Understanding the organization and positioning of individual elements within complex machinery is essential for effective upkeep and troubleshooting. Whether dealing with essential replacements or routine checks, having a clear visual reference of each component’s placement can save time and effort during maintenance procedures.

A detailed overview of the internal and external mechanical layout enables users to pinpoint issues quickly, ensuring that the operational efficiency remains intact. This kind of visualization is particularly beneficial for anyone handling equipment repairs, helping to maintain smooth functionality over time.

By familiarizing yourself with the layout of various mechanical assemblies, you can ensure proper alignment and compatibility when replacing worn-out elements, ensuring a longer lifespan

Overview of the John Deere X300 Components

The equipment in question consists of several key mechanical and structural elements designed to ensure smooth operation and optimal performance. Each unit within the machinery serves a specific function, contributing to the overall functionality and longevity of the device. Understanding these essential elements can help with routine upkeep and potential repairs.

Core Mechanical Systems

- Power transmission system: This ensures the effective transfer of energy from the engine to the wheels, enabling the machine to move and perform its tasks efficiently.

- Steering mechanism: This system allows for precise maneuverability, ensuring the operator has full control over the direction and movement.

- Cutting system: Comprised of blades and a deck, this component is responsible for handling grass cutting and achieving a clean, even finish.

Additional Structural Elements

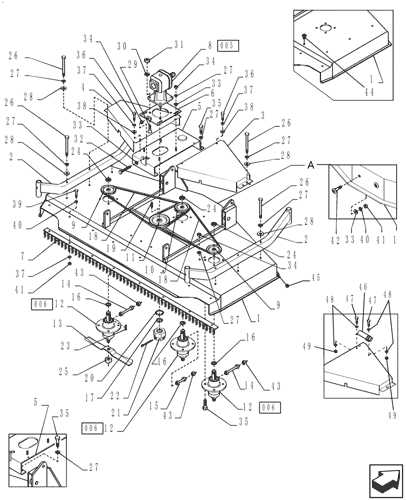

Understanding the X300 Mower Deck Structure

The mower deck is a critical component that ensures efficient cutting performance and durability in any lawn maintenance equipment. By examining its structure, you can better understand how each part works together to achieve precise cutting and smooth operation. Understanding its assembly and features will help in maintaining the system for optimal results.

Key elements of the deck include blades, pulleys, and belts, all working together to ensure a clean cut and even grass distribution. Here’s a breakdown of the essential components:

- Blades: These are the primary cutting tools, responsible for slicing the grass evenly.

- Pulleys: These mechanisms help drive the blades and maintain their speed during operation.

- Belts: The belts connect various parts, ensuring synchronized movement and efficient cutting power.

- Spindles:

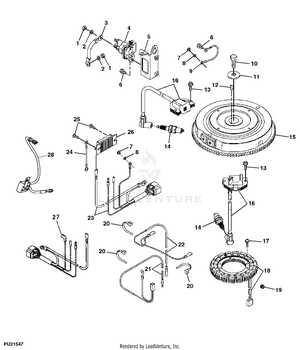

Key Elements of the X300 Electrical System

The electrical system of this type of vehicle is essential for powering its various components and ensuring smooth operation. It integrates different key elements, which work together to manage power distribution, safety mechanisms, and overall functionality. Understanding how these elements interconnect can help in identifying and resolving issues related to performance or malfunctions.

Battery and Charging System

The battery serves as the primary power source, supplying energy to the vehicle’s electrical circuits. It is recharged by an alternator, ensuring that all components, from lights to ignition, continue to receive power during operation. Maintaining a healthy charging system is crucial for preventing battery drain and ensuring long-lasting performance.

Starter and Ignition Circuit

The starter motor plays a pivotal role in initiating the engine’s operation. It draws energy from the battery and engages with the engine to start combustion. The ignition circuit, consisting of switches, fuses, and wiring, ensures that the power is correctly

Brake System Components in the X300 Model

The brake system in this model is designed to ensure safe and reliable operation, providing control over the machine during both normal use and emergency situations. Understanding the key elements involved is crucial for maintaining the overall efficiency and safety of the machine.

Main Brake Mechanism

The primary braking mechanism consists of several critical components working together to stop or slow down the machine. These include a robust set of discs and pads that create friction, helping to halt the wheels when pressure is applied through the pedal. Regular inspection and replacement of worn components are essential to ensure optimal performance.

Parking Brake Assembly

The parking brake is an essential part of the system, designed to hold the machine in place when stationary. It includes a locking mechanism that engages when the

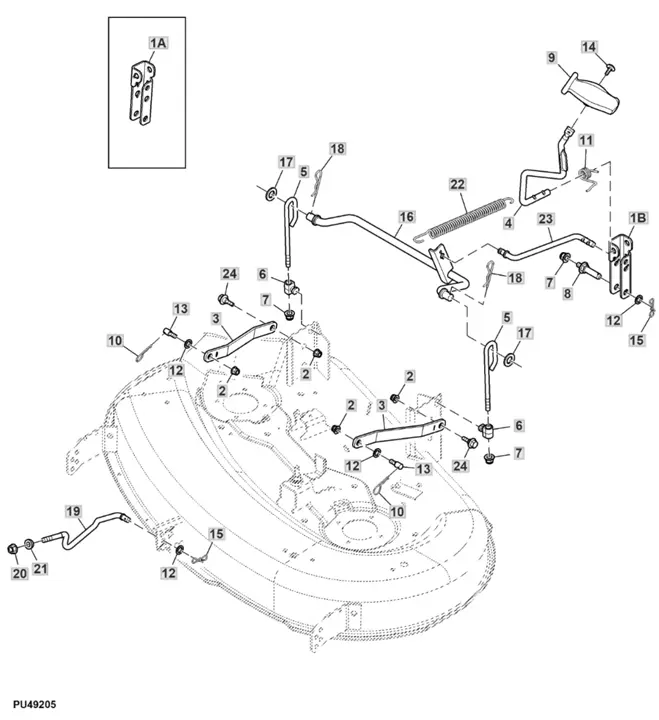

Steering Mechanism Breakdown of the X300

The steering system of this model is a complex yet essential component that ensures smooth control and precise handling. Understanding its structure can help in diagnosing potential issues and performing repairs efficiently. The mechanism is built to withstand regular usage, but with time, certain parts may wear out, making maintenance crucial for optimal performance.

Key Components of the Steering System

The steering setup includes several interconnected elements, such as the steering wheel, linkage rods, and the pinion gear. These components work together to transfer the driver’s input into directional movement. Each part must function correctly to guarantee the seamless operation of the vehicle, whether turning or navigating uneven terrain.

Common Issues and Maintenance Tips

One of the frequent problems that may arise is excessive play in the steering, which can be caused by worn-out bushings or loose connections. Regular inspections and timely lubrication can prevent such issues, ensuring that

Essential Parts of the X300 Engine

The engine of this model is a crucial component that ensures optimal performance and efficiency. Understanding the fundamental elements that comprise the engine can greatly enhance maintenance and repair efforts. This section delves into the vital components that contribute to the overall functionality of the engine.

Power Unit is the heart of the system, generating the necessary force to propel the machine forward. Its design and configuration are tailored for reliability and durability, making it suitable for various applications.

Fuel Delivery System plays a significant role in ensuring the engine receives the right amount of fuel for combustion. This system includes a fuel tank, pump, and injectors that work together to optimize fuel flow and enhance efficiency.

Cooling Mechanism is essential for maintaining optimal operating temperatures. It consists of a radiator and coolant circulation system, preventing overheating and prolonging engine life.

Exhaust System is responsible for expelling combustion gases from the engine. It includes components like mufflers and exhaust pipes, designed to reduce noise and emissions while improving overall performance.

Lubrication System ensures that all moving parts receive adequate oil, reducing friction and wear. This system typically includes an oil pump, filter, and oil reservoir, vital for maintaining engine health.

By familiarizing oneself with these key elements, operators can better appreciate the intricacies of the engine and carry out effective maintenance practices, ensuring longevity and optimal performance.

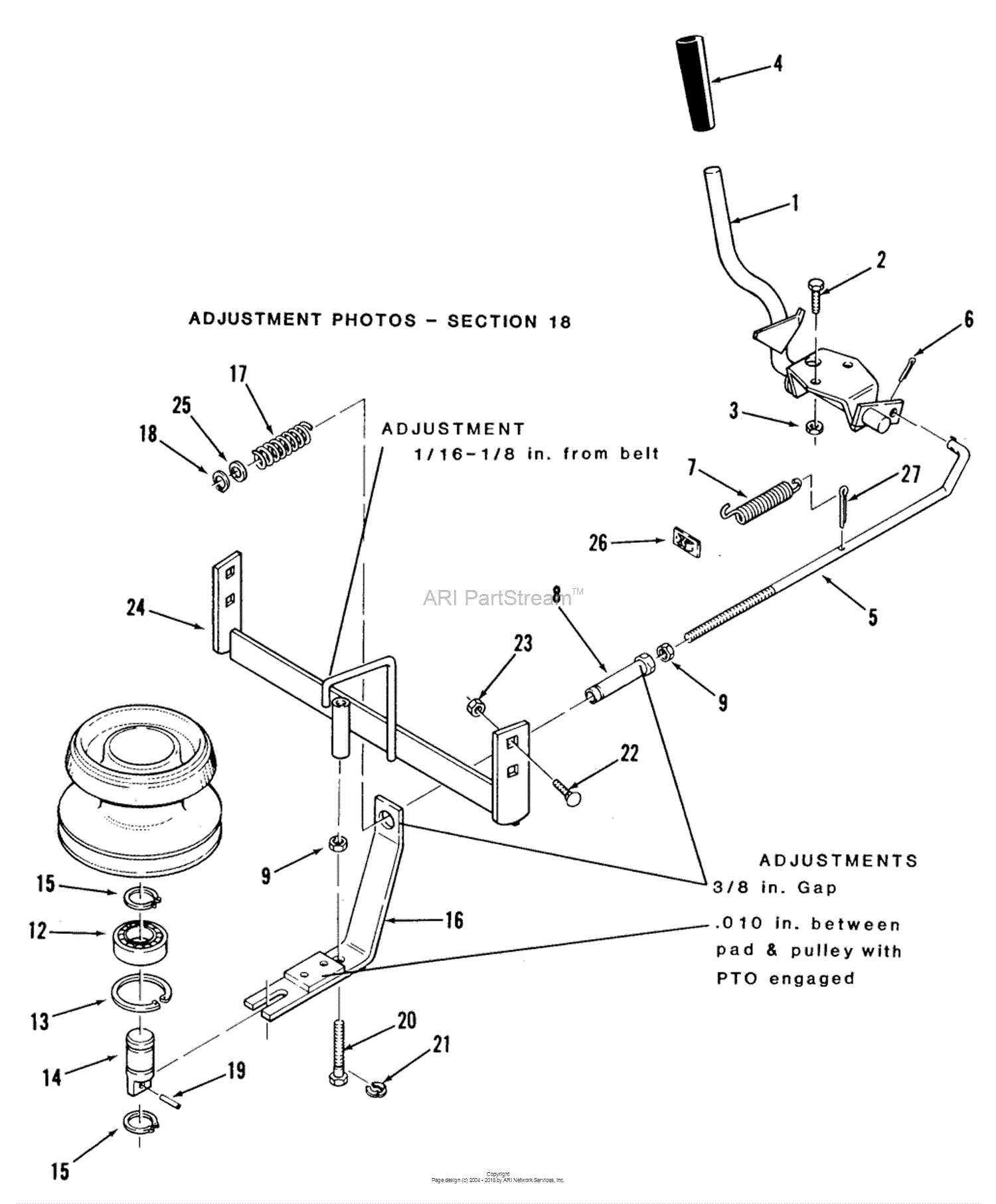

Drive Belt and Transmission Assembly

This section focuses on the critical components responsible for power transfer and movement within the machinery. Understanding the assembly’s structure and function is essential for maintaining optimal performance and ensuring longevity.

The drive belt and transmission system play a vital role in connecting the engine to the wheels, facilitating efficient motion. A well-maintained assembly ensures smooth operation and reduces the risk of mechanical failure. Here are the key elements involved:

- Drive Belt: This flexible loop transmits power from the engine to various components, allowing for controlled movement.

- Transmission Housing: The protective casing that contains the transmission system, safeguarding internal mechanisms from debris and damage.

- Gears: These toothed wheels interact to change the speed and torque, adapting the machine’s performance to different tasks.

- Pulleys: Circular components that guide the drive belt and optimize power transfer between the engine and the wheels.

- Clutch Assembly: A crucial part that engages and disengages power flow, enabling smoother starts and stops.

Regular inspection and timely replacement of worn-out components are essential for maintaining the efficiency of the drive belt and transmission assembly. Proper alignment and tension adjustment can significantly enhance performance and prevent premature wear.

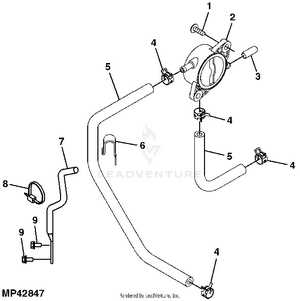

Fuel System and Related Components

The fuel delivery mechanism is essential for the efficient operation of small engine equipment. This system ensures the proper flow of fuel to the engine, enabling optimal performance and reliability. Understanding the various components involved is crucial for effective maintenance and troubleshooting.

Key Components of the Fuel Delivery System

- Fuel Tank: Stores the fuel needed for operation.

- Fuel Pump: Responsible for transporting fuel from the tank to the engine.

- Fuel Filter: Removes impurities from the fuel to protect the engine.

- Fuel Lines: Pathways through which fuel flows from the tank to the engine.

- Carburetor: Mixes air and fuel for combustion in the engine.

Maintenance Tips for the Fuel System

- Regularly check the fuel tank for cleanliness and proper sealing.

- Replace the fuel filter as per the manufacturer’s recommendations.

- Inspect fuel lines for leaks or wear, and replace as necessary.

- Ensure the carburetor is clean to maintain efficient fuel-air mixing.

- Use high-quality fuel to enhance performance and reduce deposits.

Wheels and Axles Configuration in the X300

The configuration of wheels and axles plays a crucial role in ensuring optimal performance and stability in garden tractors. A well-designed system enhances maneuverability, support, and overall functionality, allowing for effective operation across various terrains.

In this model, the wheels are strategically positioned to provide excellent traction and balance. Front wheels are typically smaller in diameter, which aids in steering and agility, while the rear wheels are larger, offering stability and power during operation. This combination allows for efficient handling, especially when navigating tight corners or uneven surfaces.

The axle assembly is engineered to withstand significant stress and load. Heavy-duty axles ensure durability, while the spacing between them is optimized to maintain alignment and enhance stability. This setup minimizes the risk of wear and tear, prolonging the lifespan of the entire system.

Additionally, the ability to adjust the wheel settings allows operators to tailor the machine for specific tasks, whether it’s mowing, hauling, or transporting materials. By modifying the wheel configuration, users can improve performance in different conditions, making it a versatile choice for various gardening needs.

John Deere X300 Safety Features Diagram

This section provides an overview of the safety mechanisms integrated into the lawn care equipment. These features are designed to ensure user protection and enhance operational reliability during use.

Key components that contribute to the safety of the machine include:

- Operator Presence System: This feature automatically halts the machine if the operator leaves the seat, reducing the risk of accidents.

- Safety Switches: These switches are strategically placed to prevent unintended machine activation.

- Roll-Over Protection Structure (ROPS): This robust frame safeguards the user in case of accidental rollovers, promoting safety in challenging terrains.

- Emergency Stop Controls: Easily accessible buttons allow for quick shutdown of the machine in emergencies, ensuring immediate cessation of operation.

- Secure Storage: Compartments for tools and accessories are designed to keep items secure and out of the way, minimizing distractions during operation.

Understanding these safety elements is crucial for effective and secure operation. Regular inspections and maintenance of these features can significantly enhance safety while using the equipment.

Maintenance Points for the X300 Tractor

Regular upkeep is essential for ensuring the longevity and efficiency of your tractor. By adhering to a structured maintenance routine, you can prevent unexpected breakdowns and prolong the lifespan of your equipment. This section outlines key areas to focus on during maintenance sessions.

Key Areas of Focus

- Engine Care

- Check oil levels and replace oil filters regularly.

- Inspect air filters for dirt and replace if necessary.

- Monitor coolant levels and maintain optimal temperatures.

- Transmission Maintenance

- Regularly inspect transmission fluid levels.

- Change transmission fluid according to the manufacturer’s recommendations.

- Tire Inspection

- Check tire pressure to ensure proper inflation.

- Inspect treads for wear and replace if needed.

- Electrical System

- Inspect battery connections and clean terminals.

- Check wiring for any signs of wear or damage.

Scheduled Maintenance Tasks

- Change engine oil every 50 hours of operation.

- Replace air filters every 100 hours or as needed.

- Inspect belts and hoses every 200 hours for any signs of wear.

- Perform a comprehensive check of all systems before seasonal use.