When it comes to efficient landscaping and yard maintenance, having a reliable cutting tool is essential. Each model is equipped with various elements that work together seamlessly to enhance performance and ease of use. Recognizing the configuration and functionality of these components is crucial for both maintenance and troubleshooting, ensuring that the device operates optimally for years to come.

In this section, we will explore a detailed overview of the various elements involved in this specific model. By examining how these parts interact and contribute to the overall functionality, users can gain valuable insights into the mechanics behind their tool. This understanding not only aids in effective repairs but also fosters a deeper appreciation for the engineering that makes modern landscaping equipment effective and reliable.

Furthermore, having a comprehensive reference of the arrangement and roles of each component allows for easier identification of potential issues. Whether you’re an enthusiast looking to enhance your skills or a professional seeking efficiency, mastering the intricacies of your cutting tool can significantly impact your experience and outcomes. Equip yourself with knowledge and ensure your equipment remains in top condition.

Maintaining power equipment often necessitates the replacement of specific components to ensure optimal performance. Familiarity with frequently changed parts can enhance efficiency and prolong the lifespan of the equipment. This section outlines common components that users may need to replace over time.

Key Components

Identifying essential components that may wear out or break is crucial for effective maintenance. Below is a table detailing these components along with their typical functions.

| Component | Function |

|---|---|

| Battery | Provides power to the equipment for operation. |

| Motor | Drives the cutting mechanism, allowing for efficient trimming. |

| Cutting Blade | Engages in the actual cutting process, essential for achieving desired results. |

| Handle | Facilitates control and maneuverability during operation. |

| Guard | Enhances safety by protecting the user from debris and accidental contact with the blade. |

Considerations for Replacement

When replacing components, it is essential to select high-quality replacements that match the specifications of the original parts. Regular inspections and timely replacements can significantly improve the longevity and reliability of the equipment.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your equipment requires regular care and attention. Implementing effective maintenance strategies can significantly enhance performance and durability, allowing for consistent operation over time.

Regular Cleaning: Keeping the device clean is essential. Dust and debris can accumulate, impacting efficiency and causing wear. Periodically remove any buildup from critical components using a soft brush or compressed air.

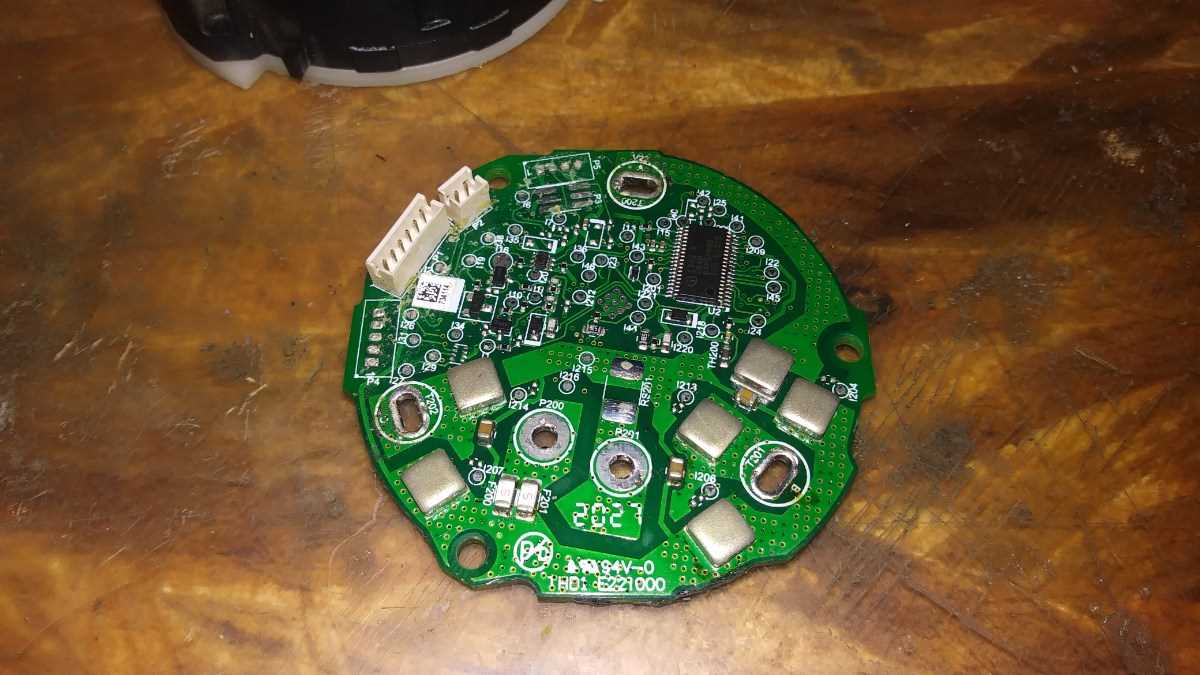

Inspection of Components: Conduct routine checks on various parts to identify signs of wear or damage. Look for cracks, frayed wires, or other issues that may compromise functionality. Addressing these problems early can prevent further damage.

Lubrication: Proper lubrication of moving parts is vital to reduce friction and wear. Use the recommended lubricant for your device, and apply it as specified in the user manual to maintain smooth operation.

Battery Care: If your equipment relies on batteries, ensure they are stored and charged correctly. Avoid deep discharges and extreme temperatures, as these can shorten battery life significantly.

Follow the Manufacturer’s Guidelines: Adhering to the manufacturer’s instructions for maintenance will ensure optimal performance and prolong the lifespan of your device. Regularly consult the manual for specific recommendations.

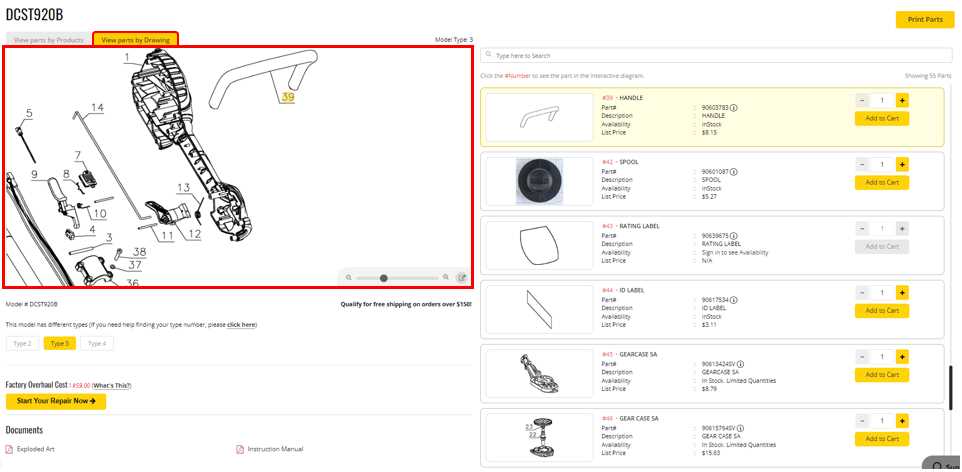

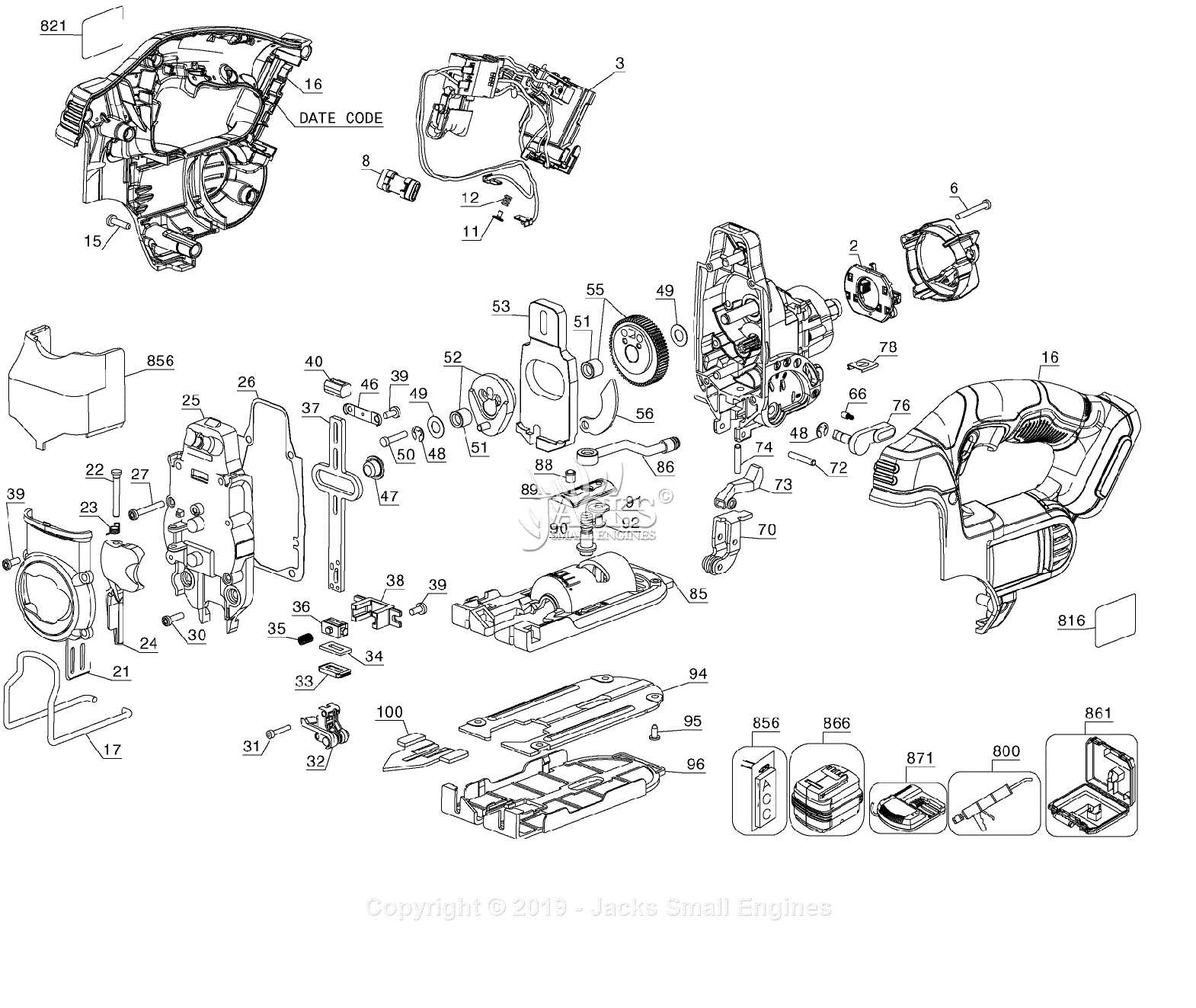

How to Read Parts Diagrams

Understanding the visual representations of components is essential for effective maintenance and repair. These illustrations simplify the complexity of machinery, allowing users to identify individual elements and their interconnections. By familiarizing oneself with the structure and symbols used in these images, one can easily locate specific items and comprehend their functions.

When examining these visual aids, it is crucial to pay attention to the following aspects:

| Element | Description |

|---|---|

| Legend | This section provides explanations for symbols and notations used in the illustration. |

| Part Numbers | Each component is typically assigned a unique identifier, essential for ordering replacements. |

| Sections | Diagrams are often divided into segments, each focusing on specific areas of the equipment. |

| Connections | Look for lines indicating how different pieces interact and fit together. |

By mastering these key elements, individuals can enhance their understanding of equipment and improve their ability to perform repairs or modifications effectively.

Resources for Spare Parts

Finding reliable sources for replacement components is essential for maintaining the longevity and efficiency of your tools. Whether you need specific items for repairs or general upgrades, having access to a variety of resources can streamline the process. Here are some options to consider when searching for suitable alternatives.

- Official Retailers: Check the manufacturer’s authorized dealers for genuine replacements. This ensures compatibility and quality.

- Online Marketplaces: Websites like Amazon, eBay, and others often have a wide selection of components, both new and used, at competitive prices.

- Local Hardware Stores: Many local shops carry essential parts or can order them for you, providing personal assistance and advice.

- Specialized Repair Shops: These establishments focus on specific tools and may offer parts and expertise tailored to your needs.

- DIY Forums and Communities: Engaging with online communities can provide insights and recommendations on where to find components.

Always compare prices and check for warranties or return policies to ensure that you make informed purchasing decisions. This diligence can save you time and money in the long run.

Step-by-Step Assembly Guide

Assembling your tool requires careful attention to detail and a methodical approach to ensure optimal functionality. This guide will take you through the necessary steps to effectively put together your device, allowing you to work with confidence and efficiency. Follow these instructions closely for a successful assembly process.

Gather Your Components

Before starting, ensure you have all the necessary components and tools at hand. This includes the main body, handle, cutting attachment, and fasteners. Double-check that you have everything needed to avoid interruptions during the assembly process.

Assemble the Components

Begin by attaching the handle securely to the main body. Use the provided fasteners to secure it firmly in place. Next, attach the cutting mechanism, making sure it is aligned properly for smooth operation. Once all components are in position, perform a final inspection to confirm that everything is tightened and correctly assembled.

By following these steps, you will ensure that your device is assembled correctly, allowing you to utilize it effectively for various tasks.

Troubleshooting Common Issues

When operating power tools, encountering difficulties can be a common experience. Identifying and resolving these challenges promptly is essential to ensure optimal performance and longevity of the equipment. This section provides insights into prevalent problems and their potential solutions.

1. Difficulty Starting: If the equipment fails to start, first check the power source. Ensure that the battery is charged and properly connected. Inspect the switch for any damage and confirm that all safety features are engaged. If the issue persists, further investigation of the internal components may be necessary.

2. Reduced Cutting Efficiency: A noticeable decrease in cutting power may indicate a dull blade or improper alignment. Examine the cutting element for wear and replace it if needed. Additionally, ensure that the tool is set at the correct angle and speed for the task at hand.

3. Excessive Vibration: Unusual vibrations during operation can signal loose parts or imbalanced components. Check for any loose screws or fasteners and tighten them accordingly. Balancing the cutting element may also help to mitigate excessive shaking.

4. Overheating: If the tool becomes excessively hot during use, it may be working harder than necessary. Allow the equipment to cool down and evaluate the workload. Inspect for any blockages that may restrict airflow, leading to overheating issues.

5. Electrical Problems: Flickering lights or intermittent power issues can stem from electrical connections. Inspect the wiring for any signs of damage or fraying. Ensuring a secure connection can often resolve these electrical concerns.

By systematically addressing these common issues, users can enhance the reliability and effectiveness of their tools, ensuring a smoother working experience.

Safety Precautions During Repairs

When undertaking maintenance or repairs on equipment, prioritizing safety is essential. Ensuring a secure working environment helps prevent accidents and injuries. Proper awareness and preparation can significantly reduce risks associated with handling tools and components.

Proper Gear and Equipment

Wearing appropriate protective gear is crucial when performing repairs. This includes safety goggles to shield your eyes, gloves to protect your hands, and sturdy footwear to ensure stability. Using tools that are well-maintained and suitable for the task at hand also minimizes the chance of accidents.

Work Area Organization

A tidy workspace contributes to a safer repair process. Keeping tools organized and removing any unnecessary items from the area can prevent tripping hazards. Adequate lighting is also important; it enhances visibility and allows for precise work, reducing the likelihood of errors or mishaps.