The efficiency and performance of any machinery greatly depend on the quality and compatibility of its essential elements. Understanding the structure and arrangement of these components allows for better maintenance and smoother operation over time. This section offers a thorough exploration of the crucial elements that ensure optimal functionality.

Examining individual units is important for identifying areas that may require attention or replacement. With clear visualization and organization, users can quickly pinpoint necessary adjustments or upgrades to improve the machine’s overall performance.

Regular upkeep of these core elements can extend the lifespan of the equipment and prevent unexpected malfunctions. Ensuring that each element is in proper working order is key to maintaining a high level of efficiency and durability.

Overview of Key Components

The following section offers a detailed look at the fundamental elements that make up the equipment’s core. Understanding these components is essential for efficient maintenance and optimal performance.

- Engine Unit: This is the powerhouse, responsible for driving the entire machine. It needs regular checks to ensure reliability.

- Transmission System: This system transfers power to the wheels, allowing for smooth movement. Its upkeep is crucial for mobility.

- Cutting Mechanism: This part includes the blades and deck, vital for efficient trimming. Proper adjustments and sharpening are required for consistent results.

- Control Panel: Provides the operator with access to various functions, including speed and direction cont

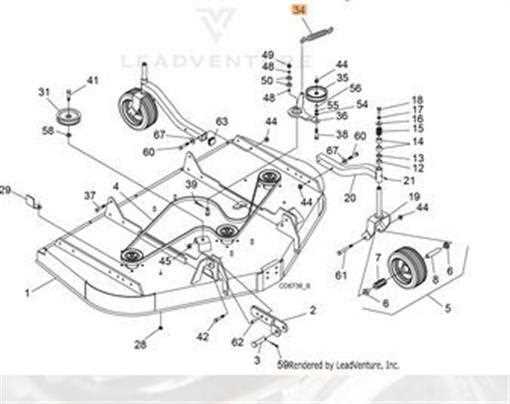

How the Cutting Deck Operates

The functioning of the cutting deck is a vital component of maintaining efficient grass management. It ensures that the blades cut smoothly and uniformly across different terrains. The deck’s operation involves multiple mechanisms working together to deliver precise cuts, enhancing the overall performance of the machine.

Main Components of the Deck

The cutting deck comprises several key elements that collaborate to achieve a smooth mowing process.

- Blades: These rotate rapidly to slice through grass, ensuring an even cut.

- Deck shell: It houses the blades and provides protection while channeling clippings.

- Height adjustment mechanism: This allows the operator to modify the cutting height for different grass lengths.

Blade Rotation Mechanism

The

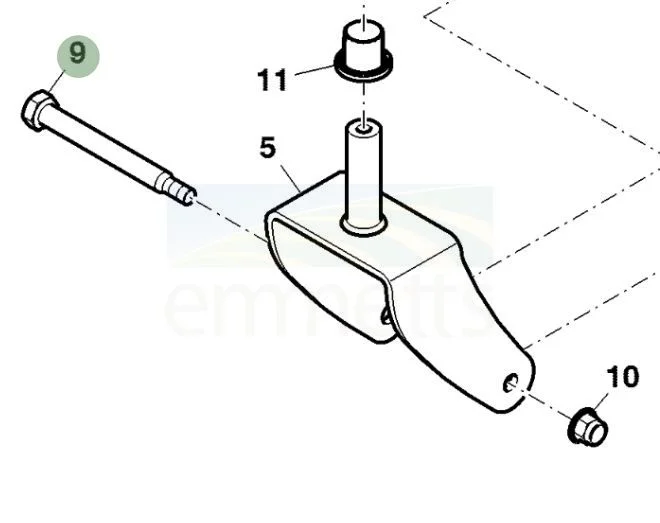

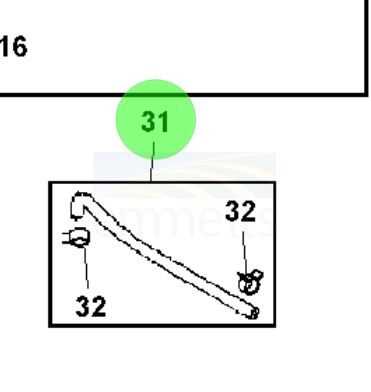

Drive Belt and Pulley System Explained

The drive belt and pulley configuration is essential for ensuring smooth and efficient transmission of power within various machinery. This system works by transferring rotational energy between components, facilitating movement and operation in a controlled manner. Understanding how these components work together is key to maintaining optimal performance.

How the Belt Functions

The belt acts as a flexible link between rotating parts, allowing the transfer of energy from the engine to different sections of the machine. Its tension and alignment are critical, as improper installation or wear can lead to inefficiencies or even mechanical failure.

The Role of Pulleys

Pulleys serve as the guiding elements in this system, directing the belt’s path while regulating the amount of force transmitted. Properly maintained pulleys ensure that the belt remains secure and operates without unnecessary friction, enhancing the longevity of both components.

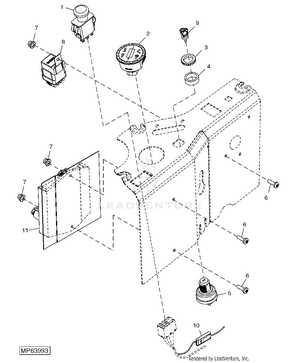

Understanding the Fuel System Layout

The structure of the fuel delivery system plays a crucial role in ensuring smooth and efficient operation. By managing the flow of fuel from the storage tank to the engine, this system helps maintain consistent power and performance. Key components work together to regulate fuel pressure, distribution, and filtration, all of which contribute to optimal functionality.

Understanding the various elements of the fuel system, such as lines, filters, and pumps, is essential for troubleshooting and maintenance. Each part is designed to perform a specific task that directly affects how efficiently fuel reaches the engine, ensuring reliable operation.

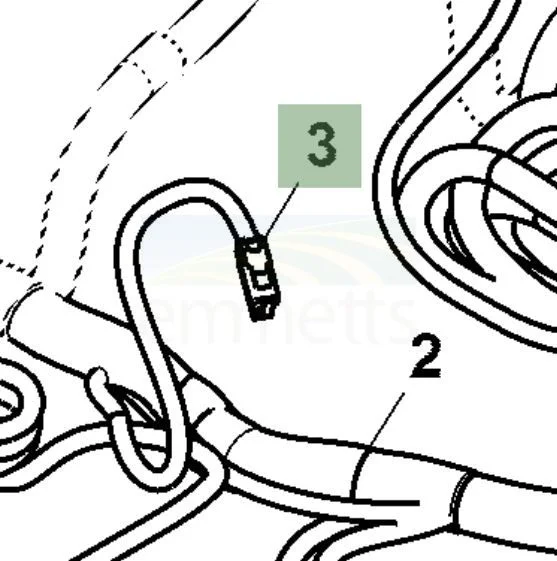

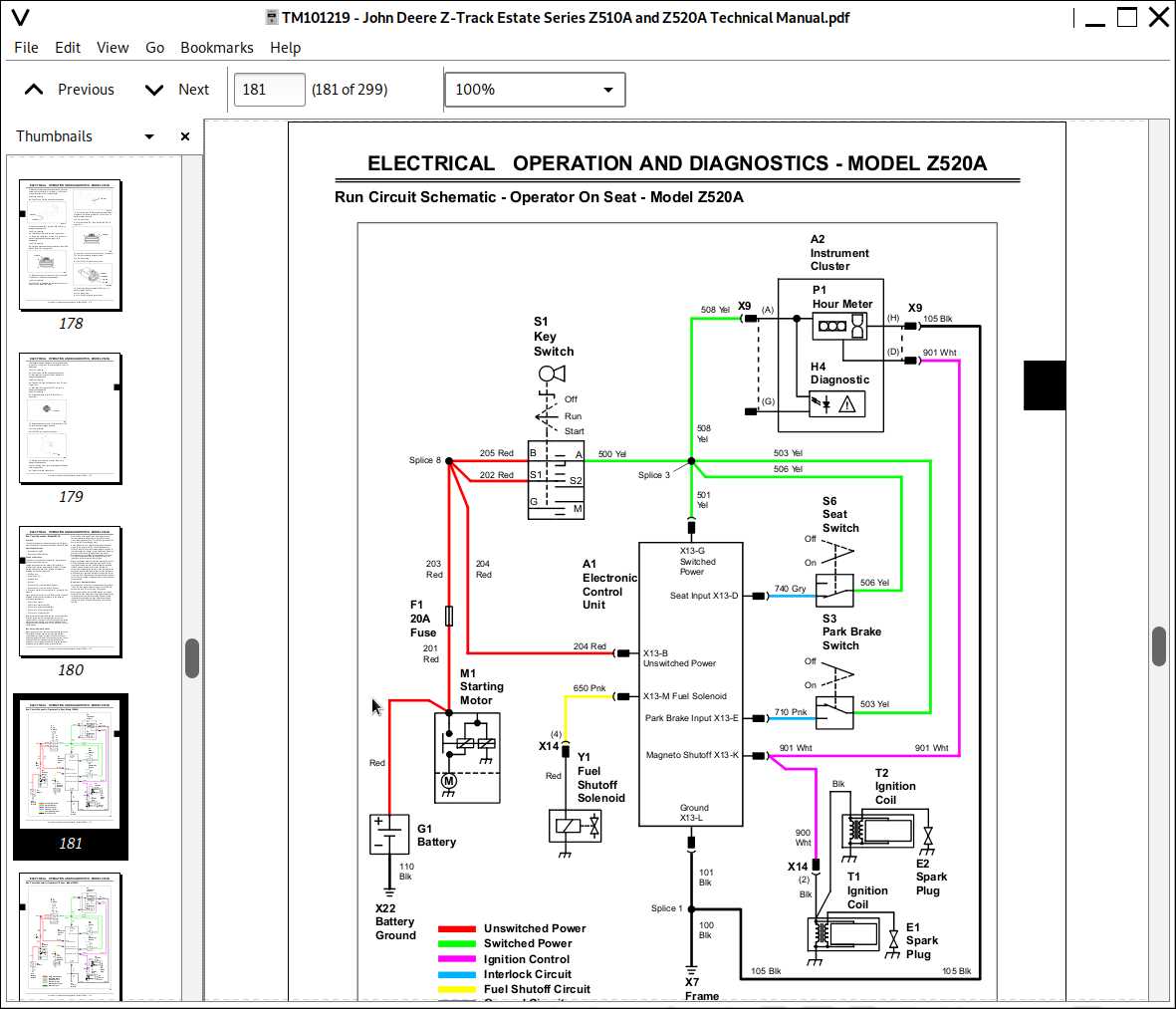

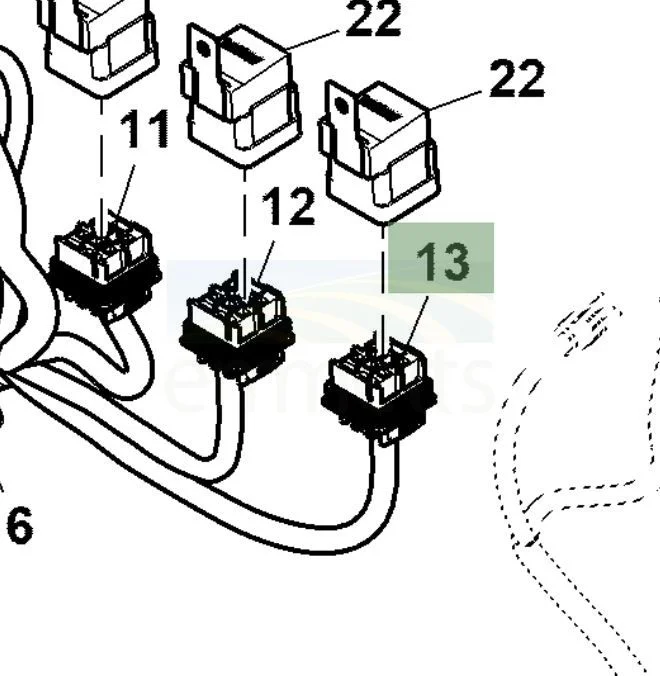

Electrical Wiring and Control Panel

The electrical system plays a crucial role in ensuring smooth and efficient operation of the equipment. Properly organized wiring and a well-designed control panel contribute to both performance and safety. The arrangement of wires must ensure stability and minimize risks, while the control panel enables the operator to interact with the machine effortlessly.

A key feature of the wiring layout is the integration of circuits for various essential functions. Each component, from ignition to lighting, is linked through a network that allows for efficient power distribution and control.

Component Function Ignition System Responsible for starting the engine. Lighting Circuit Hydraulic Mechanism Overview

The hydraulic system plays a crucial role in enhancing the performance and efficiency of machinery. This mechanism utilizes fluid power to facilitate various movements and operations, making it an essential component in numerous applications. Understanding its functionality and components is vital for effective maintenance and troubleshooting.

This system typically comprises several key elements that work in unison to convert hydraulic energy into mechanical movement. Below is a table detailing these fundamental components and their respective functions:

Component Function Pump Generates hydraulic pressure by moving fluid from the reservoir. Actuator Converts hydraulic energy into linear or rotational motion. Reservoir Stores hydraulic fluid, ensuring a continuous supply to the system. Control Valve Regulates the flow and direction of hydraulic fluid to different components. Hoses and Fittings Facilitate the transportation of hydraulic fluid between components. By recognizing the roles of these components, users can ensure optimal functionality and longevity of the hydraulic system in their equipment.

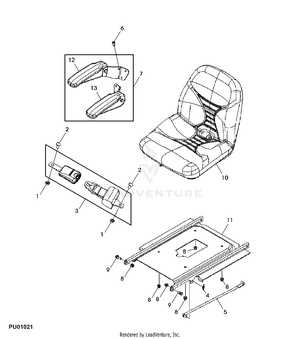

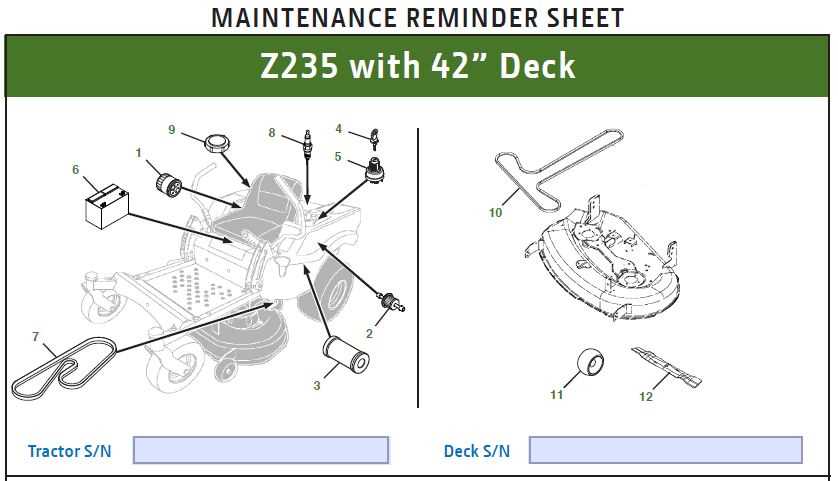

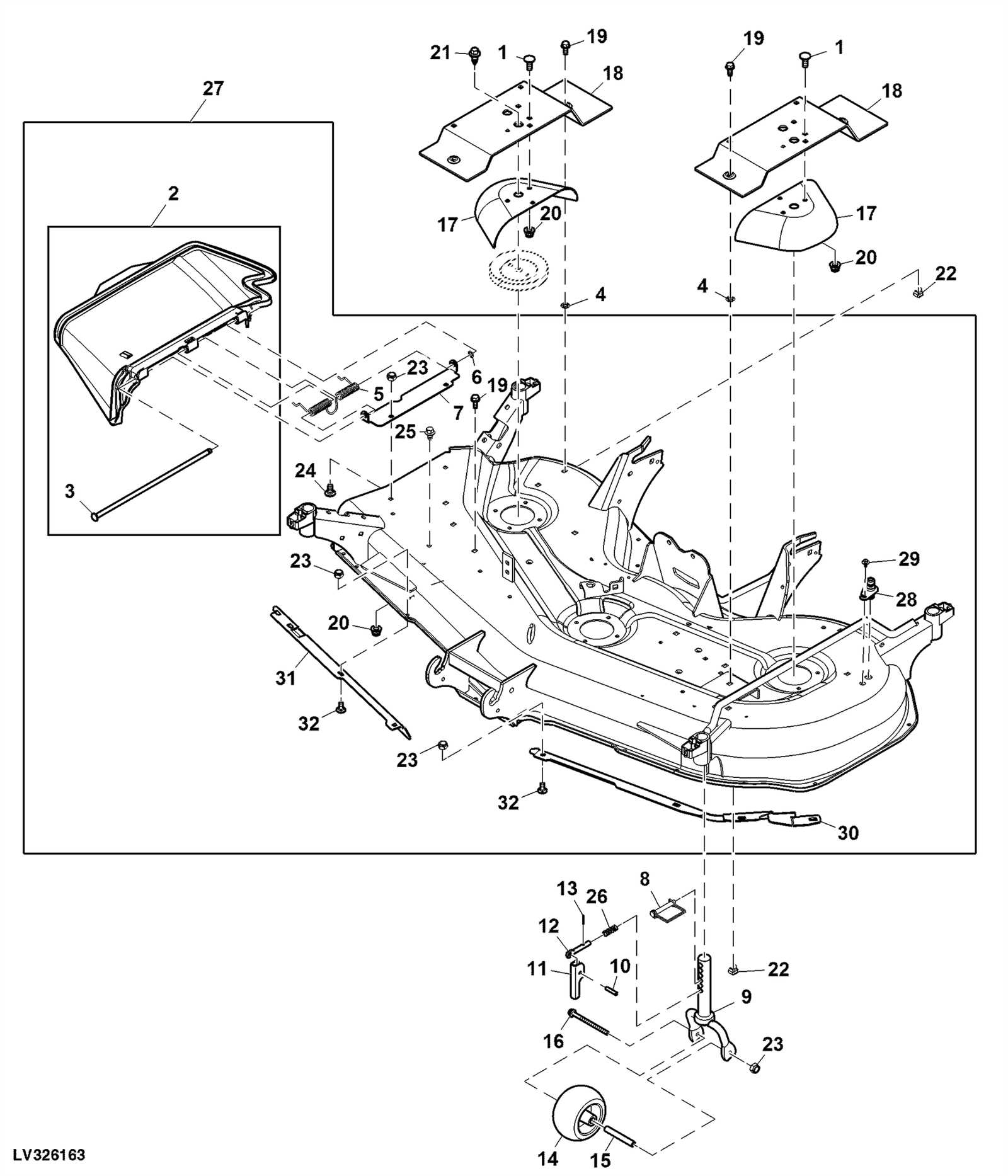

Blades and Mower Deck Assembly

The functionality of a mowing machine heavily relies on the components that interact with the cutting mechanism. Understanding how these elements fit together ensures optimal performance and longevity of the equipment.

Blade Selection is crucial, as it determines the efficiency and quality of the cut. Various designs exist, tailored to different types of grass and terrain. Regular inspection of the blades for wear and damage can significantly improve cutting performance.

Mower Deck Assembly encompasses several key parts that work in unison. The framework supports the blades and houses the motor, enabling the device to function effectively. Proper maintenance, including cleaning and checking for loose fittings, is essential to prevent issues during operation.

Adjustment of the cutting height is another vital aspect. Most assemblies allow for customization, enabling users to set the desired grass length. This feature is particularly beneficial for maintaining a healthy lawn, as different grass types may require varying cutting heights.

Frame and Chassis Structure

The framework and chassis are vital components of any machinery, providing essential support and stability for the entire system. This structure serves as the foundation upon which various elements are mounted, ensuring durability and efficient operation. Understanding the intricacies of this assembly is crucial for maintenance and performance optimization.

Importance of Structural Integrity

Maintaining the integrity of the frame is critical for the overall functionality of the equipment. A robust structure can withstand various stresses encountered during operation, thereby preventing damage and ensuring longevity. Regular inspections and timely repairs are necessary to uphold this integrity and avoid costly breakdowns.

Components of the Chassis

The chassis comprises several essential elements, each playing a specific role in the machinery’s performance. Key components include the support beams, brackets, and mounting points, which work together to provide a stable platform for the attached systems. Understanding the arrangement and function of these parts enhances the ability to troubleshoot and resolve issues effectively.

Brake and Steering System Configuration

The configuration of the braking and steering mechanisms is crucial for the overall performance and safety of any machine. These systems work in tandem to ensure that the operator can maintain control and maneuverability, particularly in challenging conditions. Understanding the components and their arrangement is essential for effective maintenance and troubleshooting.

Components of the System

- Braking Mechanism: This includes the primary elements that facilitate deceleration and stopping.

- Steering Controls: These are responsible for directing the movement of the vehicle.

- Hydraulic System: This system amplifies the force applied to the brakes and steering, enhancing responsiveness.

Configuration Overview

- The braking system is typically composed of discs and pads that create friction to slow down or halt the vehicle.

- Steering is often achieved through a combination of gears and linkages that translate the operator’s input into movement.

- Hydraulic assist can significantly improve the effectiveness of both braking and steering, providing smoother operation.

Engine Parts and Cooling System

The efficiency of a machine’s operation relies heavily on its engine components and cooling mechanisms. Proper functioning of these elements ensures optimal performance and longevity of the equipment.

Key components of the engine include:

- Cylinder block: The main structure housing various engine elements.

- Piston: Converts fuel combustion into mechanical energy.

- Crankshaft: Transforms the up-and-down motion of the pistons into rotational movement.

- Valves: Regulate the flow of air and fuel into the combustion chamber.

- Timing belt: Synchronizes the movement of the engine’s internal components.

The cooling system is vital for maintaining appropriate operating temperatures. Its primary functions involve:

- Radiator: Dissipates heat generated during engine operation.

- Coolant: Circulates through the engine and absorbs heat.

- Water pump: Ensures proper coolant flow throughout the system.

- Thermostat: Regulates the temperature by controlling coolant flow.

- Fan: Enhances airflow across the radiator for improved cooling efficiency.

Understanding these components helps in identifying potential issues and maintaining the overall health of the machinery.

Maintenance Tips for Long-Term Performance

Ensuring the longevity and optimal functioning of your equipment requires regular upkeep and attention to detail. By following a few essential guidelines, you can enhance the efficiency and lifespan of your machinery.

- Regular Inspections: Conduct frequent checks for any signs of wear and tear. This includes examining belts, blades, and fluids to identify potential issues early on.

- Proper Cleaning: Keep the equipment clean by removing debris and buildup after each use. This helps prevent corrosion and improves performance.

- Fluid Maintenance: Regularly change oil and other fluids according to the manufacturer’s recommendations. Clean fluids contribute to better engine function and reduced wear.

- Sharpening Blades: Ensure that cutting blades are sharp. Dull blades require more power and can lead to uneven cuts, affecting the overall performance.

- Storage Practices: When not in use, store the equipment in a dry, sheltered area. This protects it from environmental damage and extends its life.

- Professional Servicing: Schedule annual professional maintenance to address any complex issues and ensure everything is functioning correctly.

By adhering to these maintenance practices, you can significantly improve the performance and durability of your machinery, ensuring it serves you well for years to come.