| Battery |

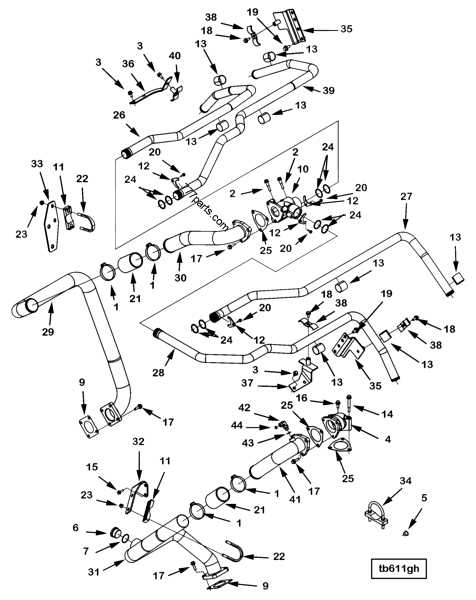

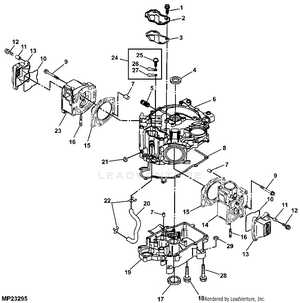

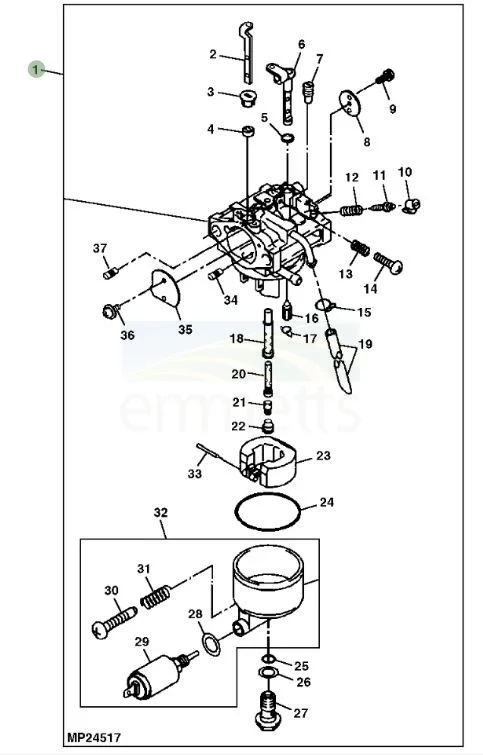

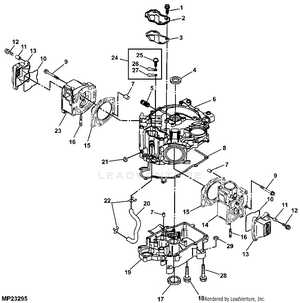

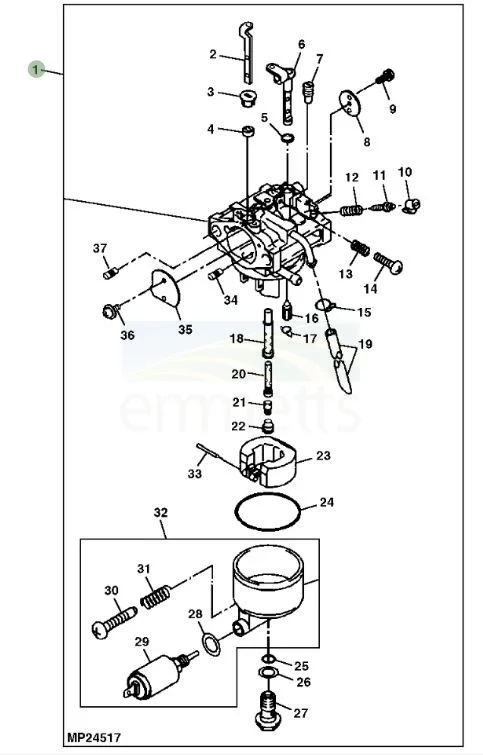

Fuel System Structure and Parts

The fuel system is a crucial component that ensures the steady flow of energy required for the machine’s engine to function efficiently. It is designed to deliver fuel from the tank to the engine while maintaining optimal pressure and flow.

Fuel Tank: The storage area where fuel is kept, playing a key role in keeping the engine supplied with the necessary energy.

Fuel Pump: This mechanism ensures the fuel moves from the tank to the engine with the correct pressure, allowing the engine to run smoothly.

Fuel Filter: Responsible for cleaning the fuel, this part prevents contaminants from reaching the engine, thus avoiding potential damage.

Fuel Lines: These conduits transport the fuel through the system, ensuring a continuous supply to all the necessary components.

Carburetor: The device that blends fuel with air in the correct proportion before it reaches the engine, optimizing combustion.

Proper maintenance of these elements is essential for the system’s durability

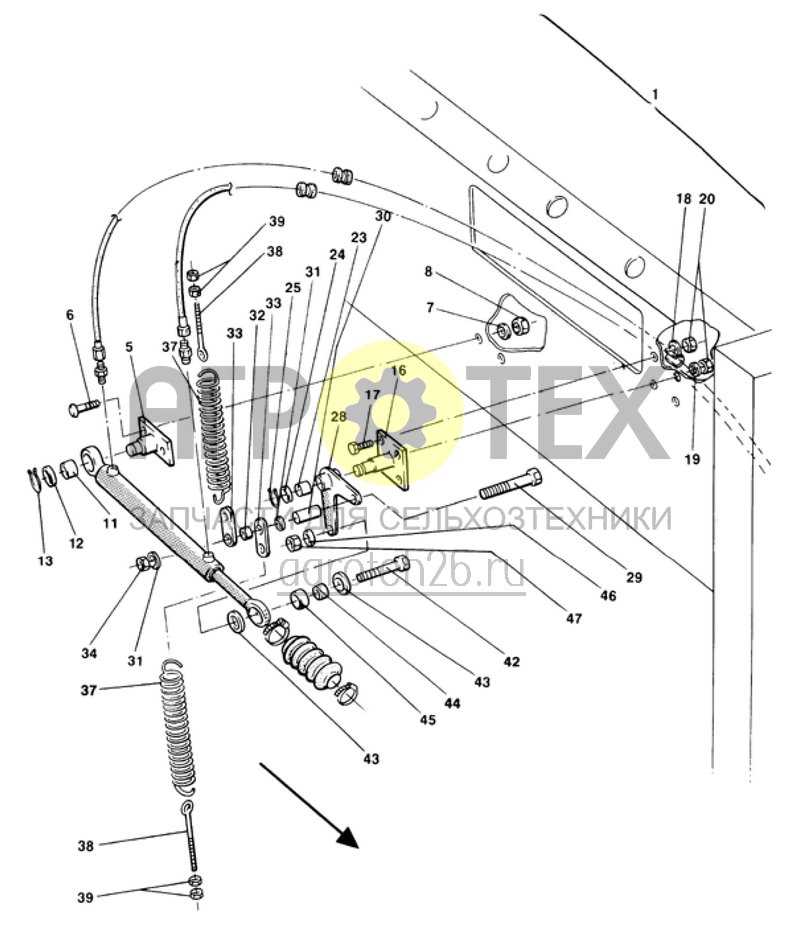

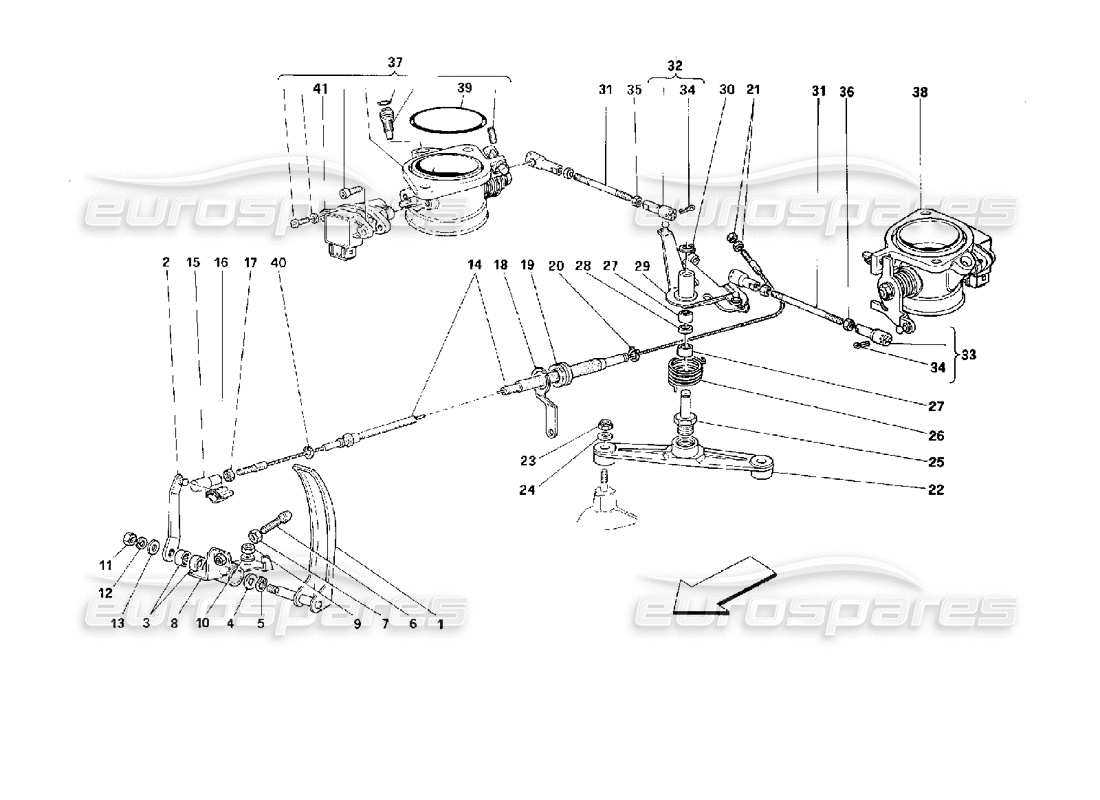

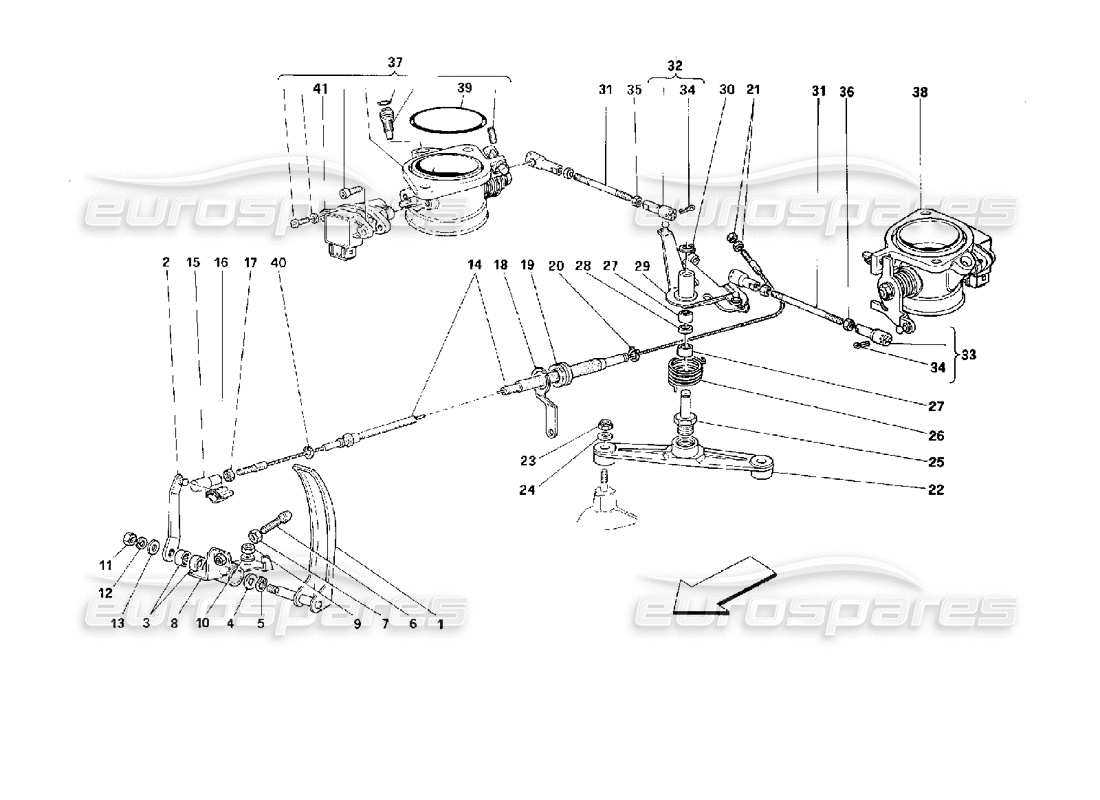

Steering Mechanism and Key Parts Overview

The steering system plays a crucial role in ensuring smooth navigation and control of the machine. It comprises various essential components that work together to provide responsive handling and direction control. Understanding the main elements of this system helps in maintaining optimal performance and identifying areas that may require attention.

Steering Wheel and Column: These elements are the driver’s primary interface for controlling direction. The wheel is connected to the column, which transmits the driver’s input to the steering system.

Linkages and Joints: These components are responsible for transmitting the motion from the steering wheel to the wheels. They are essential for precise movement and alignment during operation.

Steering Gear: The gear transforms rotational input from the wheel into the necessary mechanical force to turn the wheels. It is a vital part of ensuring smooth and responsive steering.

Axle and Spindles: The axle supports the weight and movement of the front wheels, while the sp

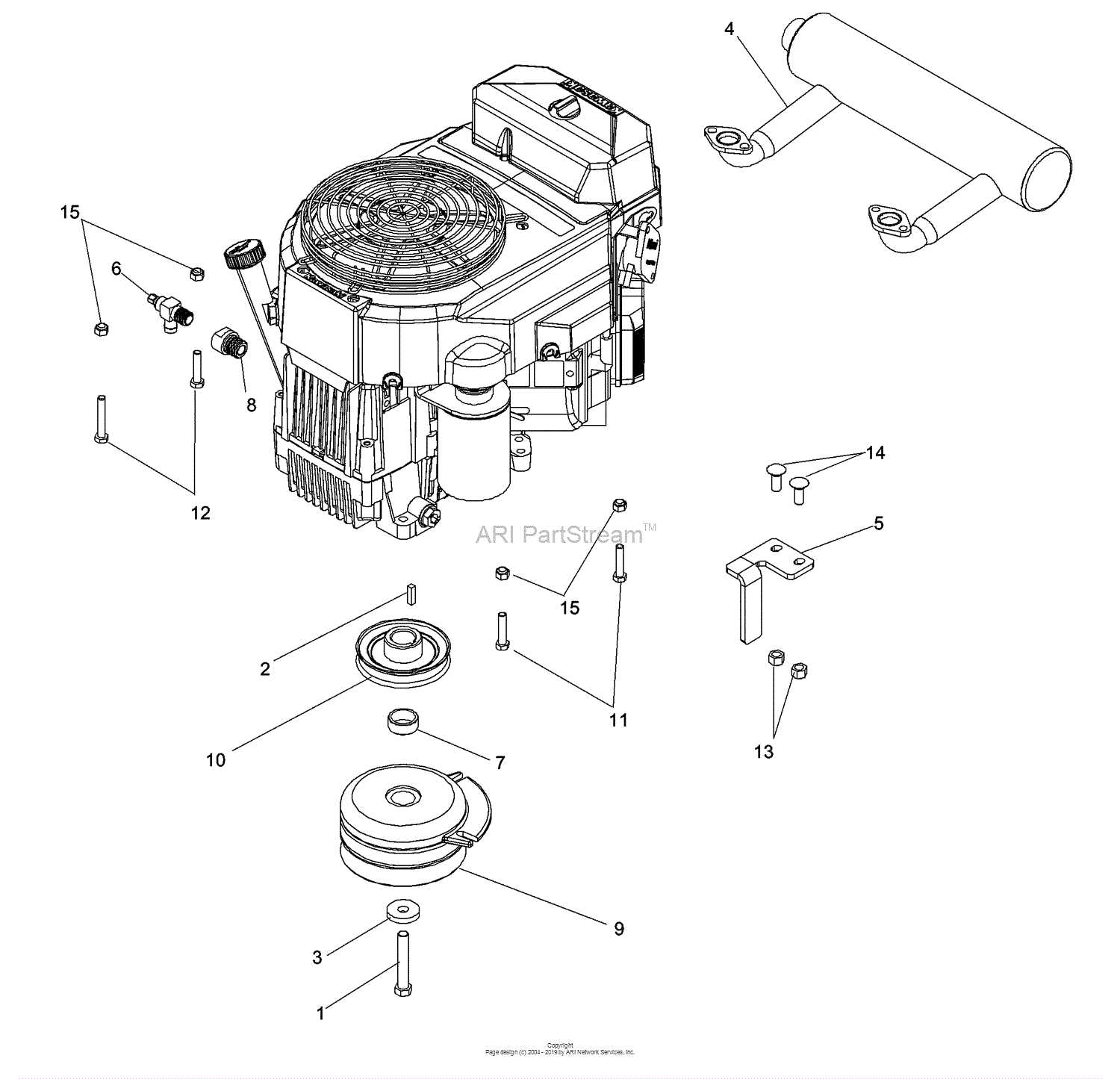

Hydraulic System Components Explained

The hydraulic system plays a crucial role in the functionality of various machinery, enabling efficient power transmission through fluid movement. Understanding the essential components of this system helps in maintaining and troubleshooting equipment effectively.

Key Components

- Pump: Converts mechanical energy into hydraulic energy by circulating fluid.

- Actuator: Transforms hydraulic energy back into mechanical energy to perform work.

- Reservoir: Stores hydraulic fluid, ensuring a continuous supply for the system.

- Valves: Control the flow and direction of the hydraulic fluid within the system.

- Hoses and Tubing: Facilitate the movement of fluid between components, providing flexibility and durability.

Functions of the Hydraulic System

The primary function of the hydraulic system is to transmit force and control movement in machinery. This is achieved through the following processes:

- Fluid circulation initiated by the pump.

- Control of flow direction via valves.

- Force application through actuators to perform tasks.

- Fluid return to the reservoir for recycling.

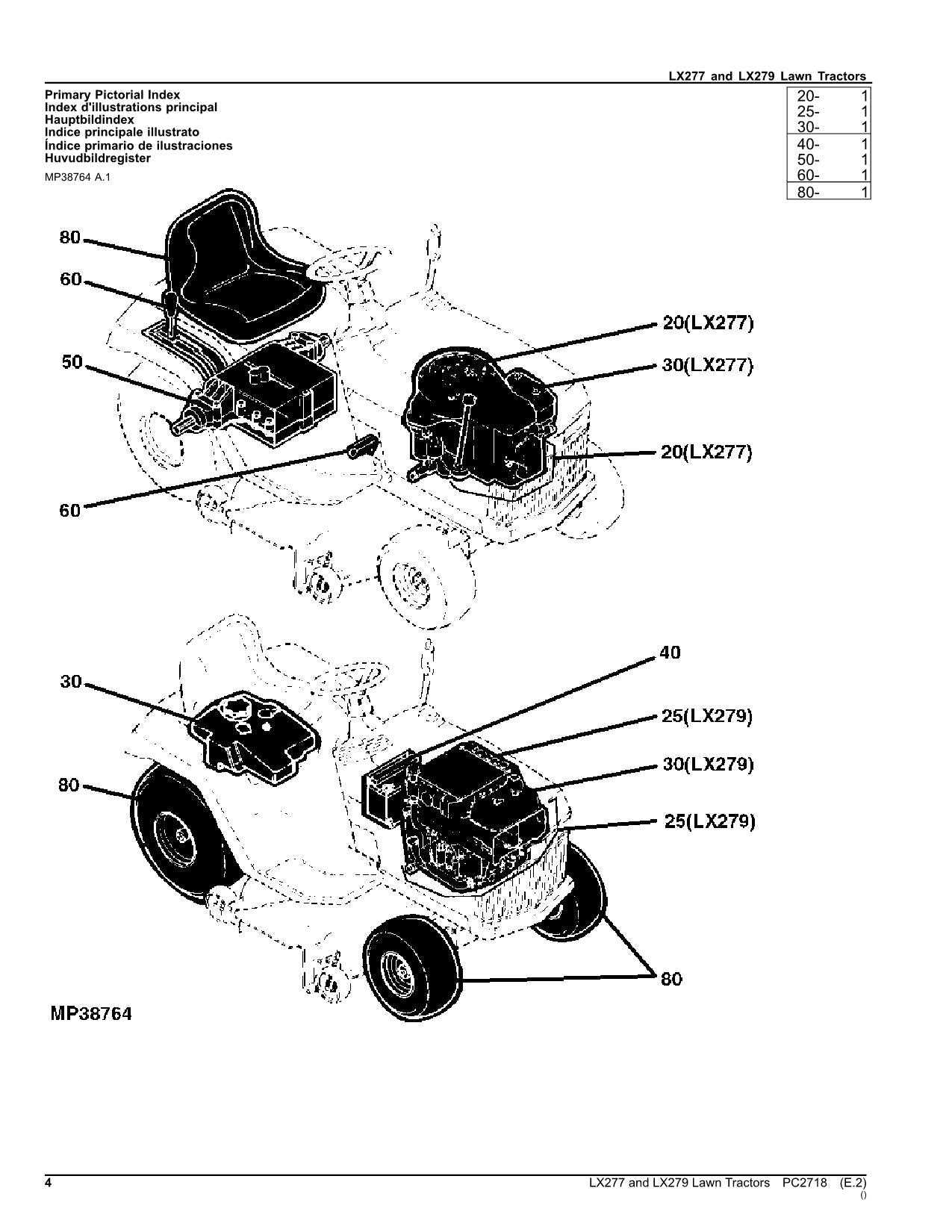

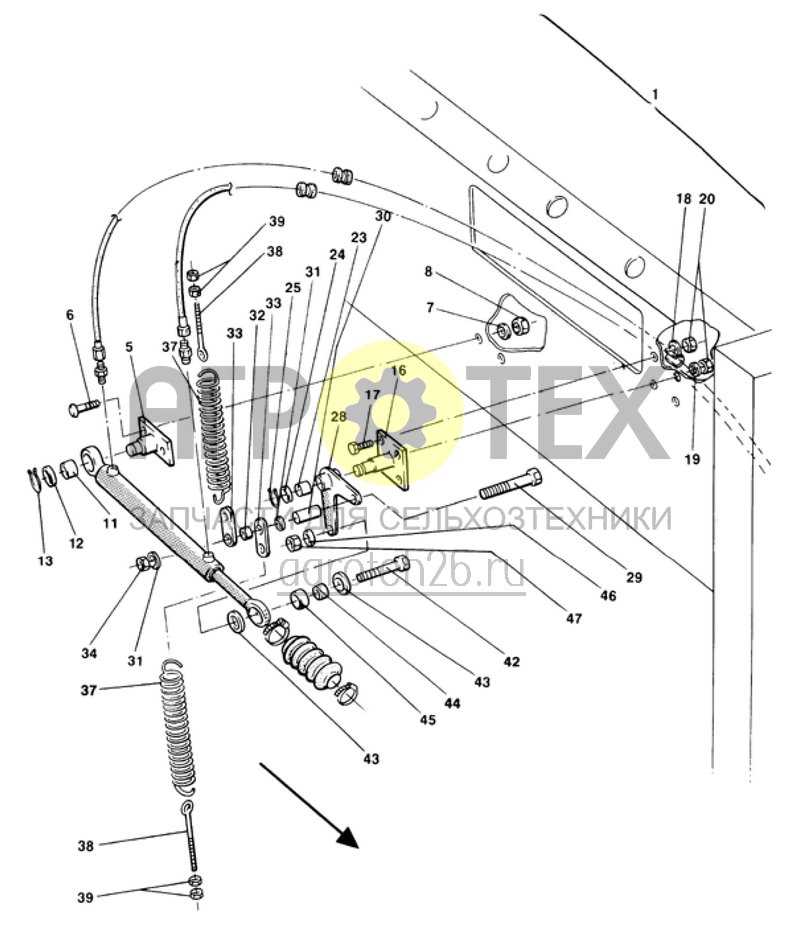

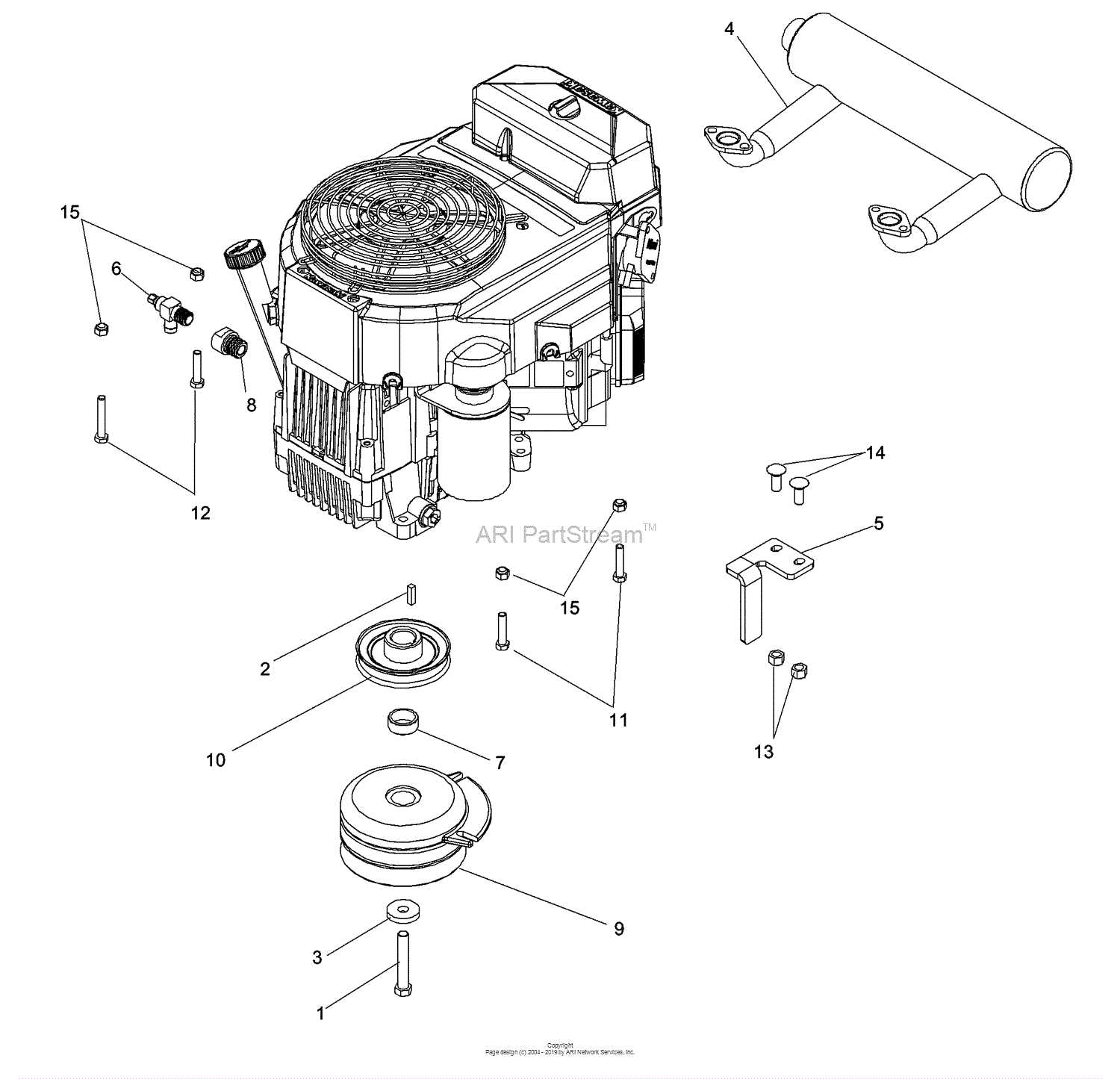

Transmission Components and Their Functions

The transmission system is crucial for the efficient operation of agricultural machinery. It facilitates the transfer of power from the engine to the wheels, ensuring optimal performance under various conditions. Understanding the different elements of this system and their specific roles is essential for maintaining the equipment effectively.

- Gearbox: This component is responsible for adjusting the torque and speed of the machine. It allows the operator to choose different power levels based on the task at hand.

- Clutch: The clutch enables the operator to engage or disengage the engine from the transmission, allowing for smooth transitions between gears.

- Driveshaft: This part transmits power from the gearbox to the wheels, playing a vital role in the overall movement of the machinery.

- Transmission Fluid: Essential for lubrication and cooling, this fluid reduces friction between moving parts, helping to prolong the lifespan of the transmission system.

- Control Linkage: This system connects the operator’s controls to the transmission components, allowing for precise manipulation of speed and torque.

Each of these elements works in concert to ensure that the equipment operates smoothly and efficiently. Regular inspection and maintenance of these components can significantly enhance the performance and reliability of agricultural machines.

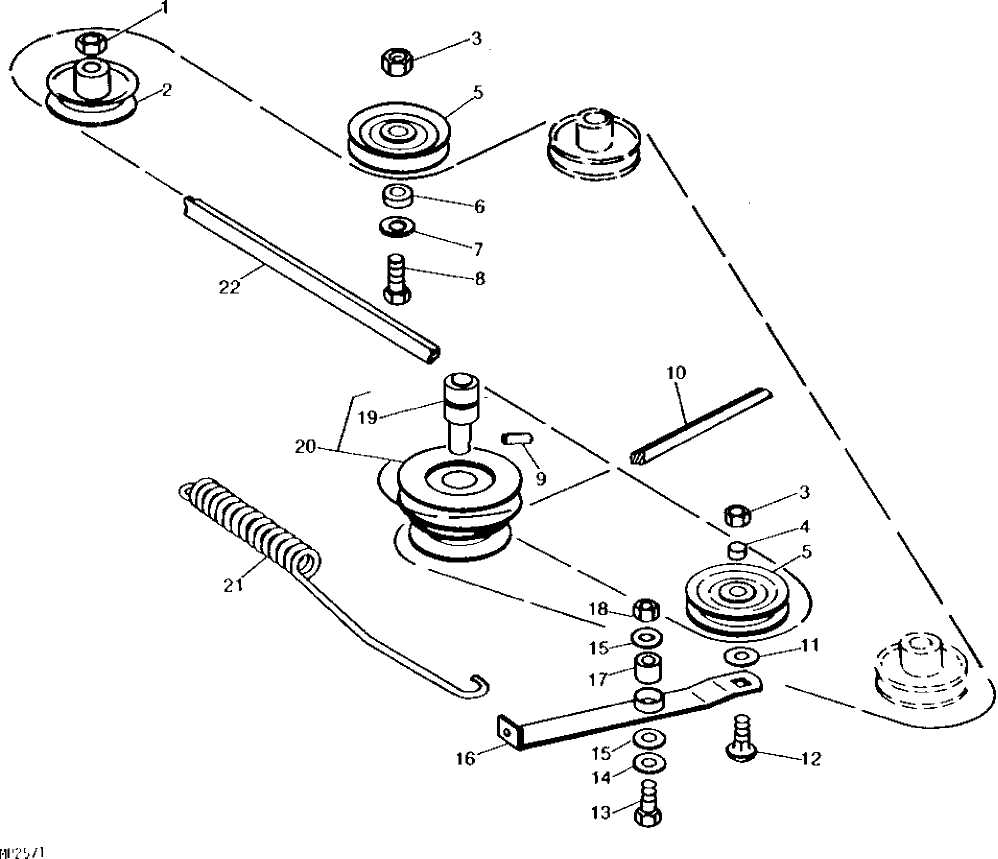

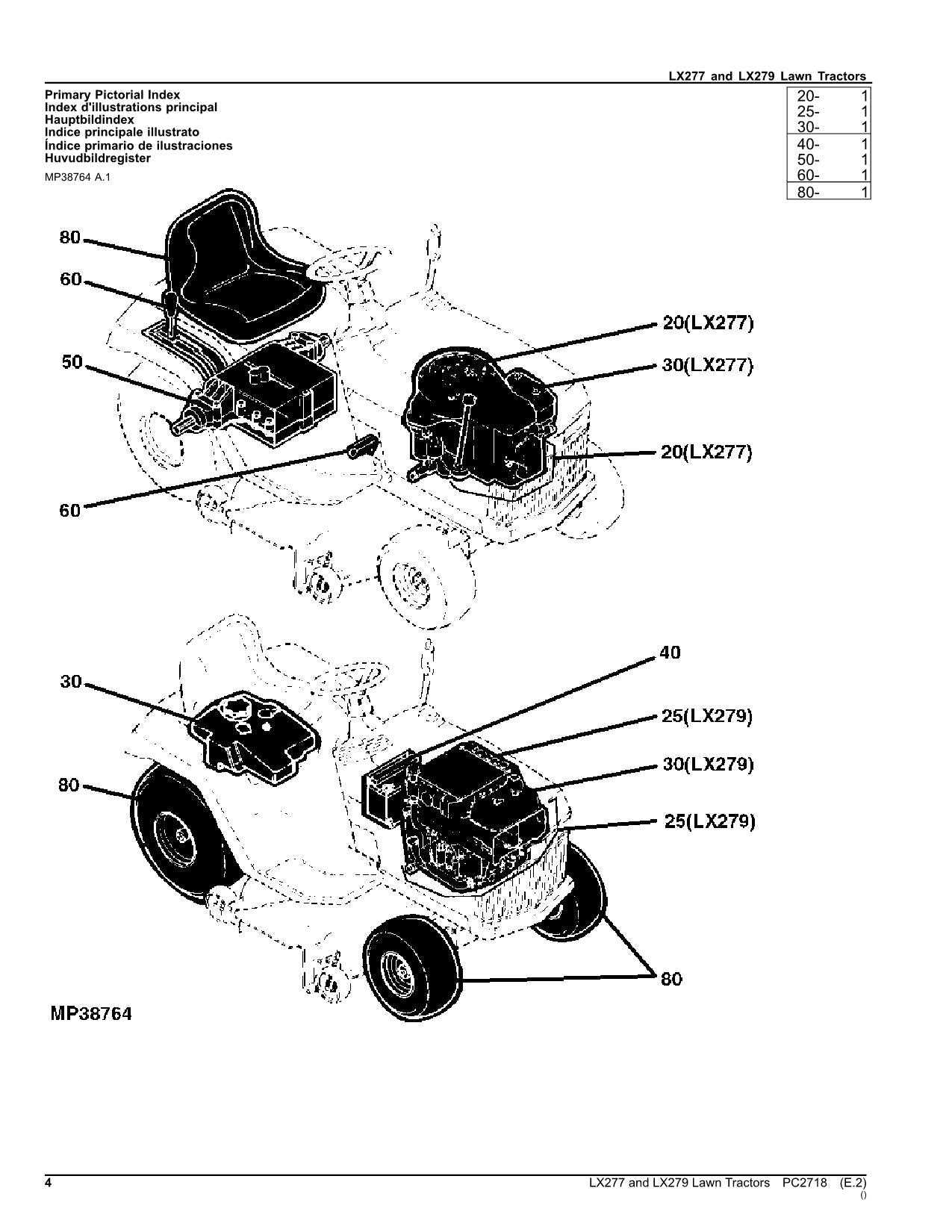

Blades and Mower Deck Assembly

The assembly of cutting elements and the mower platform is crucial for optimal performance in grass management tasks. Proper alignment and secure attachment ensure effective operation and longevity of the equipment.

Understanding the components involved in this assembly is essential for maintenance and repairs. Each part, from the blades to the deck, plays a significant role in achieving the desired cutting height and finish.

Regular inspection of these elements is recommended to identify wear and tear. Keeping blades sharp and the deck clean can enhance cutting efficiency and promote healthier lawn growth.

Braking System Components and Functionality

The braking system plays a crucial role in ensuring the safe operation of machinery. It consists of various elements that work together to effectively slow down or stop the vehicle, providing stability and control in various conditions.

Key Elements of the Braking System

At the heart of the braking system are the brake pads, which create friction against the rotors to generate stopping power. Additionally, the hydraulic system transfers force from the brake pedal to the calipers, enhancing responsiveness. Other essential components include brake lines, which facilitate fluid movement, and the master cylinder, responsible for maintaining pressure within the system.

Functionality and Operation

The overall functionality of the braking system relies on the interaction between these components. When the operator applies the brake pedal, hydraulic fluid is directed to the calipers, causing the brake pads to engage with the rotors. This action generates the necessary friction to decelerate the vehicle efficiently. Regular maintenance of these components is vital to ensure optimal performance and safety during operation.

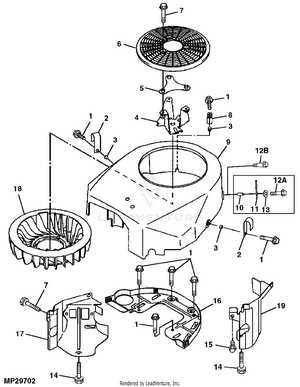

Cooling System Parts and Diagrams

The cooling system plays a vital role in maintaining the optimal temperature of machinery, ensuring smooth operation and preventing overheating. Understanding the components involved in this system is essential for effective maintenance and repairs.

Key elements of the cooling system include:

- Radiator: Facilitates heat exchange by dissipating heat from the coolant.

- Water Pump: Circulates coolant throughout the system, ensuring consistent flow.

- Thermostat: Regulates the temperature by controlling coolant flow based on temperature readings.

- Cooling Fan: Assists in air circulation around the radiator to enhance cooling efficiency.

- Coolant Hoses: Transport coolant between various components of the system.

In addition to these components, there are various configurations and layouts that illustrate how these parts interact within the overall cooling system. Familiarity with these arrangements aids in troubleshooting and ensuring that each component functions correctly.

Regular inspections and maintenance of the cooling system are crucial for preventing potential issues that may arise due to wear and tear. This proactive approach helps extend the life of machinery and ensures its reliability in operation.

Identifying Key Bearings and Seals

In the realm of machinery maintenance, understanding the essential components that ensure smooth operation is crucial. Among these, bearings and seals play a vital role in minimizing friction and preventing the ingress of contaminants. Proper identification of these elements can lead to enhanced performance and longevity of the equipment.

Bearings are pivotal in allowing rotational movement with reduced friction. They are available in various types, each designed for specific applications and load capacities. When assessing bearings, pay attention to their size, load rating, and material composition to ensure compatibility with your machinery.

Seals, on the other hand, are designed to retain lubricants and exclude dirt and moisture. Their integrity is essential for maintaining optimal operating conditions. When inspecting seals, consider their type–such as lip or O-ring seals–and check for signs of wear or damage that could compromise their functionality.

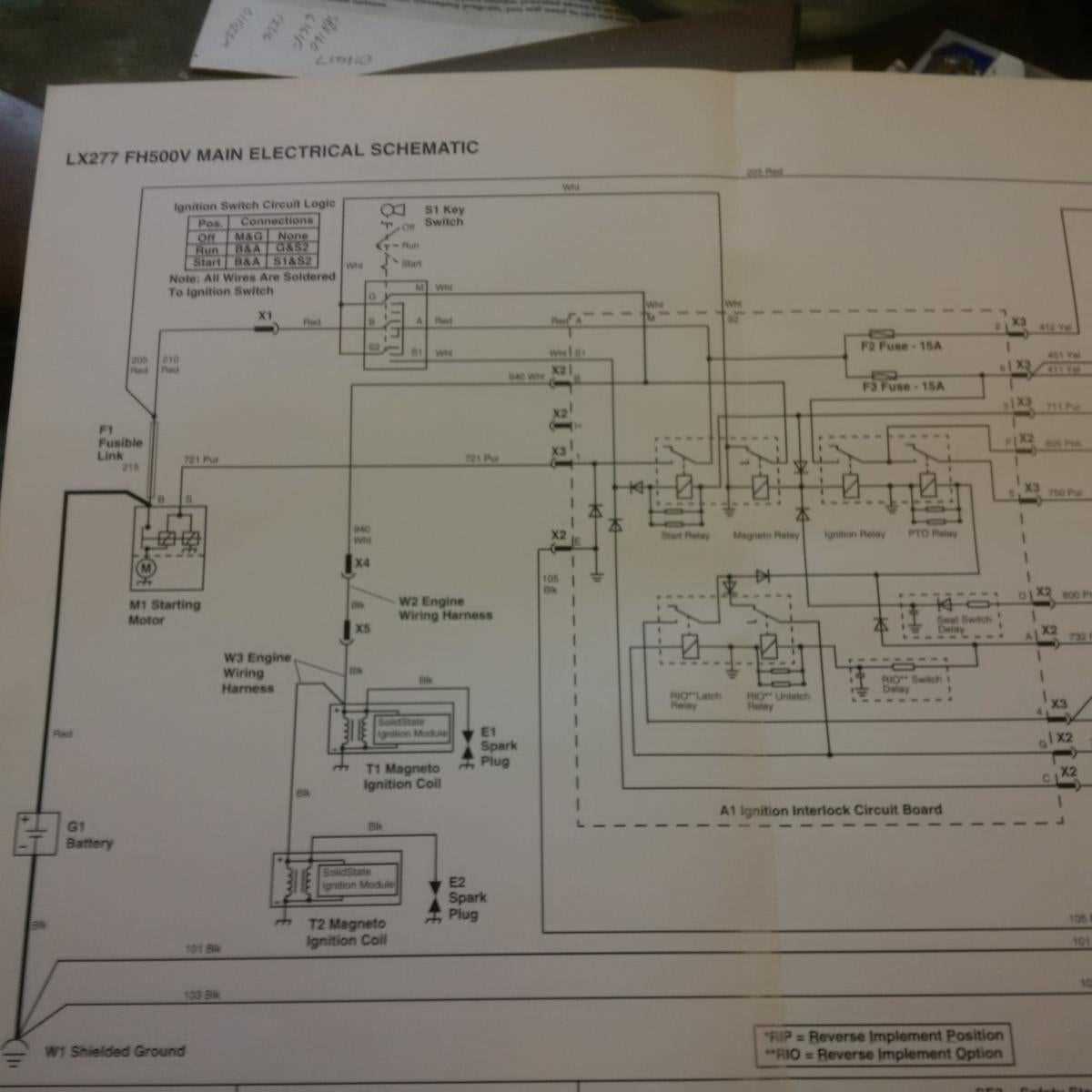

Safety Features and Related Components

When operating machinery, the importance of safety cannot be overstated. This section delves into the essential safety mechanisms and their associated elements that contribute to the secure functioning of the equipment. Understanding these features is vital for ensuring both operator protection and equipment longevity.

Emergency Shutdown Systems

Emergency shutdown systems play a crucial role in halting operations swiftly in case of unforeseen circumstances. These systems are designed to immediately disable the machine, minimizing the risk of accidents. Regular checks and maintenance of these components ensure they function effectively when needed.

Operator Safety Shields

Operator safety shields are integral to safeguarding users from potential hazards. These barriers help prevent direct exposure to moving parts and flying debris, offering an additional layer of protection. Utilizing high-quality materials for these shields enhances their durability and effectiveness.