In the world of power equipment, familiarity with the structure and components of a tool is essential for both maintenance and effective usage. This section delves into the intricate layout of a well-known model, focusing on its essential elements and how they contribute to overall functionality. Grasping these details not only enhances the user experience but also aids in troubleshooting and repairs.

The significance of comprehending the configuration of various components cannot be overstated. By exploring the relationships between individual pieces, users can develop a deeper understanding of their equipment. This knowledge empowers operators to make informed decisions regarding upgrades, repairs, and best practices for operation, ensuring longevity and efficiency.

Furthermore, having a clear visual reference of the tool’s assembly provides an invaluable resource for those looking to familiarize themselves with its workings. Whether you are a seasoned professional or a newcomer, understanding the layout can simplify maintenance tasks and enhance your overall proficiency with the equipment.

Overview of Dewalt DW708 Type 4

This section provides a comprehensive look at a specific model of power tool renowned for its efficiency and versatility in various applications. Designed for both professionals and DIY enthusiasts, it combines innovative features with user-friendly controls, making it a popular choice in the woodworking community.

Key features of this equipment include:

- Robust construction for durability and longevity.

- Accurate cutting capabilities, ensuring precision in every project.

- Adjustable settings to cater to different tasks and materials.

- Safety mechanisms to protect users during operation.

Its design incorporates several advanced elements that enhance performance and ease of use. Users can expect:

- Enhanced stability during cutting operations.

- Simple adjustments for various angles and depths.

- Compatibility with a range of accessories for increased functionality.

In summary, this model stands out in its category due to its combination of power, precision, and ease of use, making it an essential tool for those seeking high-quality performance in their projects.

Key Features of the Model

This model stands out in the market due to its exceptional design and functionality, catering to both professionals and DIY enthusiasts. Its robust construction ensures durability, while innovative features enhance usability and efficiency in various applications.

One of the most notable aspects is its powerful motor, which provides ample torque for demanding tasks. The precision engineering of the cutting mechanism ensures clean and accurate cuts, making it an ideal choice for woodworking projects.

Additionally, the user-friendly interface simplifies operation, allowing users to adjust settings with ease. Enhanced safety features, such as blade guards and emergency stops, provide peace of mind during use. This model truly exemplifies a blend of performance and reliability, making it a valuable addition to any toolkit.

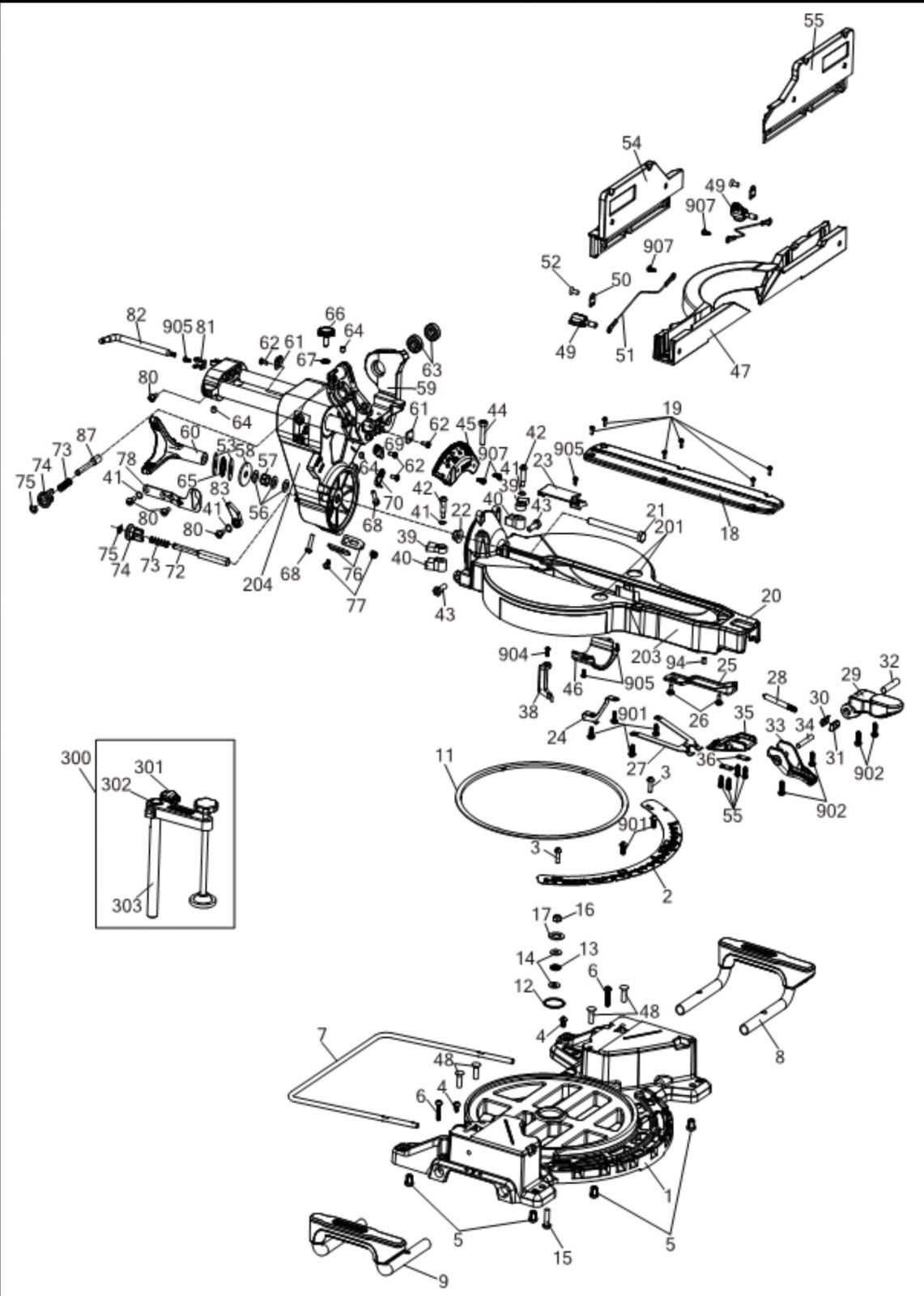

Understanding the Parts Diagram

This section delves into the visual representation of components, providing insights into how various elements interact within a mechanical assembly. A clear and organized illustration can significantly aid in grasping the functionality and arrangement of each segment.

Importance of Visual Aids

Visual aids serve as crucial tools for understanding complex machinery. They allow users to quickly identify different components and their respective functions, making maintenance and repairs more efficient. By examining a well-structured illustration, one can gain clarity on how individual elements contribute to the overall operation of the equipment.

Navigating the Illustration

When analyzing the visual representation, pay close attention to the labeling of each section. Understanding how to interpret these labels can facilitate easier troubleshooting and parts replacement. Moreover, familiarizing oneself with the layout helps in recognizing potential issues and ensuring proper functionality of the entire system.

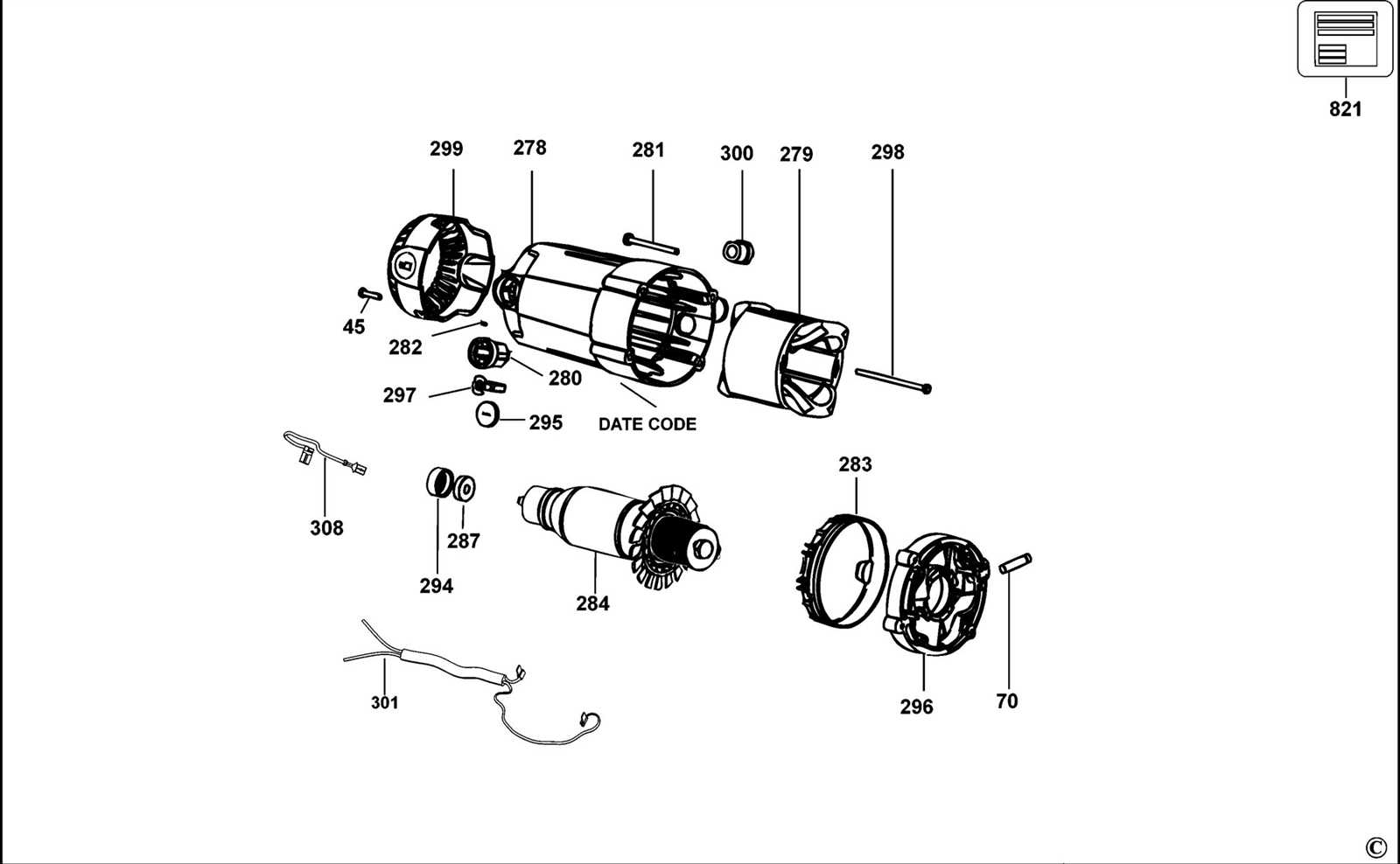

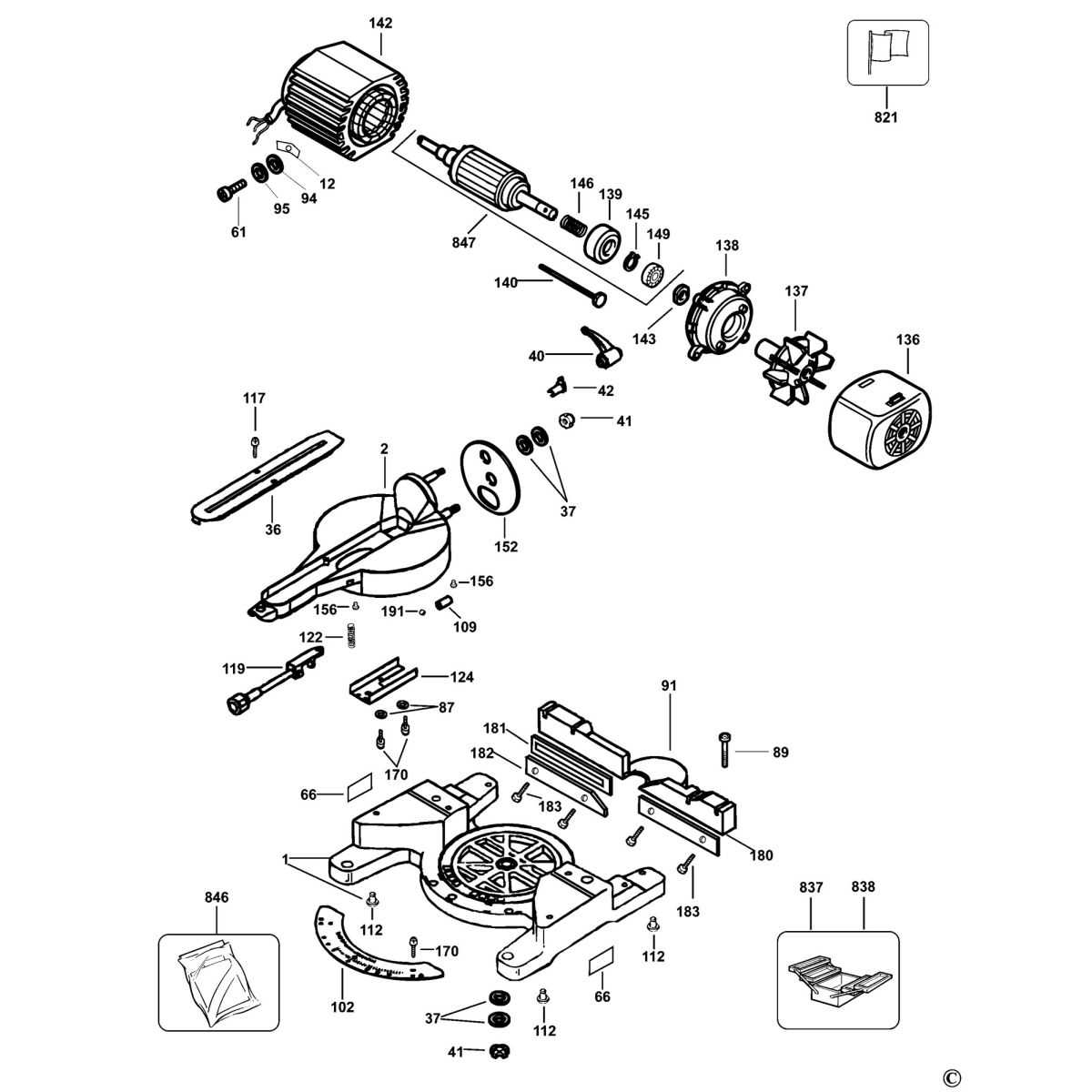

Identifying Essential Components

Understanding the crucial elements of a power tool is vital for effective operation and maintenance. Each piece plays a significant role in ensuring the device functions smoothly and reliably. By recognizing these components, users can better appreciate how the tool works and identify potential issues that may arise during its usage.

Key Elements to Consider

When analyzing the inner workings of a tool, several key components come into play. These parts can include the motor assembly, cutting mechanism, and safety features. Familiarizing oneself with these elements allows for more informed decision-making regarding repairs or upgrades.

Component Overview

| Component | Description |

|---|---|

| Motor | Powers the device, enabling it to perform various tasks efficiently. |

| Cutting Assembly | Facilitates the cutting action, critical for achieving precise results. |

| Safety Guard | Protects the user from debris and accidental contact with moving parts. |

| Base Plate | Provides stability and supports the tool during operation. |

Maintenance Tips for Longevity

To ensure the extended life and optimal performance of your equipment, regular upkeep and care are essential. Proper maintenance not only enhances functionality but also prevents unexpected breakdowns and costly repairs. By adopting a few simple practices, you can significantly extend the lifespan of your tools and machinery.

Regular Cleaning

Keeping your tools clean is fundamental to their longevity. Dust, debris, and residue can accumulate and affect performance. After each use, take the time to wipe down surfaces and clear away any particles that may hinder operation. A gentle brush or cloth can effectively remove dirt from intricate parts.

Periodic Inspections

Conducting regular inspections can help identify potential issues before they escalate. Check for any signs of wear, loose components, or damage. Early detection allows for timely repairs, ensuring that your equipment remains in top condition and operates smoothly.

Common Issues and Solutions

In any power tool, certain problems may arise that can affect performance and efficiency. Understanding these common challenges and their solutions can help users maintain optimal functionality and extend the lifespan of their equipment. This section outlines frequent complications encountered by users and offers practical advice to address them effectively.

Power Supply Problems

One of the most prevalent issues is a lack of power, which may stem from various sources, including faulty cords or connections. If the device does not turn on, first inspect the power source and ensure that all connections are secure. Replacing damaged cords or checking the outlet for functionality may resolve the issue. Additionally, ensure that any switches or safety features are engaged properly.

Blade Alignment and Performance

Another common challenge involves blade misalignment, which can lead to uneven cuts. Regularly checking and adjusting the blade to ensure it is square with the base can enhance cutting precision. If the blade is dull, replacing it promptly will improve performance. Utilizing appropriate lubricants on moving parts can also reduce friction and improve overall efficiency.

Assembly Instructions for Beginners

Building a complex device can be a rewarding experience, especially for those who are new to the craft. This section aims to provide straightforward guidance for assembling various components, ensuring that each step is clear and accessible. With the right approach, even novices can successfully complete their projects, gaining confidence and skills along the way.

Essential Tools and Materials

Before starting the assembly process, it’s crucial to gather all necessary tools and materials. Here’s a list of items you will need:

| Tool/Material | Purpose |

|---|---|

| Screwdriver | For fastening screws securely |

| Wrench | To tighten bolts |

| Pliers | For gripping and bending materials |

| Measuring Tape | To ensure accurate measurements |

| Safety Goggles | To protect eyes from debris |

Step-by-Step Assembly Guide

Once you have collected the necessary tools, follow these steps to assemble your device:

- Start by laying out all components in an organized manner.

- Refer to the instructions carefully to understand how each part fits together.

- Begin with the base structure, ensuring it is level and stable.

- Attach subsequent components, following the prescribed order.

- Check all connections and tighten fasteners to secure the assembly.

- Finally, review your work to confirm everything is correctly aligned.

Comparison with Other Dewalt Models

When evaluating different tools from the same manufacturer, it is essential to consider their features, specifications, and overall performance. Each model is designed to cater to various user needs, and understanding these distinctions can help in making an informed decision. This section explores how one particular model stacks up against its peers, focusing on key aspects such as versatility, power, and usability.

In terms of versatility, some models offer enhanced capabilities for specific tasks, while others may excel in portability and ease of use. Power is another critical factor; certain tools come equipped with more robust motors, providing improved cutting performance and efficiency. Additionally, the ease of operation varies across different models, with some featuring advanced technologies that simplify complex tasks.

Furthermore, comparing design aspects can reveal how well each model adapts to various job sites. Weight, compactness, and ergonomics play significant roles in user experience, affecting everything from maneuverability to comfort during extended use. Ultimately, recognizing these differences allows users to select the tool that best aligns with their requirements and preferences.

Safety Precautions During Use

When operating power tools, ensuring a safe working environment is paramount. Adhering to proper safety measures helps prevent accidents and injuries, enabling users to focus on their tasks with confidence. Understanding the necessary precautions and implementing them consistently can significantly reduce risks.

Always wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and ear protection. This gear safeguards against potential hazards like flying debris and loud noises. Additionally, maintain a clean and organized workspace to minimize tripping hazards and ensure that tools are easily accessible.

Before initiating any task, thoroughly inspect the equipment for any signs of wear or damage. If any issues are detected, do not attempt to use the tool until it has been properly repaired. Furthermore, it is essential to follow the manufacturer’s instructions regarding operation, maintenance, and storage of the equipment.

Keep hands and other body parts away from moving parts and avoid distractions while operating the tool. If necessary, ask for assistance when handling large or heavy materials. Being aware of your surroundings and the location of others can also contribute to a safer work environment.

Lastly, always disconnect power sources when changing blades or making adjustments to the equipment. By following these essential safety guidelines, users can enhance their protection and efficiency while working.

Accessories to Enhance Performance

Utilizing various enhancements can significantly boost the functionality and efficiency of your tools. These additional components not only improve usability but also extend the versatility of your equipment, allowing for a wider range of applications.

Essential Add-ons

- Quality Blades: Upgrading to high-performance blades can lead to smoother cuts and increased precision.

- Replacement Parts: Having spare components ensures consistent performance and minimizes downtime during projects.

- Protective Accessories: Safety gear and protective casings help maintain both user safety and tool integrity.

Performance Boosters

- Dust Collectors: Installing a dust extraction system can keep your workspace clean and improve visibility during use.

- Guide Rails: These provide accurate cuts and enhance stability, ensuring better results on your projects.

- Adjustable Stands: Using height-adjustable supports can make operations more comfortable and reduce fatigue.

Customer Reviews and Feedback

This section aims to provide insights into the experiences and opinions of users regarding a particular power tool. User feedback can be invaluable in assessing the effectiveness, durability, and overall satisfaction associated with the product. Through a collection of reviews, potential buyers can gain a clearer understanding of what to expect from their purchase.

Positive Feedback

Many customers have shared their satisfaction with the following aspects:

- Reliability: Users appreciate the tool’s consistent performance in various applications.

- Ease of Use: Reviewers often highlight how user-friendly the design is, making it suitable for both professionals and DIY enthusiasts.

- Durability: Several testimonials mention the sturdy construction and longevity of the product, even under heavy usage.

Areas for Improvement

While feedback is predominantly positive, some users have noted a few areas where enhancements could be made:

- Weight: A number of customers have pointed out that the tool can be somewhat heavy, which may affect prolonged use.

- Noise Level: Some reviewers mentioned that the operating sound could be reduced for a more pleasant user experience.

- Accessories: A few users expressed the desire for more included attachments or add-ons to maximize versatility.

Where to Buy Replacement Parts

Finding the right components for your tools can greatly enhance their functionality and longevity. Whether you need a specific item for repairs or maintenance, several options are available to ensure you can locate what you need efficiently.

One of the best starting points is the official retailer associated with the brand. They often provide a wide selection of original components, ensuring compatibility and quality. Additionally, numerous authorized distributors and local hardware stores may stock various necessary items.

Online marketplaces are also excellent resources for sourcing essential components. These platforms typically offer competitive pricing and convenience, allowing you to compare different options easily. Always check customer reviews and ratings to gauge the reliability of the sellers.

| Source | Description |

|---|---|

| Official Retailer | Best for original items, ensuring compatibility and quality. |

| Authorized Distributors | Local stores that carry a range of necessary components. |

| Online Marketplaces | Competitive pricing with the ability to compare multiple sellers. |

| Specialty Websites | Focus on particular tools and accessories, often with extensive inventories. |

In conclusion, exploring various avenues can help you find the necessary components to keep your tools in optimal working condition. By utilizing a combination of local and online resources, you can ensure you have access to quality items that meet your needs.

FAQs About the DW708 Type 4

This section addresses common inquiries regarding a specific model of power tools. Here, we provide insights into frequently asked questions to enhance user understanding and satisfaction. Whether you are a novice or a seasoned user, the information below aims to clarify any uncertainties.

Common Questions

| Question | Answer |

|---|---|

| What is the primary use of this equipment? | This tool is primarily designed for precise cutting tasks, making it ideal for both professional and home use. |

| How do I maintain this tool? | Regular cleaning, blade sharpening, and ensuring proper lubrication are essential for optimal performance. |

| Can I find replacement components easily? | Yes, many suppliers offer a variety of replacement components for this model, ensuring easy access for repairs. |

Operating Tips

For best results, always follow the manufacturer’s guidelines regarding usage. Safety precautions, such as wearing protective gear and ensuring a clear workspace, should not be overlooked.