Every power tool comprises a series of interconnected elements that contribute to its overall functionality. Understanding these components is crucial for effective maintenance and repair, ensuring that the equipment operates at peak performance. This section aims to provide insights into the intricate workings of a popular model, emphasizing the importance of each individual piece.

By familiarizing yourself with the various parts of this tool, you will be better equipped to troubleshoot issues, perform upgrades, and extend its lifespan. Knowledge of the layout and function of each element can significantly enhance your efficiency during tasks, whether you are a professional or a hobbyist.

This guide will serve as a valuable resource, highlighting the essential components, their relationships, and how they work together to create a reliable tool. Equipped with this understanding, you can confidently tackle repairs and optimize the use of your equipment, maximizing its potential for any project.

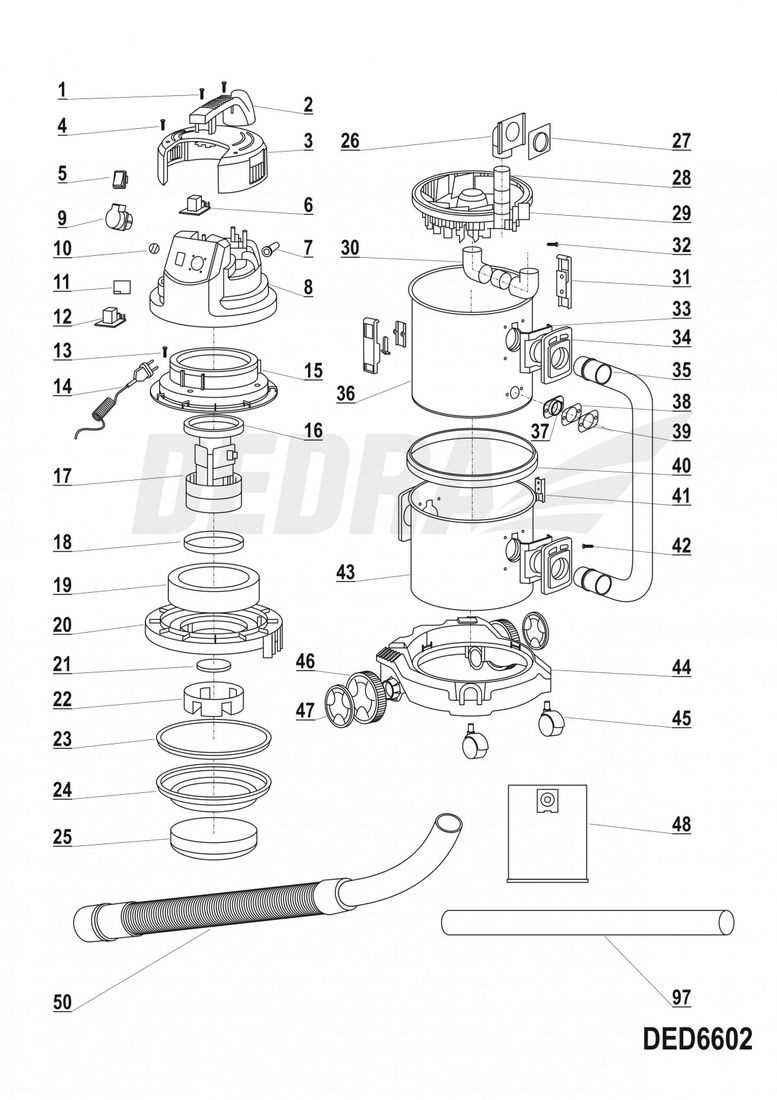

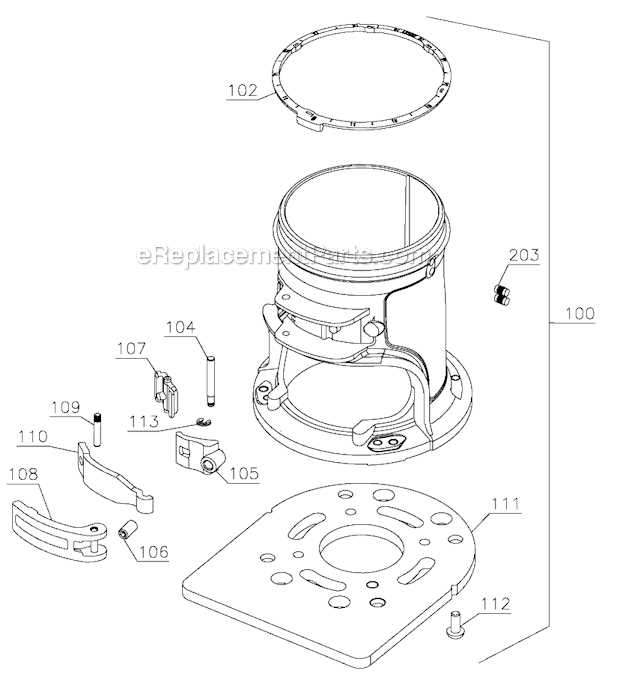

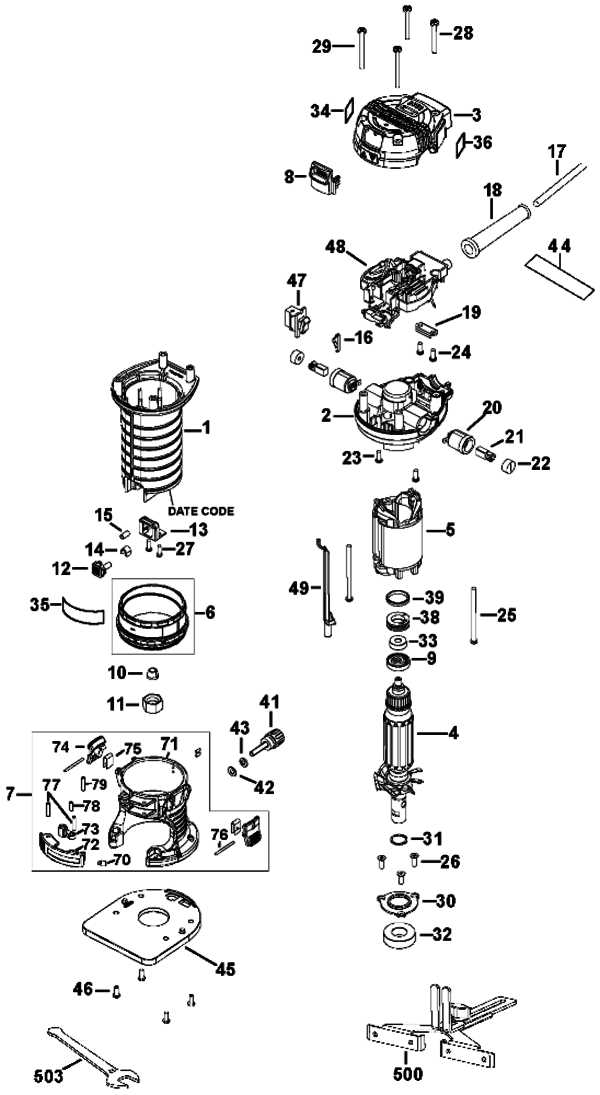

Dewalt DW618 Parts Diagram

This section provides a detailed overview of the components and assembly of a popular woodworking tool. Understanding the structure of the device is essential for maintenance and repairs, ensuring that each element functions optimally.

Component Overview

Every tool consists of various elements that work together seamlessly. Familiarity with these parts can enhance your ability to troubleshoot issues and perform necessary upgrades. Whether you are a professional or a hobbyist, knowing the main components will improve your overall experience.

Maintenance Tips

Regular upkeep is crucial for extending the lifespan of your equipment. Ensure that you routinely check for wear and tear, clean the components, and replace any worn-out items promptly. This proactive approach will maintain the efficiency and reliability of your tool.

Overview of Dewalt DW618 Model

The tool in question is designed for precision and versatility, catering to a variety of woodworking applications. It boasts a robust construction, ensuring durability and long-lasting performance. Ideal for both amateur enthusiasts and professional craftsmen, this model features user-friendly controls that enhance ease of use and efficiency in various tasks.

Equipped with a powerful motor, the device delivers consistent power for a range of routing functions. Its adjustable speed settings allow for customization based on specific requirements, making it suitable for intricate work as well as heavy-duty projects. The thoughtful design incorporates safety features that provide peace of mind during operation.

This model also includes various accessories, enhancing its functionality and enabling users to tackle a diverse array of tasks. With a focus on ergonomic design, it promotes comfortable handling, reducing fatigue during extended periods of use. Overall, this tool stands out as a reliable choice for those seeking quality and performance in their woodworking endeavors.

Importance of Parts Diagrams

Understanding the components of any machinery is crucial for effective maintenance and repair. Visual representations that detail the various elements allow users to quickly identify each part’s function and location. This knowledge is essential for ensuring the longevity and efficiency of equipment.

Moreover, these visual aids serve as valuable references during troubleshooting processes. By pinpointing specific sections of the machinery, users can efficiently address issues without unnecessary delays. This capability enhances productivity and reduces downtime, which is particularly important in professional environments where time is of the essence.

| Benefits | Description |

|---|---|

| Improved Understanding | Visual aids enhance comprehension of machine components. |

| Efficient Troubleshooting | Quick identification of issues leads to faster resolutions. |

| Enhanced Maintenance | Regular reference helps maintain optimal equipment performance. |

| Reduced Downtime | Less time spent on repairs increases overall productivity. |

Common Components of the DW618

Understanding the essential elements of this power tool is crucial for maintenance and operation. Various key components contribute to its performance and durability, ensuring that it meets the needs of both professional and amateur users alike.

Motor Assembly

The motor assembly is the heart of the tool, providing the necessary power for various applications. It typically features a robust design that enhances efficiency and reduces wear over time. Users should regularly inspect this component for signs of damage or wear to maintain optimal functionality.

Base and Subbase

The base and subbase play a vital role in stability and precision during operation. These components are designed to support the tool effectively, allowing for accurate cuts and enhancing overall control. Proper maintenance, including cleaning and checking for any cracks or deformities, is essential for safe and effective usage.

Identifying Replacement Parts Easily

Finding the right components for your tools can be a straightforward task if you approach it methodically. Understanding the various elements of your equipment and how they fit together is crucial for efficient replacement. By familiarizing yourself with the assembly and the specific characteristics of each piece, you can streamline the identification process.

Start by gathering the necessary documentation or resources that outline the configuration of your tools. This will help you visualize how the components interact. Once you have a clear picture, check online resources or manufacturers’ websites that offer detailed illustrations or catalogs. These resources often include images and descriptions that simplify the search for the correct item.

It is also beneficial to categorize the components by their function. Grouping similar items together allows for quicker access and comparison, especially when dealing with multiple replacements. Additionally, note any identifying numbers or labels present on the original parts. This information can be invaluable when seeking out suitable alternatives.

Finally, don’t hesitate to reach out to customer support or community forums. Engaging with other users can provide insights and recommendations that might not be available through standard channels. By leveraging these strategies, you can efficiently identify and acquire the necessary replacements for your equipment.

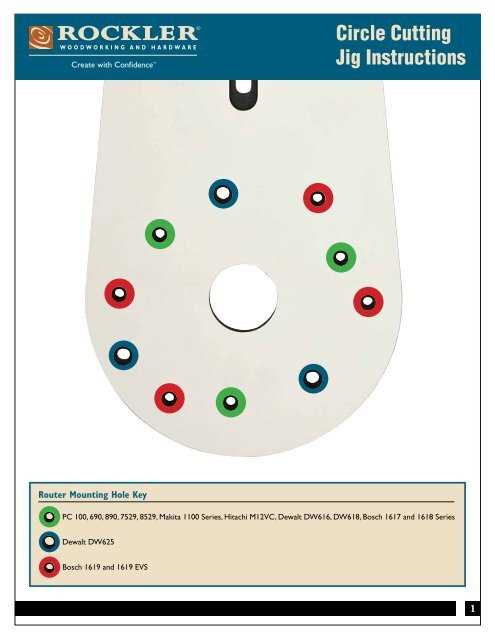

How to Use the Diagram

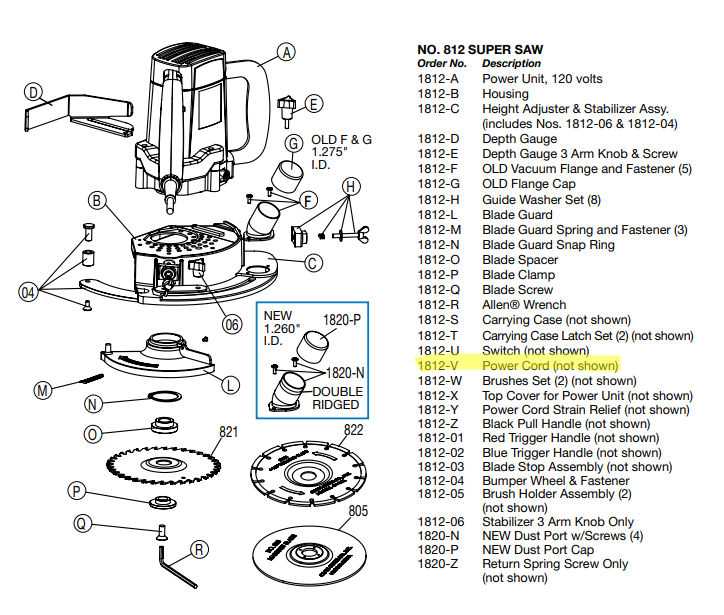

Understanding the visual representation of components is essential for effective maintenance and repairs of your tools. This illustration serves as a guide, enabling users to identify individual elements and their respective functions. By familiarizing yourself with this schematic, you can streamline your repair process and ensure all necessary pieces are accounted for.

Start by locating the specific section relevant to your project. Each element will be labeled, making it easier to find parts that may require replacement or adjustment. Use the key provided in the illustration to interpret any symbols or notations, as this will enhance your comprehension of the layout.

As you work through your project, refer back to the visual representation to confirm that you have the correct components at hand. This will help prevent errors during assembly and ensure that everything fits together seamlessly. Additionally, if you encounter difficulties, revisiting the schematic can provide clarity on how different parts interact with one another.

Utilizing this visual tool not only aids in identifying the necessary components but also enhances your overall understanding of how the equipment operates. This knowledge can lead to more effective troubleshooting and maintenance, ultimately extending the lifespan of your tools.

Maintenance Tips for Your Router

Proper upkeep of your router is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances the efficiency of the tool but also helps prevent potential issues that could arise from neglect. Following a few simple practices can keep your device in excellent working condition.

Regular Cleaning

Cleaning your router frequently is crucial. Dust and debris can accumulate on the exterior and within the motor, leading to overheating and decreased performance. Use a soft brush or a dry cloth to remove any buildup on the surface. For more thorough cleaning, you may need to disassemble certain components, ensuring that you refer to the manufacturer’s guidelines for proper procedures.

Inspection of Components

Periodically checking the various parts of your router can help identify wear or damage before it becomes a significant issue. Inspect the collet, bearings, and base for signs of wear. If you notice any irregularities, replacing those components promptly can prevent further damage and ensure smooth operation. Additionally, lubricating moving parts according to the manufacturer’s recommendations will enhance performance and reduce friction.

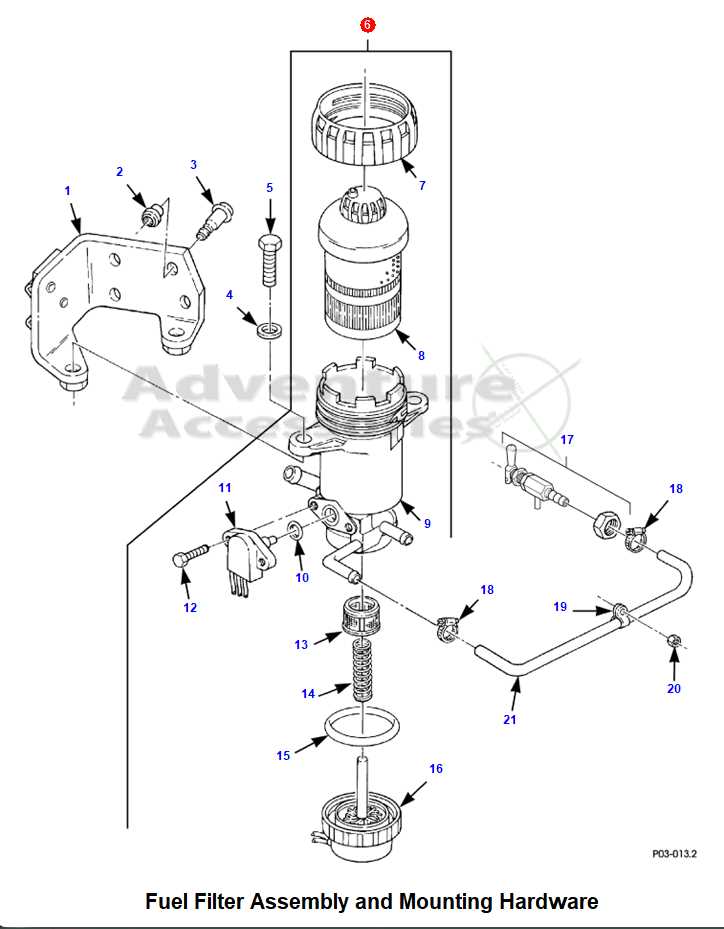

Finding OEM Replacement Parts

When your power tool requires maintenance or repair, sourcing high-quality original equipment manufacturer components is crucial for optimal performance. These parts ensure compatibility and reliability, helping to extend the lifespan of your equipment. Understanding how to find these essential components can save time and improve your repair experience.

Where to Search for Components

Many avenues exist for locating authentic components. Consider the following options:

| Source | Description |

|---|---|

| Manufacturer’s Website | Direct access to an extensive catalog of original components. |

| Authorized Retailers | Resellers that specialize in genuine equipment and provide additional support. |

| Online Marketplaces | Platforms where reputable sellers list authentic components, often at competitive prices. |

| Repair Shops | Local businesses that can order specific components or offer repair services with genuine parts. |

Benefits of Using OEM Components

Opting for authentic parts brings several advantages, including improved reliability, enhanced performance, and warranty protection. Ensuring that your equipment operates with the correct specifications is vital for safety and efficiency.

Aftermarket Options for Components

Exploring alternative sources for replacement parts can be a practical solution for users seeking cost-effective or enhanced performance. Many third-party manufacturers provide compatible items, which often meet or exceed original specifications.

- Cost Efficiency: Aftermarket products are typically more affordable, offering significant savings without compromising on quality.

- Enhanced Durability: Some third-party suppliers

Troubleshooting Common Issues

When dealing with malfunctioning equipment, it’s essential to identify typical issues that arise over time. Understanding the root causes can help address these malfunctions quickly and efficiently, minimizing downtime and improving tool performance. Regular maintenance and awareness of common failures are key to keeping tools operating at their best.

One frequent problem users encounter is overheating, which often occurs due to clogged vents or overuse without proper breaks. To resolve this, ensure that airflow is unobstructed and the device is allowed to cool periodically during extended use. Regular cleaning can prevent debris buildup, which contributes to this issue.

Another common challenge is inconsistent performance, where the equipment may start to stutter or slow down. This can result from worn components or loose connections. Inspecting internal parts and tightening any loose screws can often restore smooth operation

Step-by-Step Disassembly Guide

This section provides a clear process for taking apart the unit in a structured manner. The goal is to ensure each component is safely removed without causing damage, allowing for easy maintenance or replacement. Following the instructions carefully will help you avoid potential issues during reassembly.

Step 1: Unplug the device from the power so Reassembly Techniques for Efficiency

Ensuring a smooth and effective reassembly process requires a combination of organization, precision, and the right techniques. With careful planning and attention to detail, time spent reassembling can be minimized, and the overall outcome will be more reliable.

Organizing Components

One of the most crucial steps is to categorize and lay out each component methodically. By sorting everything into logical groups, such as fasteners, mechanical parts, and smaller elements, the reassembly will flow more smoothly.

- Use labeled containers or trays to keep similar components together.

- Ensure that screws and bolts are placed near their respective parts for easy identification.

- Take photos during disassembly to provide a visual reference for reassembly.

Resources for Further Information

When looking to dive deeper into the functionality and upkeep of various woodworking and power tools, a range of resources can help you find more detailed insights. These include manuals, instructional guides, and communities where enthusiasts and professionals share their knowledge.

Manufacturer Websites

Official websites are a reliable source of accurate and up-to-date information. Here, you can typically find user manuals, maintenance guides, and product specifications. Many manufacturers offer downloadable PDFs that cover the specifics of each model.

Tool Communities and Forums

Online communities and discussion forums are a goldmine for practical advice. Many professionals and hobbyists regularly share their