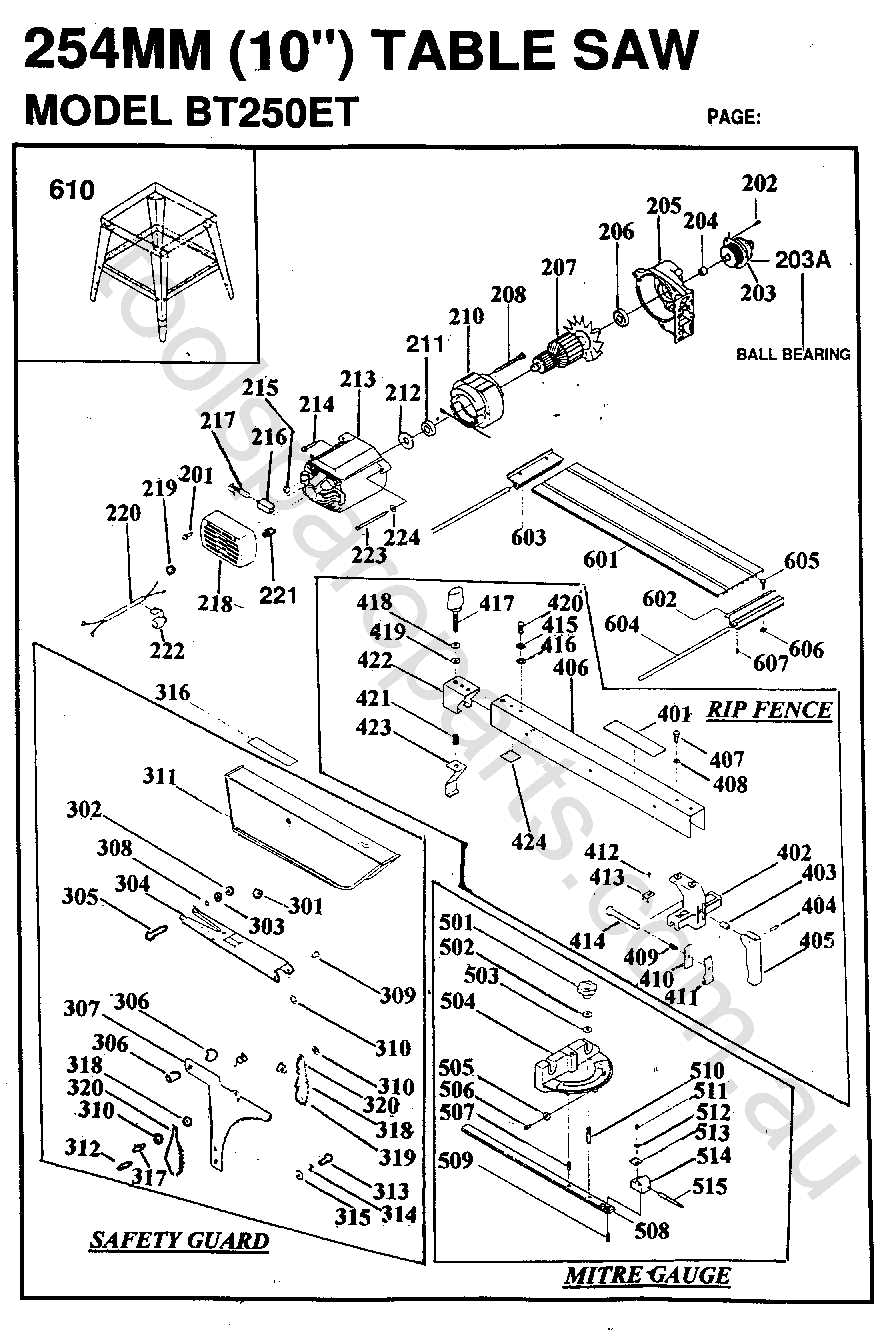

Understanding how different elements of a machine come together is essential for both maintenance and repair. This guide provides a clear breakdown of the internal structure, allowing you to pinpoint various elements within the equipment and their respective connections. Familiarity with these components can simplify the process of troubleshooting and replacement.

The visual representation of the internal arrangement plays a crucial role in ensuring that each element is placed and secured correctly. Whether you’re performing routine maintenance or addressing specific operational issues, having access to a detailed layout can help you avoid mistakes and ensure long-lasting functionality.

For those looking to enhance their technical knowledge, this breakdown offers an invaluable reference. By exploring the relationships between the different sections of the equipment, you can gain a deeper understanding of how the machine operates as a cohesive system.

Key Component Overview

When analyzing the internal structure of this precision tool, it’s essential to understand the core mechanisms that ensure its smooth operation. Each element has been carefully designed to contribute to overall performance, enhancing durability and accuracy in every use.

Cutterhead Assembly plays a pivotal role in delivering clean and precise cuts. It rotates at high speeds, ensuring that materials are processed efficiently. Proper maintenance of this component is crucial for long-term functionality.

Depth Adjustment Mechanism allows for fine-tuning the cutting depth, providing users with the flexibility to work on various projects. This adjustable feature helps to achieve consistent results across different types of materials.

The motor unit powers the entire system, driving the blades and ensuring consistent performance. Its robust design supports prolonged use without compromising efficiency.

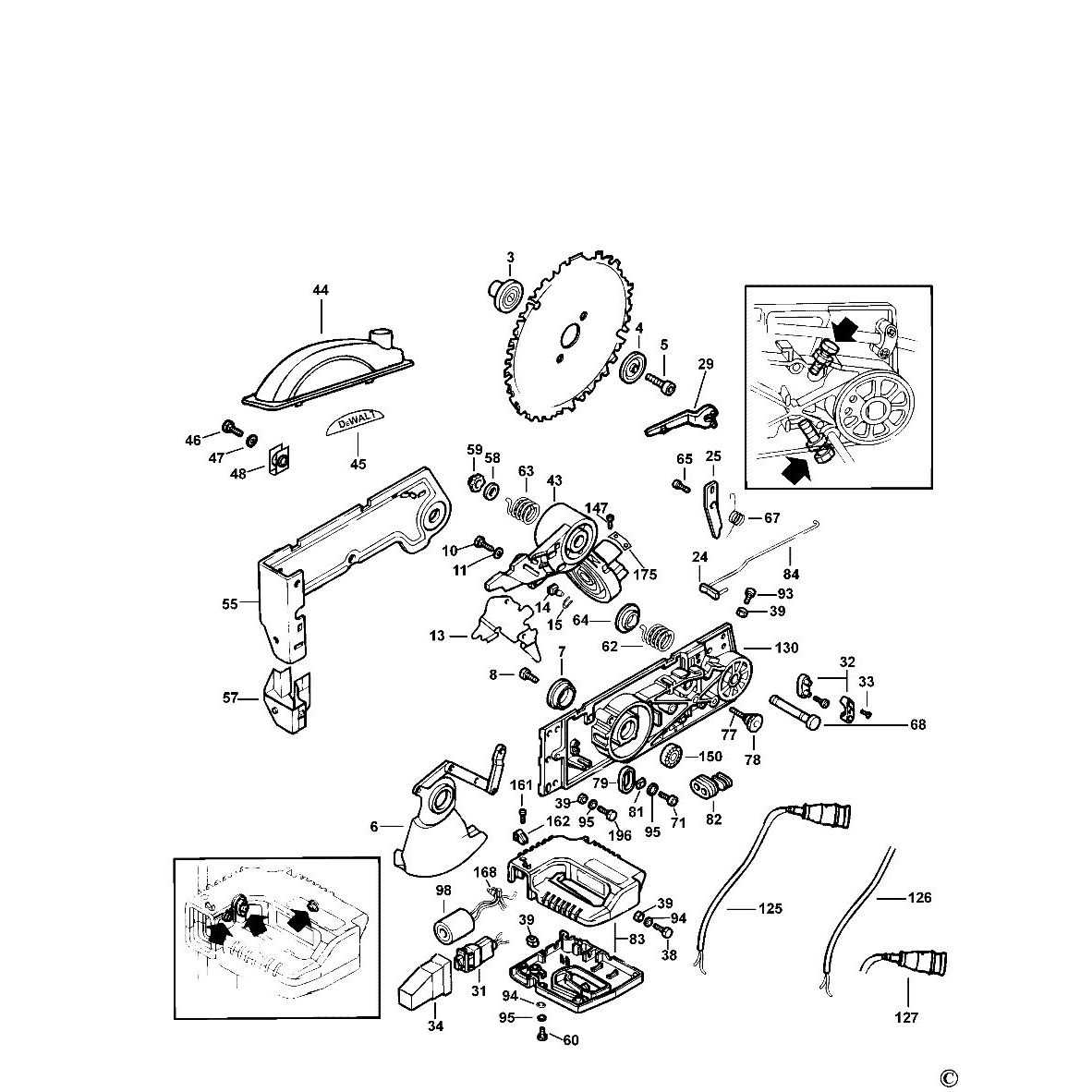

Understanding the Blade Assembly Structure

The blade assembly structure plays a crucial role in the overall performance and efficiency of any woodworking tool. It consists of several interconnected components that work in unison to ensure precise and smooth cutting operations. Each part within this structure is designed to handle specific tasks, and their proper alignment is key to achieving optimal results.

At the heart of this system is the cutting edge itself, which must be securely fastened and positioned to maintain consistent accuracy. Surrounding the blade, support mechanisms work to reduce vibrations and provide stability

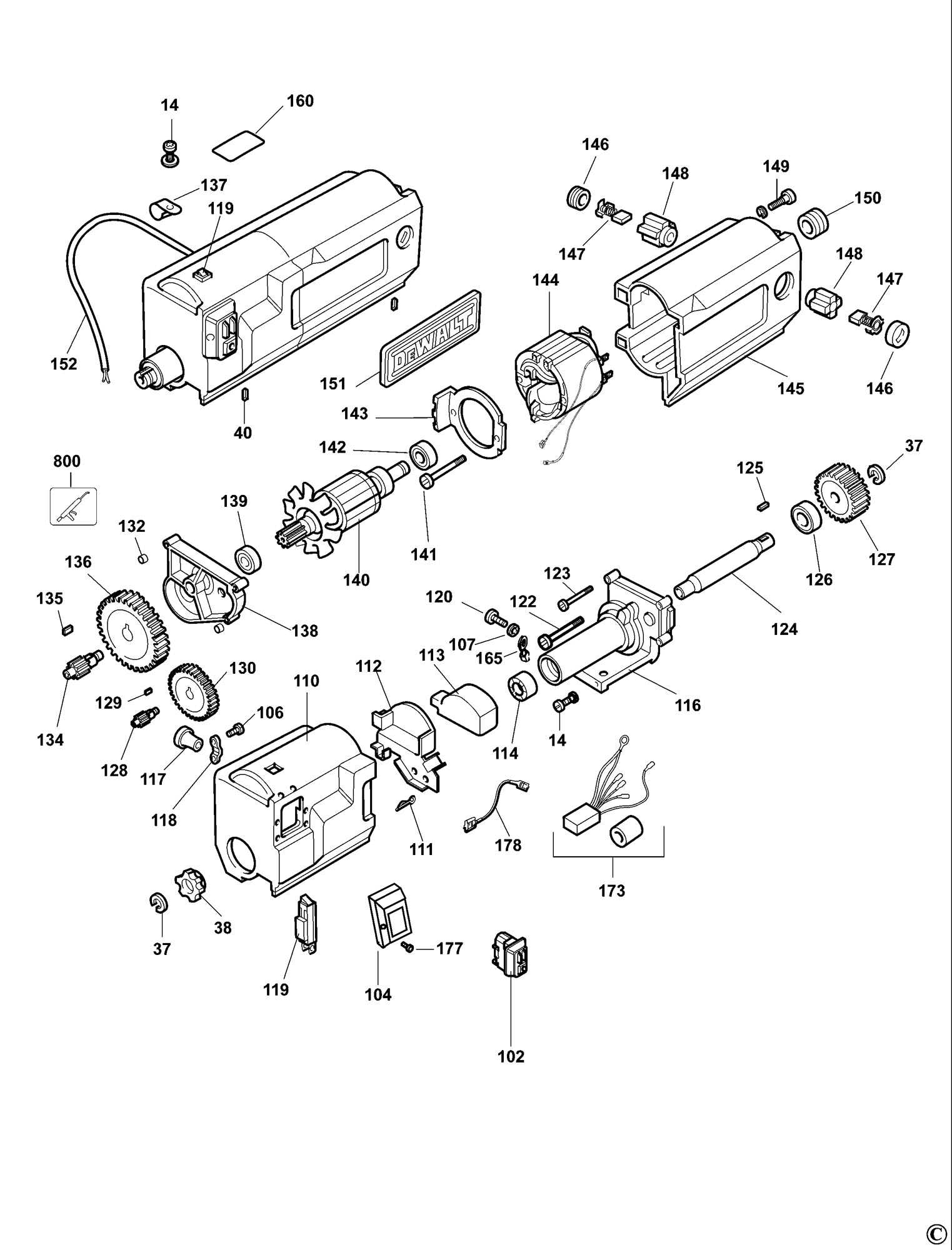

Motor Unit Breakdown for Dewalt 735

The motor assembly consists of several key components that work in unison to ensure smooth and efficient operation. Each element plays a crucial role in driving the system, from power transmission to maintaining consistent performance. Understanding the structure and interworking of these elements is essential for maintaining and troubleshooting the equipment.

Core components of the motor system include the rotor, stator, and fan assembly. These parts interact to create rotational movement and ensure cooling during extended use. The internal wiring and connections are also vital, ensuring proper electrical flow and preventing malfunctions.

Regular inspection and maintenance of the motor unit can extend the lifespan of the equipment. Replacing worn or damaged elements, such as bearings or brushes, helps maintain optimal performance and prevents unexpected breakdowns during operation.

How the Cutterhead Mechanism Works

The cutterhead mechanism is a vital component in ensuring smooth and efficient wood processing. It rotates at high speeds to remove material from the surface, providing a clean and even finish. Understanding how this system operates can help maintain consistent performance and extend the longevity of the tool.

Main Components of the Cutterhead

The mechanism consists of several key elements, including a series of rotating blades attached to the cylindrical shaft. These blades are precisely aligned to cut through the wood as the cylinder spins. The speed of rotation and the sharpness of the blades are crucial factors that influence the overall quality of the cut.

Operation and Maintenance

The cutterhead is powered by the motor, which drives the rotation of the blades. Regular maintenance, such as blade sharpening and debris removal, is essential to keep the mechanism running smoothly. Ensuring that all components are well-lubricated and securely fast

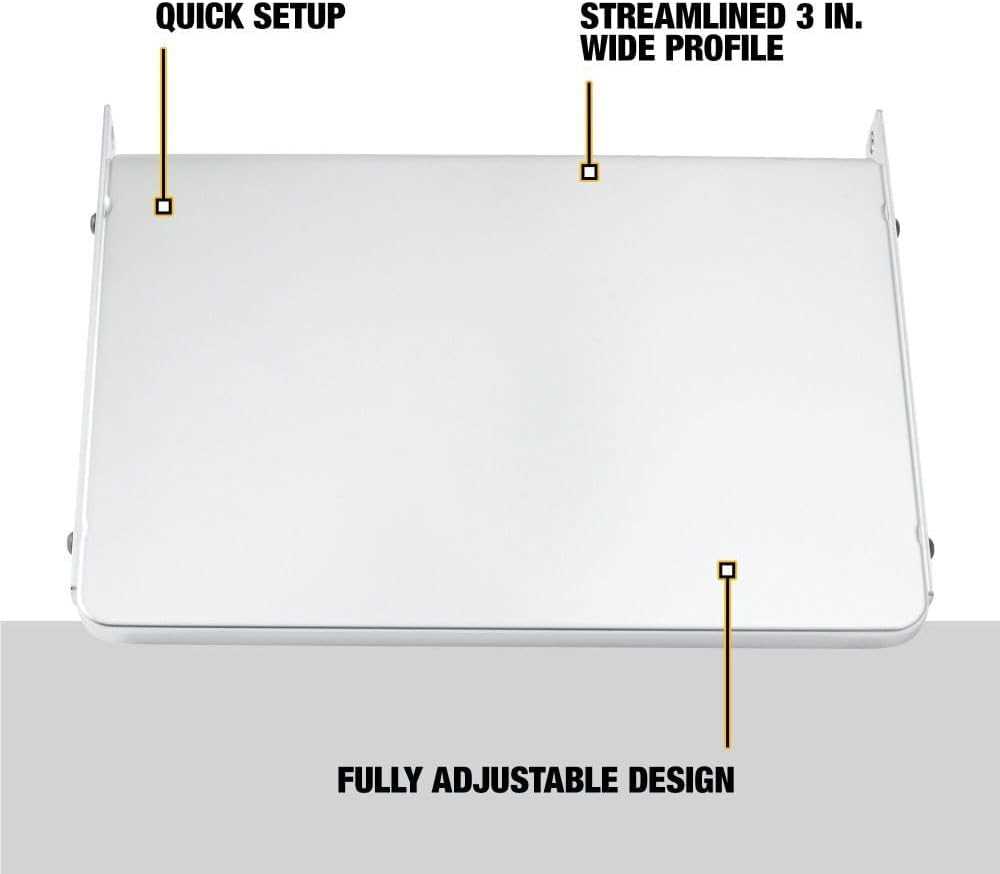

Guide to the Infeed and Outfeed Tables

The infeed and outfeed tables play a crucial role in ensuring the smooth movement of material during processing. They provide stability, minimizing snipe and allowing for more accurate results. Proper alignment and adjustment of these tables are essential to maintaining an even flow, especially when working with longer workpieces.

Infeed Table: The infeed table helps to guide the material into the machine, supporting it as it moves towards the

Exploring the Depth Adjustment Components

Understanding the mechanisms that control depth settings is crucial for achieving precise results in woodworking tasks. These components play a significant role in how effectively one can adjust the cutting depth of the tool, enhancing accuracy and performance.

The depth adjustment system typically comprises several essential elements that work together seamlessly. Here’s a closer look at the key components involved:

- Adjustment Lever: This lever allows for quick changes to the depth setting, providing user-friendly operation.

- Guide Scale: Marked indicators on this scale assist in measuring the desired depth, ensuring consistency in cuts.

- Locking Mechanism: This feature secures the selected depth, preventing any accidental adjustments during operation.

- Adjustment Screw: Fine-tuning of the depth can be achieved through this screw, allowing for minute changes as needed.

By familiarizing oneself with these components, users can optimize their experience and improve the overall quality of their woodworking projects.

Maintenance of the Chip Ejection System

The chip ejection mechanism is a crucial component in ensuring the smooth operation of woodworking tools. Regular maintenance of this system helps prevent clogs and ensures optimal performance. Proper attention to this area can significantly enhance the efficiency and longevity of the equipment.

To maintain the chip ejection system, start by regularly checking for any debris buildup. Accumulated materials can impede the flow of shavings and create potential blockages. A thorough cleaning after each use is advisable, using compressed air or a soft brush to remove any particles that may have settled.

Additionally, inspect the ejection chute for any signs of wear or damage. If any cracks or deformities are noticed, it’s essential to replace the affected parts to maintain proper functionality. Lubricating moving components can also prevent friction and ensure smooth operation, thereby extending the lifespan of the mechanism.

Lastly, following the manufacturer’s guidelines regarding service intervals and procedures will help in keeping the chip ejection system in top condition. Regular maintenance not only improves performance but also contributes to the overall safety of the tool.

Drive Belt Setup and Functionality

The drive belt is a crucial component in the operation of various machinery, playing a vital role in transferring power from the motor to different mechanisms. Proper installation and maintenance of this element ensure optimal performance and longevity of the equipment. Understanding its setup can aid in troubleshooting and enhancing efficiency.

Installation Procedure

To achieve effective performance, the installation of the drive belt must be executed with precision. Begin by ensuring that the machine is turned off and disconnected from any power source. Carefully position the belt over the designated pulleys, ensuring that it is aligned correctly to avoid slippage. Tension adjustments should be made as needed to secure proper function.

Maintenance and Troubleshooting

Regular inspection of the drive belt is essential for maintaining machine efficiency. Look for signs of wear, such as fraying or cracking, and replace the belt if any damage is detected. Additionally, monitoring tension levels will prevent slippage and ensure smooth operation. Keeping the pulleys clean and free of debris will also contribute to the longevity of the drive belt.

| Issue | Symptoms | Solutions |

|---|---|---|

| Belt Slippage | Unusual noises, reduced power | Check tension, realign belt |

| Excessive Wear | Fraying, visible cracks | Replace belt, inspect pulleys |

| Misalignment | Belt tracking issues | Realign components, adjust setup |

Importance of the Fan Housing in Dewalt 735

The fan enclosure plays a crucial role in the efficient functioning of woodworking machinery. This component is essential for managing airflow, ensuring that the motor remains cool during operation. Proper ventilation not only enhances performance but also prolongs the lifespan of the equipment.

A well-designed fan housing contributes to optimal air circulation, minimizing overheating risks. This is particularly vital when the tool is used for extended periods, as excessive heat can lead to mechanical failures. By effectively dissipating heat, the fan housing helps maintain consistent operational temperatures, which is key for reliable performance.

Moreover, the construction of the fan housing can influence noise levels. A robust design can help reduce vibrations and sound, creating a more comfortable working environment. Therefore, attention to the quality and design of this component is imperative for both functionality and user satisfaction.

Roller System and Its Role in Operation

The roller mechanism plays a crucial part in the functionality of woodworking machinery, enhancing efficiency and precision. This system ensures smooth movement and stability during operation, contributing significantly to the overall performance of the tool.

Functionality of the Roller Mechanism

This mechanism is designed to facilitate the seamless passage of materials through the machine. By maintaining an even pressure, it helps to reduce the risk of jams and ensures that each cut or finish is uniform. The smooth rollers minimize friction, allowing for quicker and more accurate processing of wood.

Maintenance Considerations

Proper upkeep of the roller system is essential for optimal performance. Regular inspections and cleaning can prevent debris buildup, which may hinder operation. Ensuring that the rollers are correctly aligned and lubricated will extend their lifespan and enhance the overall efficiency of the machinery.

Replacing

When it comes to maintaining tools, the process of swapping out worn or damaged components is crucial for ensuring optimal performance. Understanding how to effectively replace these elements can greatly enhance the lifespan and efficiency of your equipment.

Essential Steps for Replacement

- First, disconnect the power source to ensure safety while working on the machine.

- Carefully disassemble the housing to access the internal mechanisms.

- Identify the specific parts that require replacement.

- Remove the faulty components using the appropriate tools.

- Install the new elements, ensuring they fit snugly and securely.

- Reassemble the tool, making sure all screws and fasteners are tightened properly.

- Finally, reconnect the power source and perform a test to verify functionality.

Tips for a Successful Replacement

- Always refer to the user manual for specific guidance related to your tool.

- Keep a clean workspace to avoid losing small components.

- Consider wearing safety goggles and gloves to protect yourself during the process.

- If unsure about any steps, consult a professional to prevent further damage.