Understanding how each element of your lawn equipment is interconnected is crucial for effective maintenance and repair. This guide provides a detailed look at the internal workings and configurations of key elements within your machinery, helping you navigate through its structure and optimize its performance.

Regular upkeep and timely replacements are essential to ensuring that your equipment runs smoothly. In this section, we will explore the various mechanisms, detailing how each section connects and functions together. You will gain insights into how to identify key components and keep your equipment in top shape.

For those aiming to extend the lifespan of their lawn machinery, knowing how to approach technical breakdowns and replacements can make all the difference. The following layout breakdown offers a clear, accessible reference to help you keep everything running efficiently.

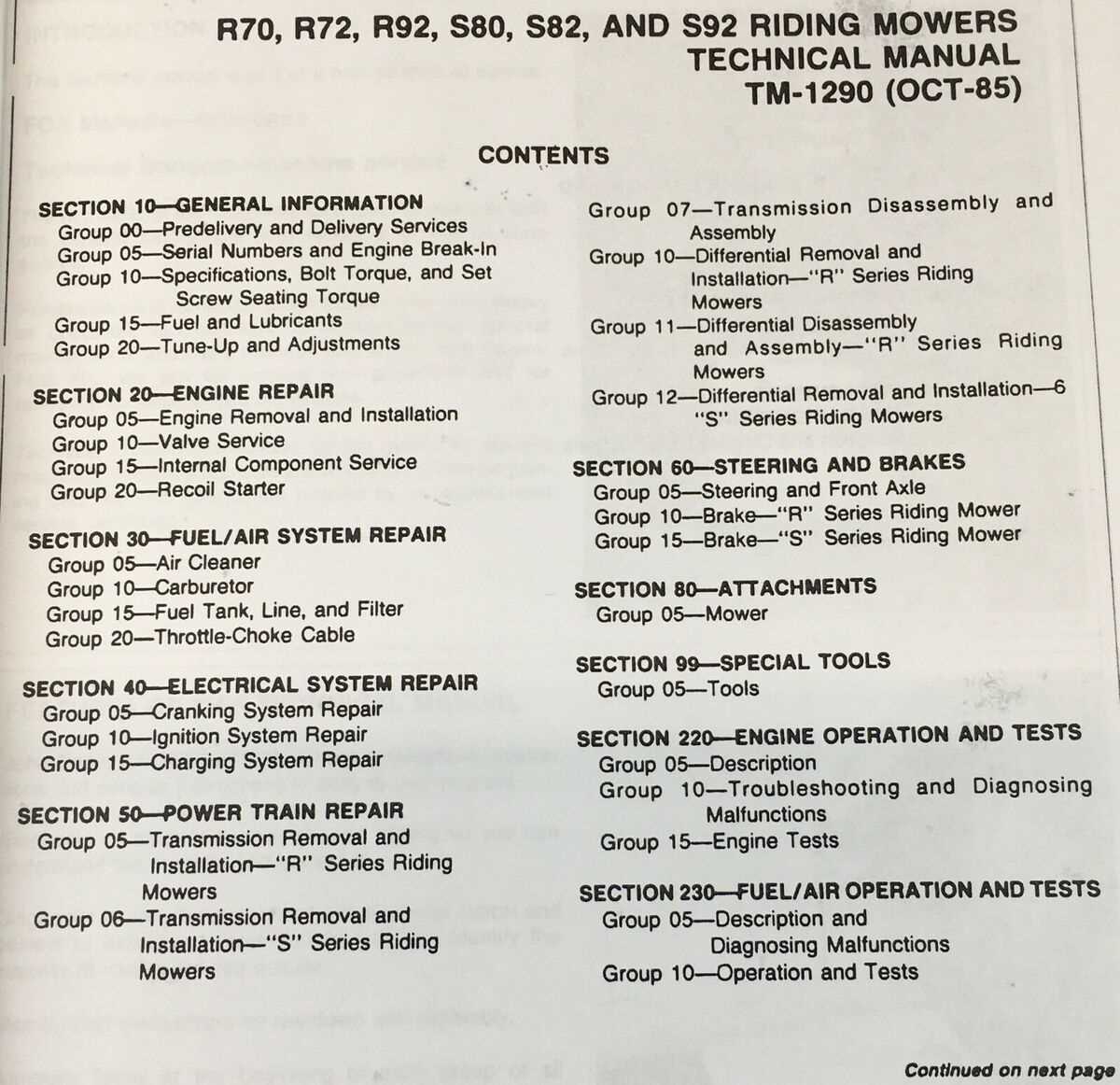

Overview of John Deere R72 Components

Understanding the structure and key elements of this lawn equipment model is essential for effective maintenance and operation. Each section of the machinery works together to ensure smooth performance and durability, providing a well-coordinated system for tackling various tasks in the yard. Here, we take a closer look at the essential components that make up the machine’s framework.

Key Mechanical Systems

- Power Source: The engine drives the entire system, ensuring that the machine operates efficiently during extended use.

- Transmission Mechanism: Responsible for transferring power from the motor to the wheels, this system controls speed and direction with precision.

- Cutting Unit: A central feature that allows for an even and clean trimming of grass, offering multiple height adjustments to fit user needs.

Additional Operational Components

- Steering System

Engine Parts Breakdown for John Deere R72

The engine is composed of various essential elements that work in unison to ensure smooth operation and performance. Each component plays a critical role in the overall functioning, from the ignition system to the cooling mechanisms. Understanding how these individual elements interact can help in maintaining and servicing the engine effectively, extending its lifespan and enhancing its efficiency.

Among the most important elements are those responsible for fuel delivery, ignition, and temperature regulation. Ensuring each of these systems is functioning optimally will guarantee the machine continues to operate reliably, even under challenging conditions. Regular checks of these elements can prevent issues before they arise, keeping performance at its peak.

In addition to these, there are various fasteners, connectors, and seals that ensure everything remains secure and operates without leaks or disruptions. Paying attention to even the smallest components can significantly impact overall efficiency and longevity.

Cutting Deck Assembly and Maintenance Guide

The cutting deck is a crucial component of any lawn care machine, ensuring efficient trimming of grass. Proper assembly and regular upkeep of this element are essential for achieving optimal performance and longevity. This section will provide guidance on how to correctly assemble the deck and perform essential maintenance tasks to keep it in excellent working condition.

Assembly Steps: To begin, ensure all necessary tools are available. Carefully align the deck with the machine’s main body and securely fasten it. Tighten all bolts and connections to prevent any potential loosening during use. It’s important to check that the blades are properly positioned and balanced before moving forward.

Maintenance Tips: Regular cleaning of the deck is vital to avoid buildup of debris that could impact performance. After each use, remove any clippings or dirt that may have accumulated. Additionally, sharpening the blades periodically ensures efficient cutting and prevents unnecessary strain on the equipment. Lubricate all moving parts as recommended to reduce wear and extend the life of the mechanism.

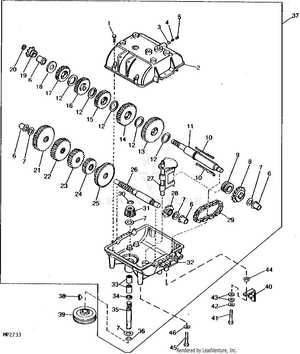

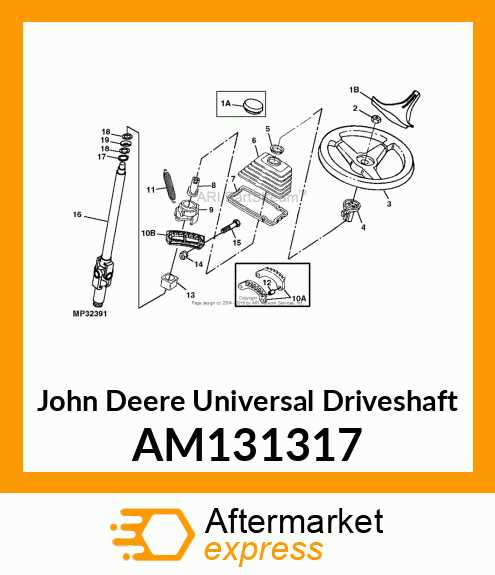

Detailed View of Transmission System

The transmission mechanism plays a critical role in converting power to the movement system. This section provides an overview of how the power is transferred through a network of components that ensure smooth and efficient operation. Understanding the structure and function of the transmission is essential for maintaining optimal performance and diagnosing any potential issues.

Component Description Gear Assembly Responsible for adjusting speed and torque, the gear assembly ensures proper motion and flexibility across different terrains. Drive Belt This component links the power source to the wheels, transmitting the necessary force for movement. Pulleys Acting as support points, pulleys guide the belt, ensuring stable movement and preventing slippage. Transmission Housing Encloses and protects the internal parts from external elements while maintaining lubrication for smooth operation. Steering Mechanism and Key Elements

The steering system plays a crucial role in ensuring smooth and precise control of the machine’s direction. It is a complex assembly that allows the operator to maneuver the equipment effortlessly across various terrains. Understanding its components and how they interact is essential for maintaining optimal performance.

At the heart of the steering mechanism is the linkage system, which connects the operator’s input to the wheels. The movement from the control lever is transferred through several interconnected parts that adjust the direction. Key components include control arms, rods, and pivot points that work in unison to provide responsive handling.

In addition to the basic elements, the steering system also incorporates several adjustment points, ensuring that wear and tear over time can be compensated for. This enables long-term precision and smooth operation, making the mechanism reliable under different conditions.

Electrical System and Wiring Layout

The electrical infrastructure of a machinery model plays a crucial role in its overall functionality and efficiency. A well-structured wiring setup ensures proper communication between various components, allowing for seamless operation. This section will provide an overview of the electrical layout, highlighting key elements and their interconnections.

Main Components of the Electrical System

The primary elements of the electrical setup include the battery, alternator, starter motor, and various sensors. Each of these components serves a specific function, contributing to the machine’s performance. The battery provides the necessary power to start the engine, while the alternator charges it during operation. The starter motor initiates the engine’s function, and sensors monitor different parameters to optimize performance.

Understanding the wiring configuration is essential for troubleshooting and maintenance. Each wire in the system is color-coded and labeled, facilitating easy identification during inspections. The connections between components are designed to minimize interference and ensure reliability. Proper grounding techniques are also implemented to enhance safety and prevent electrical faults.

Drive Belt Configuration and Replacement Tips

Proper alignment and maintenance of the drive belt are crucial for optimal performance in various equipment. This component ensures efficient power transfer, which is essential for the machinery’s overall functionality. Understanding the configuration and replacement process can help extend the lifespan of the belt and prevent operational issues.

Understanding Belt Alignment

Maintaining correct alignment is key to ensuring that the drive belt operates smoothly. Misalignment can lead to excessive wear, causing premature failure. Regularly check the tension and positioning to ensure everything is in order. A well-aligned belt minimizes strain on the system, enhancing durability and performance.

Replacement Steps

When it’s time to replace the drive belt, follow these simple steps for a successful installation. First, ensure the machinery is powered off and disconnected from any energy sources. Remove the protective covers to access the belt. Carefully detach the old belt and inspect pulleys for damage. Install the new belt, ensuring it fits snugly within the grooves. Finally, recheck the alignment and tension before closing everything up. Following these guidelines will promote efficient operation and longevity of the equipment.

Blade System Components and Functions

The blade system is a crucial aspect of many outdoor machinery, playing a vital role in ensuring effective cutting and operation. This system comprises various elements that work in harmony to deliver optimal performance. Understanding these components and their functions can significantly enhance maintenance and operational efficiency.

Key Components

Essential elements of the blade system include the cutting blades, drive mechanism, and related hardware. Each part contributes to the overall functionality, ensuring smooth operation and durability over time.

Component Function Cutting Blades Designed to slice through grass and other materials efficiently. Drive Mechanism Transfers power from the engine to the blades, enabling rotation. Spindle Assembly Supports the blades and allows them to rotate freely. Deck Houses the blade system, providing protection and stability. Operational Efficiency

Proper maintenance of the blade system components ensures longevity and optimal functionality. Regular inspections and timely replacements can prevent issues that may hinder performance, thereby maximizing productivity during operation.

Brake System Overview and Part Locations

The braking mechanism is a crucial component of any machinery, ensuring safety and control during operation. Understanding its layout and functionality helps in maintaining optimal performance and addressing any issues that may arise.

In this section, we will explore the key elements of the braking system, including the various components and their specific locations. Familiarizing yourself with these parts will facilitate easier maintenance and repair processes.

Key Components: The primary elements of the braking system include the brake pedal, master cylinder, brake lines, and brake calipers. Each of these parts plays a vital role in the overall functionality of the system.

Locations: The brake pedal is typically located within the operator’s reach, allowing for easy engagement. The master cylinder is usually positioned near the brake pedal, while the brake lines run from the master cylinder to the calipers, which are situated near the wheels. Understanding these locations will aid in efficient troubleshooting and repairs.

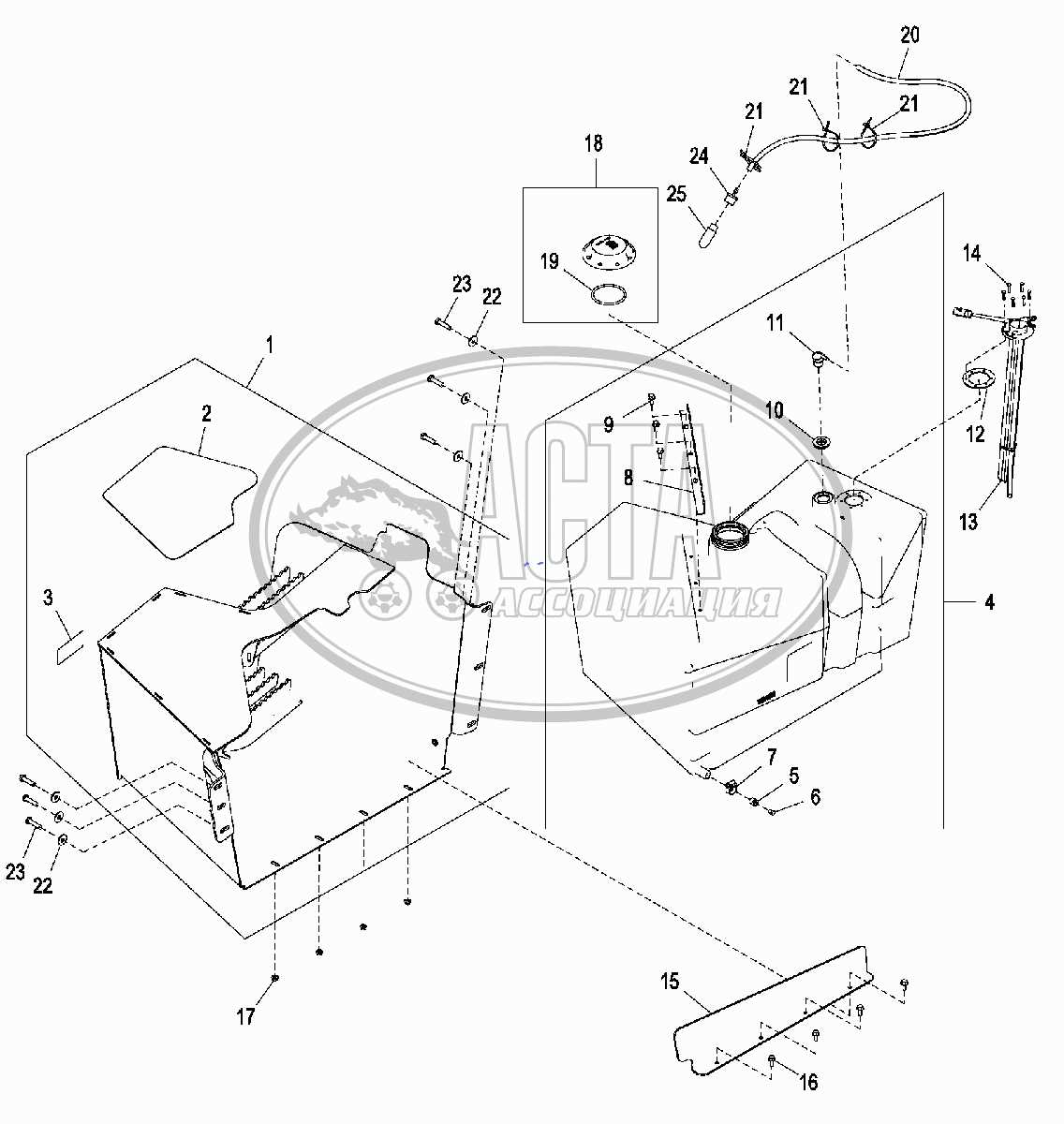

Fuel System Diagram and Important Parts

This section focuses on the essential components and layout of the fuel delivery system in the specified machinery. Understanding the configuration and functionality of these elements is crucial for efficient operation and maintenance.

Key Components of the Fuel Delivery System

The fuel delivery mechanism comprises several vital elements that work together to ensure optimal performance. Each component plays a significant role in the overall functionality of the system.

Component Description Fuel Tank The reservoir that holds the fuel supply, ensuring adequate storage for operation. Fuel Pump Responsible for moving the fuel from the tank to the engine, providing necessary pressure for efficient combustion. Fuel Filter Filters impurities and debris from the fuel to protect engine components from damage. Fuel Injector Atomizes the fuel and delivers it into the combustion chamber for efficient mixing with air. Understanding the Layout

The arrangement of these components is designed to maximize efficiency and reliability. Proper installation and regular inspection of each part can significantly enhance the system’s performance and longevity.

Maintenance Checklist for Key Parts

Regular upkeep of essential components is crucial for ensuring optimal performance and longevity of your equipment. Following a structured maintenance plan not only enhances efficiency but also helps in preventing unexpected breakdowns. Below is a comprehensive checklist to guide you through the necessary tasks for vital elements.

Weekly Inspection

Conducting a thorough inspection on a weekly basis is vital. Check for any signs of wear or damage on the following items:

- Belts: Look for fraying or cracks.

- Filters: Ensure they are clean and free from obstructions.

- Fluid Levels: Verify that oil and coolant levels are within the recommended range.

Monthly Maintenance Tasks

In addition to weekly inspections, perform these tasks monthly to maintain optimal operation:

- Lubrication: Apply lubricant to all moving parts to reduce friction.

- Tightening Bolts: Check and tighten any loose bolts or screws.

- Battery Check: Inspect battery terminals for corrosion and ensure connections are secure.

By adhering to this checklist, you can significantly enhance the performance and reliability of your machinery, ensuring it operates smoothly throughout its lifespan.