When maintaining an older vehicle, it’s crucial to have a clear understanding of the various systems that keep it running smoothly. Knowing the layout of crucial elements can help with both routine checks and more significant repairs, ensuring the longevity and performance of your vehicle.

In this guide, we will explore the arrangement of pivotal elements in one of the popular models of that era. These components play a vital role in the stability, steering, and overall control of the vehicle. A well-maintained structure ensures a safer driving experience, reducing the chances of breakdowns or accidents.

By familiarizing yourself with the specific configuration and connections, you’ll be better equipped to identify wear and tear early, allowing for timely repairs. This knowledge is not only beneficial for seasoned mechanics but also for enthusiasts looking to take a more hands-on approach to vehicle upkeep.

Overview of 1997 Dodge Ram 1500 Components

The vehicle’s structure comprises various mechanical systems working together to ensure stability, smooth operation, and safety. These essential elements play a crucial role in handling, driving comfort, and overall performance on the road. Understanding how these parts interact can help maintain reliability and extend the life of the vehicle.

Key Systems and Their Functions

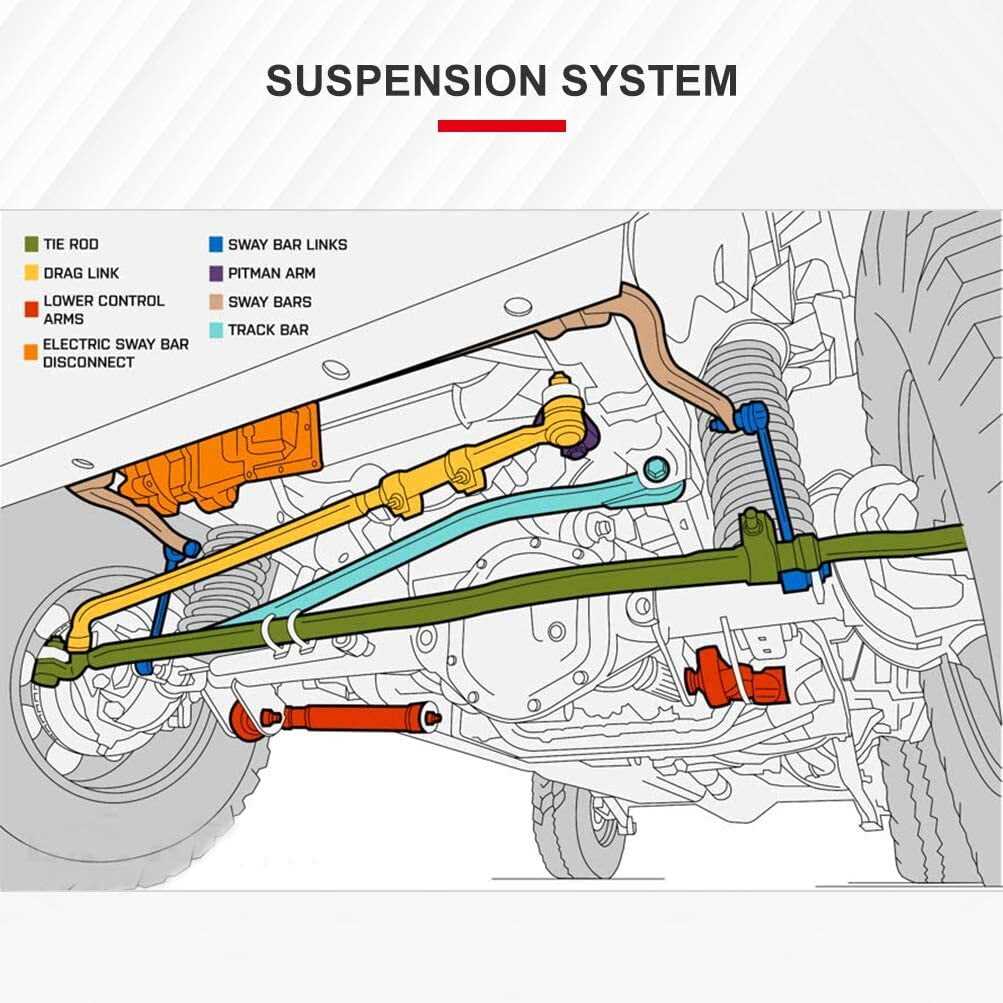

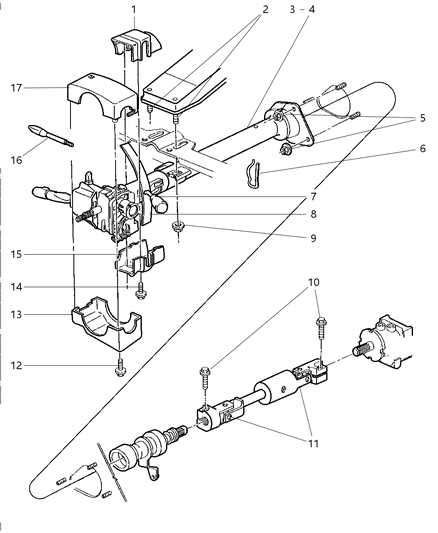

Several interconnected systems provide the foundation for the vehicle’s performance. The steering mechanism, suspension system, and braking components ensure control, balance, and safety during operation. Each of these systems is made up of multiple components that must function harmoniously.

Essential Components Breakdown

| System | Main Components | Function | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Steering | Steering Gear, Tie Rods, Ball Joints | Allows directional control and stability | ||||||||||||||||

| Suspension |

| Component | Function | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Brake Caliper | Holds the brake pads and uses hydraulic pressure to apply them to the rotor. | ||||||||||

| Brake Pads | Press against the rotor to create the friction needed to slow down the vehicle. | ||||||||||

| Rotor | Disc that rotates with the wheel, providing a surface for the brake pads to press against.

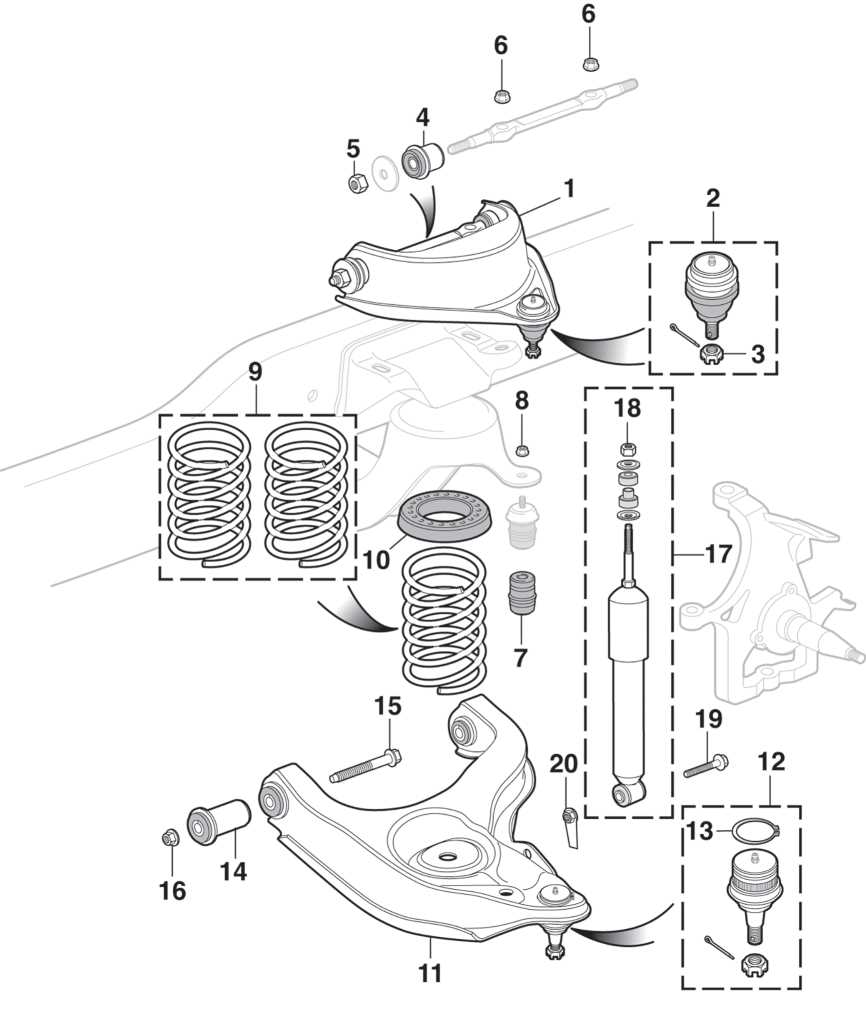

Shock Absorber and Strut ConfigurationThe configuration of dampers and suspension components plays a crucial role in the overall performance and comfort of a vehicle. These elements work together to manage road impacts, ensuring a smooth ride while maintaining stability. Understanding how these components interact is essential for proper maintenance and upgrades. Types of Shock AbsorbersVarious types of dampers are utilized in automotive applications, each offering unique benefits. Conventional hydraulic dampers, gas-charged options, and adjustable units cater to different driving preferences and conditions. Selecting the right type can significantly enhance ride quality and handling characteristics. Strut Assembly Features

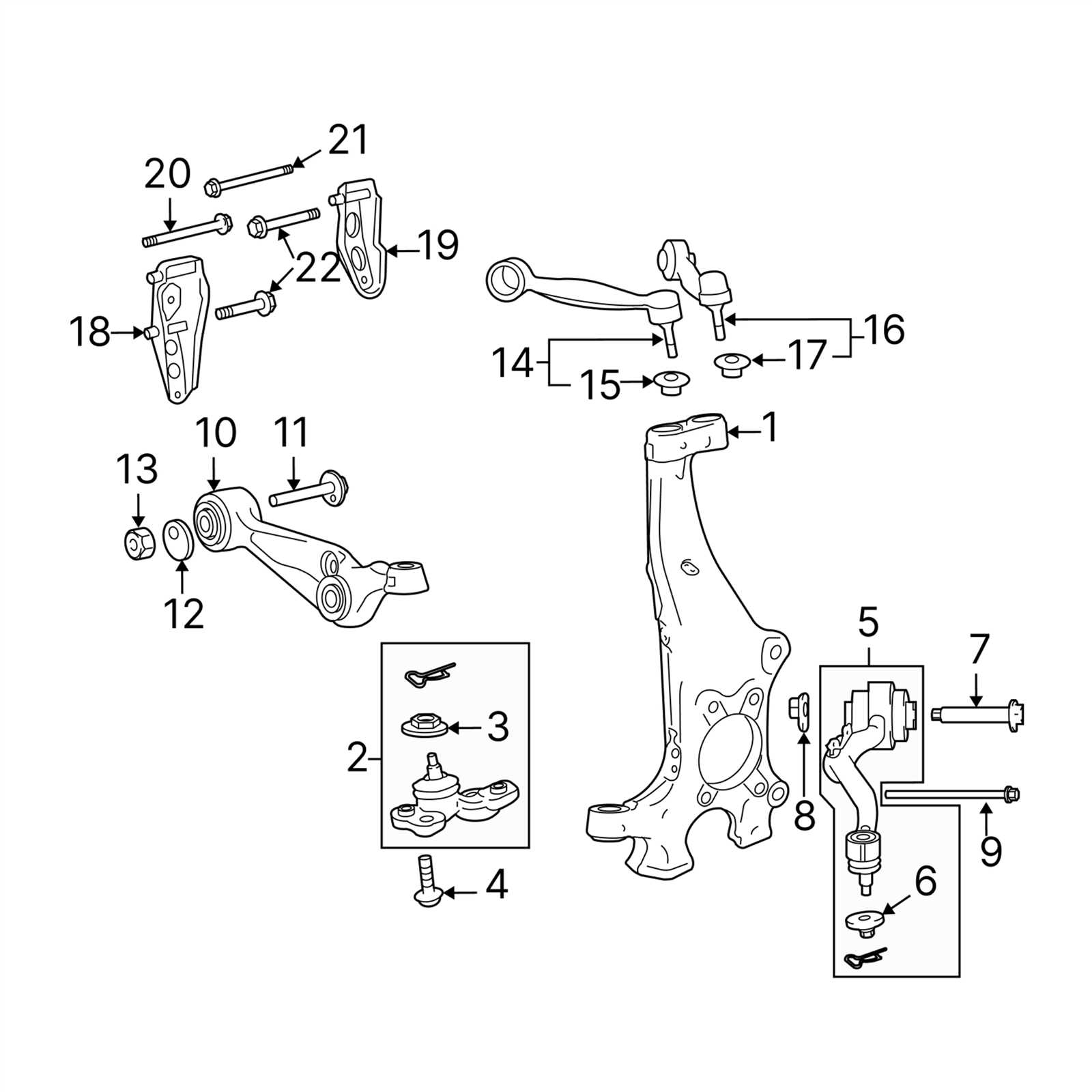

Strut assemblies combine the functionalities of dampers and structural support for the vehicle’s suspension system. Key features include coil springs that support vehicle weight and alignment, along with integrated mounts that facilitate smooth movement. Proper installation and maintenance of these assemblies are vital for optimal performance and safety. Upper and Lower Control Arm FunctionsThe control arms play a crucial role in the suspension system of a vehicle, connecting the wheel hub to the chassis. They facilitate vertical movement while maintaining the proper alignment of the wheels, contributing to overall vehicle stability and handling. Purpose of Control Arms

Control arms serve several essential functions within the suspension assembly:

Types of Control ArmsThere are generally two types of control arms, each with distinct characteristics:

Both types work together to ensure a smooth and stable ride, enhancing the vehicle’s overall performance. Tie Rods and Their Importance in Alignment

Tie rods play a crucial role in the steering and suspension systems of vehicles. They connect various components, enabling precise control over wheel movement. This connection is essential for maintaining proper alignment, which directly impacts vehicle handling and safety. When the tie rods are functioning correctly, they ensure that the wheels are aligned and track in the same direction. If they become worn or damaged, misalignment can occur, leading to uneven tire wear and difficulty in steering. Regular inspections of these components can prevent potential issues and enhance overall vehicle performance. Additionally, maintaining the integrity of tie rods contributes to a smoother ride. They absorb shocks and vibrations, which helps in reducing the strain on other suspension elements. Investing time in checking and replacing faulty tie rods not only extends the life of your vehicle but also ensures a safer driving experience. Understanding the Role of the Ball Joints

Ball joints are vital components in a vehicle’s suspension system, serving as pivot points that facilitate smooth movement between various parts. They play a crucial role in connecting the steering knuckles to the control arms, allowing for precise handling and stability while driving. Their functionality is essential for maintaining proper alignment and ensuring that the wheels move in sync with the steering mechanism. Functionality and Importance

These joints allow for both vertical and horizontal movement, which is necessary for navigating uneven terrains and responding to driver inputs. Over time, wear and tear can affect their performance, leading to issues such as poor handling, uneven tire wear, and even compromised safety. Regular inspection and timely replacement of ball joints can prevent these problems, ensuring a smoother ride and enhancing overall vehicle performance. Signs of WearDetecting worn ball joints early can save significant repair costs and improve safety. Symptoms may include clunking noises while driving, excessive vibration in the steering wheel, or uneven tire wear patterns. Addressing these signs promptly is essential for maintaining the integrity of the vehicle’s suspension system and ensuring optimal driving conditions. Front Hub Assembly and Bearing OverviewThe hub assembly is a crucial component of a vehicle’s wheel system, providing a secure connection between the wheel and the axle. This assembly houses various essential elements, including the bearings that facilitate smooth rotation and support the weight of the vehicle. Understanding its structure and function is vital for proper maintenance and repair. Typically, the hub assembly consists of several key components that work together to ensure optimal performance. The bearings, which are critical for reducing friction, allow the wheel to turn with minimal resistance. Additionally, the assembly may include seals and retaining rings that help protect the bearings from dirt and debris, extending their lifespan.

Link Between Sway Bar and Stability

The connection between the stabilizer bar and vehicle stability plays a crucial role in enhancing handling performance. This component is designed to reduce body roll during cornering, thereby ensuring that the vehicle remains level and responsive. A stabilizer bar, also known as an anti-roll bar, works by linking opposite wheels together. When the vehicle encounters a turn, the bar transfers force from one side to the other, minimizing the weight shift that can lead to instability. This interaction is vital for maintaining traction and control, particularly in challenging driving conditions. Moreover, proper maintenance of the stabilizer bar and its associated bushings and links is essential for optimal performance. Worn or damaged components can compromise the vehicle’s stability, resulting in decreased handling capabilities and an increased risk of accidents. Regular inspections and timely replacements can help ensure that the stabilizer system functions effectively, contributing to overall safety on the road. |