Understanding the intricate layout of essential components in lawn care machinery is vital for efficient maintenance and operation. A detailed overview can provide valuable insights into how each element interacts within the overall system. This knowledge is beneficial not only for troubleshooting but also for enhancing performance and longevity.

By examining the configuration of various components, users can identify specific parts that may require attention or replacement. This exploration enables individuals to grasp the functionality of each section, ensuring they can address any issues promptly. Familiarity with these components ultimately leads to improved upkeep and operational success.

In this article, we will delve into a structured representation of the essential elements, highlighting their roles and interconnections. Gaining a clear understanding of this arrangement empowers users to make informed decisions regarding their machinery, fostering a more productive and effective lawn care experience.

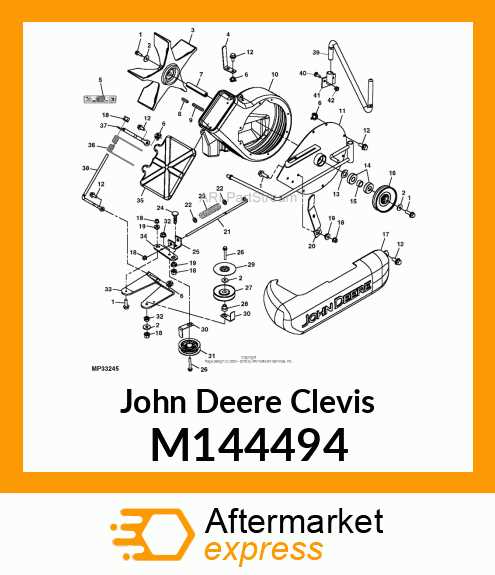

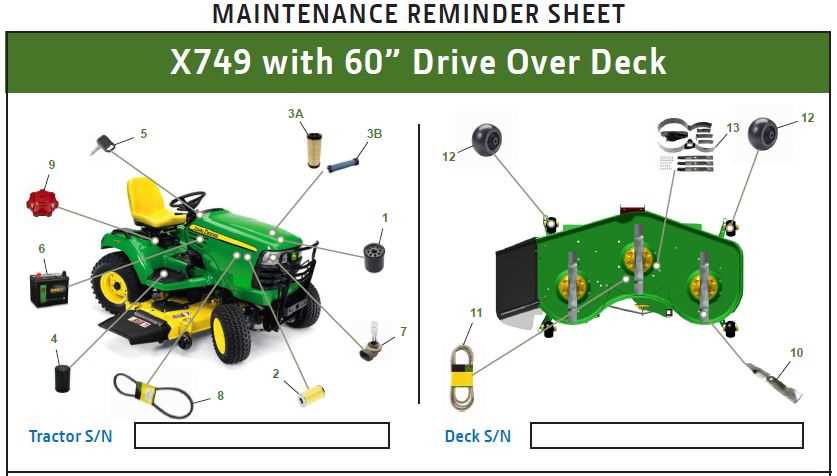

Understanding John Deere X749 Components

This section delves into the intricate elements that contribute to the functionality and performance of this well-known machine. Gaining insight into these various components can help users appreciate their importance and how they work in unison to ensure optimal operation.

Key Features of the Machine

- Powerful engine providing reliable performance

- Robust transmission system for smooth operation

- Advanced steering mechanism ensuring precision handling

- Durable chassis supporting overall stability

Essential Accessories

- Attachment options enhancing versatility

- Maintenance tools ensuring longevity

- Safety features promoting secure operation

Essential Parts for Efficient Operation

Maintaining optimal functionality in machinery requires a comprehensive understanding of its key components. These elements play a crucial role in ensuring smooth performance and longevity. By focusing on the fundamental components, operators can achieve enhanced reliability and productivity.

Key Components to Consider

Several crucial components significantly impact the overall effectiveness of machinery. Understanding their functions helps in proper maintenance and timely replacements, which can prevent costly breakdowns.

| Component | Function | Importance |

|---|---|---|

| Engine | Powers the machinery | Critical for operation |

| Transmission | Transfers power from the engine | Ensures efficient movement |

| Hydraulic System | Controls various functions | Essential for versatility |

| Steering Mechanism | Enables directional control | Important for maneuverability |

| Chassis | Supports all components | Provides structural integrity |

Benefits of Regular Maintenance

Routine upkeep of essential components not only prolongs the lifespan of the equipment but also enhances operational efficiency. By identifying and addressing wear and tear early, operators can avoid unexpected failures and ensure seamless performance.

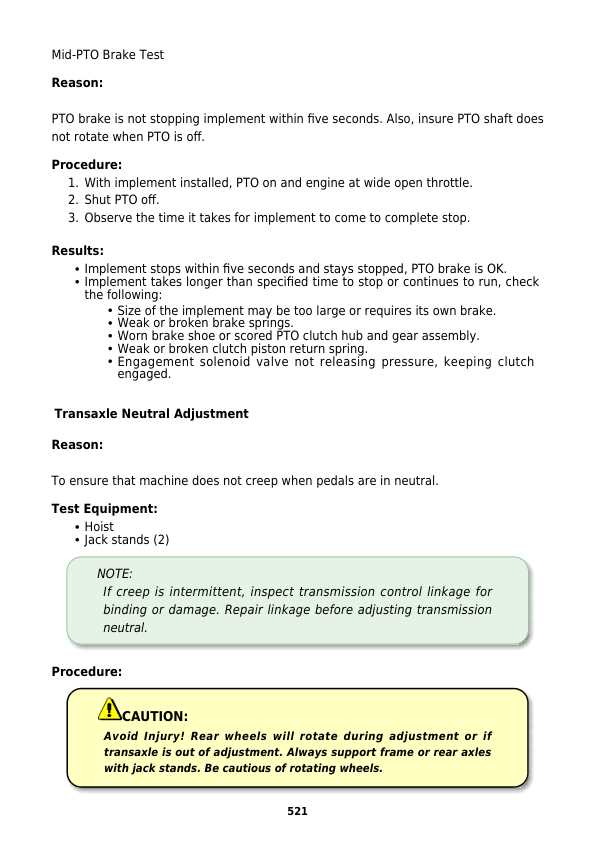

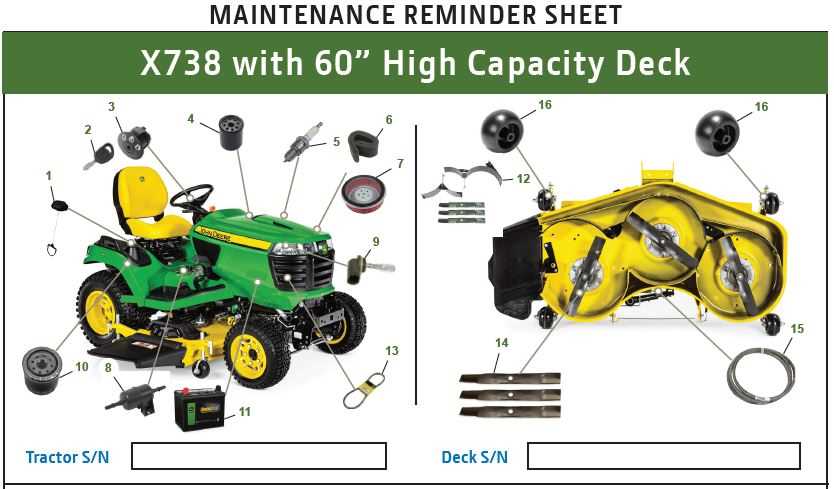

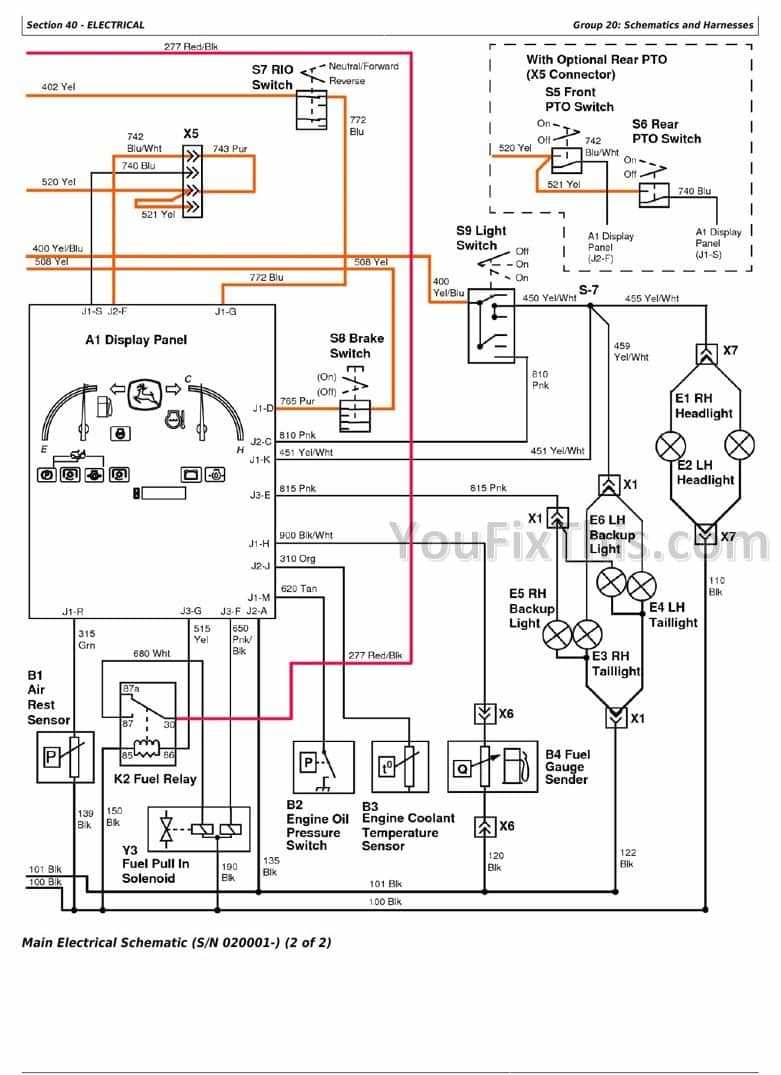

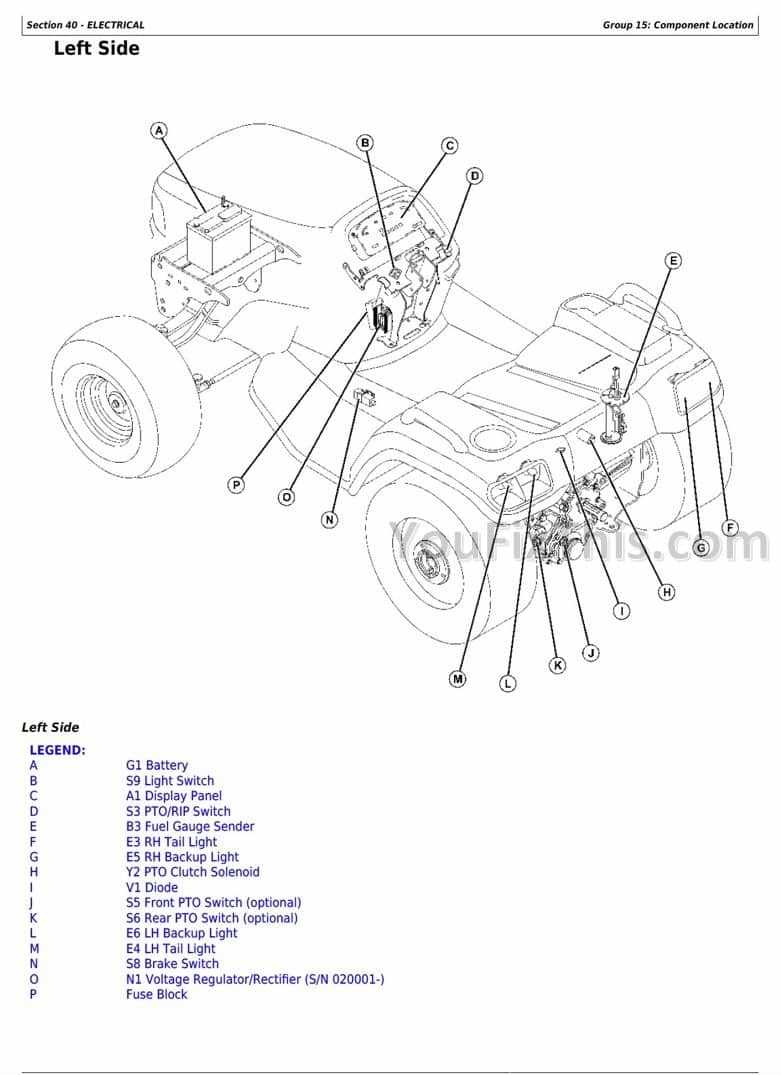

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair of machinery. These visual representations provide essential information about the components of a machine and their relationships. By mastering the art of interpreting these visuals, users can enhance their ability to identify specific elements and their functions.

Begin by examining the overall layout. The illustration typically includes a comprehensive view of the machinery, highlighting various sections and assemblies. Familiarizing yourself with the general organization will make it easier to locate individual components.

Next, pay attention to the labels and numbers. Each part will often be marked with a unique identifier, which corresponds to a list or legend that details the specifications. This system helps streamline the identification process, ensuring that users can quickly find the necessary components for repairs or replacements.

Additionally, look for arrows and lines that indicate connections or relationships between different elements. Understanding how these parts interact can provide insight into the overall functioning of the machinery and guide troubleshooting efforts.

Finally, refer to supplementary documentation, such as manuals or guides, that accompany the illustrations. These resources can offer valuable context and additional details about maintenance procedures, making the entire process more manageable.

Common Issues with X749 Parts

Various components in heavy-duty equipment can experience wear and tear over time. Understanding the most frequent problems that occur helps to address them efficiently, ensuring smooth operation and preventing costly breakdowns. Identifying common malfunctions early on extends the lifespan of the machine.

Wear and Tear of Mechanical Components

Over time, mechanical systems tend to degrade due to constant use. The most common issues include deterioration of essential moving parts, leading to decreased efficiency and potential failure if left unaddressed.

- Reduced performance due to friction

- Failure of bearings or joints

- Worn-out belts

Replacement Parts: What to Consider

When maintaining heavy-duty equipment, choosing the right components is essential for ensuring long-term performance and durability. Understanding the specifications and compatibility of each item with your machinery is key to avoiding frequent breakdowns and unnecessary costs. Identifying the correct replacement involves more than just finding a similar model; there are crucial factors to consider for a seamless fit and optimal function.

Compatibility and Fit

One of the first aspects to evaluate is whether the new component aligns perfectly with your machine’s design. Improper fit can cause operational issues and may lead to further mechanical failures. Checking dimensions, materials, and functional requirements ensures smooth integration and prevents potential malfunctions.

Quality and Durability

Opting for high-quality components will directly impact the longevity of your equipment. It’s important to assess the material strength and resistance to wear, esp

Maintenance Tips for Longevity

Ensuring the durability of your equipment involves regular care and attention. By following some essential maintenance practices, you can enhance performance and extend the lifespan of your machinery.

Regular Inspections

- Check for any signs of wear or damage.

- Inspect fluid levels and replenish as necessary.

- Examine belts and hoses for signs of deterioration.

Cleaning and Lubrication

- Clean components to prevent dirt buildup.

- Lubricate moving parts to reduce friction.

- Ensure filters are clean for optimal airflow and function.

By adopting these practices, you will contribute to the efficient operation of your machinery and minimize the need for repairs, ultimately saving time and resources.

Identifying OEM vs. Aftermarket Parts

When maintaining machinery, understanding the differences between original manufacturer components and those produced by third-party suppliers is crucial. This distinction can affect not only the performance and longevity of equipment but also the warranty and overall value. Recognizing the characteristics of each type can help in making informed decisions for repairs and replacements.

Characteristics of Original Equipment Manufacturer Components

Original components are designed specifically for a particular model, ensuring compatibility and quality. These items typically come with a guarantee from the manufacturer, providing peace of mind regarding their reliability. Additionally, they often retain resale value better than alternatives due to their perceived quality and authenticity.

Benefits of Third-Party Components

Third-party offerings can provide cost-effective alternatives, often with comparable functionality. They may also come in a wider range of options, allowing for customization and potential performance enhancements. However, it is essential to research the reputation of suppliers to ensure that these components meet necessary standards for safety and effectiveness.

Tools Needed for Parts Replacement

Replacing components of machinery requires specific implements to ensure efficiency and safety. Having the right tools on hand simplifies the process, minimizes risks, and promotes a smoother workflow.

Commonly needed implements include wrenches for loosening and tightening fasteners, screwdrivers for handling various screws, and pliers for gripping and bending materials. Additionally, socket sets are essential for reaching hard-to-access areas.

To enhance safety, consider using gloves and goggles while working. A well-organized toolbox will also keep everything easily accessible, allowing for a more efficient repair experience.

Finding Genuine John Deere Parts

When maintaining your equipment, ensuring the use of authentic components is crucial for optimal performance and longevity. Genuine items are designed to meet the exact specifications of your machine, providing reliability that aftermarket alternatives often cannot match.

Importance of Authentic Components

Using original components ensures that your machine operates efficiently and minimizes the risk of unexpected failures. These items undergo rigorous testing and adhere to stringent quality standards, which can significantly impact the overall functionality of your machinery.

Where to Source Original Items

To locate authentic components, consider visiting authorized dealers or reputable retailers specializing in agricultural machinery. Online platforms also offer a variety of options, but it’s vital to verify the credibility of the source to avoid counterfeit items. Always check for warranty information and return policies to safeguard your investment.

Assembly Process of Key Components

The assembly of essential elements in machinery is a critical process that ensures optimal functionality and longevity. Each component must fit together precisely to create a cohesive system that operates efficiently.

Initially, it is vital to organize all necessary components and tools. This step aids in streamlining the process and preventing any delays. Each part should be inspected for quality to guarantee that it meets the required standards before assembly begins.

During the assembly, careful attention must be paid to the alignment of components. Proper alignment minimizes wear and tear, ensuring a longer lifespan for the assembly. Securing parts with appropriate fasteners is crucial; this guarantees stability and reduces the risk of malfunction.

Finally, testing the assembled unit is essential to confirm its operational integrity. Identifying any issues at this stage allows for timely adjustments, ultimately enhancing the performance of the entire system.

Resources for Troubleshooting X749 Issues

Effective troubleshooting relies on a variety of resources to identify and resolve complications. Whether you are facing mechanical challenges or electronic malfunctions, utilizing comprehensive guides and community support can streamline the process of diagnosing and fixing problems. This section provides essential tools and references to assist you in your troubleshooting efforts.

Useful Manuals and Guides

Accessing well-structured manuals and guides can provide step-by-step instructions for diagnosing issues. These resources often include detailed schematics, troubleshooting tips, and maintenance schedules that are invaluable for both novice and experienced users.

Online Communities and Forums

Engaging with online forums and communities dedicated to equipment maintenance can facilitate problem-solving. These platforms allow users to share experiences, offer advice, and discuss common issues, creating a collaborative environment for troubleshooting.

Resource Type Description Link Manuals Detailed guides for equipment operation and maintenance. View Manuals Forums Community discussions and support for troubleshooting. Visit Forums Tutorials Step-by-step videos demonstrating common repairs. Watch Tutorials