Exploring the layout and structure of various machinery elements is essential for efficient maintenance and troubleshooting. By gaining insights into how different segments are interconnected, users can better address potential issues and perform routine servicing with ease. Diagrams that detail the arrangement of mechanical systems offer a clear view into the inner workings of complex devices.

A thorough breakdown of component relationships ensures that users can identify the exact area in need of attention. This structured approach minimizes downtime and prevents costly mistakes during repairs. Understanding the full configuration allows operators and technicians to keep their equipment running smoothly, ensuring optimal performance at all times.

Whether you are an experienced professional or a new user, having access to detailed schematics will significantly enhance your ability to manage and maintain your machinery effectively. Such visual guides offer an invaluable resource when navigating complex mechanical assemblies, allowing for a better understanding of the equipment as a whole.

Understanding Key Components of a Powerful Mower

The structure of any advanced lawn equipment relies on a combination of durable and well-designed parts, ensuring efficiency and reliability during operation. Understanding the main elements that contribute to the seamless functioning of such machines is essential for anyone looking to maintain or optimize their equipment’s performance.

Engine and Transmission

The core of any high-performance lawn vehicle is its engine, providing the necessary power to handle tough terrains and large areas. Paired with a robust transmission system, it allows smooth transitions between different speeds and gears, making it adaptable for various tasks and conditions.

Cutting and Steering Systems

Precision in cutting is achieved through a well-crafted mowing deck, equipped with sharp blades capable of handling dense grass and uneven surfaces. The steering mechanism ensures control and maneuverability, allowing the operator to navigate tight corners and obstacles effortlessly. Together, these systems define

Engine System Overview

The engine system plays a critical role in ensuring the optimal performance and reliability of any heavy-duty machine. It combines multiple interconnected components that work together to deliver the necessary power for various tasks. Understanding the structure and function of the engine system is essential for efficient maintenance and troubleshooting.

Main Components

- Cylinder block: The core of the engine, where fuel combustion takes place to generate power.

- Pistons: Move within the cylinder block to transfer the force of combustion into mechanical energy.

- Crankshaft: Converts the reciprocating motion of the pistons into rotational energy.

- Fuel injectors: Ensure precise fuel delivery for effective combustion.

- Cooling system: Maintains the temperature within

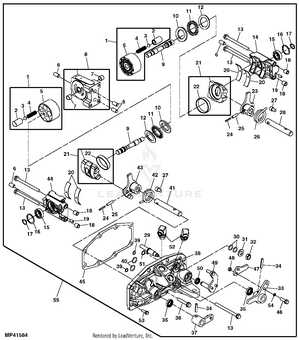

Transmission and Drive Parts Layout

Understanding the layout of the transmission and drive components is essential for ensuring smooth operation and proper maintenance of your equipment. These mechanical systems play a critical role in transferring power efficiently, allowing the vehicle to move and function as designed. A clear grasp of their arrangement can help identify issues more effectively and guide proper servicing procedures.

Key Components and Their Function

The transmission system consists of several interrelated elements, including gear sets, shafts, and a clutch mechanism. Each of these key components works together to control speed and torque, ensuring optimal power delivery to the drive system. The drive itself typically consists of axles, wheels, and differential gears, all of which contribute to

Hydraulic System Breakdown

The hydraulic system plays a crucial role in the overall operation, ensuring fluid control and power distribution to various components. This mechanism enables efficient movement and functionality of different elements, providing smooth and reliable performance under diverse conditions.

Pumps are at the heart of the system, driving the flow of hydraulic fluid throughout the machine. Proper maintenance of these pumps is essential for avoiding potential leaks or pressure drops, which can negatively impact performance. Regular inspection can help identify any wear or damage early on.

Equally important are the valves, which regulate the flow and direction of the fluid. These control elements ensure that the right amount of pressure is applied to the necessary areas, allowing for precise operation. Their calibration and upkeep are

Steering Mechanism and Key Parts

The steering system plays a crucial role in ensuring precise control and maneuverability of the vehicle. It is designed to provide smooth and accurate navigation, even in challenging conditions. The components within this system work together to convert driver inputs into seamless directional changes, ensuring optimal performance during operation.

Key Components of the Steering System

The primary elements of the steering system include the steering wheel, which serves as the main interface between the operator and the machine, and the linkage assembly, responsible for transferring the rotational movement to the wheels. Each part must be in optimal condition for proper handling and reliability.

Steering Control and Functionality

A well-maintained steering system is essential for effective control. Key factors like responsiveness, ease of turning

Fuel System Connections

The efficiency of any machinery heavily relies on the proper integration of its fuel system. This network of components ensures that fuel is delivered effectively from the tank to the engine, enabling optimal performance. Understanding the layout and functionality of these connections is crucial for maintaining operational reliability.

At the core of the fuel system lies the tank, which serves as the primary reservoir for the liquid energy source. From this point, various hoses and connectors facilitate the movement of fuel. Clamps play a vital role in securing these hoses, preventing leaks and ensuring a steady flow. Filters are also integral, as they remove impurities that could harm the engine’s internals.

Additionally, the fuel pump is a critical component, responsible for drawing the fuel from the tank and pushing it toward the engine. Its placement and connection to the rest of the system must be accurate to maintain pressure and efficiency. Regular inspections of these connections can help identify wear or potential issues before they escalate, thereby extending the life of the machinery.

Electrical Wiring and Key Components

The electrical system in modern machinery plays a crucial role in ensuring optimal performance and reliability. This section provides an overview of the essential wiring configurations and significant components that facilitate the proper functioning of the equipment. Understanding these elements is vital for effective troubleshooting and maintenance.

Wiring Configuration Overview

A well-organized wiring layout is essential for efficient operation. It ensures that electrical signals are transmitted effectively across various components, allowing for seamless interaction and functionality. The arrangement typically includes connectors, fuses, and wiring harnesses that serve as pathways for current flow.

Key Components of the Electrical System

Several vital elements contribute to the overall electrical performance. These components are designed to manage power distribution, enhance safety, and provide operational control. Below is a summary of the primary electrical components:

Component Function Batteries Supply electrical energy to start the engine and power accessories. Alternator Generates electrical power while the engine is running, recharging the battery. Fuses Protect electrical circuits from overloads and short circuits. Relays Act as switches to control larger electrical loads using smaller signals. Connectors Join electrical wires, ensuring secure connections for reliable operation. Cooling System Structure

The cooling mechanism of outdoor power equipment is vital for maintaining optimal operating temperatures and preventing overheating. This system consists of various components that work in harmony to dissipate heat generated during operation, ensuring that the engine runs efficiently and reliably. Understanding the layout and function of each part can help in maintaining and troubleshooting the system effectively.

Typically, this assembly includes a series of interconnected elements, such as radiators, hoses, and fans, designed to regulate the temperature of the engine. The circulation of coolant is crucial for transporting heat away from the engine block, while the radiator cools the liquid before it re-enters the system. A robust cooling system not only enhances performance but also extends the lifespan of the machinery.

Component Function Radiator Dissipates heat from the coolant into the atmosphere. Coolant Absorbs heat from the engine and transfers it to the radiator. Water Pump Circulates the coolant through the engine and radiator. Thermostat Regulates coolant flow based on temperature to maintain optimal operating conditions. Cooling Fans Enhance air flow through the radiator, improving heat dissipation. Front and Rear Axle Configuration

The configuration of axles plays a critical role in the overall performance and stability of a vehicle. Understanding how these components interact can significantly enhance the efficiency and handling of machinery, particularly in challenging terrains.

Importance of Axle Design

Axles serve as the backbone of any machine, facilitating the transfer of power from the engine to the wheels. The design of both front and rear axles affects various aspects, including:

- Load distribution

- Traction and maneuverability

- Stability and control

Front and Rear Axle Characteristics

Each axle type has distinct features tailored to its specific function:

- Front Axle:

- Typically designed for steering and weight-bearing

- Can feature independent suspension for improved handling

- Rear Axle:

- Primarily responsible for power delivery and stability

- Often incorporates a differential to enhance traction on uneven surfaces

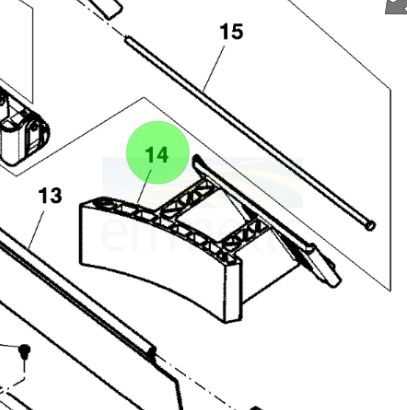

Deck and Mower Parts Distribution

The arrangement of components related to cutting equipment plays a vital role in the overall efficiency and functionality of the machinery. Understanding the layout and distribution of these elements allows users to maintain and repair their equipment more effectively.

Components Overview: The cutting assembly consists of various elements, including blades, spindles, and housings, all designed to work in harmony. Each part has a specific role, ensuring optimal performance during operation.

Maintenance Considerations: Regular inspection and replacement of worn or damaged components are crucial for preserving the integrity of the mowing system. Proper distribution of these elements facilitates smooth operation and enhances longevity.

Assembly and Compatibility: Knowing how components interact and fit together is essential for effective repairs. Compatibility among different parts can influence performance, so it’s important to select the right items for replacements.

Exhaust and Emission Control Elements

The components responsible for managing exhaust and emissions play a vital role in enhancing engine performance and ensuring compliance with environmental standards. These elements work together to minimize harmful outputs while optimizing the efficiency of the machine.

Key Components

- Exhaust Manifold: Collects and directs exhaust gases from the engine cylinders to the exhaust system.

- Catalytic Converter: Reduces harmful emissions by converting them into less harmful substances through chemical reactions.

- Muffler: Silences engine noise while allowing exhaust gases to escape efficiently.

- Oxygen Sensors: Monitor the oxygen levels in the exhaust gases to adjust fuel mixture for optimal combustion.

Importance of Maintenance

Regular inspection and maintenance of these components are essential for reliable operation. Neglecting exhaust and emission control systems can lead to increased emissions, reduced fuel efficiency, and potential damage to the engine.

Braking System Assembly

The braking system plays a crucial role in ensuring safety and control during operation. This assembly is designed to provide reliable stopping power while enhancing maneuverability. Understanding the components and their arrangement is essential for effective maintenance and repair.

Components of the Assembly

The braking mechanism comprises several key elements, including the brake pads, rotors, and calipers. Each component interacts seamlessly to deliver optimal performance. Regular inspection of these parts is vital to prevent wear and maintain efficiency.

Maintenance Tips

To ensure longevity, it is important to follow proper maintenance procedures. Regularly check the brake fluid level and inspect for any leaks or damage. Additionally, replacing worn-out pads and rotors will help maintain the system’s functionality and safety. Regular maintenance not only enhances performance but also extends the life of the braking system.

Chassis and Frame Construction

The structure of a machine is fundamental to its overall performance and durability. A robust chassis and frame provide the necessary support for various components, ensuring stability during operation. This section explores the intricacies involved in the design and assembly of these essential elements, focusing on their significance in enhancing functionality and reliability.

Materials Used in Frame Design

Frame construction typically involves a combination of high-strength steel and lightweight alloys. These materials are chosen for their ability to withstand stress while minimizing overall weight. The careful selection of components plays a crucial role in balancing strength and efficiency, resulting in a vehicle that is both resilient and agile.

Assembly Techniques

Assembly of the chassis requires precision engineering to ensure all parts fit together seamlessly. Techniques such as welding, bolting, and riveting are employed to create a solid structure that can endure demanding tasks. Each method contributes to the overall integrity of the frame, facilitating long-term reliability and performance under various operating conditions.