Maintaining the functionality of machinery is essential for ensuring efficiency and reliability in various tasks. To achieve this, it’s important to familiarize oneself with the different elements that contribute to the overall operation of equipment. Recognizing the need for regular upkeep and knowing which components to focus on is the first step in preserving long-term performance.

Proper care and timely replacements can greatly extend the lifespan of any machine. Each part, no matter how small, plays a critical role in the seamless operation of the entire system. By understanding how these elements work together, operators can prevent breakdowns and costly repairs.

Identifying individual components within a complex system may seem challenging, but having the right guidance and resources can simplify this process. Whether you’re troubleshooting or simply performing routine checks, knowing where each element fits can help ensure everything runs smoothly.

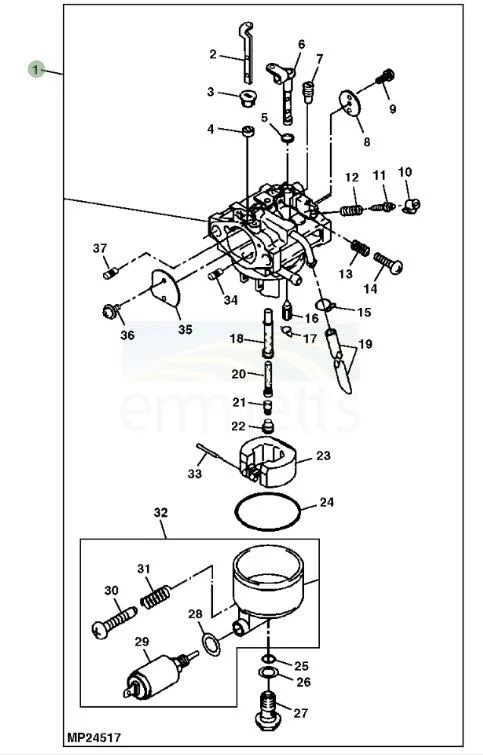

John Deere X585 Parts Overview

This section provides an overview of the essential components of a popular lawn and garden vehicle. Understanding these elements is crucial for maintenance, repair, and overall functionality of the machine. Each piece plays a significant role in ensuring the equipment operates smoothly and efficiently.

Key Components

Among the vital elements of this model, the engine stands out as the powerhouse, delivering the necessary performance for various tasks. Additionally, the transmission system is integral, allowing for seamless operation across different terrains. Other important components include the cutting deck, which ensures a clean cut, and the wheels, which provide stability and maneuverability.

Maintenance and Care

Regular inspection and upkeep of these crucial elements will extend the lifespan of the equipment. It is advisable to consult manuals for specific guidelines on maintenance practices. Utilizing quality replacements and adhering to recommended service schedules can enhance performance and reliability.

Engine Components and Their Functions

The engine serves as the heart of any machinery, playing a crucial role in its overall performance. Understanding the various components that make up this essential system and their respective roles can greatly enhance the maintenance and functionality of the equipment.

| Component | Function |

|---|---|

| Crankshaft | Transforms linear motion from the pistons into rotational motion, driving the machinery. |

| Pistons | Move up and down within the cylinders, compressing the fuel-air mixture and converting energy into mechanical work. |

| Camshaft | Controls the opening and closing of the engine valves, ensuring proper airflow and fuel intake. |

| Valves | Regulate the entry of air and fuel into the combustion chamber and the exit of exhaust gases. |

| Fuel Injector | Delivers precise amounts of fuel into the combustion chamber, optimizing performance and efficiency. |

| Cooling System | Maintains the engine’s operating temperature, preventing overheating and ensuring longevity. |

| Oil Pump | Circulates lubricating oil throughout the engine, reducing friction and wear on moving parts. |

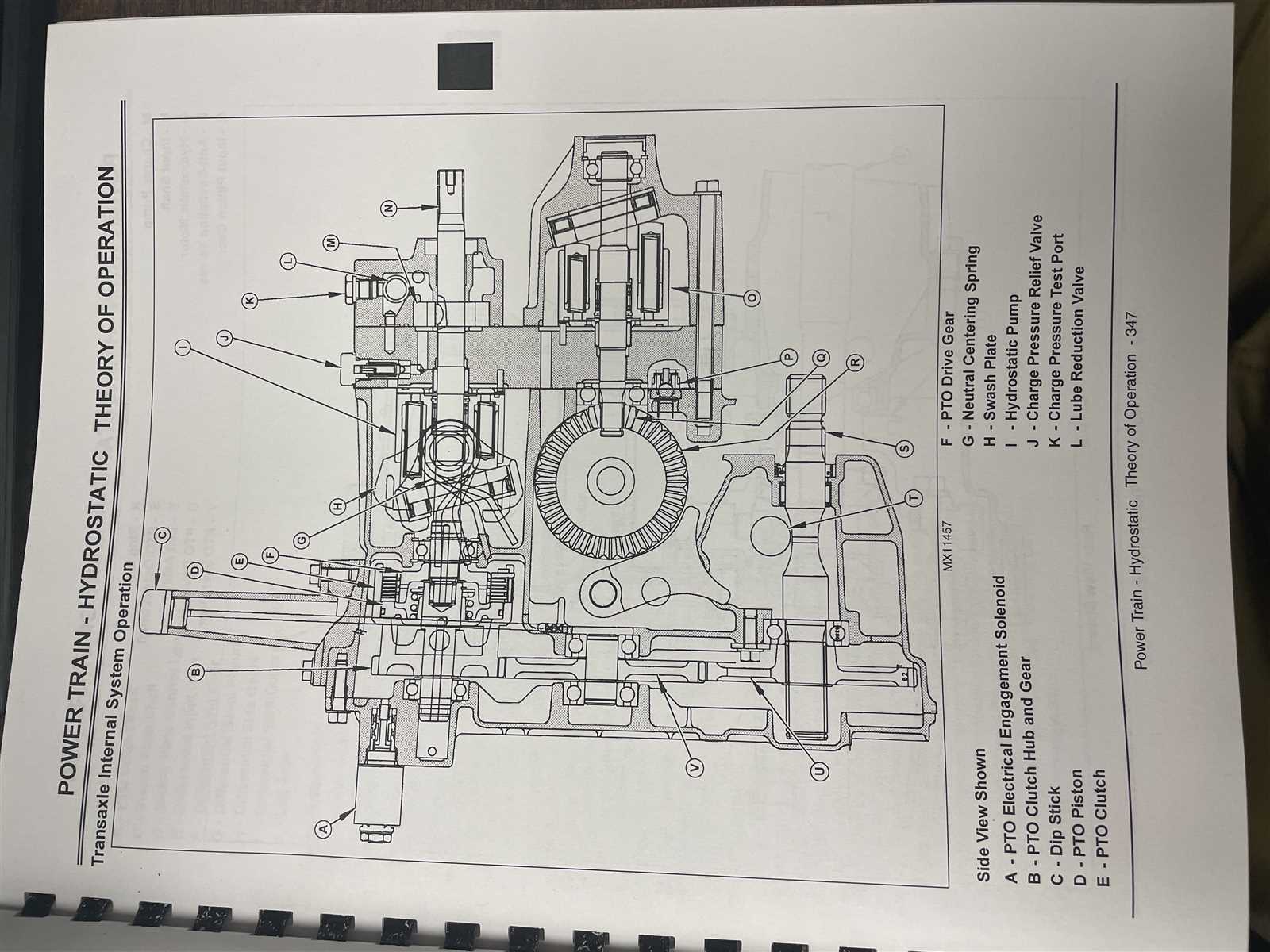

Transmission System Breakdown

The transmission system is a crucial component that ensures the efficient transfer of power from the engine to the wheels. Understanding its structure and functionality is essential for maintenance and troubleshooting. This section delves into the various elements that make up this vital mechanism, highlighting their roles and interconnections.

Key Components

The main elements of a transmission system include gears, clutches, and shafts. Gears facilitate the necessary speed adjustments, while clutches allow for smooth engagement and disengagement of power. Shafts serve as the conduits through which torque is transmitted to the wheels. Each component must work in harmony to ensure optimal performance.

Common Issues and Maintenance

Regular inspection and maintenance of the transmission system are critical to prevent potential failures. Common issues may arise from wear and tear, resulting in slipping gears or unusual noises. Timely lubrication and replacement of worn parts can significantly extend the lifespan of this essential system.

Steering Assembly and Key Elements

The steering mechanism of a vehicle plays a crucial role in ensuring smooth navigation and control. It comprises various components that work together to enable precise handling and responsiveness during operation. Understanding the individual elements of this system is essential for effective maintenance and repair.

Key Components include the steering wheel, which serves as the primary interface for the operator, allowing for directional adjustments. Attached to this is the steering column, which connects the wheel to the rest of the system and facilitates the transfer of motion. The rack and pinion mechanism converts rotational movement into linear motion, directly influencing the vehicle’s trajectory.

Additionally, the tie rods link the steering mechanism to the wheels, ensuring that the desired direction is accurately conveyed. Regular inspection of these elements is vital, as wear and tear can significantly affect performance and safety. Proper alignment and functionality of the steering assembly are crucial for a reliable driving experience.

Hydraulic System Parts Guide

The hydraulic system is a critical component in various machinery, providing the necessary power for effective operation. Understanding the different elements involved is essential for maintaining optimal performance and ensuring longevity. This section will delve into the essential components that make up this system, highlighting their functions and importance.

Key Components of the Hydraulic Mechanism

Several vital elements contribute to the functionality of the hydraulic system. Each component plays a significant role in the overall operation:

- Pump: This device is responsible for circulating hydraulic fluid, generating the pressure needed for movement.

- Hoses: These flexible tubes transport the hydraulic fluid between components, facilitating seamless operation.

- Cylinders: Hydraulic cylinders convert fluid pressure into mechanical force, enabling various movements.

Maintenance Considerations

Regular maintenance of the hydraulic system is crucial for ensuring reliable operation. Key practices include:

- Fluid Checks: Regularly inspect and replace hydraulic fluid to prevent contamination and maintain efficiency.

- Leak Inspection: Routinely examine hoses and connections for any signs of leaks that may compromise system integrity.

- Component Testing: Perform checks on pumps and cylinders to ensure they are functioning correctly and delivering expected performance.

Electrical Wiring and Main Connections

This section explores the essential aspects of electrical wiring and connections crucial for the efficient operation of machinery. Understanding the layout and functionality of these components ensures proper maintenance and troubleshooting, ultimately enhancing performance and longevity.

Overview of Electrical Components

Electrical systems in machinery typically consist of various components, including batteries, switches, and wiring harnesses. Each element plays a pivotal role in facilitating power distribution and signal transmission throughout the system. A well-organized electrical setup minimizes the risk of faults and enhances reliability.

Connection Schemes

Proper connection schemes are vital for ensuring that all electrical parts function harmoniously. The following table outlines common connection types and their respective functions:

| Connection Type | Description |

|---|---|

| Battery Connection | Links the power source to the electrical system, providing necessary voltage. |

| Ground Connection | Ensures safety by directing excess current away from components. |

| Signal Connection | Facilitates communication between different electrical components. |

| Fuse Link | Protects the system by interrupting the circuit during overloads. |

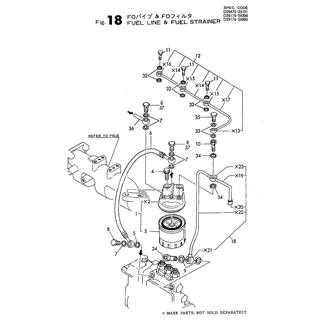

Fuel System Components Explored

The fuel system is a crucial part of any machinery, ensuring that the engine receives the necessary energy to operate efficiently. Understanding the various elements within this system helps in maintaining optimal performance and longevity of the equipment. This section delves into the different components that contribute to the effective functioning of the fuel delivery mechanism.

| Component | Description |

|---|---|

| Fuel Tank | Stores the fuel, providing a reservoir for the system. |

| Fuel Pump | Draws fuel from the tank and delivers it to the engine at the required pressure. |

| Fuel Filter | Removes impurities and contaminants from the fuel before it reaches the engine. |

| Fuel Injector | Atomizes the fuel, ensuring a fine mist is delivered to the combustion chamber for efficient burning. |

| Fuel Lines | Hoses that transport fuel between the tank, pump, filter, and engine. |

Cooling System Parts Diagram

The cooling system is essential for maintaining optimal performance in any machinery. Understanding its components and their functions can significantly enhance maintenance and troubleshooting efforts. This section provides an overview of the key elements involved in the cooling mechanism, illustrating how they work together to prevent overheating.

Key Components of the Cooling System

Within the cooling assembly, several crucial elements contribute to efficient temperature regulation. These include the radiator, coolant reservoir, water pump, and thermostat. Each component plays a vital role in ensuring that the engine remains within a safe operating temperature.

Functionality of Cooling Elements

The radiator acts as a heat exchanger, dissipating excess heat from the coolant. The reservoir serves as a storage unit for the coolant, allowing for expansion and contraction as temperatures fluctuate. The water pump circulates the coolant through the system, while the thermostat regulates the flow based on temperature. Proper functioning of these components is crucial for effective heat management.

Brake Mechanism and Related Parts

The braking system is a critical component of any vehicle, ensuring safety and control during operation. This section delves into the various elements that contribute to the effective functioning of the braking mechanism, highlighting their roles and interconnections.

- Brake Pads: These components create friction against the rotors, enabling the vehicle to slow down or stop.

- Brake Rotors: These circular discs provide a surface for the brake pads to press against, facilitating the stopping process.

- Calipers: These devices house the brake pads and apply pressure to them, ensuring proper contact with the rotors.

- Brake Lines: These tubes transport hydraulic fluid from the master cylinder to the calipers, allowing for effective force application.

- Master Cylinder: This component converts the force from the brake pedal into hydraulic pressure, initiating the braking action.

Understanding these elements is essential for maintaining optimal performance and ensuring safety during operation. Regular inspection and maintenance of the braking mechanism can prevent issues and enhance longevity.

Deck and Mower Attachment Components

This section explores the essential elements associated with lawn cutting equipment and its attachments. These components play a crucial role in enhancing the functionality and efficiency of mowing machinery, ensuring optimal performance during operation.

The assembly typically includes various parts designed for smooth integration and effective operation. Key elements consist of the cutting deck, which houses the blades, and the mounting brackets that secure the deck to the main unit. Additionally, a range of pulleys and belts are present to facilitate movement and power transmission.

Maintenance of these components is vital for sustaining performance. Regular inspections can help identify wear and tear, enabling timely replacements and adjustments. Keeping the blades sharp and ensuring proper alignment of attachments can significantly improve the quality of the cut and the overall efficiency of the machine.

Understanding the interplay between these parts allows operators to make informed decisions regarding upgrades or replacements, ultimately leading to a better mowing experience and longevity of the equipment.

Suspension and Chassis Parts Layout

The layout of the suspension and chassis components plays a crucial role in the overall performance and stability of a vehicle. These elements are designed to work together seamlessly, ensuring that the machine can navigate various terrains while providing a smooth ride. A thorough understanding of the arrangement and functionality of these components is essential for effective maintenance and troubleshooting.

Key Components of the Suspension System

Several key components contribute to the effectiveness of the suspension system. Shock absorbers are vital for dampening vibrations, while coil springs help support the weight of the vehicle and absorb shocks from the ground. Additionally, control arms facilitate the movement of the wheels, maintaining proper alignment and handling.

Chassis Structure and Support

The chassis serves as the foundation for the entire vehicle, providing structural integrity and support for various systems. Components such as the frame and cross members distribute weight evenly and withstand forces during operation. Proper attention to these elements ensures optimal performance and longevity of the machine.

Exhaust System Components Overview

The exhaust system plays a crucial role in the performance and efficiency of an engine. It is responsible for directing exhaust gases away from the engine, reducing emissions, and ensuring optimal operation. Understanding the various elements of this system is essential for effective maintenance and troubleshooting.

Key components of the exhaust system include:

- Exhaust Manifold: This part collects exhaust gases from the engine cylinders and channels them into the exhaust pipe.

- Catalytic Converter: This component converts harmful gases into less harmful emissions before they exit the system.

- Muffler: The muffler reduces noise produced by the exhaust gases as they exit the vehicle.

- Exhaust Pipe: This pipe carries exhaust gases from the manifold to the rear of the vehicle.

- Exhaust Tips: These are the visible ends of the exhaust system, often designed for aesthetics and improved airflow.

Each of these components works together to ensure that the exhaust system functions efficiently, contributing to both performance and environmental considerations.

Maintenance and Replacement Parts Guide

This section provides essential information regarding upkeep and component substitution for your equipment. Regular maintenance is crucial to ensure optimal functionality and longevity. Understanding the necessary elements for service can significantly enhance performance and reduce downtime.

To maintain your machine effectively, familiarize yourself with the critical components that may require periodic inspection or replacement. This includes checking fluids, filters, and belts to prevent potential issues. By adhering to a scheduled maintenance routine, you can prolong the life of your machinery.

Key Areas for Attention:

- Fluids: Ensure that oil and coolant levels are regularly monitored and topped off.

- Filters: Change air and fuel filters as recommended to maintain efficient operation.

- Belts: Inspect drive belts for wear and replace them when necessary to avoid failure.

- Tires: Regularly check tire pressure and tread for optimal traction and stability.

By focusing on these crucial aspects, you can maintain the reliability of your machine and avoid unexpected breakdowns. Always refer to the manufacturer’s guidelines for specific maintenance schedules and recommendations.