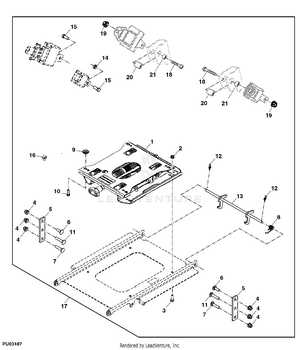

Understanding the detailed structure and elements of modern machinery is crucial for maintaining its operational efficiency. Each component plays a specific role in ensuring the smooth functioning of the entire system. Whether it’s for routine maintenance or an unexpected repair, having a clear representation of these elements can significantly ease the process.

A well-organized visual layout of mechanical systems allows operators and technicians to quickly identify necessary components. By offering a clear breakdown, this approach enhances both the speed and accuracy of troubleshooting or replacement efforts, ensuring that everything runs as intended.

Exploring the internal configuration and assembly of the various parts helps provide insight into how each section contributes to overall performance. Such detailed knowledge can be especially beneficial for long-term upkeep and optimizing the machine’s lifespan.

Essential Components for John Deere Z950A

Maintaining peak performance of your equipment requires understanding the vital elements that ensure smooth operation. These key components work together to keep the machine functioning efficiently, whether for routine tasks or more demanding jobs.

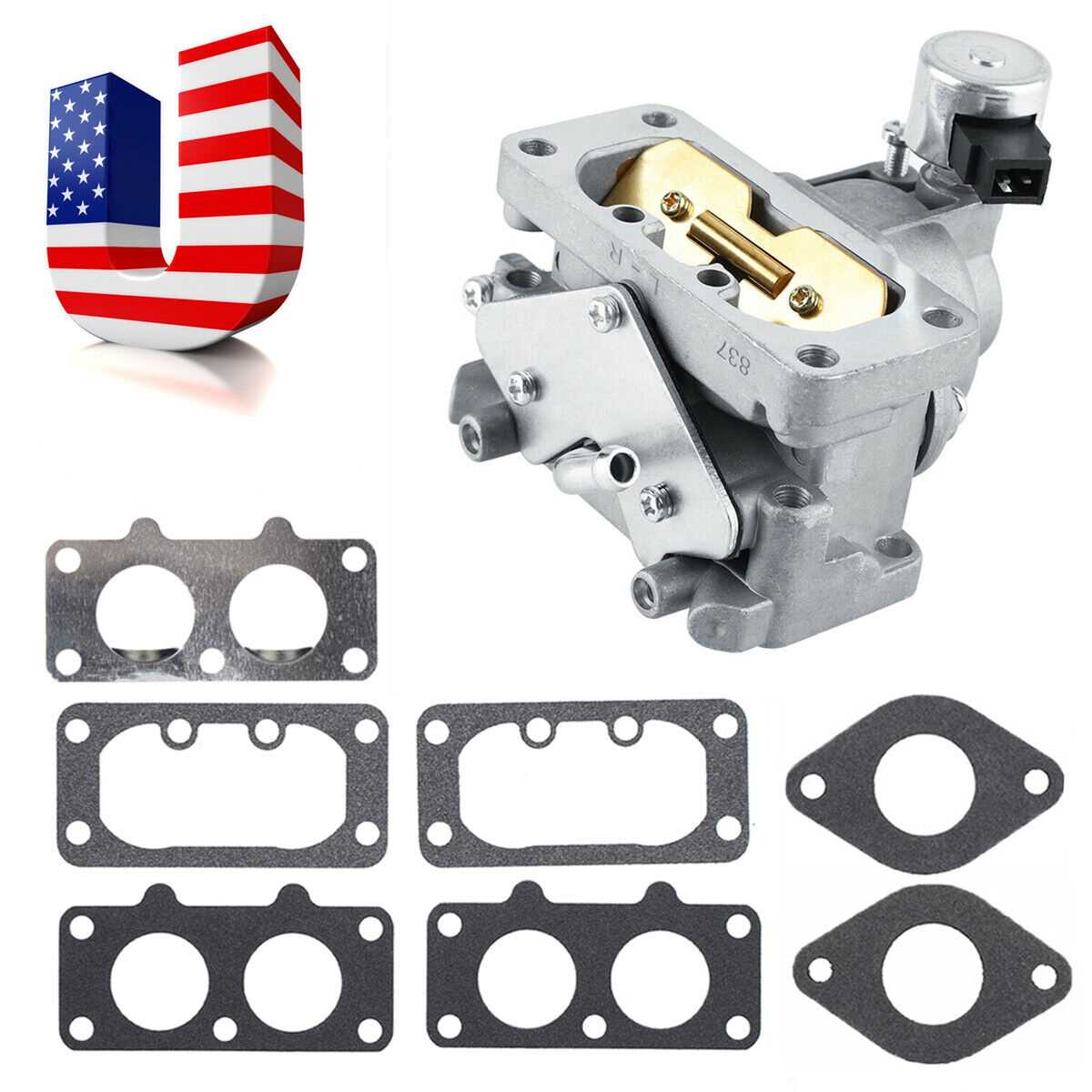

- Engine System: The heart of any machinery, ensuring sufficient power delivery to handle varying terrains and workloads.

- Hydraulic System: Responsible for managing fluid pressure and enabling responsive control of movements and attachments.

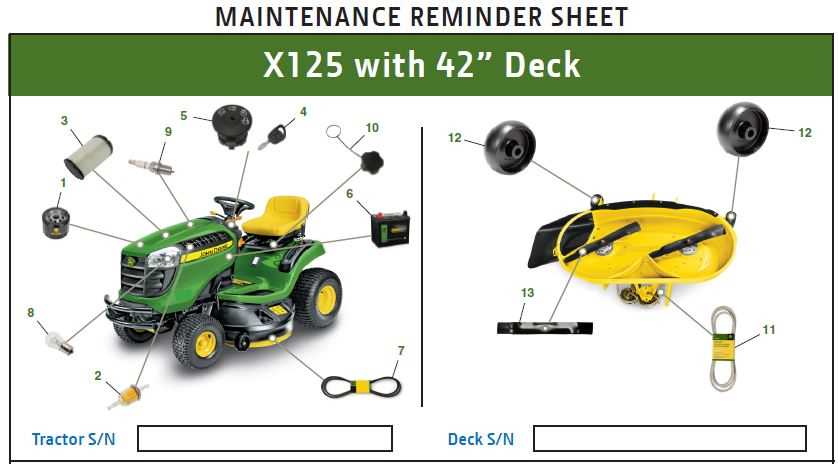

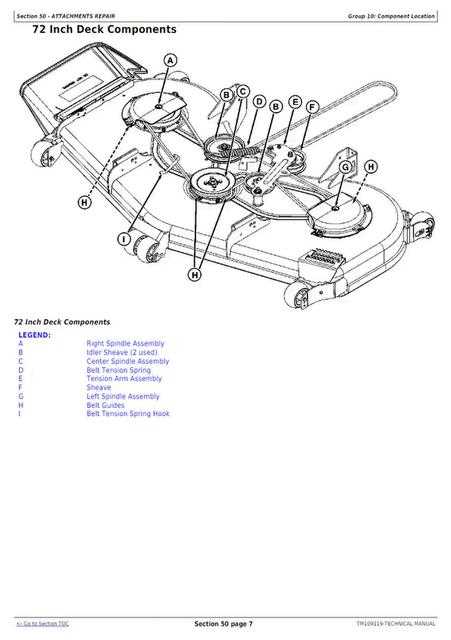

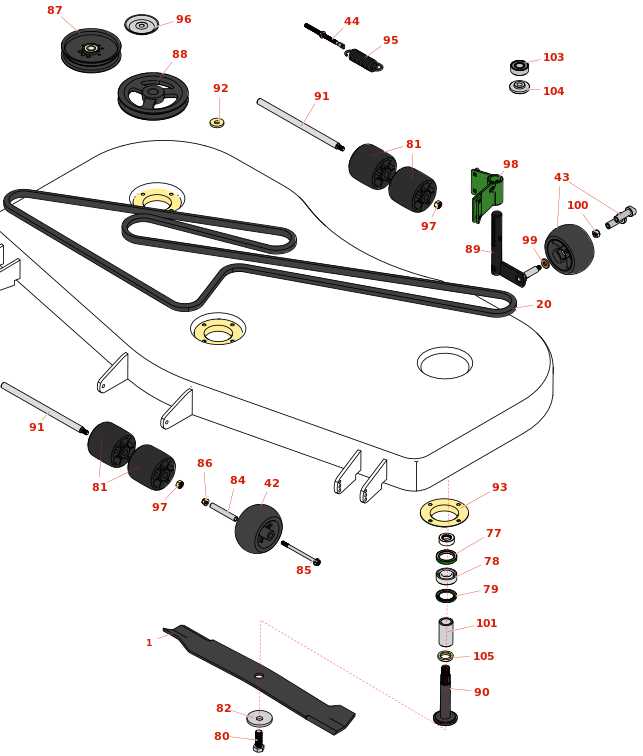

- Cutting Deck: Essential for precise trimming, designed to offer a smooth and even finish, crucial for maintaining uniformity on various surfaces.

- Tires and Wheels: Provides stability and traction, ensuring the unit handles different ground conditions with ease.

- Transmission: A critical component in transferring engine power to the wheels, allowing for smooth shifts and optimized speed control.

- Control Panel: Offers an intuitive interface for monitoring performance and making real-time adjustments while operating.

How to Identify Key Parts in Z950A

When working with a specific model of equipment, understanding its essential components is crucial for proper maintenance and repair. Each part has a unique function, and knowing how to locate and distinguish these elements will help ensure efficient operation and long-term performance. In this guide, we’ll explore practical methods to identify the critical elements within the system.

Primary Components to Focus On

To start, familiarize yourself with the machine’s major areas, including the drive system, the power source, and the cutting mechanism. Each of these sections houses vital elements that contribute to the machine’s overall function. The cutting mechanism, for instance, contains the blades, belt, and spindle, which require regular checks.

Step-by-Step Identification Process

By breaking down the structure into smaller sections, you can easily identify each component. Start by locating the engine area, which connects to other key systems. From there, work your way to the drive system and cutting mechanism, examining the connections between different elements.

| Component | Location |

Understanding the Function of Z950A Components

The intricate system of various mechanical elements within this equipment model is essential for its overall operation. Each piece plays a vital role in ensuring smooth performance, contributing to both efficiency and durability. Engine mechanism is the heart of the machine, driving the power needed for effective functioning. Proper understanding of how energy is generated and transferred can help maintain optimal performance. The cutting system is another critical component, responsible for delivering precise results. The sharpness and alignment of the blades are key factors that directly impact the quality of the task. Other essential parts include the transmission system, which controls the motion and ensures smooth operation, and the hydraulic components that provide the necessary force for various adjustments and movements. Maintenance Tips for Z950A MowerProper care is essential for ensuring long-term performance and reliability of your lawn equipment. Regular upkeep minimizes breakdowns and enhances efficiency, making sure the machine operates smoothly during every use. Routine Inspections

Engine Care

By following these tips, you ensure the longevity and reliability of your mower, keeping it in top working condition for every season. Replacement Guide for Z950A Parts

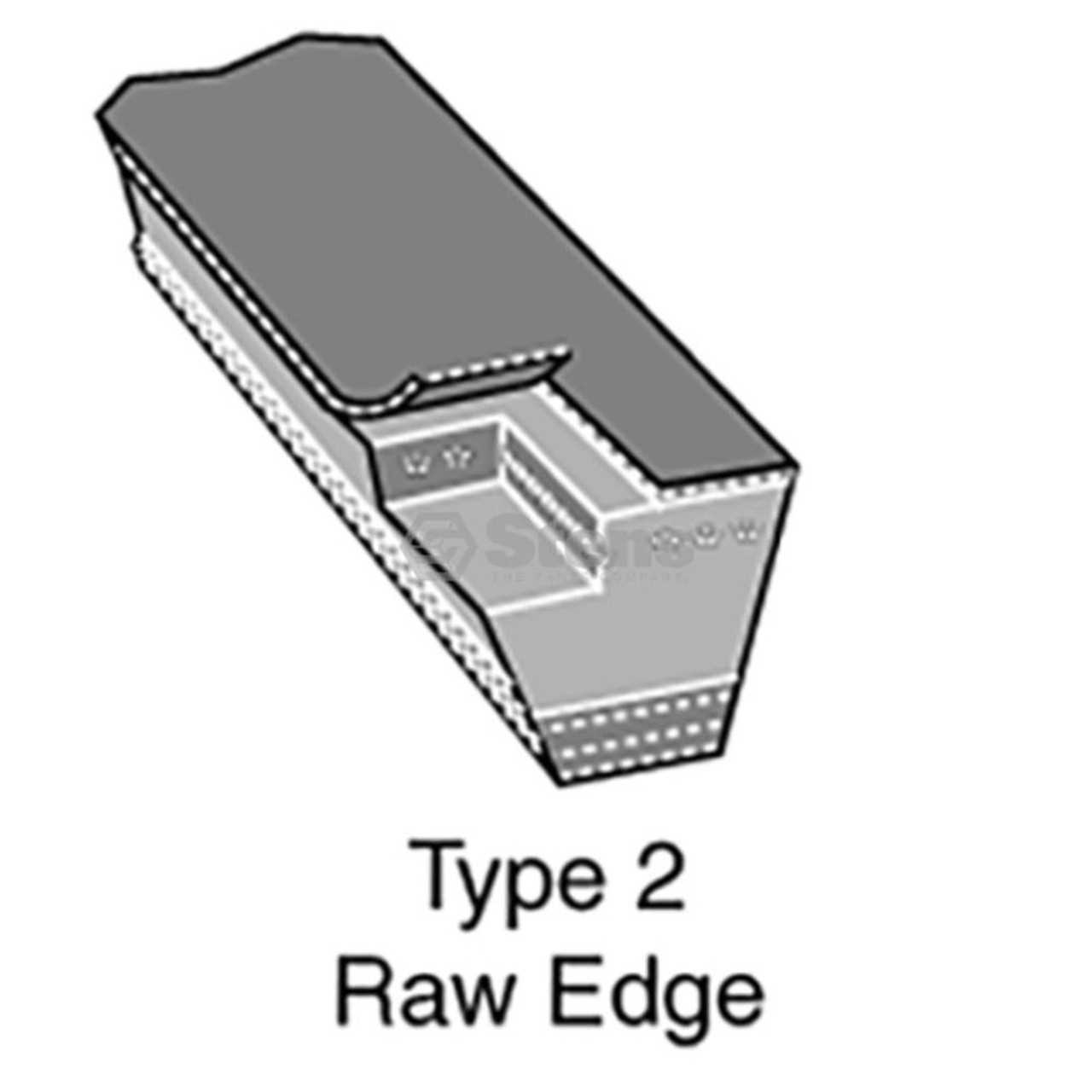

Maintaining the longevity and performance of your equipment requires careful attention to worn-out components. When key elements show signs of wear, it’s crucial to replace them promptly to avoid further damage and ensure smooth operation. This guide provides essential tips for identifying and replacing necessary components, ensuring your machinery continues to function efficiently. Identifying Worn ComponentsOver time, certain elements may begin to deteriorate due to regular use. Key indicators include unusual noises, diminished performance, or visible signs of wear. Inspect these areas regularly, focusing on mechanical and moving parts that experience the most strain. Addressing these issues early can prevent costly repairs in the future. Choosing the Right Replacement

Selecting appropriate replacements is vital for maintaining the functionality of your machine. Ensure compatibility by checking the specifications of the new component, as mismatched elements can lead to inefficiency. Always opt for high-quality alternatives to maximize durability and performance, safeguarding your equipment’s longevity. Where to Find Original Z950A Parts

Locating authentic components for your machinery is crucial for maintaining optimal performance and longevity. High-quality replacements ensure that your equipment operates smoothly and efficiently, reducing the likelihood of breakdowns. One of the best places to search for genuine components is through authorized dealers. These establishments typically offer a wide selection of certified replacements that meet manufacturer specifications. Additionally, many online retailers specialize in these products, providing the convenience of home delivery. Another valuable resource is local repair shops that focus on servicing similar equipment. These professionals often have access to quality parts and can provide recommendations based on your specific needs. It is advisable to inquire about the sources they use to procure their inventory. Lastly, consider joining forums or communities dedicated to equipment maintenance. Members often share information about reputable suppliers and can offer insights into their personal experiences with various components. Engaging with fellow enthusiasts can lead to discovering lesser-known sources for quality replacements. Common Issues with Z950A ComponentsUnderstanding the frequent challenges encountered with the components of this mowing machine is essential for optimal maintenance and performance. Several elements may present issues over time, impacting the overall efficiency and functionality of the equipment. Wear and Tear of Engine Parts

One of the primary concerns involves the degradation of engine components. Regular usage can lead to excessive wear, affecting performance. Noticing unusual noises or vibrations can indicate that specific parts require immediate attention or replacement. Problems with the Cutting Deck

The cutting deck is crucial for achieving a clean cut. Clogging can occur due to grass buildup, which may hinder performance. Additionally, checking for uneven wear on blades is necessary to ensure efficient cutting and to avoid damaging the lawn. Improving Z950A Performance with New PartsEnhancing the efficiency of your mowing equipment can significantly impact its overall functionality and longevity. Upgrading certain components with high-quality replacements can lead to improved operation, reduced wear, and better fuel economy. This approach not only optimizes performance but also ensures a smoother user experience. When considering enhancements, it is essential to focus on the critical areas that affect productivity. Below is a table outlining various components that can be upgraded to maximize the efficiency of your equipment:

Investing in these essential components will result in a noticeable upgrade in performance, leading to a more productive and enjoyable mowing experience. Safety Considerations for Z950A Parts Installation

Ensuring a secure and effective installation process is crucial for any machinery maintenance. Prioritizing safety measures not only protects the operator but also enhances the longevity and performance of the equipment. This section outlines essential precautions to take during the assembly and replacement of components. Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is vital during the installation procedure. Essential gear includes gloves, safety goggles, and steel-toed boots. These items safeguard against potential hazards, such as sharp edges and falling objects. Work Area SafetyMaintaining a clean and organized workspace significantly reduces the risk of accidents. Ensure that tools and components are readily accessible and stored in designated areas. Additionally, it’s important to check that the installation site is well-lit and free from any obstructions.

Enhancing Durability of Z950A Through Part Upgrades

Improving the longevity of your machinery often requires thoughtful enhancements and modifications. Upgrading certain components can significantly extend the life of the equipment, ensuring optimal performance and reliability. By selecting high-quality alternatives, operators can effectively mitigate wear and tear, ultimately reducing downtime and maintenance costs. Key Components for Improvement

Each of these areas plays a crucial role in overall functionality and resilience. Prioritizing the upgrade of essential elements can lead to a remarkable increase in durability. Benefits of Upgrading

By investing in superior replacements, operators can achieve remarkable improvements in durability and reliability, ultimately maximizing the value of their investment. |

|---|