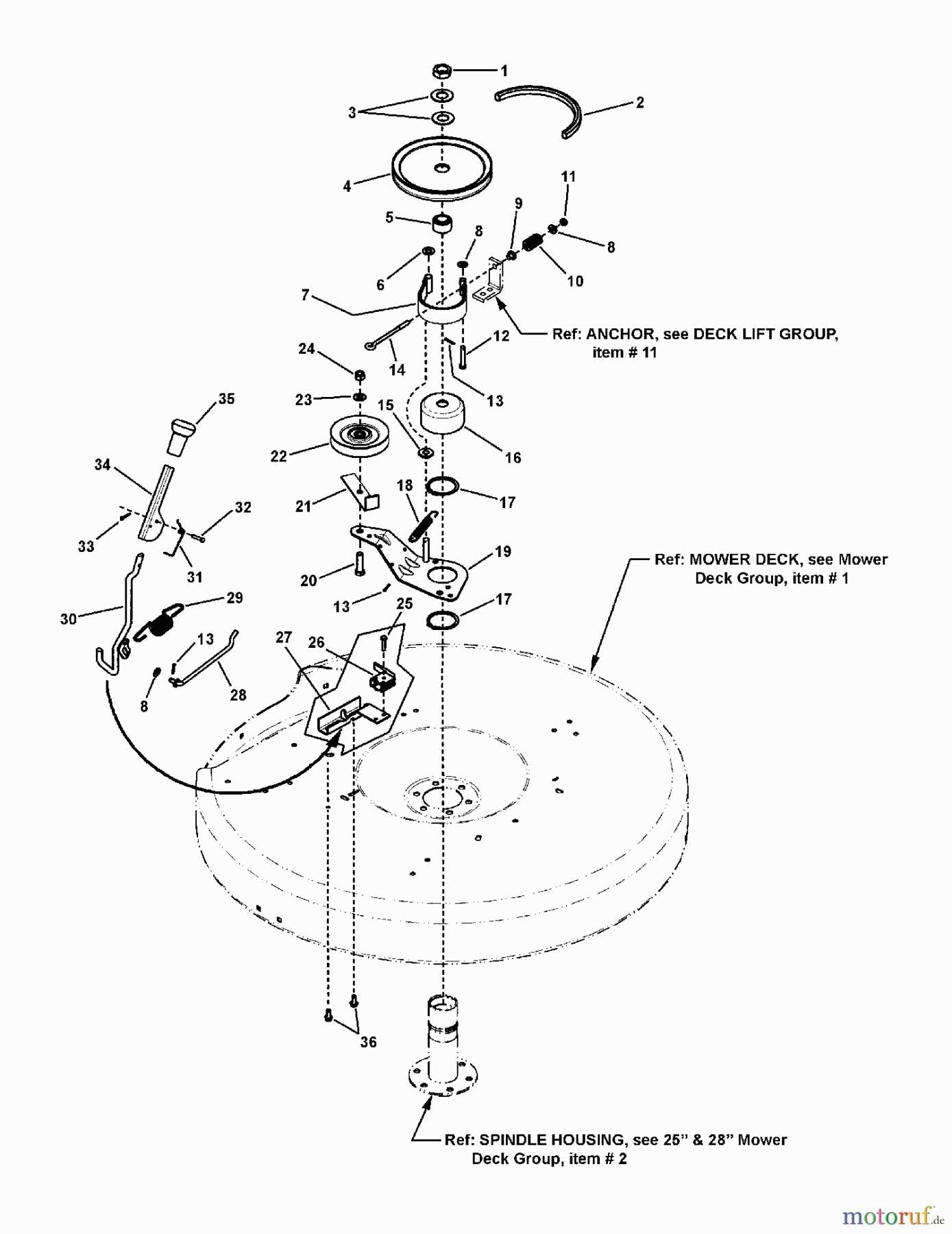

Blade Assembly and Maintenance Tips

Proper assembly and care of the cutting blade are essential for achieving efficient performance and prolonging the lifespan of your equipment. Regular maintenance and correct installation can prevent issues like uneven cutting, excessive wear, and potential damage to the machine.

Steps for Blade Installation

When installing a new blade, always ensure it is securely fastened and positioned correctly to guarantee safe operation. Make sure the sharp edge faces in the correct direction, and the bolts are tightened properly to avoid any imbalance during rotation.

Routine Blade Care

Sharpening the blade periodically ensures clean and precise cuts, which helps maintain the overall health of your lawn. It’s also crucial to inspect the blade for signs of wear, cracks, or damage, and replace it if necessary to maintain safety and functionality.

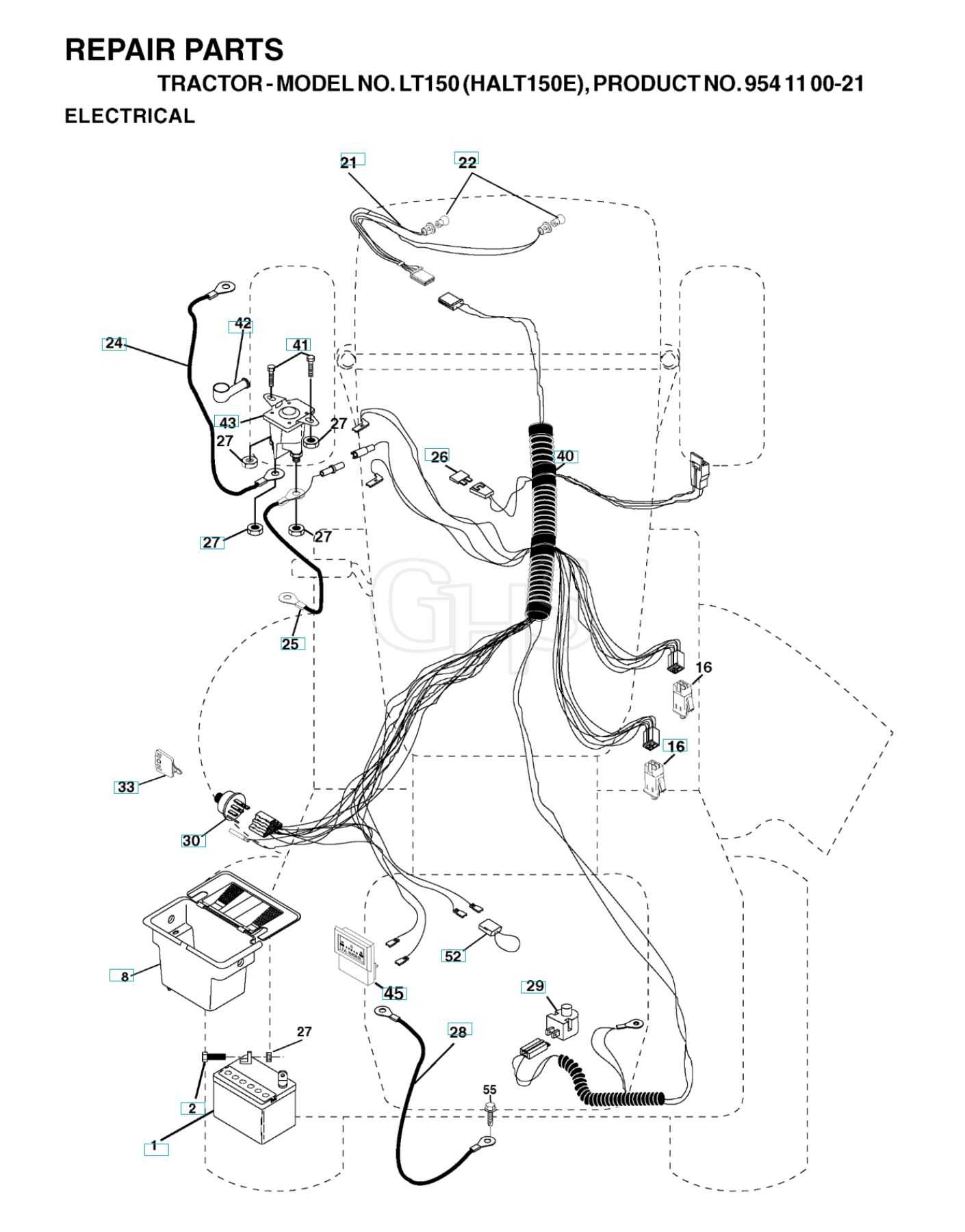

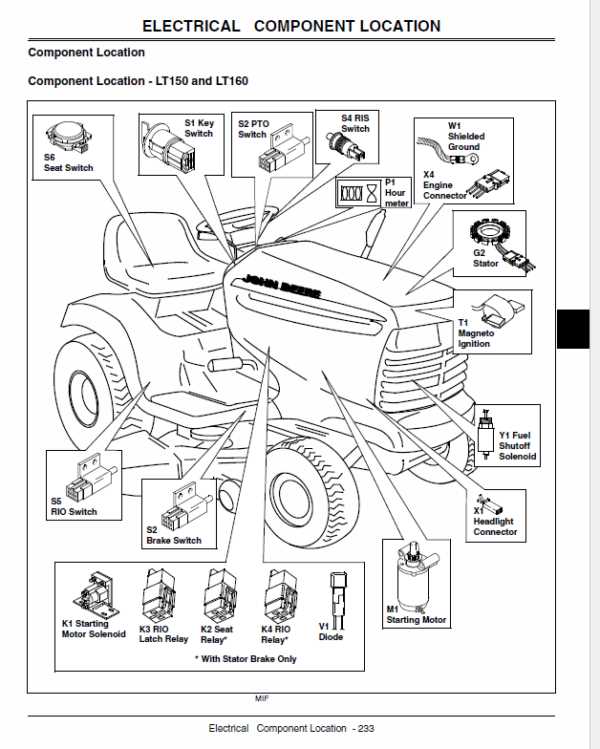

Electrical System and Wiring Diagram Guide

The electrical system in any machinery plays a crucial role in ensuring that all components operate efficiently and safely. A clear understanding of the system’s layout and connections is essential for maintenance and troubleshooting. The wiring layout provides a detailed overview of the connections between various electrical components, which helps in diagnosing potential issues and performing necessary repairs.

Main Components of the Electrical System

Key elements include the battery, ignition system, alternator, and various switches and relays. Each of these components is interconnected through a series of wires and connectors, ensuring smooth operation. Regular checks of the wiring are vital to prevent malfunctions and ensure that all parts receive adequate power.

Wiring Maintenance Tips

To maintain the efficiency of the electrical system, it is important to inspect wires for wear, fraying, or corrosion. Secure connections,

Fuel System Breakdown for Efficient Performance

The fuel system is a crucial component in ensuring optimal functionality and performance of any machinery. Understanding its intricacies can lead to improved efficiency and longevity. This section delves into the key aspects of the fuel system, highlighting its components and their roles in maintaining effective operation.

Key Components of the Fuel System

- Fuel Tank: Stores the fuel, providing a reservoir that feeds the engine.

- Fuel Pump: Delivers fuel from the tank to the engine, ensuring consistent flow and pressure.

- Fuel Filter: Removes impurities and contaminants from the fuel, protecting the engine from damage.

- Fuel Injectors: Atomize the fuel, allowing for efficient combustion within the engine cylinders.

- Carburetor (if applicable): Mixes air with fuel in the appropriate ratio for combustion in engines not equipped with fuel injection.

Maintenance Tips for Optimal Performance

- Regularly check and replace the fuel filter to prevent clogging.

- Inspect fuel lines for leaks or cracks to ensure proper flow.

- Clean or replace injectors as needed to maintain efficient fuel atomization.

- Monitor fuel levels to avoid running the engine on empty, which can lead to debris entering the fuel system.

- Use high-quality fuel to minimize deposits and improve combustion efficiency.

By understanding and maintaining the fuel system, operators can significantly enhance the performance and reliability of their machinery, leading to more efficient operations and reduced downtime.

Transmission and Drive Belt Configuration

The configuration of the transmission and drive belt is crucial for the optimal functioning of any lawn care equipment. Understanding the arrangement of these components ensures that the machinery operates smoothly, enhancing efficiency and longevity. Proper alignment and tension of the drive belt directly influence the performance of the transmission system, which is responsible for transferring power from the engine to the wheels.

Components Overview

The transmission system comprises several essential components, including gears, pulleys, and the drive belt itself. Each part plays a significant role in the overall functionality. The drive belt connects the engine to the transmission, allowing for the seamless transfer of power. Ensuring that these elements are in good condition and correctly positioned is vital for preventing operational issues.

Maintenance Tips

Regular inspection of the drive belt for wear and proper tension is recommended to maintain optimal performance. Replacing a worn or damaged belt can prevent further complications within the transmission system. Additionally, keeping the pulleys clean and free from debris will enhance the effectiveness of the drive mechanism.

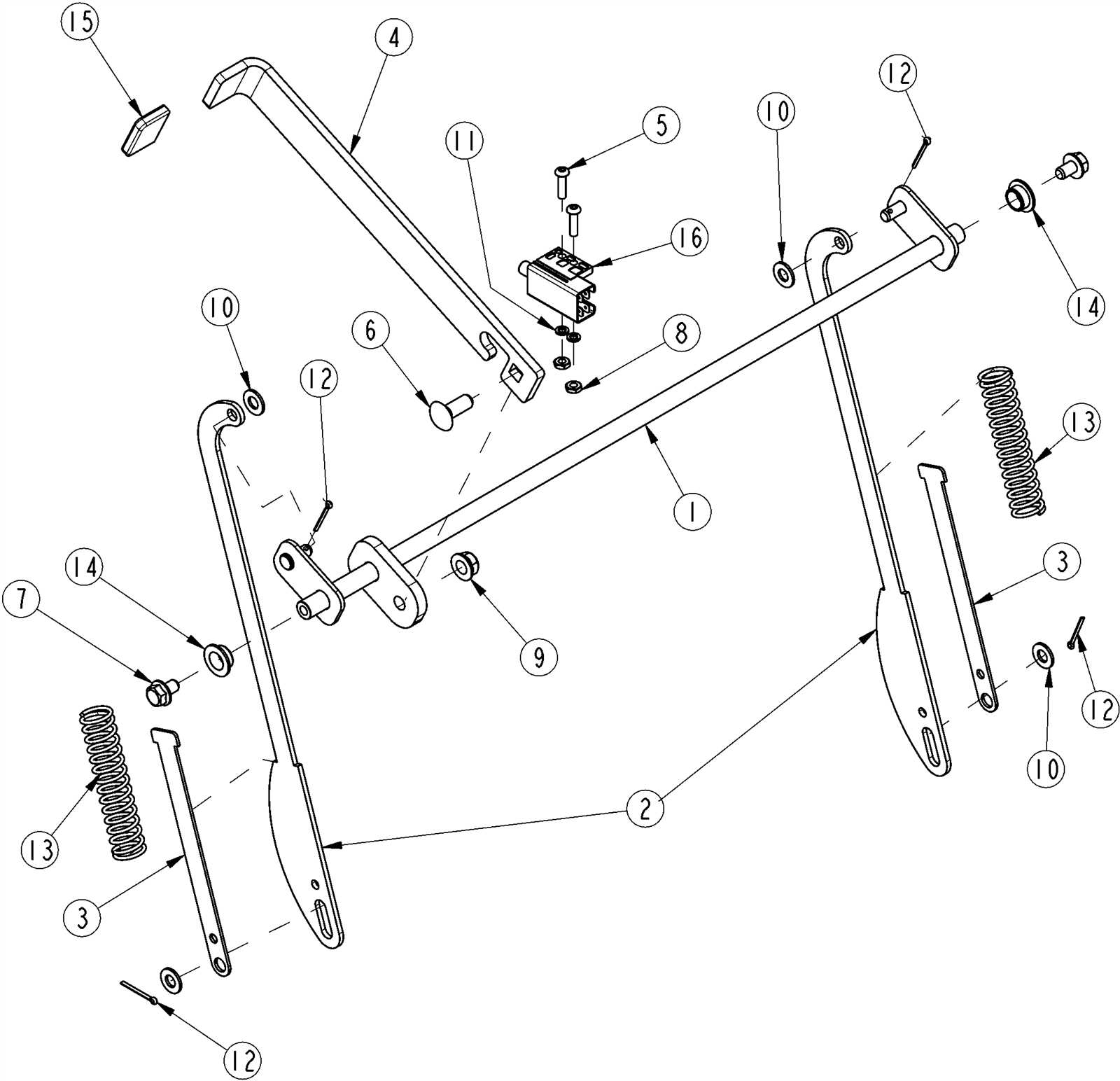

Steering Mechanism and Parts Layout

The steering system of a lawn tractor is crucial for maneuverability and control. This mechanism enables operators to navigate various terrains with ease, ensuring a smooth and precise operation. Understanding the arrangement and function of the components involved is essential for maintenance and repairs.

Key components of the steering system include:

- Steering Wheel

- Steering Column

- Sector Gear

- Spindle Assembly

- Drag Link

- Pivot Bracket

The layout of these elements plays a significant role in the overall performance of the vehicle. Each part contributes to the effectiveness of the steering process:

- Steering Wheel: Provides the interface for the operator to direct the vehicle.

- Steering Column: Connects the wheel to the rest of the mechanism, allowing for smooth transmission of movement.

- Sector Gear: Translates the rotational motion from the wheel into lateral movement.

- Spindle Assembly: Facilitates the rotation of the front wheels, allowing for turns.

- Drag Link: Connects the sector gear to the spindle, ensuring responsive steering.

- Pivot Bracket: Acts as the anchor point for the steering system, allowing for controlled movement.

Regular inspection and maintenance of these components can help prevent steering issues and ensure the longevity of the vehicle.

Hydraulic System Components and Functionality

The hydraulic system is a vital part of many machinery, providing the necessary power to operate various functions. Its efficiency relies on several interconnected components that work together to ensure smooth operation and effective performance. Understanding these elements is essential for proper maintenance and troubleshooting.

Key Components

At the heart of the hydraulic system are several critical components. These include the hydraulic pump, which generates pressure; hydraulic cylinders that convert hydraulic energy into mechanical force; and valves that control the flow of fluid throughout the system. Each component plays a specific role in facilitating the transfer of power and ensuring that the system operates optimally.

Functionality Overview

The functionality of a hydraulic system is based on the principles of fluid mechanics. When the pump is activated, it moves hydraulic fluid through the system, creating pressure that drives the cylinders. This process enables the machinery to perform tasks such as lifting, steering, and other movements. Regular checks on the components and fluid levels are necessary to maintain system performance and prevent breakdowns.

Deck Lift System and Adjustments

The deck lift system plays a crucial role in the overall functionality of lawn maintenance equipment. It allows users to raise and lower the cutting deck, enabling efficient grass cutting at various heights. Proper adjustment and maintenance of this system are essential for achieving optimal performance and ensuring a clean cut.

To effectively manage the deck lift system, consider the following key points:

- Regularly check the lift mechanism for wear and tear.

- Ensure all connections are secure and free of debris.

- Adjust the lift height according to the type of grass and desired cutting results.

Here are some steps for adjusting the lift system:

- Locate the adjustment lever or knob, typically found near the operator’s seat.

- Raise or lower the deck to the preferred cutting height.

- Test the functionality by operating the equipment and making further adjustments as necessary.

By maintaining the deck lift system and making precise adjustments, users can enhance the efficiency of their lawn care tasks and extend the lifespan of their equipment.

Troubleshooting Common LT150 Issues

Identifying and resolving common problems in lawn care equipment can significantly enhance performance and prolong its lifespan. Understanding the typical challenges faced during operation helps users take proactive measures to ensure efficient functionality.

Starting Problems: If the machine fails to start, check the battery and connections. A weak or dead battery can hinder ignition, while corroded terminals may impede electrical flow. Ensure the fuel is fresh and the tank is adequately filled.

Engine Performance: If the engine runs roughly or loses power, inspect the air filter for clogs. A dirty filter restricts airflow, affecting combustion efficiency. Additionally, examining the spark plug for wear can help maintain optimal engine function.

Cutting Issues: Uneven cutting may be a result of dull blades. Regularly sharpening or replacing the blades ensures a clean cut. Furthermore, checking tire pressure can aid in achieving an even cutting height.

Overheating: If overheating occurs, verify that the cooling system is free from debris. A blocked cooling fan or radiator can lead to excessive heat buildup. Cleaning these components regularly will help prevent overheating and potential damage.