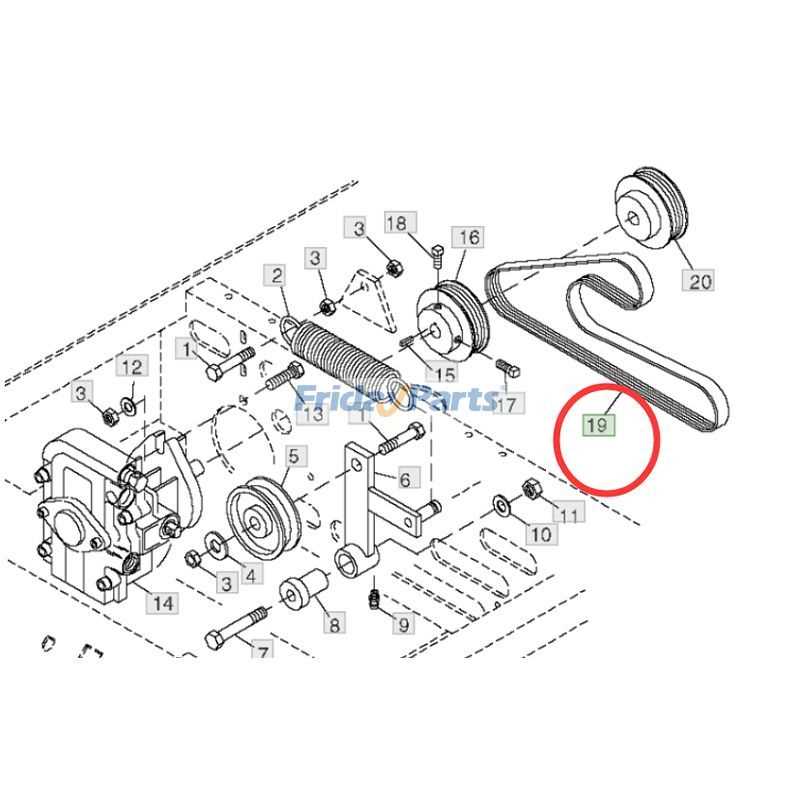

To ensure efficient performance and longevity of your equipment, it is crucial to have a clear overview of how various elements interact with each other. Each element plays a specific role, and understanding their placement can help in maintaining and troubleshooting. The proper arrangement and connectivity of these parts provide stability and enhance overall functionality.

Identifying essential elements within the machinery can simplify routine maintenance and assist in identifying potential issues early on. A structured overview offers clarity on how individual components are linked, ensuring smoother operation and easier repairs when necessary.

In addition, visual representations of these mechanical setups enable users to swiftly navigate through the complexities of the system. With the right approach, even intricate systems become more manageable and understandable, allowing for timely interventions and adjustments.

John Deere M655: Comprehensive Parts Overview

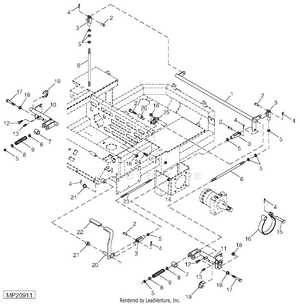

When maintaining a robust zero-turn model, understanding its intricate components is essential for ensuring long-term efficiency and performance. The machinery’s design integrates several key systems that work harmoniously, contributing to smooth operation across various terrains. This overview aims to highlight those integral elements, giving users insight into how each part plays a crucial role in the machine’s functionality.

Key Components and Their Functions

The machinery features a well-organized structure where each element has a specific function, supporting overall performance. From the drive system to the cutting mechanisms, each section operates efficiently to handle heavy-duty tasks. These components are engineered for durability, allowing the machine to endure challenging conditions.

Regular maintenance and timely replacements of essential elements can drastically improve both lifespan and reliability, making the machine a trusted tool for various applications. Understanding how these pieces fit together ensures smooth operation and prevents potential issues during intensive use.

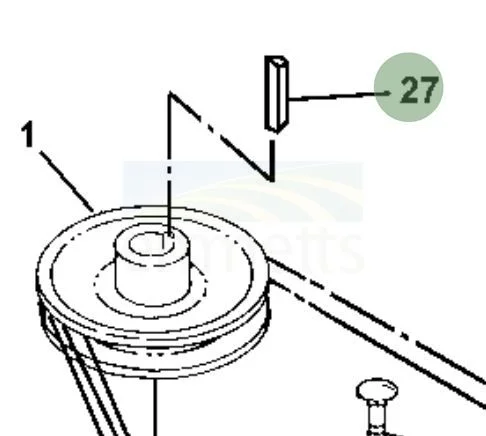

Understanding the Mower Deck Components

The mower deck is a critical part of any lawn care machine, ensuring a clean and even cut. It is designed with several key elements that work together to provide efficient performance. Each piece plays a role in delivering smooth operation and maintaining the overall quality of the mowing process.

Below is an overview of the essential components found in a typical mower deck, which contribute to its functionality and durability:

| Component | Function | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Blades | Responsible for cutting the grass with precision. | ||||||||||||

| Spindles | Connect the blades to the deck and allow for rotation. |

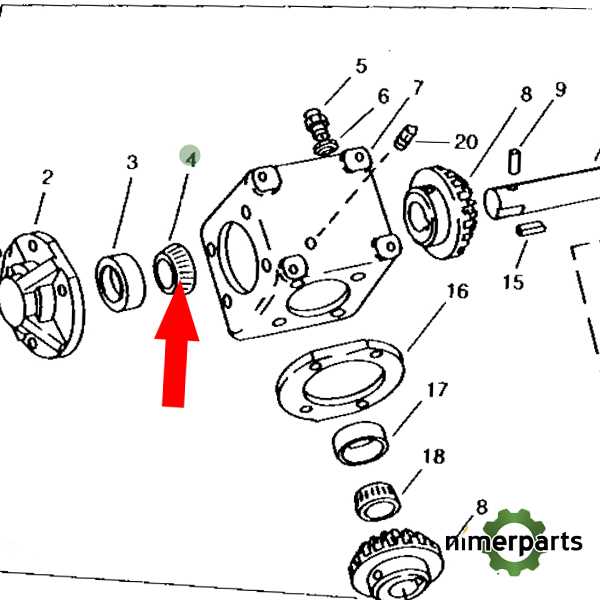

| Component | Function |

|---|---|

| Gearbox | Regulates the speed and torque output to the wheels. |

| Clutch | Facilitates engagement and disengagement of power transmission. |

| Shift Lever | Allows the operator to select different speed ranges. |

| Drive Shaft | Transmits power from the engine to the wheels. |

| Transmission Fluid | Provides lubrication and cooling for smooth operation. |

Brake System Components and Diagram

The braking mechanism plays a crucial role in the overall functionality and safety of machinery, ensuring effective stopping power and control during operation. Understanding the key elements of this system is essential for maintenance and troubleshooting. Each component contributes to the overall performance and reliability of the braking process, making it vital for operators to be familiar with their functions and interconnections.

In a typical braking assembly, several fundamental elements work together to facilitate smooth operation. The actuator initiates the braking process, translating force into movement. Additionally, brake pads and discs interact to create the necessary friction for deceleration. Hydraulic lines and reservoirs ensure that the fluid dynamics remain effective, while sensors may monitor system performance for optimal safety. Together, these components form a cohesive unit that is essential for reliable performance in demanding environments.

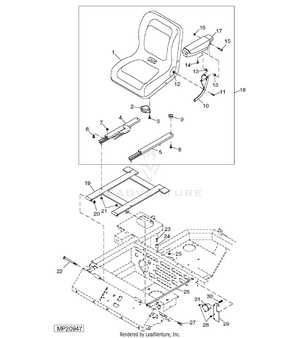

Seat and Operator Station Components

The operator’s environment is crucial for both comfort and efficiency during operation. This section delves into the various elements that contribute to the functionality and usability of the seating area and control center, ensuring an optimal experience for the user.

- Seat: The primary component designed for the operator’s comfort, often adjustable to suit individual preferences.

- Armrests: Provide support and enhance comfort, allowing for extended periods of operation without strain.

- Control Panel: Houses various controls and indicators, offering easy access to essential functions.

- Footrest: Ensures a stable platform for the operator’s feet, contributing to overall comfort during operation.

- Seat Belt: Enhances safety by securing the operator in place while minimizing the risk of injury.

- Dashboard: Displays critical information regarding machine performance, making it easier for the operator to monitor operations.

- Steering Wheel: Facilitates precise maneuvering, ensuring smooth handling of the machine.

Each component plays a vital role in creating a cohesive and effective operator station, enhancing both safety and productivity during use.

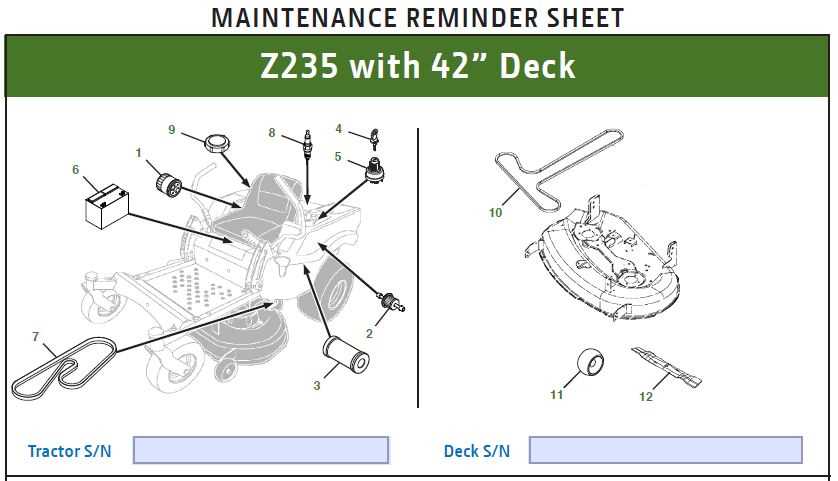

John Deere M655 Maintenance Parts and Locations

This section focuses on the essential components required for maintaining the equipment and their respective placements. Understanding where each element is located is crucial for effective upkeep and ensuring the machinery operates efficiently.

Key elements involved in routine maintenance include filters, belts, and lubricants. Each of these components plays a vital role in the overall functionality of the machinery. For instance, filters are typically situated in accessible areas to facilitate regular changes, while belts may be found in engine compartments, necessitating periodic checks to prevent wear and tear.

Additionally, lubrication points are strategically placed to allow for easy access during maintenance tasks. Regular inspections of these locations help identify any potential issues early, ensuring optimal performance and longevity of the machinery. Familiarity with these components and their placements will empower operators to perform maintenance tasks with confidence.