Understanding the detailed layout of essential mechanical elements is crucial for maintaining and repairing any equipment. A well-organized schematic provides clarity on how each individual piece interacts with the system as a whole, ensuring smoother operation and effective troubleshooting. The importance of this cannot be overstated for those looking to extend the lifespan of their machines through proper care and maintenance.

In this section, we delve into the structural breakdown of key elements, offering a close look at how various mechanisms work together seamlessly. By examining each segment in detail, operators and technicians alike can gain valuable insight into both assembly and potential problem areas, making future repairs more efficient and less daunting.

Having access to a clear and precise visual representation of the mechanical components ensures that every maintenance step is accurate. The overall functionality of the machine relies on the proper arrangement of each element,

John Deere Z425 54C Parts Diagram Overview

This section provides a detailed examination of the essential components and their layout, offering a clear understanding of how various elements are arranged. It simplifies maintenance and repair tasks by illustrating the interconnection of mechanical and functional pieces. By breaking down each unit, users can easily identify and replace any worn-out or damaged elements.

- Engine system and related components

- Drive mechanisms and connections

- Cutting assembly and blade setup

- Steering and control modules

- Frame structure and mounting points

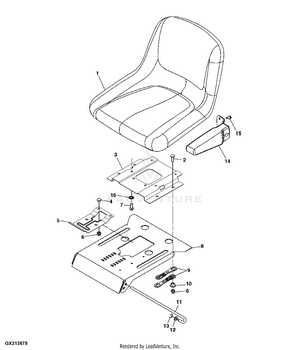

Key Components of the Z425 Mower

The structure of this lawn mower consists of several essential elements, each contributing to its efficient performance. Understanding these parts helps in maintaining the machine and ensuring smooth operation over time.

- Engine Unit: The core power source, ensuring steady performance and the ability to handle various mowing conditions.

- Cutting Deck: A vital feature responsible for achieving a precise cut, the deck’s width determines the coverage area during each pass.

- Blades: These sharpened components play a crucial role in cutting the grass efficiently, en

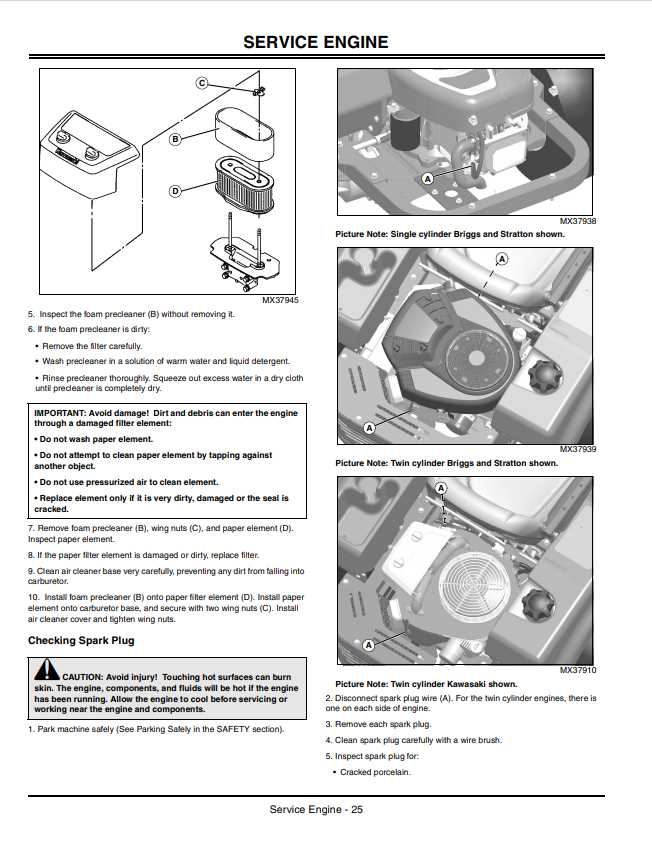

Engine Diagram and Specifications

The engine layout provides a clear understanding of how the various mechanical components are organized and work together. It is essential for maintaining and troubleshooting the motor, ensuring all parts function efficiently.

Main Components Overview

This section outlines the primary elements of the engine, including key mechanical and functional parts necessary for operation. Each component plays a specific role in delivering optimal performance and durability.

- Crankshaft – Transmits power from the engine to other systems.

- Pistons – Move within the cylinders to generate motion.

- Cylinder Head – Houses the intake and exhaust valves.

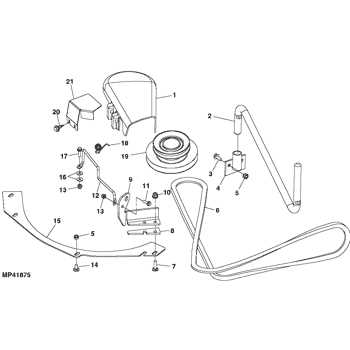

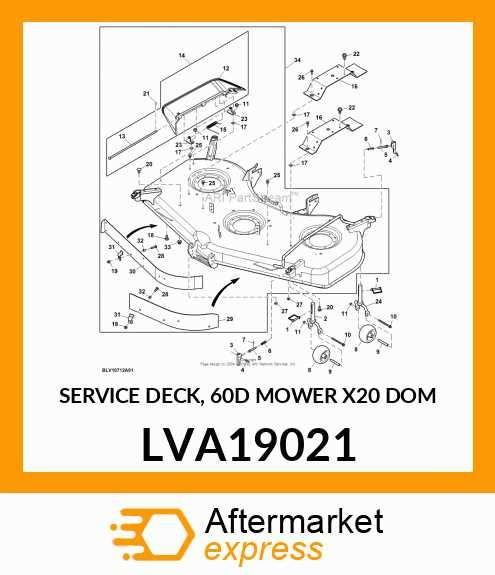

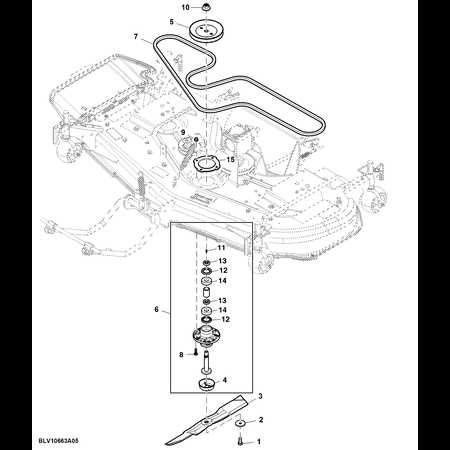

Understanding the Cutting Deck Assembly

The cutting deck assembly plays a crucial role in ensuring efficient grass cutting and even trimming. It consists of various components that work together to deliver a smooth and uniform cut. Familiarizing yourself with how these elements interact can help in maintaining the deck, diagnosing issues, and performing necessary adjustments to optimize performance.

The assembly includes the blade mechanism, pulleys, belts, and other parts that enable the cutting function. Proper alignment and maintenance of these components are vital for effective operation, ensuring durability and preventing uneven wear. Regular inspection and upkeep can extend the longevity of the cutting system and improve overall mowing efficiency.

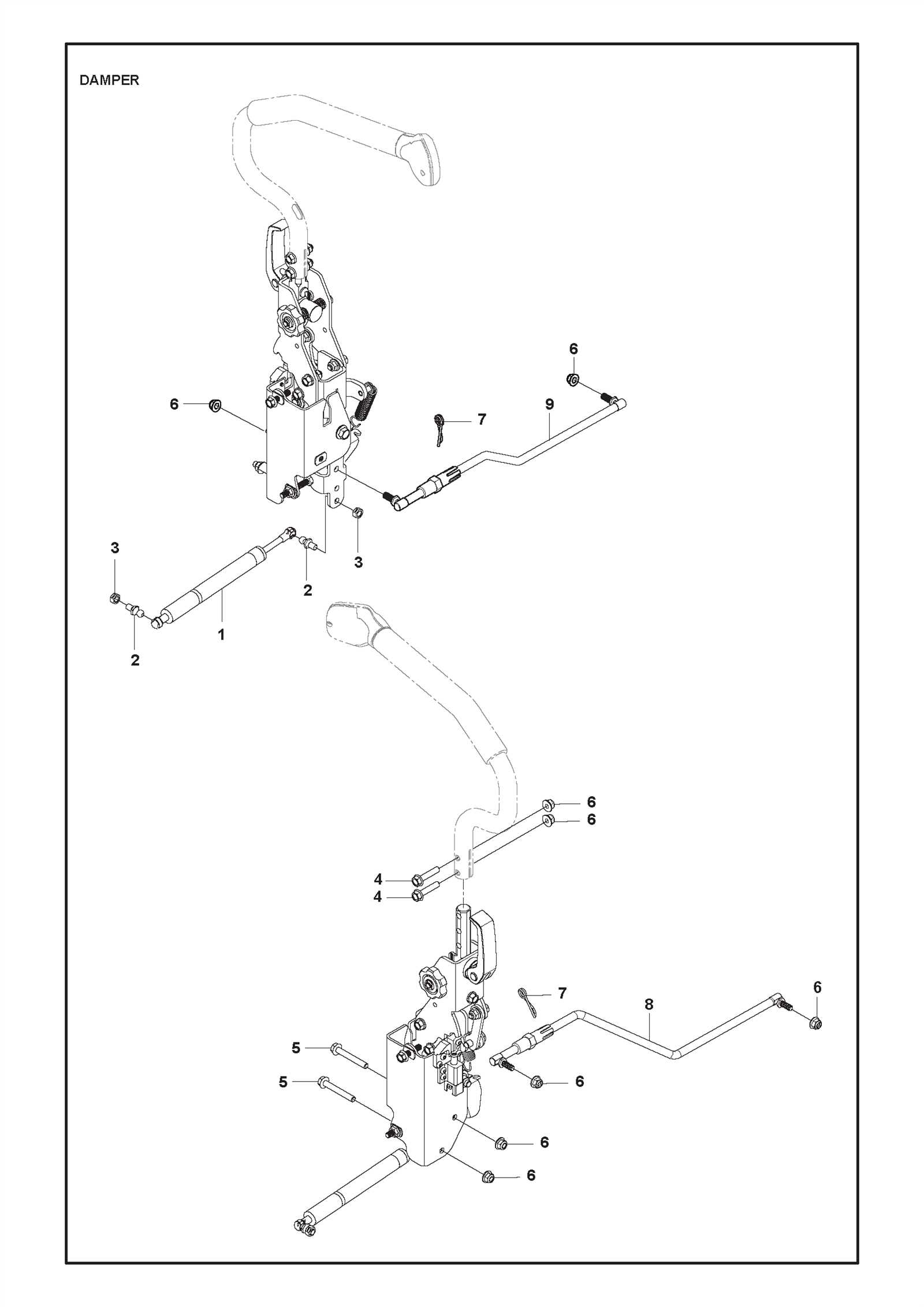

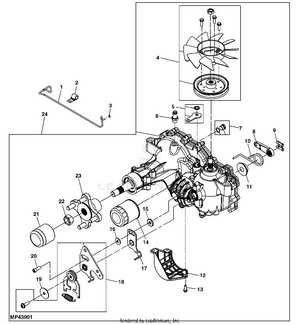

Drive System Parts Breakdown

The drive system consists of multiple interconnected components that work together to ensure smooth operation and efficient power transmission. Understanding the breakdown of these elements can help with maintenance and troubleshooting, ensuring that each part functions optimally.

- Transmission Assembly – This section manages the transfer of power from the engine to the wheels, ensuring consistent speed and control.

- Hydraulic Lines – These are responsible for channeling fluid to control various system functions, contributing to the smooth movement of the vehicle.

- Drive Belt – A key component in transferring engine power to the drive mechanism, ensuring the proper operation of the vehicle.

- Pulleys – They guide and support the belts, enabling effecti

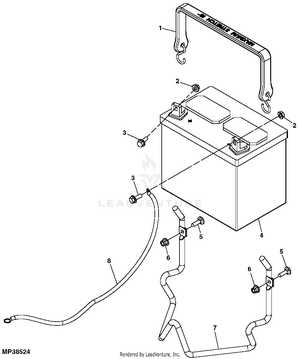

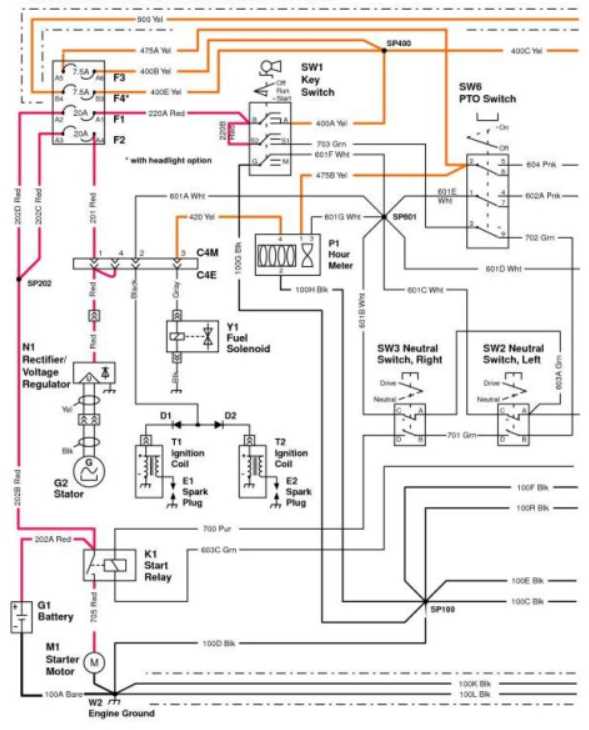

Electrical System Overview

The electrical system of a lawn care machine plays a crucial role in ensuring smooth operation and functionality. It encompasses various components that work together to provide power, control, and safety features, making it essential for effective performance and maintenance.

Key Components

- Batteries: Supply the necessary energy to start the engine and power electrical systems.

- Wiring Harness: Connects different electrical parts and facilitates the flow of electricity throughout the machine.

- Ignition System: Initiates the combustion process, allowing the engine to run efficiently.

- Control Modules: Manage various functions, including speed and engine performance.

- Safety Switches: Ensure safe operation by preventing accidental starts and shutting down the engine in emergencies.

Maintenance Tips

- Regularly inspect wiring for wear and tear.

- Check battery connections and clean terminals to prevent corrosion.

- Test safety switches to ensure they are functioning correctly.

- Replace blown fuses promptly to maintain operational integrity.

Understanding the electrical system’s layout and components is vital for troubleshooting and maintaining optimal performance of the machine. Proper care and attention can enhance longevity and reliability, making it an essential aspect of routine maintenance.

Steering and Control Mechanisms

The effectiveness of maneuvering a lawn mower significantly relies on its steering and control systems. These components are designed to provide operators with precision handling, ensuring smooth navigation across various terrains. Understanding how these mechanisms function enhances the overall user experience and promotes better maintenance practices.

Components Overview

The steering system typically consists of a combination of levers, linkages, and a steering wheel or control sticks. Each element plays a crucial role in enabling the operator to direct the mower efficiently. Levers allow for intuitive adjustments, while linkages translate the operator’s movements into actionable responses from the mower’s wheels.

Importance of Regular Maintenance

Regular inspection and maintenance of the steering and control mechanisms are essential for optimal performance. Worn-out components can lead to decreased responsiveness and potential safety hazards. Ensuring that all parts are in good condition not only extends the lifespan of the equipment but also enhances the overall mowing experience.

Blades and Belt Configuration

Understanding the arrangement and setup of cutting elements and drive systems is essential for optimal performance and efficiency in lawn maintenance equipment. This section outlines the critical aspects of how these components interact, ensuring a smooth operation and precise cutting capabilities.

The cutting blades are designed to provide a clean and even cut, and their configuration is vital for achieving the desired grass height. Proper alignment and sharpness of these blades contribute to effective mowing and reduce the strain on the engine. Regular inspection and maintenance of these elements are recommended to prevent damage and ensure longevity.

Equally important is the belt system, which transmits power from the engine to the cutting mechanism. The correct tension and alignment of the belts are crucial for reliable operation. Over time, belts may stretch or wear, leading to decreased efficiency. Regular monitoring and timely replacement of these components are necessary to maintain peak performance.

By paying close attention to the configuration of both blades and belts, users can enhance the functionality of their equipment, ensuring a pristine lawn with minimal effort. Adhering to maintenance guidelines will lead to improved durability and performance, ultimately extending the lifespan of the machine.

Hydraulic System and Its Components

The hydraulic system plays a crucial role in the functionality of various machinery, enabling efficient movement and operation through the use of fluid power. This system is designed to convert mechanical energy into hydraulic energy, facilitating the operation of essential components within the equipment.

At the core of the hydraulic system are several key elements that work in harmony. The pump serves as the heart of the system, drawing fluid from the reservoir and generating pressure to propel it through the various lines and valves. The valves regulate the flow and direction of the hydraulic fluid, allowing for precise control over the movement of attachments and mechanisms.

Additionally, the cylinders are integral components that convert hydraulic energy back into mechanical force. They expand and contract based on the pressure of the fluid, enabling the movement of different parts of the machinery. Moreover, the system is equipped with filters that ensure the cleanliness of the hydraulic fluid, protecting the components from contamination and wear.

Understanding the components and functionality of the hydraulic system is essential for proper maintenance and troubleshooting, ensuring the machinery operates smoothly and efficiently in various tasks.

Fuel System Layout and Parts

The layout of the fuel system is crucial for the optimal performance of any machinery. It encompasses various components that work together to ensure a steady supply of fuel to the engine, facilitating efficient operation. Understanding the arrangement of these elements can significantly aid in maintenance and troubleshooting processes.

Fuel Tank: This component serves as the reservoir, holding the necessary fuel before it is delivered to the engine. Regular checks for leaks or corrosion are essential to maintain functionality.

Fuel Pump: Positioned to draw fuel from the tank, this part is responsible for transporting fuel under pressure to the engine. A malfunctioning pump can lead to starting issues or engine stalling.

Fuel Filter: Critical for maintaining the purity of the fuel, this element removes impurities that could damage the engine. Periodic replacement of the filter is recommended to ensure longevity and efficiency.

Fuel Lines: These conduits transport fuel from the tank to the engine and must be free from blockages or leaks. Inspections should be performed regularly to avoid potential failures.

Injector System: This mechanism introduces fuel into the engine’s combustion chamber, ensuring the correct air-fuel mixture for optimal performance. Any issues with the injectors can significantly affect engine efficiency and emissions.

Understanding the layout and function of each component in the fuel system can enhance the overall maintenance practices, ensuring smooth and reliable operation of the equipment.

Maintenance Parts and Replacement Guide

Ensuring the longevity and performance of your equipment relies on regular upkeep and timely replacements of essential components. This section provides guidance on key items that should be monitored and replaced as needed to maintain optimal functionality.

Essential Maintenance Components

- Air Filters: Regularly check and replace filters to maintain airflow and engine efficiency.

- Blades: Inspect the cutting blades for wear and sharpen or replace them to ensure clean cuts.

- Belts: Monitor drive and mower belts for signs of wear and replace them to prevent operational issues.

- Fluids: Regularly check and change engine oil, transmission fluid, and coolant as recommended.

- Batteries: Inspect battery condition and connections to ensure reliable starting and operation.

Replacement Recommendations

When replacing components, it is crucial to choose high-quality replacements that meet the manufacturer’s specifications. Consider the following:

- Refer to the equipment manual for part numbers and specifications.

- Purchase from authorized dealers or trusted suppliers to ensure authenticity.

- Keep a record of replaced items and maintenance dates for future reference.

Troubleshooting Common Issues with Z425

When operating any equipment, encountering challenges is not uncommon. Understanding how to address frequent problems can enhance performance and extend the lifespan of the machinery. This section focuses on identifying and resolving typical complications that users may face, ensuring a smooth experience.

One of the most prevalent issues is difficulty starting the engine. This can often be traced back to the battery, fuel system, or ignition components. Ensuring that the battery is fully charged, the fuel lines are clear, and the spark plugs are in good condition can resolve this problem quickly.

Another common challenge involves irregular cutting performance. This issue may arise from dull blades, incorrect cutting height, or uneven terrain. Regularly sharpening the blades and adjusting the cutting height to match the lawn conditions can significantly improve cutting efficiency.

Additionally, users may experience overheating, which could result from a clogged air filter or low coolant levels. Regular maintenance of the air intake system and checking the coolant levels can help prevent overheating and ensure optimal operation.

Lastly, vibrations during operation can indicate loose components or worn-out parts. Inspecting all bolts and connections for tightness and replacing any damaged parts will help maintain a smooth and safe operation.

Finding

Locating essential components for maintenance and repairs is crucial for ensuring the longevity and efficiency of your machinery. By utilizing various resources, you can easily identify the specific items you need, facilitating a smoother repair process.

Resource Identification

To effectively find what you’re looking for, start by exploring reputable online retailers and manufacturer websites. These platforms often provide extensive catalogs and filtering options to help you narrow down your search quickly. Additionally, local dealers can offer personalized assistance and may have parts in stock, saving you time.

Utilizing Diagrams

Visual aids play a significant role in identifying components. Detailed schematics or breakdowns of machinery not only help you understand the layout but also allow you to pinpoint the exact parts needed for your tasks. These resources can often be found in manuals or dedicated online repositories.

Resource Type Benefits Online Retailers Wide selection and easy navigation Local Dealers Personalized service and immediate availability Manufacturer Websites Access to official documentation and support Visual Schematics Improved understanding of machinery layout