Understanding the structure and function of water control mechanisms is essential for maintaining effective fluid management systems. This section provides an in-depth look at the various elements that make up these devices, ensuring they operate smoothly and efficiently.

By familiarizing yourself with individual components, you can quickly identify and address potential issues that may arise during installation or repair. Each part plays a critical role in controlling water flow, and recognizing their function helps streamline maintenance processes.

We will also explore how these elements work together to ensure a reliable

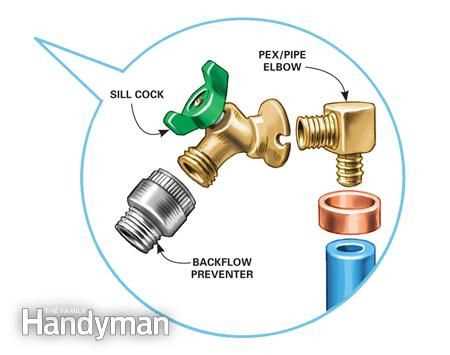

Outdoor Spigot Parts Diagram

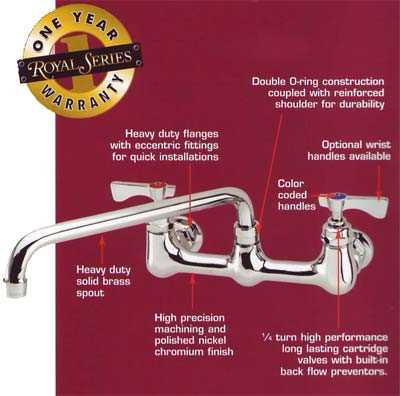

A reliable connection for water flow requires several interconnected components working in harmony. The structure includes elements designed to manage pressure, prevent leakage, and ensure smooth operation, forming a unified system that delivers water efficiently.

Key Elements and Their Roles

The system incorporates valves that control the flow, seals to prevent drips, and connectors that maintain a tight fit between sections. Each piece is carefully chosen to handle exposure to different weather conditions, ensuring durability and consistent performance.

Water outlets used in external environments consist of multiple interconnected elements that ensure smooth operation and reliable water flow. These units are designed to endure varying weather conditions and provide ease of use for various household and garden activities.

Valve Mechanism: This element controls the release and cessation of water, offering precise regulation to prevent waste. It typically includes a handle or knob for easy manipulation.

Sealing Components: Washers or O-rings prevent leakage by maintaining a tight seal between the internal segments. Their integrity is essential for efficient water conservation.

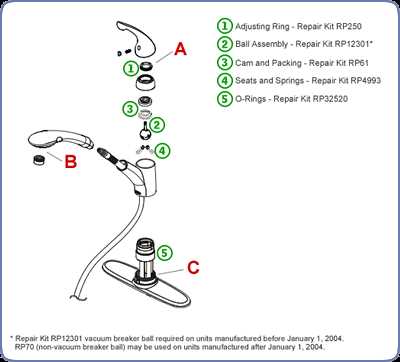

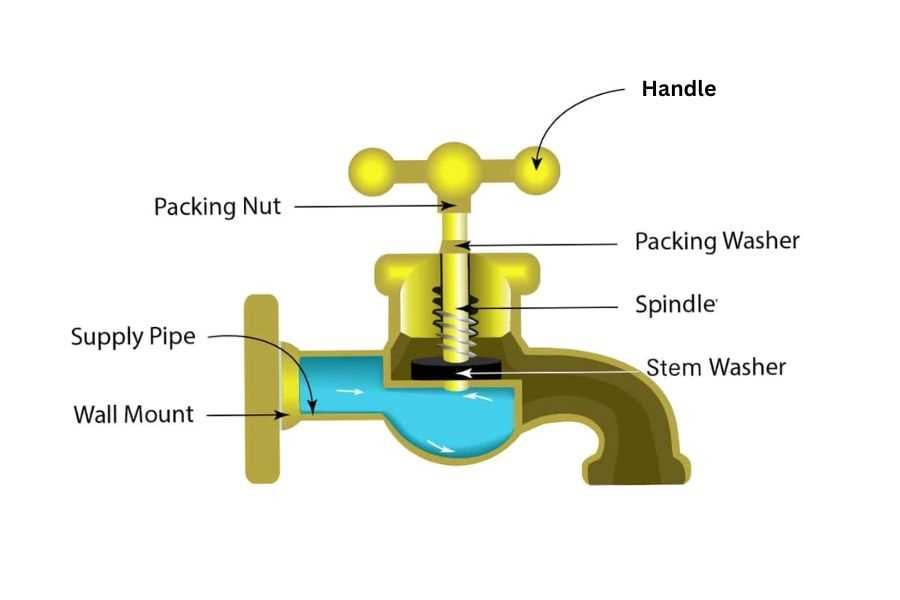

Identifying Valve and Stem Assembly

The valve and stem components play a key role in regulating water flow. Understanding how these elements fit together ensures smooth operation and helps with maintenance or repairs. Recognizing the signs of wear and knowing where each part belongs is essential for keeping the entire system functional.

Valve Structure and Key Elements

The valve includes several interconnected elements, such as seals, washers, and a control mechanism that adjusts water pressure. Each piece must align correctly to prevent leaks and ensure efficiency. Over time, components like washers may degrade, which can cause malfunctions if not addressed promptly.

Stem Functional

Spigot Handle Types and Variations

Water valve handles come in a range of designs, each tailored for different applications and user preferences. Their structure and material affect functionality, ease of use, and durability, ensuring smooth water control in diverse conditions.

Common Handle Designs

The most familiar types are T-shaped and round handles. T-handles offer better leverage, making them ideal for situations where extra force is needed. Round knobs, on the other hand, are often preferred for their

Rubber Washer and Seal Functions

Rubber washers and seals play a vital role in maintaining efficient water flow by preventing leakage. These components are essential for ensuring that joints remain secure under pressure, reducing the need for frequent maintenance.

- Leak Prevention: Rubber washers create a tight seal between connections, blocking water from escaping at the joints.

- Vibration Dampening: In dynamic systems, seals absorb vibrations, minimizing wear and tear on connected parts.

- Pressure Resistance: Seals help

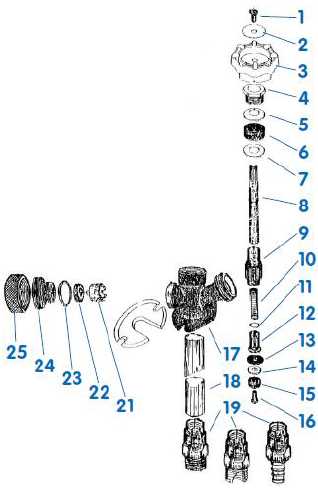

Importance of Anti-Siphon Valves

In various fluid transfer systems, the presence of specific components is crucial for maintaining safety and functionality. One such element is the anti-siphon device, which plays a vital role in preventing the backflow of liquid. This mechanism ensures that contaminants do not infiltrate the primary water supply, thereby safeguarding both the system and the surrounding environment.

Functionality and Mechanism

The primary purpose of these devices is to eliminate the risk of backflow, which can occur due to various pressure changes. They work by automatically sealing off the flow when negative pressure is detected. This action effectively blocks any reverse flow that could introduce harmful substances into the main line.

- Prevention of contamination

- Protection of potable water supply

- Compliance with plumbing codes

Benefits of Installing Anti-Siphon Devices

Incorporating these mechanisms into a plumbing setup offers numerous advantages:

- Health Safety: Ensures that drinking water remains uncontaminated by preventing the introduction of pollutants.

- Regulatory Compliance: Helps meet local building codes and regulations regarding plumbing safety.

- Cost Efficiency: Reduces potential costly repairs and health risks associated with contamination incidents.

Faucet Threads and Hose Attachments

The connections between water outlets and hoses are crucial for efficient water flow and usage. Understanding the threading types and attachment methods is essential for ensuring compatibility and preventing leaks. This section delves into various aspects of these connections, providing insights on how to choose the right fittings for different applications.

Types of Threads

There are several standard threading types commonly used for attaching hoses and connectors:

- National Pipe Thread (NPT): A tapered thread design that creates a tight seal when connected.

- Garden Hose Thread (GHT): A non-tapered thread commonly found on garden hoses, ensuring easy attachment.

- Metric Threads: These threads follow international standards, often used in various regions and applications.

Attachment Methods

Connecting hoses to faucets can be done in various ways:

- Screw-On Fittings: These allow for easy installation and removal, making them versatile for different tasks.

- Quick Connect Systems: These fittings provide fast and easy connections without the need for tools.

- Clamps and Adapters: Useful for securing hoses in place and adapting to various sizes and thread types.

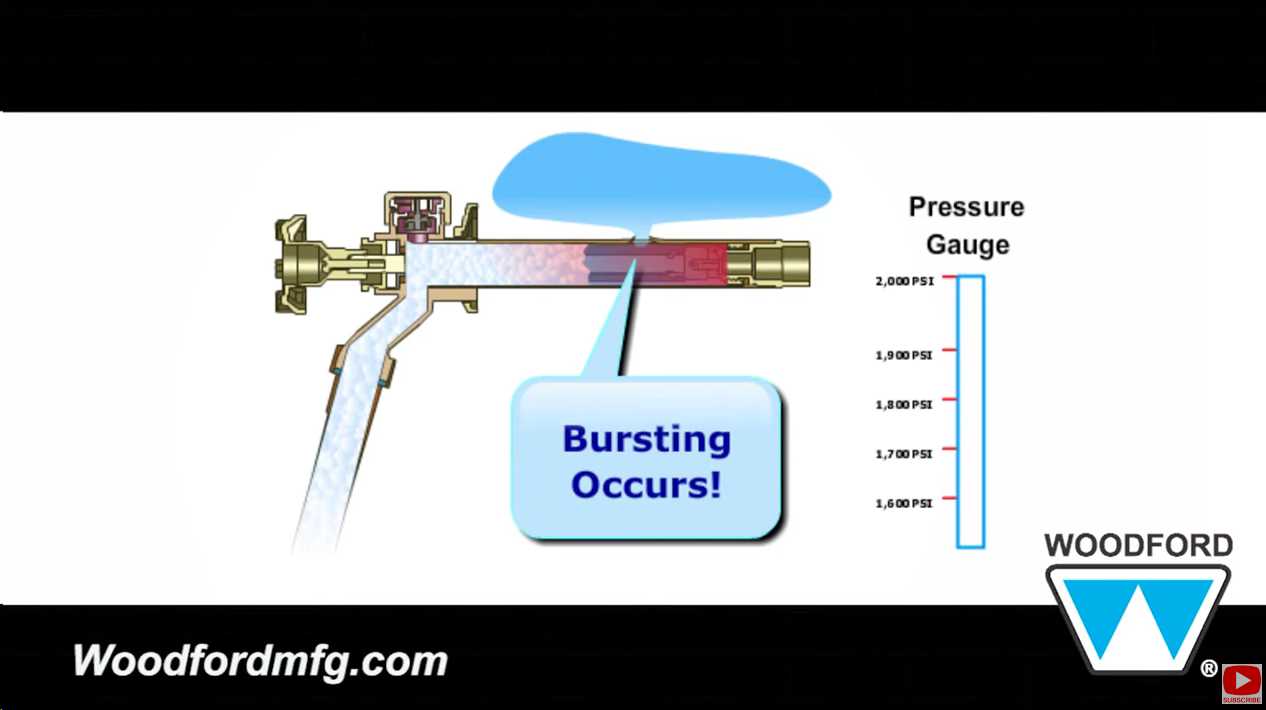

Winterizing Outdoor Water Fixtures

Preparing plumbing systems for colder temperatures is crucial to prevent damage during winter months. Properly insulating and draining these components ensures longevity and functionality when warmer weather returns. Following a few essential steps can safeguard your fixtures against freezing and bursting.

Importance of Drainage

Effective drainage is vital in preventing ice formation within the piping. It involves removing all remaining water from the lines, ensuring that there are no trapped pockets that could freeze. A thorough drainage process minimizes the risk of serious damage and costly repairs.

Insulating Components

Applying insulation to exposed sections significantly reduces the chances of freezing. Use foam sleeves or insulating tape to cover any vulnerable areas. This simple yet effective measure helps maintain a stable temperature and protects against the harsh effects of winter.

Regular maintenance during the transition to colder weather is essential for the functionality of your plumbing system. Following these steps can save you from unexpected repairs and ensure that your water fixtures remain in excellent condition year after year.

Common Spigot Leak Points

Leaks in outdoor plumbing fixtures can occur due to various factors, leading to water loss and potential damage. Identifying the most frequent areas where these issues arise is essential for effective maintenance and repair. Understanding these common leak points helps in addressing problems promptly, ensuring the longevity of your system.

Frequent Areas of Concern

Several locations are particularly prone to leaks. These include connections, valves, and seals, which may degrade over time or become damaged due to environmental factors. Regular inspections can help in detecting these issues before they escalate into significant problems.

Key Leak Points Table

Leak Point Description Potential Causes Hose Connection Joint where the hose attaches to the fixture. Loose fittings, damaged threads. Valve Seat Area where the valve closes to control water flow. Worn seals, corrosion. Handle Part used to turn the water on and off. Cracks, loose components. Pipe Joint Connection between sections of piping. Improper installation, shifting soil. Backflow Prevention Mechanism Overview

Backflow prevention is a critical aspect of plumbing systems that ensures the safe flow of water by preventing contaminants from entering the potable water supply. This mechanism plays an essential role in maintaining water quality and protecting public health. Understanding its function and components is vital for effective installation and maintenance.

Functionality of Backflow Prevention

The primary purpose of backflow prevention devices is to stop the reverse flow of water that can occur due to pressure changes in the system. These devices operate by utilizing various methods, such as check valves and air gaps, to create a barrier that keeps unwanted substances from flowing back into clean water lines.

Common Types of Backflow Preventers

Several types of backflow preventers are commonly used in plumbing applications, each designed to meet specific needs. For instance, the reduced pressure zone (RPZ) assembly is effective in high-risk scenarios, while double check valve assemblies are suitable for less hazardous situations. Selecting the appropriate type is crucial for ensuring optimal performance and compliance with local regulations.

Material Differences in Faucet Parts

Understanding the various materials utilized in the construction of faucet components is essential for making informed choices. Each material offers distinct advantages and disadvantages, impacting durability, maintenance, and overall performance. This section delves into common materials and their characteristics, highlighting key factors to consider when selecting faucet elements.

Material Advantages Disadvantages Brass Durable, corrosion-resistant, good heat conductivity Can be expensive, may tarnish over time Stainless Steel Highly resistant to rust, easy to clean, modern appearance Can be prone to scratches, more expensive than other options Plastic Lightweight, cost-effective, resistant to corrosion Less durable, can break or warp under high temperatures Ceramic Very smooth surface, resistant to wear and corrosion Brittle, can crack under impact