In this section, we delve into the intricate details of the various elements that compose the functioning mechanism of the LX172. We dissect its internal framework to understand the synergy between its diverse components, each playing a pivotal role in its operational prowess.

Unveiling the inner workings requires a keen eye for detail, as we uncover the interconnections and dependencies that characterize its structural integrity. This exploration not only reveals the physicality but also sheds light on the functional significance of each part, emphasizing their collective contribution.

Through this analysis, we aim to provide a comprehensive overview, highlighting key aspects through a nuanced lens that captures the essence of its engineering design. Stay tuned as we embark on a journey through the intricacies of its assembly, uncovering insights that define its operational efficiency.

Overview of Lawn Tractor Components

Lawn tractors consist of several key elements designed to work together, ensuring smooth operation and efficient grass management. These machines are built to handle a variety of tasks, from cutting large areas of grass to managing various attachments for other outdoor duties. Understanding the primary sections of the tractor helps in maintaining its longevity and performance.

Engine and Powertrain

The engine provides the necessary power for driving the tractor and running the cutting blades. Connected to the transmission, the powertrain converts engine output into motion, allowing for easy maneuverability across different terrains. Regular maintenance of this system is crucial to ensure optimal performance over time.

Cutting Mechanism and Deck

The cutting deck, housing the blades, plays a pivotal role in trimming grass to the desired height. Adjustable height settings allow for customization, making it possible to achieve uniform results. The blades are designed to handle different grass

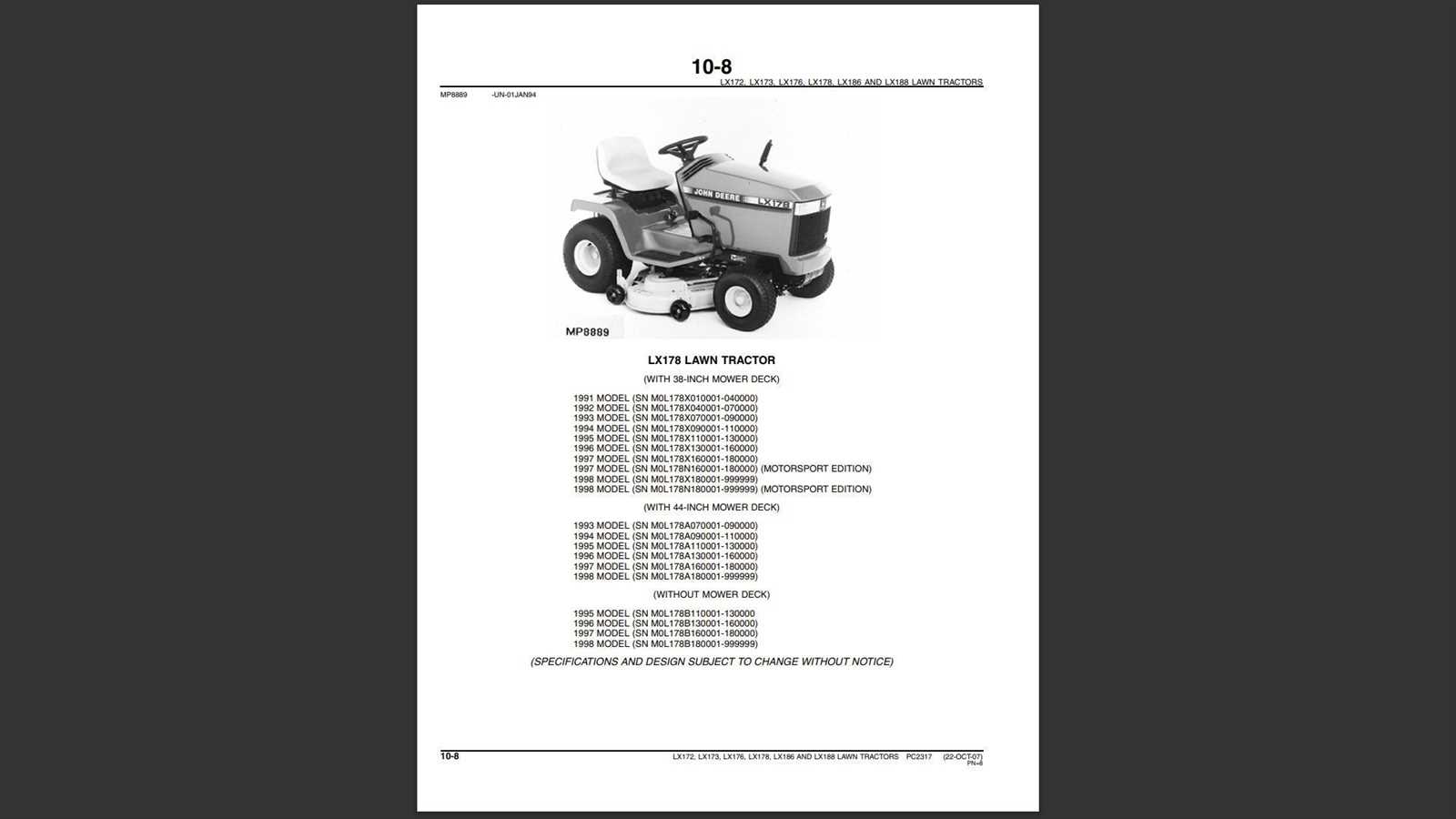

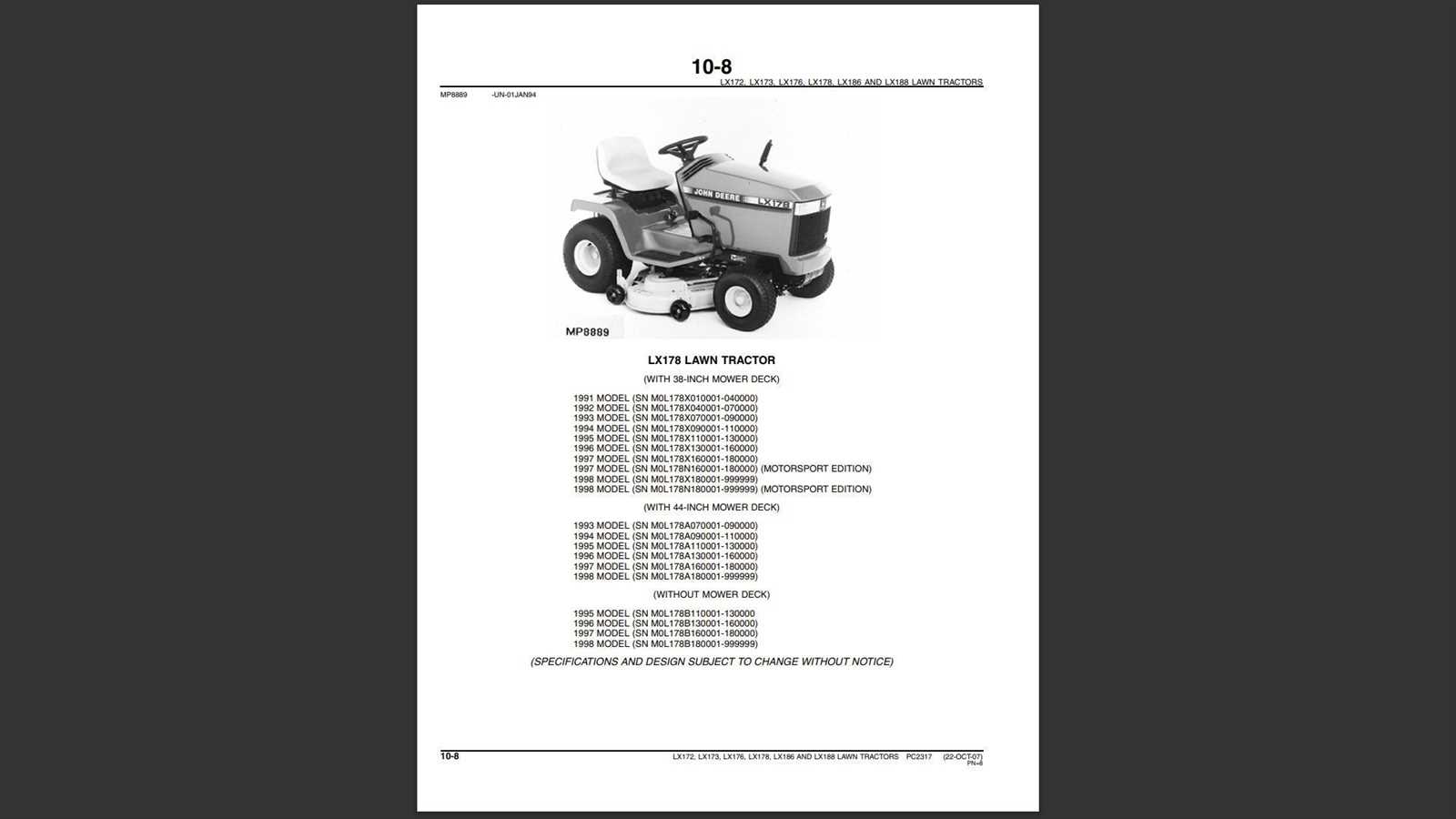

Key Features of LX172 Model

This model stands out due to its versatile design and focus on delivering efficient performance in various applications. Known for its reliability, it has been engineered to meet the demands of users looking for both durability and ease of operation. The robust construction ensures that it can handle a range of tasks, making it a valuable addition to any collection of equipment.

The machine integrates a well-balanced engine system, offering steady power and smooth handling. Its ergonomic design ensures that operators can work comfortably for extended periods, while the intuitive controls make it easy to maneuver in tight spaces. This blend of functionality and user-friendly operation enhances its appeal to both experienced users and newcomers alike

Understanding Engine and Performance Specs

Exploring the key aspects of engine capabilities and performance metrics is essential for understanding how machinery operates effectively. By evaluating technical attributes, such as power output, fuel consumption, and efficiency, users can gauge overall reliability and the potential longevity of equipment.

| Feature |

Specification |

| Power Output |

14 HP |

| Engine Type |

4-Stroke, Single Cylinder |

| Fuel Capacity |

3.5 gallons |

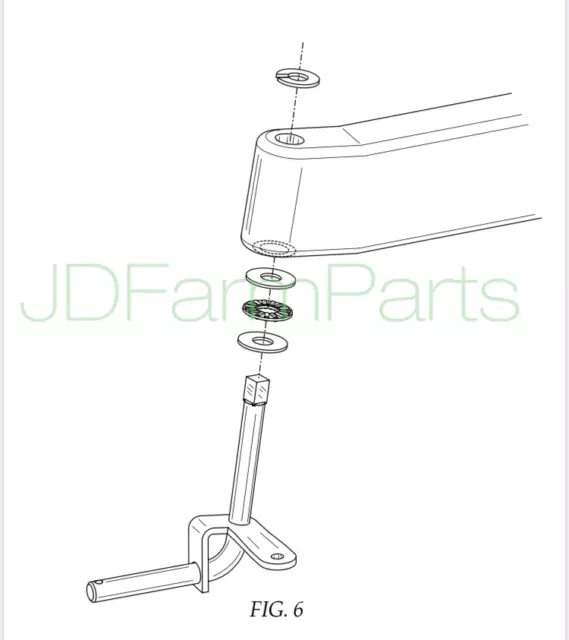

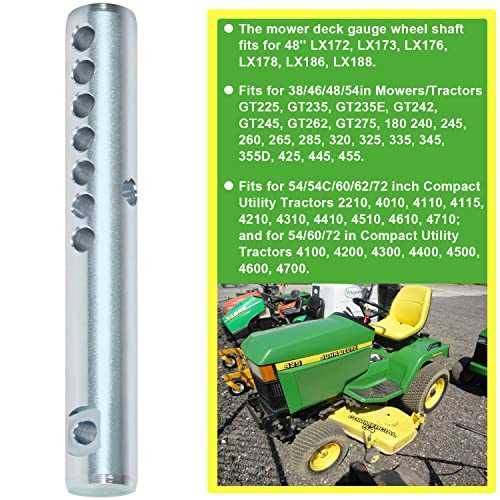

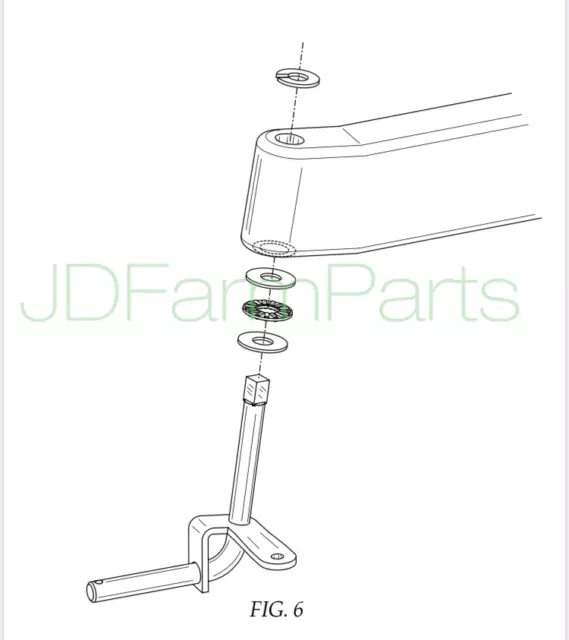

Examining the Cutting Deck Structure

The design of the cutting deck plays a vital role in ensuring efficient performance in lawn maintenance machinery. Its structure impacts both the quality of the cut and the machine’s overall functionality. The placement of essential components within the deck, as well as their interrelation, determines how effectively the system handles grass cutting and discharge.

A well-engineered cutting deck must strike a balance between durability and smooth operation. Elements such as blades, pulleys, and the housing are designed to work in harmony, offering stability and precision during use. Attention to these aspects enhances both the lifespan of the system and its cutting efficiency, ensuring reliable operation for extended periods.

Regular maintenance of the deck’s elements helps prevent wear, ensuring optimal function. Adjustments to the blade positioning or tension of the system components can be necessary for maintaining peak performance, especially in varied grass conditions or terrain.

Drive System and Maintenance Tips

The drive system of your equipment plays a crucial role in its performance and longevity. Proper maintenance ensures smooth operation and prevents premature wear and tear.

Regular Inspections

- Perform routine checks of the drive components to detect any signs of wear or damage.

- Inspect belts, pulleys, and gears for proper tension and alignment.

- Look for leaks or unusual noises that could indicate potential issues.

Lubrication and Cleaning

- Keep the drive system well-lubricated according to manufacturer recommendations.

- Clean debris and dirt from belts and pulleys to prevent slippage and overheating.

- Use appropriate cleaning agents and tools to maintain cleanliness without damaging components.

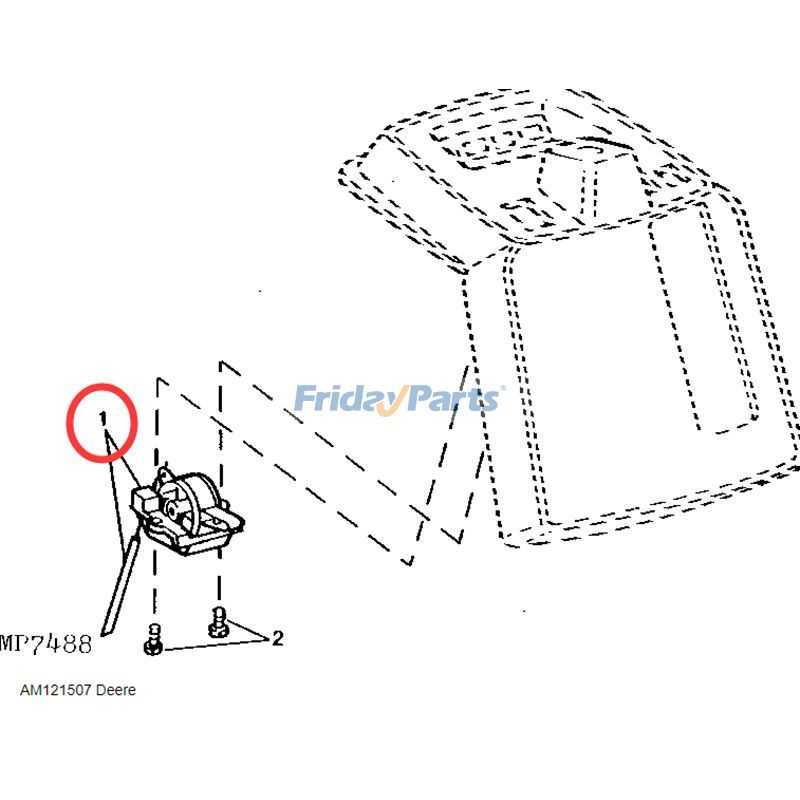

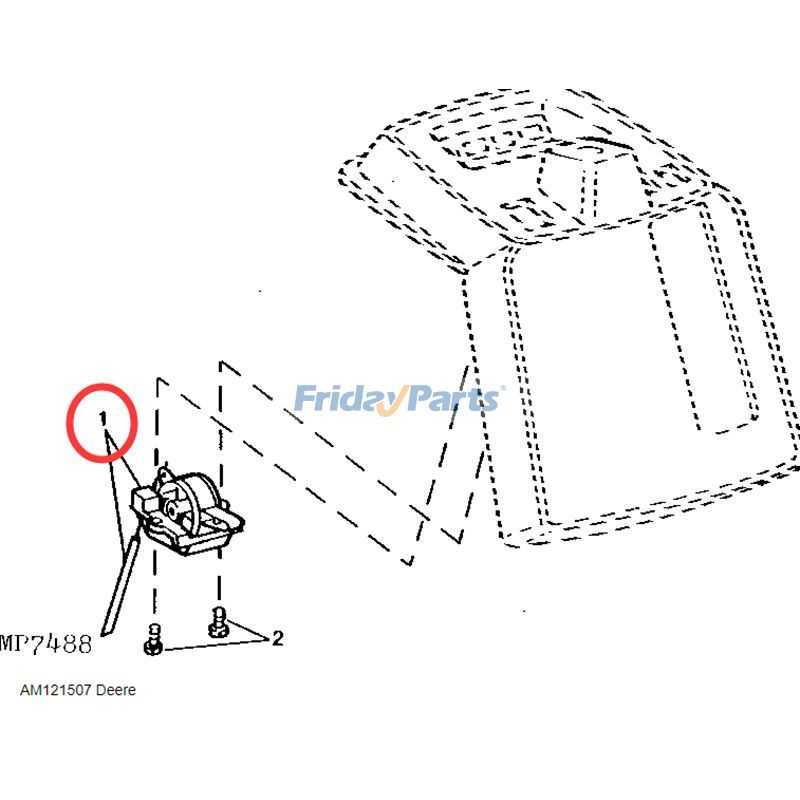

Steering and Suspension Mechanisms

The steering and suspension systems play a crucial role in providing stability and maneuverability. These components ensure that the machine responds smoothly to directional changes while maintaining balance over various terrains. Properly functioning mechanisms contribute to enhanced control and overall safety during operation.

Key elements involved in these systems include:

- Steering linkage, which connects the wheel to the control system.

- Shock absorbers, responsible for cushioning the ride and reducing vibrations.

- Suspension arms, allowing the wheels to move independently and absorb impact from uneven surfaces.

- Ball joints and bearings, enabling smooth pivoting and wheel movement.

Maintaining these mechanisms is essential for optimal performance, ensuring the equipment handles various conditions without compromising safety or control.

Electrical System and Battery Insights

The electrical network in machinery is essential for maintaining operational efficiency, powering key components, and ensuring smooth performance. A well-maintained power source is crucial for both starting the engine and keeping the electronics running optimally. Understanding how the power and charging systems work can help prevent unexpected failures and prolong the lifespan of the vehicle.

Key Components of the Power System

- Battery: Provides the initial energy required to start the machine and supports the electrical systems.

- Charging Mechanism: Regulates the energy supply, ensuring the battery is consistently charged while the engine operates.

- Wiring Network: Connects various electrical elements, facilitating the seamless flow of current.

Maintaining the Power Supply

- Regularly inspect the battery for any signs of wear, including

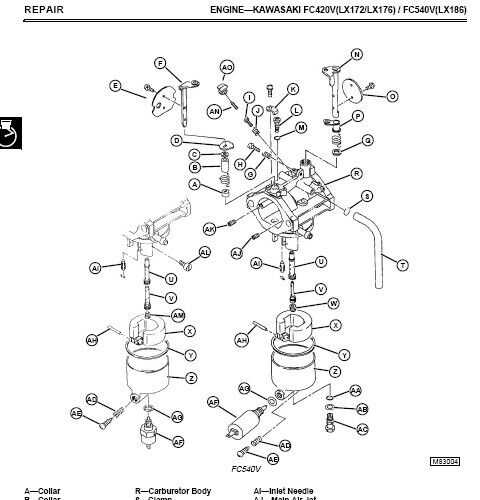

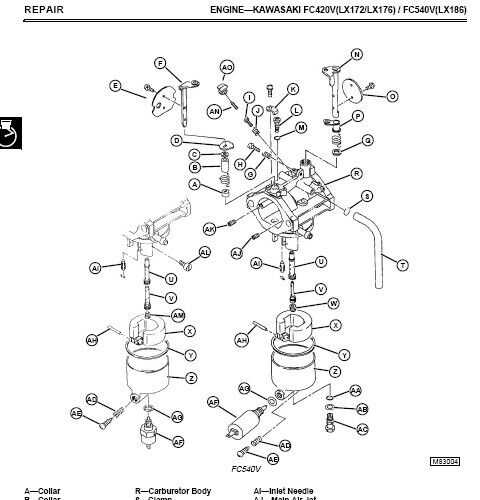

Fuel System Parts and Functions

In this section, we delve into the components essential for the efficient operation of the fuel system. Understanding these elements is crucial for maintaining optimal performance and reliability.

Fuel Tank

The fuel tank serves as the reservoir for storing gasoline or diesel fuel before it is supplied to the engine. It ensures a steady supply of fuel to meet the engine’s demands.

Fuel Pump

The fuel pump is responsible for transferring fuel from the tank to the engine. It operates under pressure to deliver fuel in the required quantities and at the correct pressure for combustion.

Various other components, such as fuel filters, fuel injectors, and fuel lines, work in conjunction to ensure the fuel system’s efficiency and reliability, contributing to the overall performance of the vehicle.

Troubleshooting Common Mechanical Issues

In this section, we delve into identifying and resolving prevalent mechanical challenges that may arise with your equipment. Understanding these issues is crucial for maintaining optimal performance and longevity.

1. Engine Performance Problems

One of the most frequent concerns encountered is related to engine performance. This can manifest as irregular idling, lack of power, or difficulty starting. Such symptoms often indicate issues with fuel delivery, ignition system, or engine timing.

2. Transmission and Drive Issues

Another critical area involves transmission and drive components. Users may notice unusual noises during operation, difficulty shifting gears, or loss of drive power. These issues could stem from transmission fluid levels, belt tension, or mechanical wear.

Common Mechanical Issues and Solutions

| Issue |

Cause |

Solution |

| Engine Misfires |

Spark plug malfunction |

Replace spark plugs |

| Noisy Transmission |

Lack of lubrication |

Check and refill transmission fluid |

| Poor Steering Response |

Worn steering components |

Inspect and replace worn parts |

This HTML segment outlines common mechanical issues without using specific terms related to “John Deere LX172 parts diagram,” focusing instead on generic equipment troubleshooting.

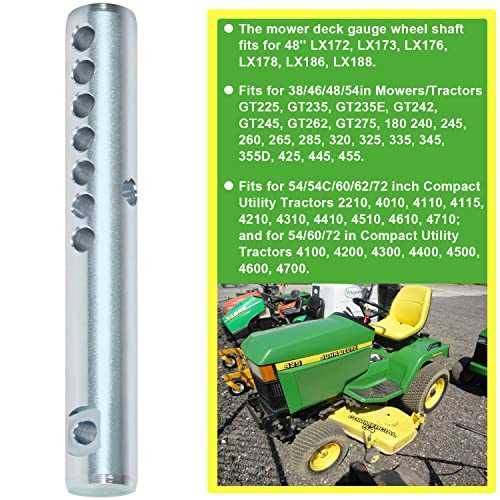

Replacement Options for Major Parts

In this section, we explore alternative solutions for critical components of the equipment, offering diverse choices to meet various needs. We delve into viable substitutes for essential elements, providing a range of options suitable for different requirements and budgets. This discussion aims to highlight the versatility and adaptability of replacement parts, ensuring optimal functionality and performance without compromising quality.