The internal workings of a riding mower can often seem complex. Each element has a specific function, working together to ensure smooth operation. Understanding how these components interact can simplify both maintenance and troubleshooting, providing a clearer picture of what keeps the machine running efficiently.

When examining the layout of the main assemblies, it’s important to recognize how integral every piece is to the overall performance. From the engine to the smallest mechanisms, every element plays a role in delivering power, control, and precision. Familiarity with these components can help prevent breakdowns and extend the equipment’s lifespan.

Gaining insight into the equipment’s layout not only aids in repairs but also improves the user’s confidence in handling various tasks. By grasping the relationship between critical parts, one can address issues more effectively and keep the machine in top condition for years to come.

Key Components of the Lawn Mower

The mechanical design of this lawn care machine relies on various essential elements that work together to ensure smooth operation and efficient performance. Understanding these fundamental parts can help users maintain and troubleshoot the equipment more effectively.

Engine – The powerhouse of the machine, responsible for driving both the cutting blades and the movement of the mower itself. A well-maintained engine ensures consistent performance and longevity.

Cutting Deck – This section houses the blades that are crucial for achieving a precise and even cut. The width of the deck determines the area covered during each pass.

Transmission System – This mechanism controls the speed and direction of the mower, offering ease of control for the operator. A properly functioning transmission is key for maneuverability.

Control Panel – The interface where the operator manages speed, blade engagement, and other vital functions. Clear and intuitive controls enhance user comfort and machine efficiency.

Wheels and Tires – Designed to provide stability and smooth movement across various terrains, these components also impact the mower’s grip and balance during operation.

Understanding the Z335E Drive System

The drive mechanism in this model is a crucial component that allows the machine to move efficiently and perform its tasks. Its configuration ensures smooth power transmission from the engine to the wheels, giving operators control and precision when maneuvering in various conditions.

Key Components of the Drive System

The primary elements responsible for the propulsion include the engine, transmission, and belt systems. These parts work together to deliver consistent power and maintain stability. Each part has a specific role in ensuring the smooth operation of the entire system.

How the System Operates

The drive setup works by transmitting energy through a belt and pulley system, which converts the engine’s rotational force into motion. This system ensures reliable movement, allowing for efficient control over speed and direction. Proper maintenance of this setup is essential to keep the machine running smoothly over time.

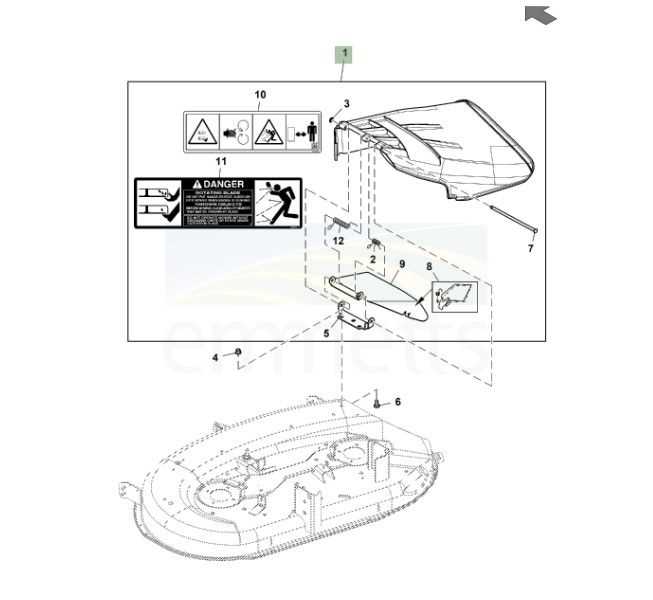

Exploring the Mower Deck Assembly

The mower deck assembly is an essential component in any lawn care equipment, directly responsible for cutting and distributing grass clippings. This section delves into the key elements that make up this assembly, ensuring efficient performance and smooth operation. Understanding the different parts involved and their functions can help in maintenance and troubleshooting.

The core structure consists of various blades, pulleys, and belts working in harmony to ensure precision cutting. Blades are mounted in specific configurations, while pulleys and belts transmit the necessary power from the engine to keep the blades rotating at optimal speed. Each piece must be properly aligned to avoid issues like uneven cuts or mechanical wear.

Proper care and regular inspection of the mower deck assembly can extend its lifespan, preventing damage to the underlying mechanisms. Whether you are performing routine maintenance or addressing specific issues, familiarizing yourself with this assembly is key to keeping your machine in peak condition.

Detailed Look at the Z-Series Steering

The steering system in this model is designed to offer precise and responsive control, allowing for smooth maneuverability, even in tight spaces. It combines essential components that work together to ensure seamless navigation, providing users with an enhanced driving experience.

Core Components of the Steering Mechanism

The steering system includes several key elements that contribute to its effectiveness. These components interact to deliver precise control and stability during operation.

- Steering Levers: These are the primary controls that allow the operator to direct the machine efficiently. By adjusting each lever, the operator can move forward, backward, or turn in place.

- Control Linkages: These parts connect the levers to the wheels, transmitting movement from the operator’s hands to the tires, ensuring quick response.

- Hydraulic System: A vital element that assists in providing smooth and effortless steering, reducing operator fatigue.

Steering Performance in Various Conditions

Whether navigating flat lawns or uneven terrain, the steering system adapts to different conditions to maintain smooth control. By leveraging advanced mechanical and hydraulic components, the machine ensures stability and ease of use.

- Maneuverability: The steering system allows for zero-turn capabilities, making it easy to work around obstacles like trees and garden beds.

- Adjustability: Operators can fine-tune the steering sensitivity to match their preferences, improving handling across different environments.

Fuel System Parts Breakdown

The fuel system is a crucial component for ensuring smooth and efficient engine performance. It involves various interconnected elements responsible for delivering fuel from the tank to the engine. Proper functioning of these elements guarantees optimal combustion, power generation, and fuel efficiency. Regular inspection and maintenance of these components are essential for reliable operation.

Key Components Overview

Among the vital elements of the fuel system are the tank, which stores the fuel, the fuel pump that regulates flow, and filters ensuring clean fuel delivery. The lines and hoses play a critical role in connecting these elements, maintaining seamless flow to the engine for combustion.

Potential Issues and Maintenance

Over time, elements of the fuel system may wear out or become clogged. Fuel filters, in particular, require frequent checks as they prevent debris from entering the engine. Hoses and lines may also need replacement if cracks or leaks are detected, ensuring the system remains leak-proof and efficient.

Blade Maintenance and Replacement Guide

Maintaining and replacing the cutting elements of your lawn care equipment is essential for optimal performance and longevity. Regular upkeep ensures that the blades operate efficiently, providing a clean cut and promoting healthy grass growth. This section offers guidance on how to effectively care for and replace these critical components.

Routine Maintenance

Regularly inspecting the cutting edges for damage is crucial. Look for signs of wear such as nicks, dents, or rust. Sharpening blades as needed can significantly enhance cutting efficiency and reduce strain on the engine. Cleaning the blades after each use prevents grass buildup, which can lead to corrosion and diminished performance over time.

Replacement Process

When it becomes necessary to replace the cutting elements, begin by ensuring the equipment is powered off and secure. Remove any debris and access the blade assembly according to the manufacturer’s instructions. Carefully detach the old blades and install the new ones, ensuring they are properly aligned and tightened. After replacement, double-check that all components are secure before resuming operation.

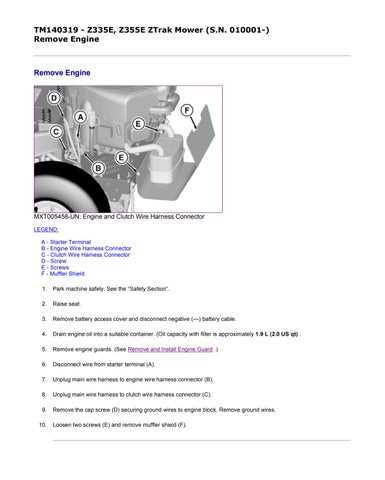

Electrical System Overview for Z335E

The electrical system is a critical component of modern mowing equipment, ensuring efficient operation and performance. This system consists of various elements that work in unison to provide power to essential functions, from starting the engine to powering accessories. Understanding the layout and functionality of these components can help in troubleshooting and maintenance.

Key Components

- Battery: The power source that provides the necessary energy to start the engine and operate electrical systems.

- Starter Motor: Engages the engine when the ignition is activated, initiating the combustion process.

- Ignition System: Responsible for igniting the fuel-air mixture in the engine, ensuring reliable starting and operation.

- Wiring Harness: Connects various electrical components, facilitating the flow of electricity throughout the system.

- Fuse Box: Protects the electrical system by interrupting the current flow in case of overloads or short circuits.

Functionality and Maintenance

Proper functionality of the electrical system is crucial for optimal performance. Regular inspection of the battery condition, ensuring tight connections, and checking for any frayed wires are essential maintenance practices. Replacing worn-out components promptly can prevent larger issues, ensuring smooth operation of the equipment.

Hydraulic System Functionality

The hydraulic system plays a crucial role in the operation of various machinery, enabling efficient power transmission and control. This system utilizes pressurized fluid to facilitate movement and force, allowing for smooth and effective operation of components such as lift mechanisms, steering systems, and attachments.

Key aspects of hydraulic systems include:

- Fluid Dynamics: The movement of hydraulic fluid is essential for transferring power within the system, ensuring that all components function seamlessly.

- Pressure Regulation: Maintaining optimal pressure is vital for the reliable operation of the hydraulic system, preventing failures and enhancing performance.

- Control Mechanisms: Various control valves are employed to direct the flow of fluid, allowing operators to manage the system’s functions with precision.

Understanding the mechanics of hydraulic systems is essential for proper maintenance and troubleshooting. Regular inspections and timely replacements of hydraulic components can significantly improve the efficiency and lifespan of the machinery.

Seat and Comfort Features

In modern riding equipment, comfort and ergonomic design are essential for an enjoyable experience. The seating arrangement and associated features play a crucial role in enhancing user satisfaction and productivity during operation.

High-quality seating systems often include several attributes that cater to the operator’s needs:

- Adjustable Seats: Customizable seating positions allow users to find the most comfortable and supportive stance, reducing fatigue during extended use.

- Padding and Cushions: Soft padding and contoured cushions provide additional comfort, promoting better posture and less strain on the back.

- Armrests: Integrated armrests offer support for the arms, allowing for a more relaxed driving position and reducing tension in the shoulders.

- Seat Suspension: Advanced suspension systems absorb bumps and vibrations, enhancing the overall ride quality and protecting the operator from jolts.

- Climate Control: Some models feature climate-controlled seating, providing heating or cooling options to ensure comfort in various weather conditions.

These features collectively contribute to a more enjoyable and productive experience, allowing operators to focus on their tasks while minimizing discomfort. Investing in equipment with superior seating and comfort features can significantly enhance performance and satisfaction.

Troubleshooting Common Parts Issues

Addressing typical component-related challenges is crucial for maintaining optimal performance and ensuring longevity in machinery. Identifying and resolving these issues promptly can prevent further complications and costly repairs. Below are some common concerns that users may encounter.

Worn Components: Over time, certain elements may experience wear and tear due to prolonged usage. Regular inspections are essential to identify any signs of deterioration, such as cracks, fraying, or discoloration. Replacing these elements at the first sign of damage can help maintain efficiency.

Improper Installation: Incorrect assembly of components can lead to operational failures. Ensure that all elements are fitted according to the manufacturer’s specifications. If issues arise, refer to the installation manual to verify that each component is secured correctly.

Inadequate Lubrication: Insufficient lubrication can cause increased friction and heat, leading to potential breakdowns. Regularly check and maintain lubrication levels to ensure smooth operation and reduce the risk of component failure.

Electrical Problems: Malfunctions in the electrical system may arise from faulty connections or damaged wiring. Inspect all electrical components, ensuring they are properly connected and free from corrosion. Addressing electrical issues promptly can prevent more significant failures.

Contaminated Fluids: Using contaminated hydraulic fluids can adversely affect performance. Regularly check fluid quality and replace it if it appears dirty or contaminated. This practice helps maintain proper operation and prolongs the life of the machinery.

By following these guidelines and addressing common issues proactively, users can ensure their machinery remains in good working order, ultimately enhancing performance and reliability.

Where to Find Genuine Replacement Parts

Finding authentic components for your machinery is crucial for maintaining optimal performance and longevity. The right replacements ensure that your equipment operates smoothly and efficiently. Here are several reliable sources where you can obtain quality replacements.

- Authorized Dealers: These establishments specialize in specific brands and provide genuine components. They often have a vast inventory and knowledgeable staff who can assist you in selecting the right parts.

- Online Retailers: Various websites specialize in offering authentic components. Ensure that you choose reputable sites with positive customer reviews to guarantee the quality of the products.

- Manufacturer’s Website: Many manufacturers have online stores or provide links to authorized retailers. This option often guarantees the authenticity of the items.

- Local Repair Shops: Many local repair centers maintain relationships with manufacturers and can source original components. They may also offer installation services.

- Trade Shows and Expos: Attending industry events can connect you with suppliers who offer genuine replacements. These events provide opportunities to learn about new products and technologies.

By utilizing these sources, you can ensure that your machinery remains in top condition with high-quality replacements.