Understanding the inner workings of any tool is essential for ensuring its long-term reliability. When tackling repairs or regular upkeep, it’s crucial to have a clear overview of the key elements involved. By familiarizing yourself with the various components and their arrangement, you can approach each task with confidence, knowing exactly where to focus your efforts.

A detailed schematic can greatly simplify the troubleshooting process, especially when dealing with more complex systems. It not only helps identify specific elements but also highlights their relationships with one another. This can streamline the maintenance process, allowing for quicker and more accurate adjustments.

Whether you’re conducting routine servicing or addressing specific malfunctions, having a visual guide to all major elements ensures that nothing is overlooked. Such a guide becomes an indispensable resource, saving both time and effort during the inspection and repair stages.

Understanding Key Components of the Device

The section explores the various elements that make up the structure of the equipment, providing insight into each part’s function and its role in ensuring efficient performance. By understanding these components, users can gain a deeper appreciation of how the device operates and learn how to maintain it properly.

Main Structural Elements

At the core of the device, several essential components work together to deliver optimal functionality. The heating system is designed to provide consistent output, supported by an adjustable control mechanism that allows for precise regulation of the output levels. Surrounding these main elements, protective casings and support frames ensure the device remains durable and safe during operation.

Control and Safety Mechanisms

In addition to the primary operational parts, the equipment includes a set of safety features designed to maintain stable operation. These include sensors that monitor the system’s temperature and pressure, triggering automatic shut-off protocols if needed. Such mechanisms not only enhance user safety but also prolong the device’s lifespan, reducing the need for frequent maintenance.

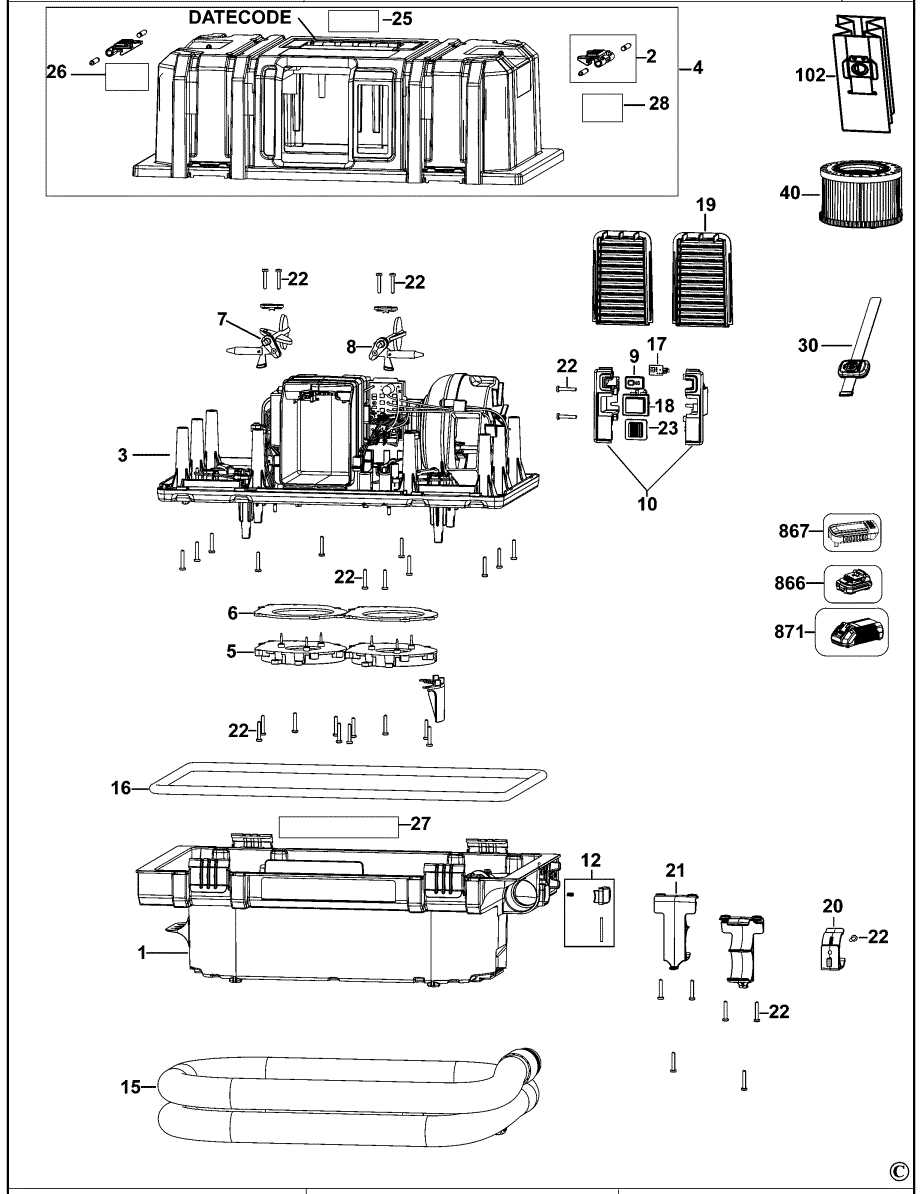

Exploded View of Heater Components

This section provides a detailed illustration of the various elements that make up the heater unit, offering a comprehensive overview of its internal construction. By examining this visual breakdown, users can better understand how each component is organized and interacts within the system.

Main Structural Elements

The primary structure includes several critical components, such as the frame, burner assembly, and heat exchanger. Each of these elements is designed to work in unison, ensuring the efficient and safe operation of the equipment. The arrangement of these parts allows for optimal heat distribution and consistent functionality.

Key Functional Units

Within the system, several essential units are highlighted, including the fuel regulator, ignition system, and safety mechanisms. These functional units are crucial for maintaining the heater’s performance and ensuring that it operates under safe conditions. The illustration emphasizes the location and connection points of each unit, helping users identify and manage these critical components effectively.

Key Elements in This Model

This section provides an overview of the essential components and main features of the device, emphasizing its construction and functionality. Understanding these elements helps in maintaining and ensuring the efficient performance of the unit.

- Fuel System: The fuel system is designed to provide optimal combustion efficiency, offering controlled fuel flow for consistent performance.

- Ignition Mechanism: An integrated ignition mechanism ensures a reliable and quick start, enhancing the convenience of using the equipment in various conditions.

- Heat Exchanger: The heat exchanger is a crucial component that maximizes thermal output, improving energy transfer and overall effectiveness.

- Control Panel: The user-friendly control panel allows for easy adjustments, providing precise regulation of temperature and other essential settings.

- Safety Features: Equipped with multiple safety measures, the unit includes sensors and automatic shut-off systems to protect users and prevent malfunctions.

Familiarity with these core aspects of the equipment is beneficial for both operation and troubleshooting, ensuring long-term durability and efficiency.

Maintenance Tips for Dewalt Heaters

Proper care and regular upkeep of your heating equipment are essential for optimal performance and extended longevity. Following a few basic guidelines ensures that your appliance remains efficient and safe during use.

Regular Cleaning: It’s crucial to keep your heater free of dust and debris. Accumulated particles can obstruct airflow, reduce efficiency, and even pose a safety hazard. Use a soft brush or a vacuum cleaner to gently clean the exterior and vents.

Check Fuel Lines: Periodically inspect fuel lines for any signs of wear or leakage. Tighten connections and replace damaged components to prevent malfunctions and ensure safe operation.

Inspect the Ignition System: Ensure the ignition system is functioning correctly by inspecting connections and components for any damage or buildup. Clean the ignition area to maintain proper functionality.

Monitor Air Filters: Air filters should be checked and cleaned regularly. If filters become clogged, it may cause the unit to overheat or operate inefficiently. Replace filters as necessary.

Performing routine checks and adhering to these maintenance practices can greatly enhance the reliability and lifespan of your equipment.

How to Identify Faulty Parts

Recognizing malfunctioning components is crucial for maintaining equipment efficiency and ensuring safety during its operation. This section outlines the steps and indicators to help you detect when a component may need replacement or repair.

To determine whether a component is malfunctioning, follow these steps:

- Visual Inspection: Carefully examine the device for any visible signs of wear, such as cracks, rust, or deformations. Pay attention to areas that are prone to damage.

- Unusual Sounds: Listen for any irregular noises when the device is in use. Rattling, grinding, or hissing sounds can indicate potential issues that need attention.

- Performance Check: Monitor if the equipment is working efficiently. A decrease in performance or abnormal behavior could signal that a specific component is not functioning correctly.

- Temperature Fluctuations: If the device is overheating or not reaching its usual operating temperature, it might indicate a problem with internal elements that regulate heat or airflow.

- Testing with Tools: Utilize diagnostic tools like multimeters or pressure gauges to measure performance levels. Abnormal readings often point to faulty components.

If you detect any of these signs, it is recommended to consult the manual or a professional technician to ensure proper maintenance and avoid further damage.

Replacing Heater Components

Maintaining a heating appliance is essential for its efficient operation and longevity. Over time, certain parts may wear out or malfunction, requiring replacement to ensure optimal performance. Understanding how to replace these components can help restore functionality and improve energy efficiency.

When addressing component replacement, it’s important to first identify the specific part that needs attention. Commonly replaced elements include heating elements, thermostats, and fans. Each of these components plays a critical role in the overall function of the device.

To begin the replacement process, make sure to disconnect the appliance from its power source. This safety measure is crucial to prevent accidents during maintenance. After ensuring safety, carefully disassemble the unit according to the manufacturer’s guidelines.

Once disassembled, locate the faulty component and remove it. It may be helpful to reference any available manuals or guides to understand the assembly and disassembly process. After the old part is removed, install the new component by reversing the removal steps.

Finally, reassemble the unit and reconnect it to the power supply. Test the appliance to ensure that it operates correctly and efficiently. Regular maintenance and timely replacements can significantly enhance the lifespan and performance of your heating unit.

Diagram Guide for Dewalt Heaters

This section serves as a comprehensive overview for understanding the structural components and layouts of specific heating devices. A well-organized representation can greatly enhance the user’s ability to identify individual elements, ensuring effective maintenance and repairs.

Familiarizing oneself with the various sections of these heating units can streamline troubleshooting processes. The following table outlines common components, their descriptions, and typical functions:

| Component | Description | Function |

|---|---|---|

| Fan Assembly | Motor-driven fan that circulates warm air | Enhances heat distribution |

| Heating Element | Coil that generates warmth when electrified | Provides the primary heat source |

| Thermostat | Device that regulates temperature | Maintains desired heat levels |

| Fuel Tank | Container for storing heating fuel | Supplies fuel to the heating element |

| Control Panel | Interface for user settings and adjustments | Allows operation control and settings |

Common Issues with Dewalt DXH70CFAV

When operating heating equipment, users may encounter various challenges that can affect performance and reliability. Understanding these common problems can help in troubleshooting and ensuring smooth operation.

One frequent issue is inconsistent heating. This can be caused by factors such as improper fuel supply, clogged filters, or malfunctioning components. Regular maintenance and timely inspections can often prevent this from becoming a significant concern.

Another common problem is excessive noise during operation. Unusual sounds may indicate that parts are loose or that there is an issue with the motor. Identifying and addressing these noises early can help avoid more extensive repairs.

Overheating is also a notable concern. If the equipment shuts down unexpectedly, it might be due to overheating caused by blocked vents or a faulty thermostat. Ensuring that ventilation is clear and components are functioning properly is crucial to maintaining safe temperatures.

Lastly, users may face ignition failures. This can result from issues with the ignition system or fuel line. Regular checks of these systems can help ensure reliable starts and consistent performance.

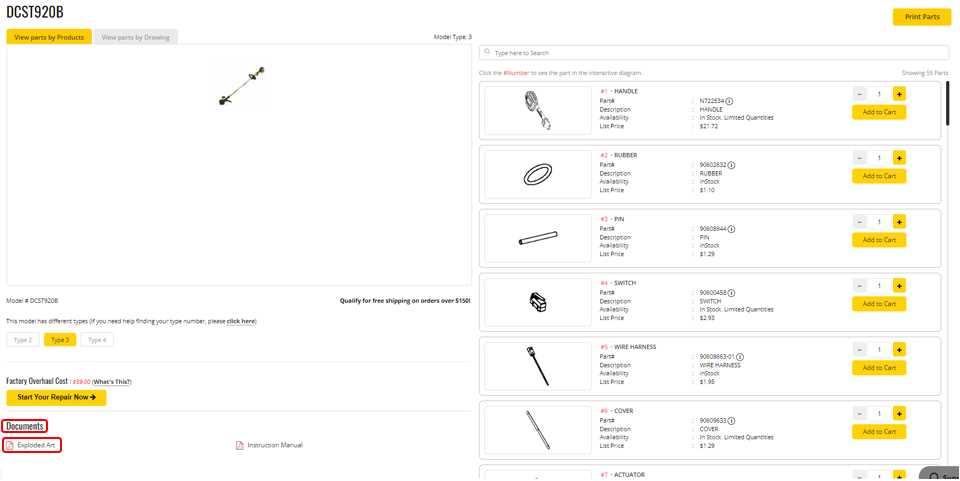

Locating Dewalt Heater Spare Parts

Finding replacement components for heating devices can be essential for maintaining efficiency and ensuring longevity. A systematic approach will simplify the process, helping users quickly identify what they need to restore functionality. Whether seeking a specific element or exploring options for upgrades, understanding where to look can save time and effort.

Here are some effective strategies to locate replacement items for your heating unit:

| Source | Description |

|---|---|

| Manufacturer’s Website | The official site often provides a comprehensive list of available components, along with diagrams and specifications. |

| Authorized Retailers | Local or online stores recognized by the manufacturer typically stock genuine replacement items and accessories. |

| Online Marketplaces | Platforms like eBay or Amazon may offer a wide selection of components, including new and used options from various sellers. |

| Repair Shops | Local repair centers might have spare items on hand or can assist in ordering them, ensuring compatibility. |

| Forums and Community Groups | Online communities can provide valuable insights and recommendations for sourcing specific items from other users. |

Utilizing these resources will facilitate the search for the necessary components, ensuring your heating device operates at peak performance.

Assembly Guide for Dewalt Heaters

This section provides a comprehensive overview of the assembly process for portable heating units. Proper assembly is crucial for ensuring optimal performance and safety. The following guidelines outline the necessary steps and components involved in the assembly of these heating devices.

Essential Components

Before beginning the assembly, gather all the essential parts. Familiarity with each component will facilitate a smoother process. Below is a list of typical components involved:

| Component | Description |

|---|---|

| Heating Element | Generates heat to warm the surrounding area. |

| Fan | Circulates warm air for even distribution. |

| Control Panel | Allows users to adjust settings and monitor performance. |

| Housing | Encases the internal components for safety and efficiency. |

Assembly Steps

Follow these steps to successfully assemble the unit:

- Start by placing the housing on a stable surface, ensuring all parts are accounted for.

- Attach the heating element securely, following the manufacturer’s instructions.

- Connect the fan to the designated area, ensuring it is properly aligned.

- Install the control panel, making sure all wiring is correctly attached.

- Finally, secure the housing and check all connections for stability and safety.

Ensuring Longevity of Dewalt DXH70CFAV

Maintaining optimal performance and extending the lifespan of heating equipment requires careful attention and proactive measures. Regular upkeep, proper usage, and timely repairs can significantly enhance the durability of your device, ensuring it continues to operate efficiently throughout its service life.

Regular Maintenance

Routine inspection and maintenance are crucial for the longevity of any machinery. Schedule periodic check-ups to clean filters, examine hoses, and verify that all components are functioning correctly. Replacing worn-out parts before they fail can prevent larger issues down the line and keep your unit operating smoothly.

Proper Usage Guidelines

Understanding how to use your equipment correctly can greatly impact its lifespan. Always follow the manufacturer’s instructions for operation and safety. Avoid overloading the machine and ensure it is suitable for the intended environment. Additionally, storing the equipment properly when not in use will protect it from unnecessary wear and tear.

In summary, taking proactive steps in maintenance and adhering to usage guidelines are essential strategies for ensuring that your heating equipment remains reliable and effective for years to come. By prioritizing these practices, you can enjoy a long-lasting, efficient performance.