Every lifting mechanism operates with a unique set of elements that work in harmony to ensure smooth functionality. Recognizing these components is essential for anyone looking to enhance their knowledge or troubleshoot issues related to the system. Each segment plays a crucial role, contributing to the overall efficiency and reliability of the mechanism.

In this section, we will explore the various elements that constitute the lifting system. By understanding the role and interconnectivity of these components, users can gain valuable insights into maintenance and repairs. This knowledge is particularly beneficial for those who wish to optimize performance or address common challenges associated with the mechanism.

With a detailed examination of each segment, readers will be better equipped to identify potential problems and implement effective solutions. Engaging with this information fosters a deeper appreciation for the intricacies of how such systems operate, paving the way for informed decision-making and proactive care.

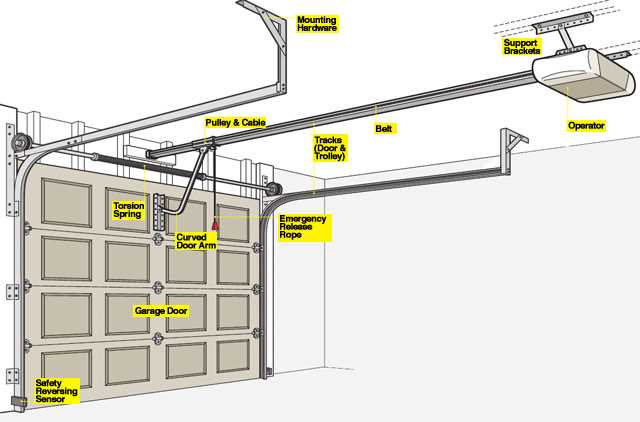

This section aims to explore the essential elements that contribute to the functionality of a lifting mechanism for an entrance. By breaking down the components, readers will gain insights into their roles, how they work together, and the importance of each piece in the overall operation of the system.

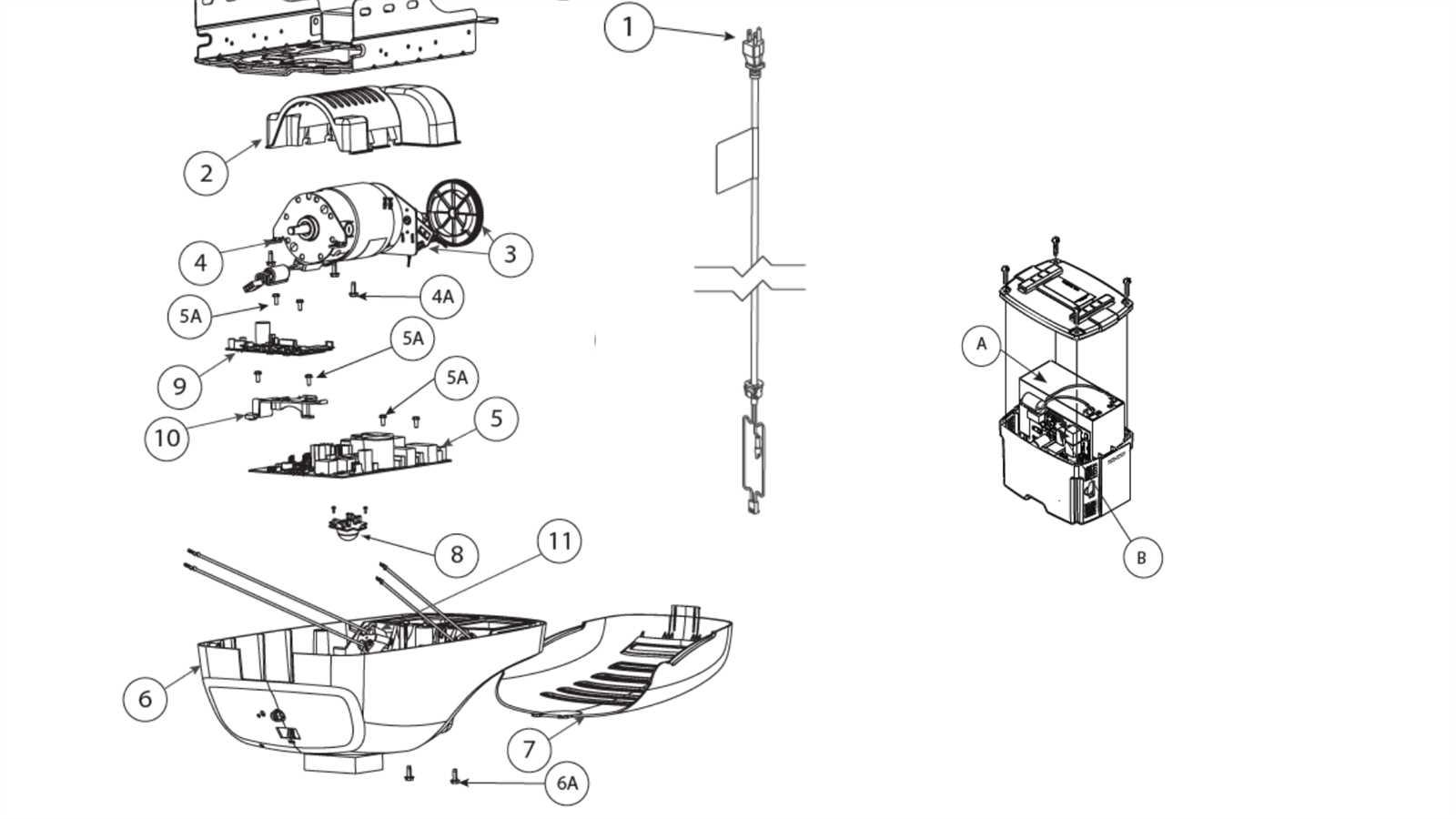

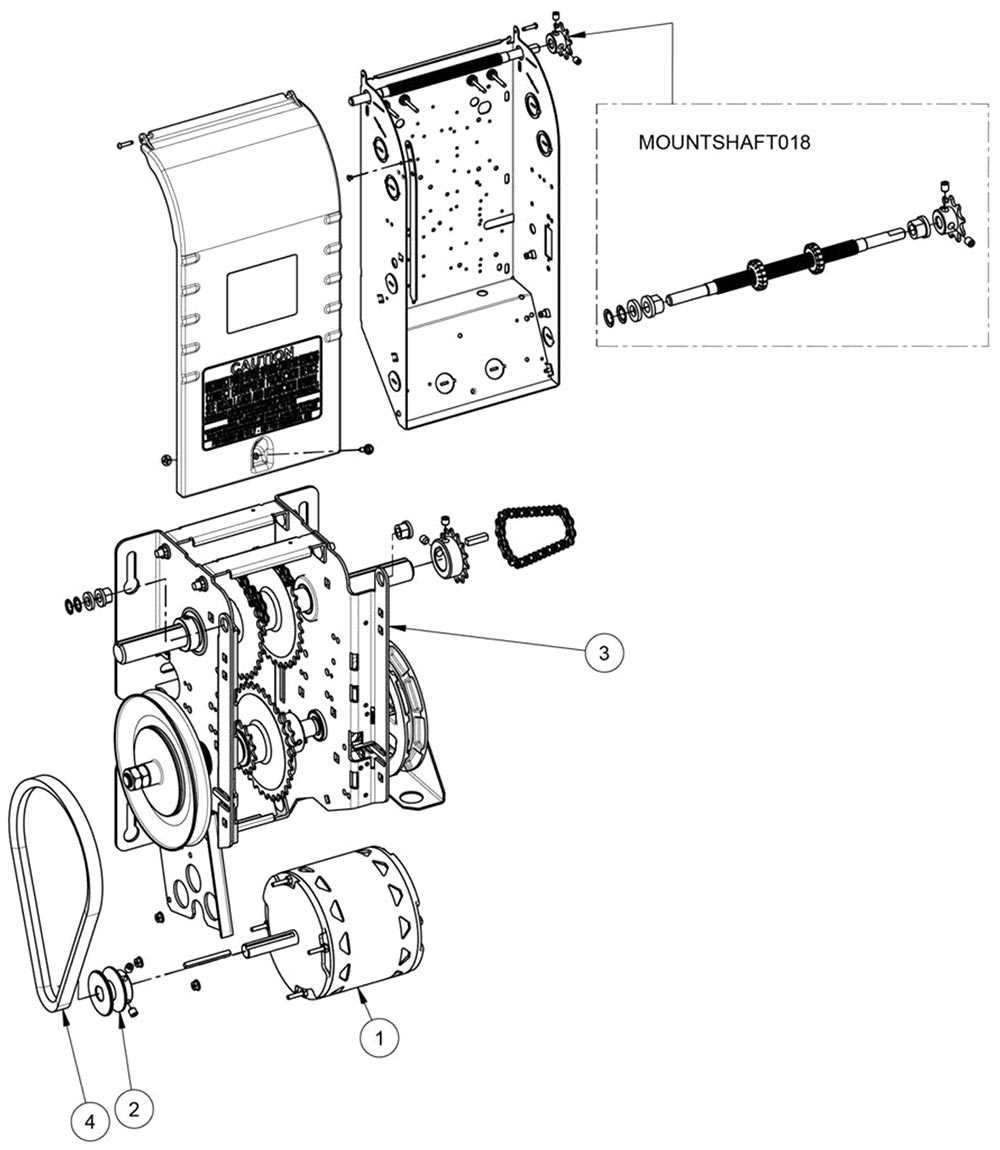

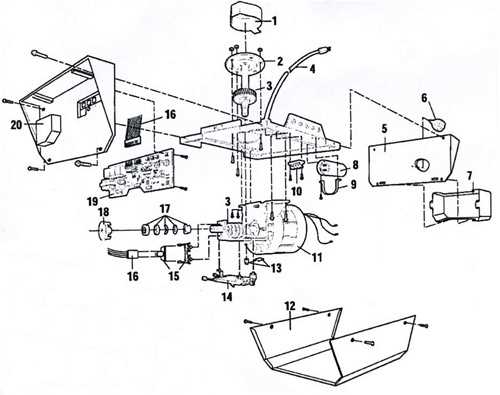

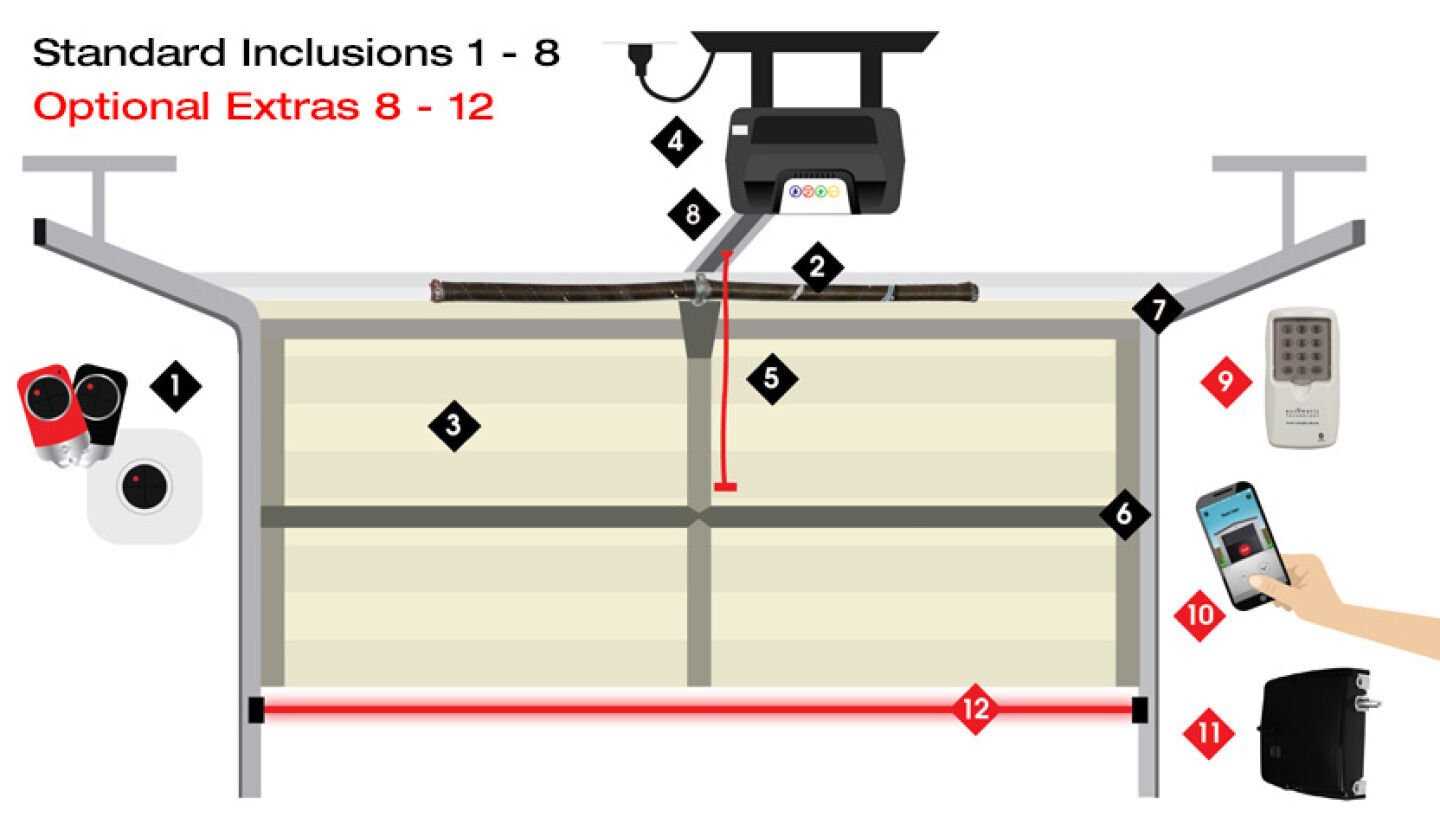

1. Main Assembly

The central structure that houses critical mechanisms and supports other components, playing a vital role in stability and functionality.

2. Lifting Mechanism

This element is responsible for raising and lowering the entrance, often utilizing a chain, belt, or screw for movement.

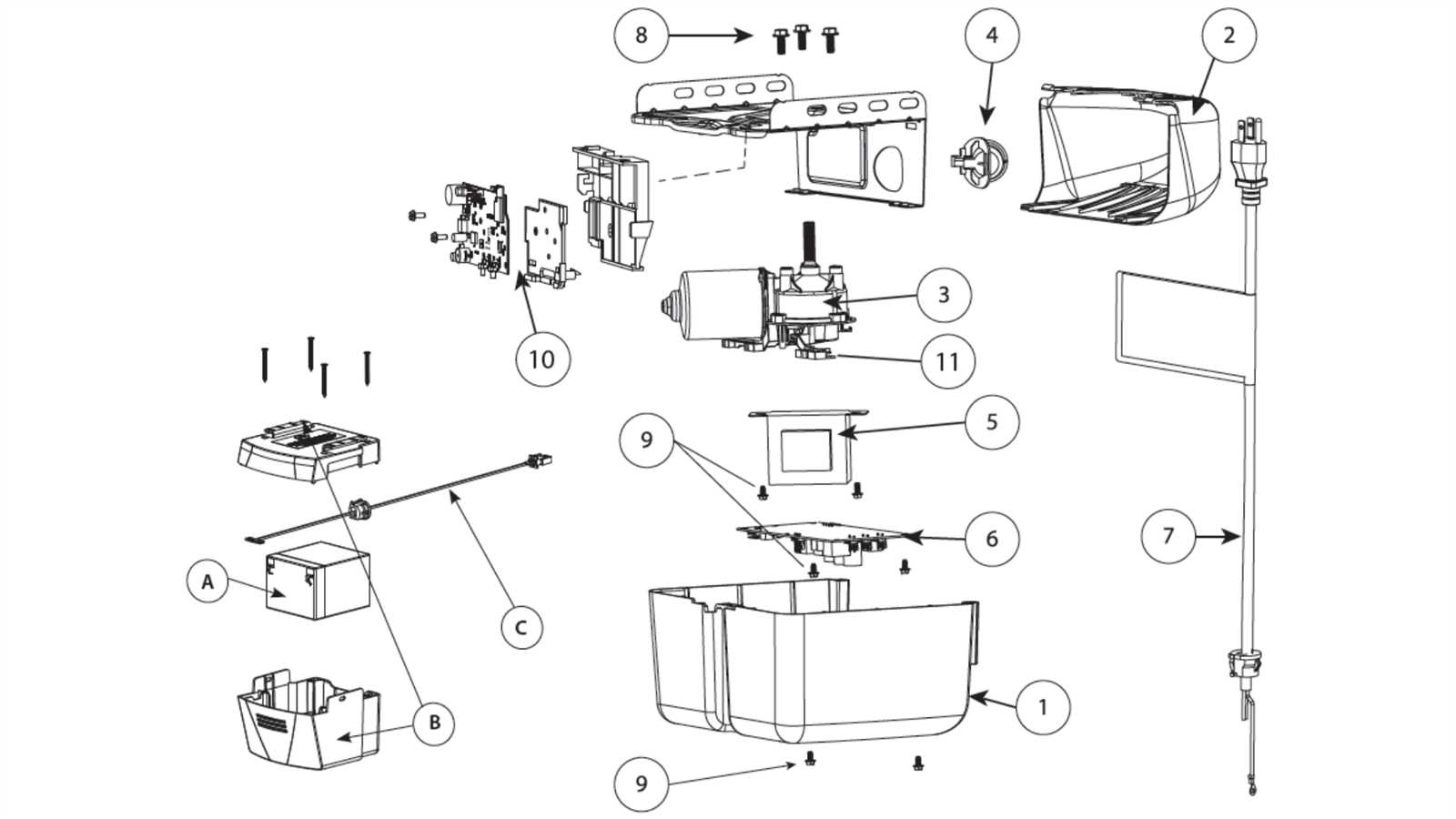

3. Control System

The brain behind the operation, allowing users to engage and disengage the lifting action with ease.

4. Safety Features

Designed to prevent accidents and ensure safe operation, these features include sensors and automatic reversals.

5. Remote Access

Devices that provide the convenience of controlling the mechanism from a distance, enhancing usability and security.

6. Power Supply

The energy source that powers the entire system, crucial for its operation.

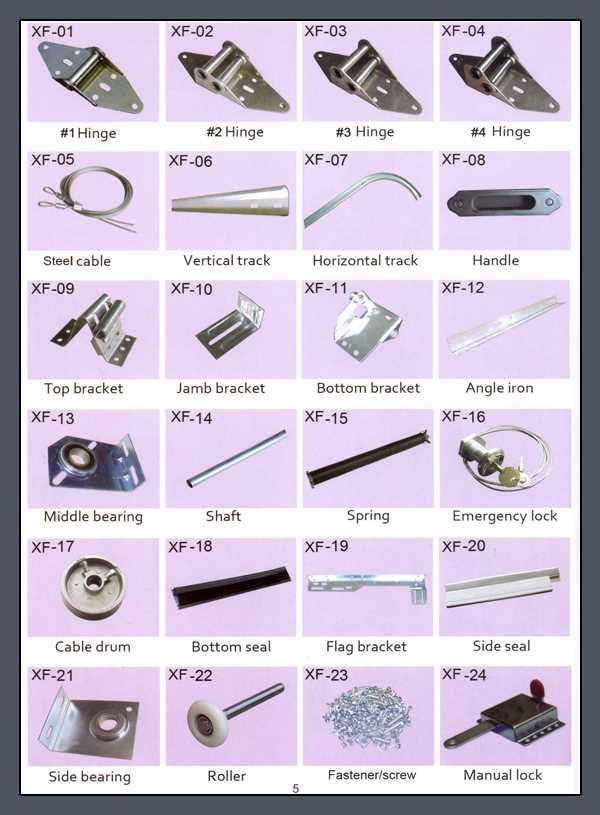

7. Tracks

Guiding structures that allow smooth movement of the lifting mechanism along designated paths.

8. Rollers

Components that facilitate movement along the tracks, contributing to the overall efficiency and noise reduction during operation.

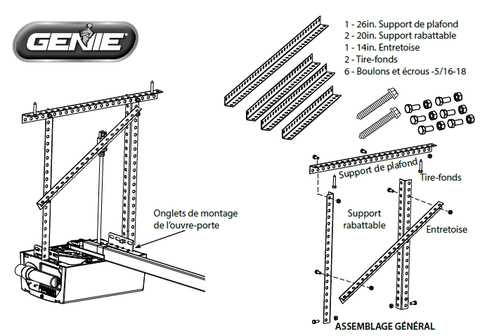

9. Mounting Hardware

Essential for securing various elements in place, ensuring durability and stability of the entire setup.

10. Emergency Release

A feature that allows manual operation in case of power failure, providing peace of mind to users.

11. Indicator Lights

Visual signals that provide information about the operational status, enhancing user awareness and safety.

12. Maintenance Components

Parts designed for easy access during service checks and repairs, ensuring longevity and reliability of the mechanism.

| Component | Description |

|---|---|

| Main Assembly | Houses critical mechanisms for stability. |

| Lifting Mechanism | Responsible for raising and lowering action. |

| Control System | Engages and disengages the operation. |

| Safety Features | Prevents accidents and ensures safe use. |

| Remote Access | Controls operation from a distance. |

| Power Supply | Powers the entire mechanism. |

| Tracks | Guides smooth movement along paths. |

| Rollers | Facilitates movement along the tracks. |

| Mounting Hardware | Secures components for stability. |

| Emergency Release | Allows manual operation if needed. |

| Indicator Lights | Signals operational status to users. |

| Maintenance Components | Facilitates easy service and repairs. |

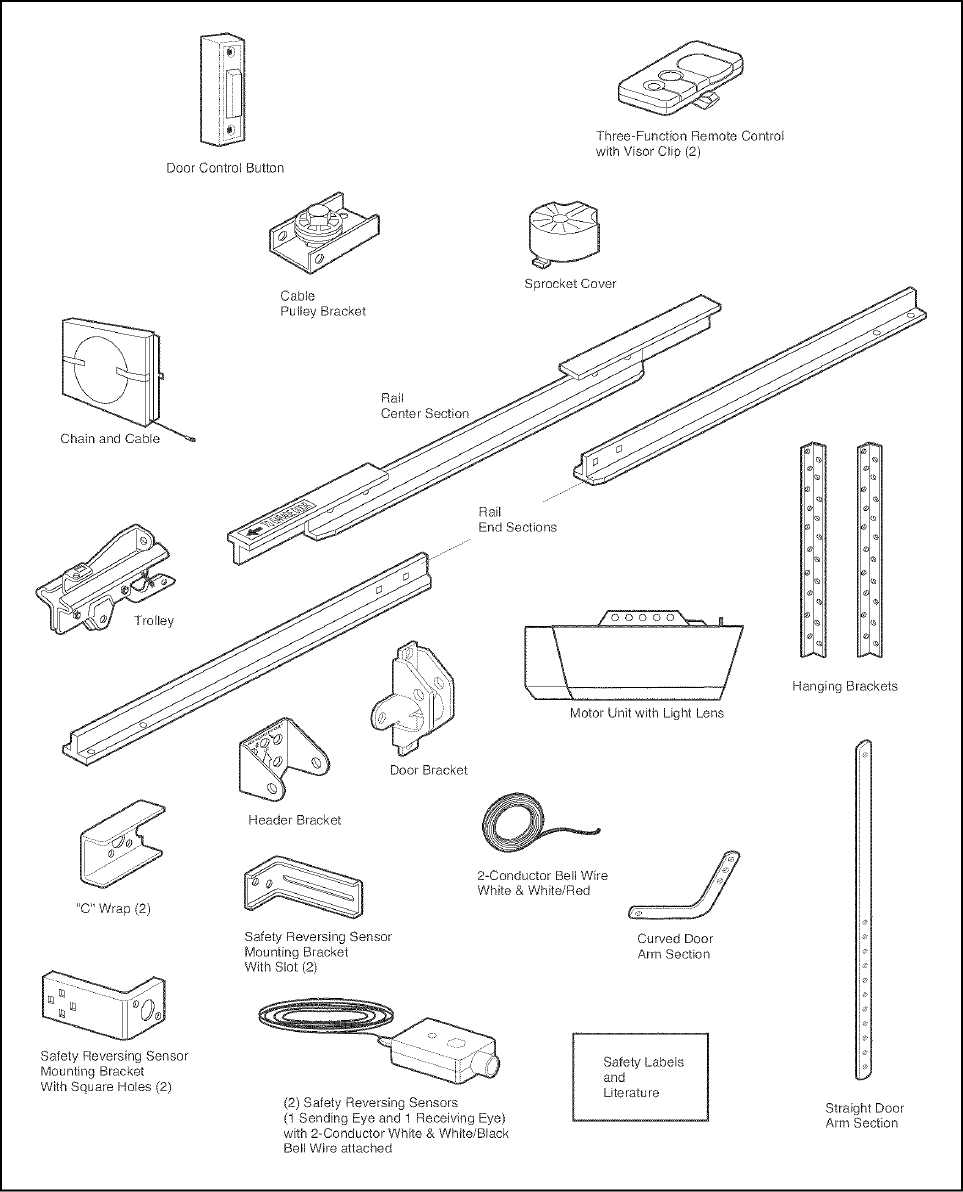

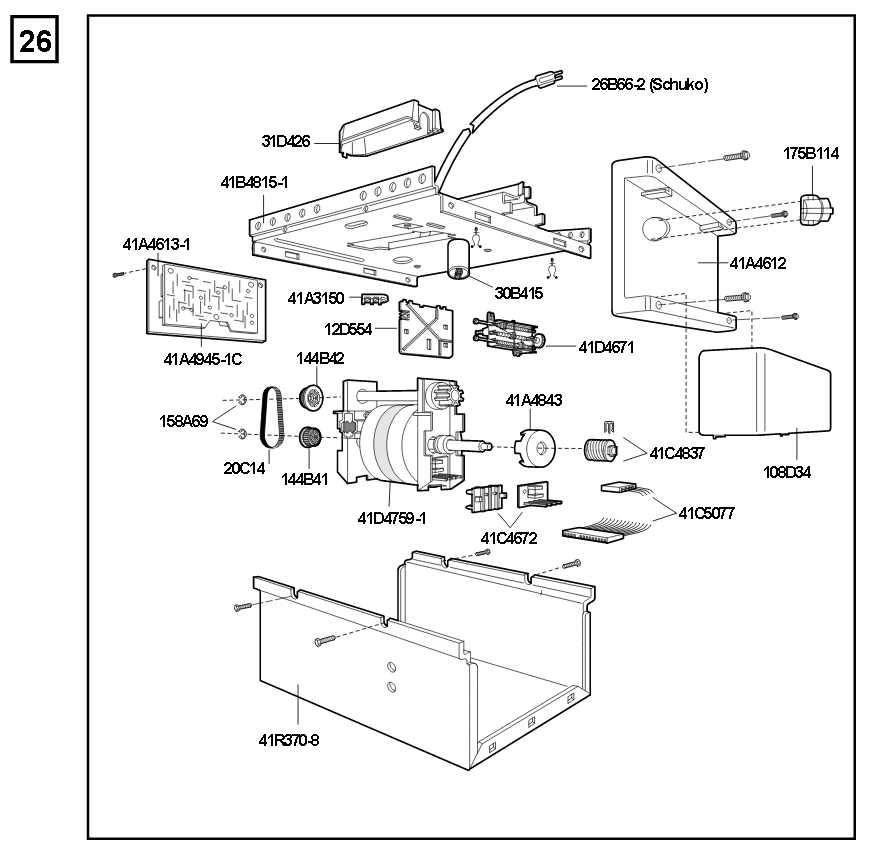

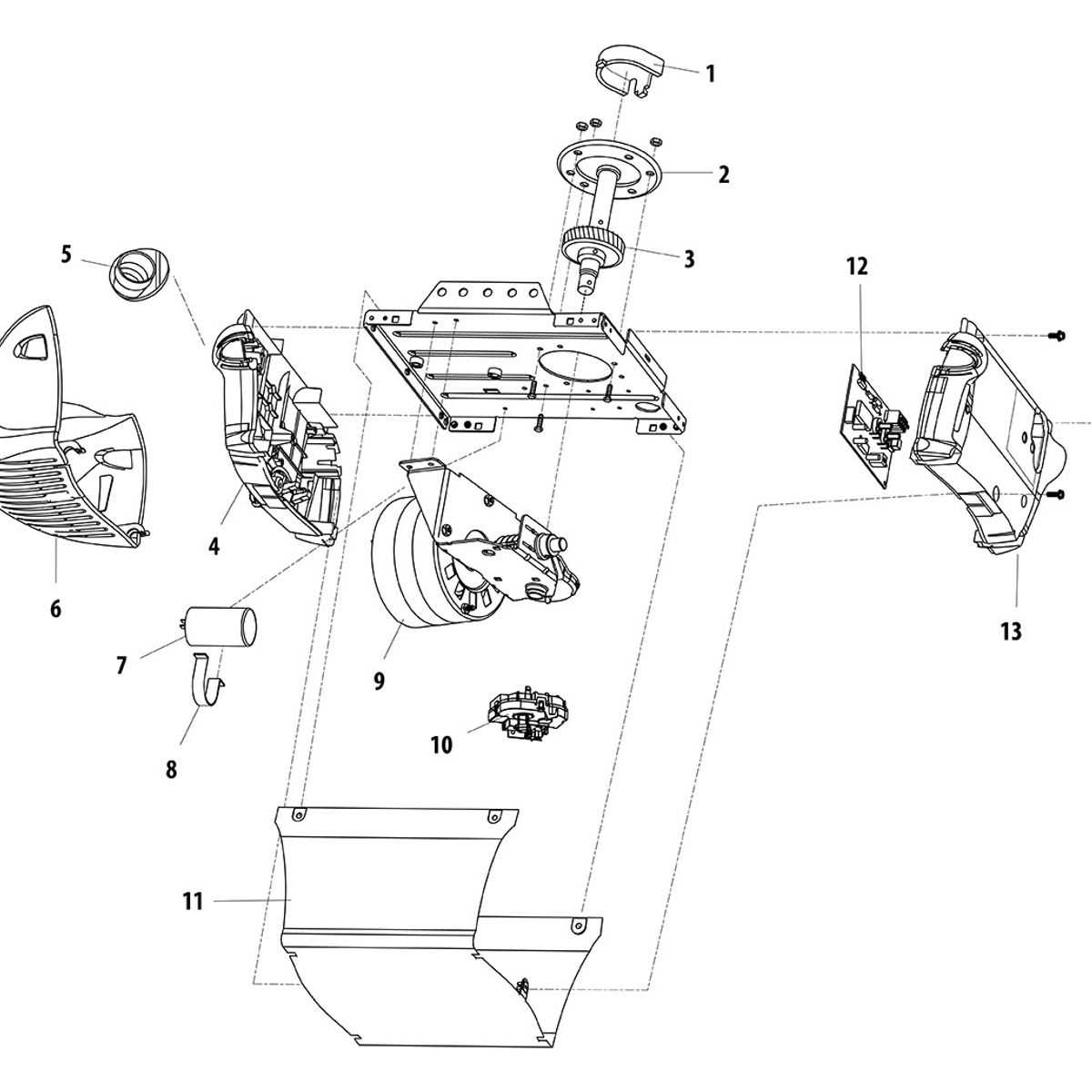

Essential Parts of Openers

The functionality of automated systems relies on several crucial components that work harmoniously to ensure smooth operation. Understanding these elements can enhance the effectiveness of the entire mechanism.

Among the key components are the motor, which serves as the driving force, and the rails, providing a guided path for movement. Additionally, sensors play a vital role in ensuring safety by detecting obstacles, while the remote control offers convenience in operation. Each of these elements contributes significantly to the overall performance and reliability of the system.

Motor Functionality Explained

The core mechanism responsible for the movement of a specific mechanism is essential for its operation. This component transforms electrical energy into kinetic energy, enabling smooth transitions and reliable performance. Understanding how this element works can provide insights into the overall efficiency and effectiveness of the entire system.

How the Mechanism Operates

At the heart of this mechanism lies an electric motor, which plays a pivotal role in initiating and controlling movement. The motor receives signals from a remote device or control panel, prompting it to start or stop as needed. Through a series of gears and belts, the rotational energy generated by the motor is transmitted to the relevant components, ensuring precise movements.

Key Features of the Motor

| Feature | Description |

|---|---|

| Power Rating | Indicates the amount of energy the motor can handle efficiently. |

| Speed Control | Allows for adjustments in the rate of movement to suit various tasks. |

| Durability | Designed to withstand frequent use and varying environmental conditions. |

| Noise Level | Engineered to operate quietly to enhance user experience. |

Types of Drive Systems

Understanding the various mechanisms that facilitate the movement of heavy barriers is essential for selecting the most suitable option for a specific application. Each system operates on distinct principles, offering different benefits and characteristics that cater to diverse needs.

Chain Drive

This mechanism utilizes a chain to connect the motor and the moving element. Known for its durability and strength, it is an excellent choice for heavy loads. However, it may produce more noise compared to other systems.

Belt Drive

Employing a rubber belt, this system operates more quietly than its chain counterpart. The belt’s flexibility allows for smooth and efficient motion, making it a popular choice for residential settings where noise reduction is a priority. It is essential to regularly check the condition of the belt to ensure optimal performance.

Safety Features in Openers

Modern lifting mechanisms incorporate various protective elements designed to enhance user safety and prevent accidents. These innovative systems aim to minimize risks associated with mechanical malfunctions or user errors, ensuring a secure environment during operation.

One essential feature includes automatic reversal, which detects obstacles in the path and promptly reverses the motion, preventing potential injuries or damage. Additionally, many units are equipped with infrared sensors that create an invisible barrier, stopping the movement if interrupted by a person or object.

Moreover, various models offer manual release mechanisms, allowing for safe disengagement in emergencies. This ensures that users can operate the system without reliance on power, providing peace of mind during outages. Overall, these safety enhancements are critical for maintaining a secure and efficient functioning environment.

Power Supply Specifications

The functionality of an automatic mechanism is significantly influenced by the characteristics of its electrical source. Understanding the requirements and standards for power supply is crucial for optimal performance and safety.

Voltage Requirements

Most systems operate within specific voltage ranges to ensure reliability and efficiency. The following points highlight the common voltage specifications:

- Typical voltage ranges include 120V, 240V, and in some cases, low voltage options around 12V or 24V.

- Devices may require a transformer to convert higher voltage to the appropriate level for operation.

Power Ratings

The power ratings determine the energy consumption and capability of the equipment. Key considerations include:

- Look for wattage ratings that indicate the maximum power consumption.

- Ensure compatibility with existing electrical systems to avoid overloads.

Remote Control Mechanisms

This section delves into the functionalities of wireless activation systems designed to operate various entrance solutions. These devices enhance convenience and security, allowing users to manage access effortlessly from a distance.

Key Components

- Transmitter: A handheld device that emits signals to initiate the mechanism.

- Receiver: An integrated unit that interprets signals from the transmitter to execute commands.

- Power Source: Typically batteries or an external supply that energizes the transmitter and receiver.

Operating Principles

- Signal Transmission: When a button is pressed, the transmitter sends a coded signal.

- Signal Reception: The receiver picks up the signal and decodes it.

- Action Execution: Based on the received command, the system performs the designated function.

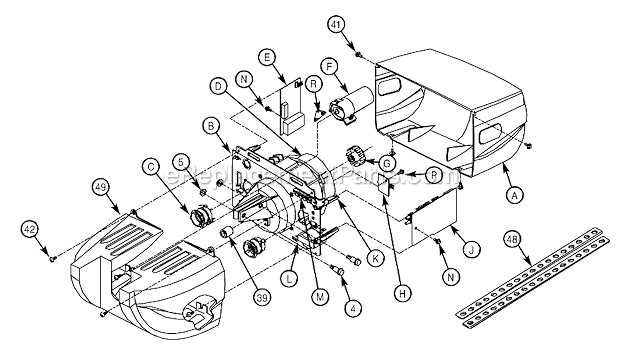

Wiring and Electrical Connections

Understanding the electrical layout is essential for the proper functionality of the system. It involves recognizing how various components interact through connections to ensure seamless operation. This section highlights the crucial aspects of wiring and how to achieve a safe setup.

Essential Components of the Electrical System

Key elements within the electrical framework play significant roles in ensuring efficient performance. These components include the power supply, circuit board, and sensors, which must be correctly linked for optimal operation.

Connection Guidelines

Establishing connections requires attention to detail and adherence to safety protocols. Proper insulation, secure fittings, and compliance with electrical standards are paramount to prevent hazards.

| Component | Function |

|---|---|

| Power Supply | Provides electrical energy to the system. |

| Circuit Board | Manages the flow of electricity and coordinates operations. |

| Sensors | Detects obstacles and ensures safety during operation. |

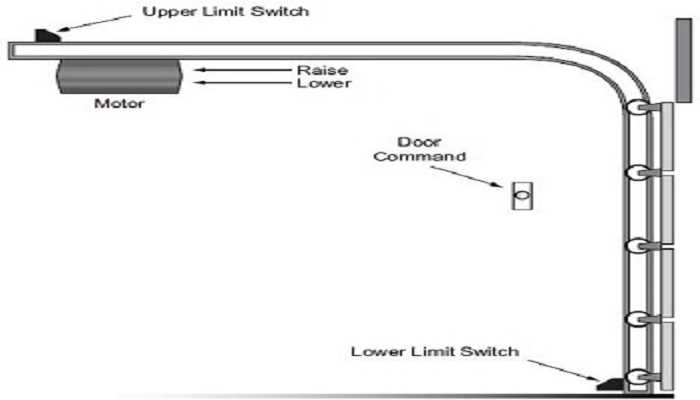

Limit Switch Operation

The mechanism responsible for controlling the movement of a lifting device relies heavily on a specific component that regulates its travel distance. This element plays a crucial role in ensuring that the system operates smoothly, preventing potential damage and ensuring user safety.

Functionality Overview

This critical component detects when the mechanism has reached a predetermined position, whether fully extended or retracted. When activated, it sends signals to halt further motion, effectively preventing overextension or misalignment. This function is vital for maintaining the integrity of the entire assembly and prolonging its lifespan.

Importance of Proper Adjustment

Correct calibration of this element is essential for optimal performance. Misalignment or improper settings can lead to malfunction, resulting in either insufficient movement or unnecessary strain on the entire system. Regular inspection and adjustment ensure that the unit operates within safe parameters, providing reliable performance over time.

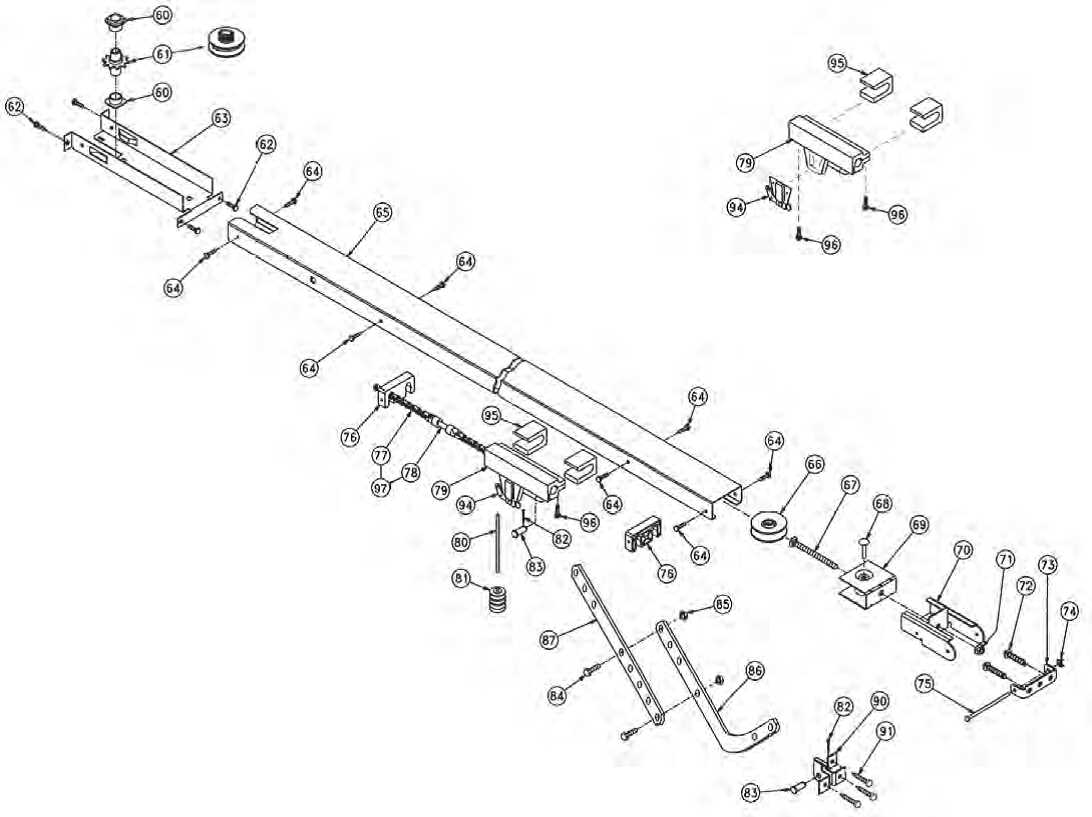

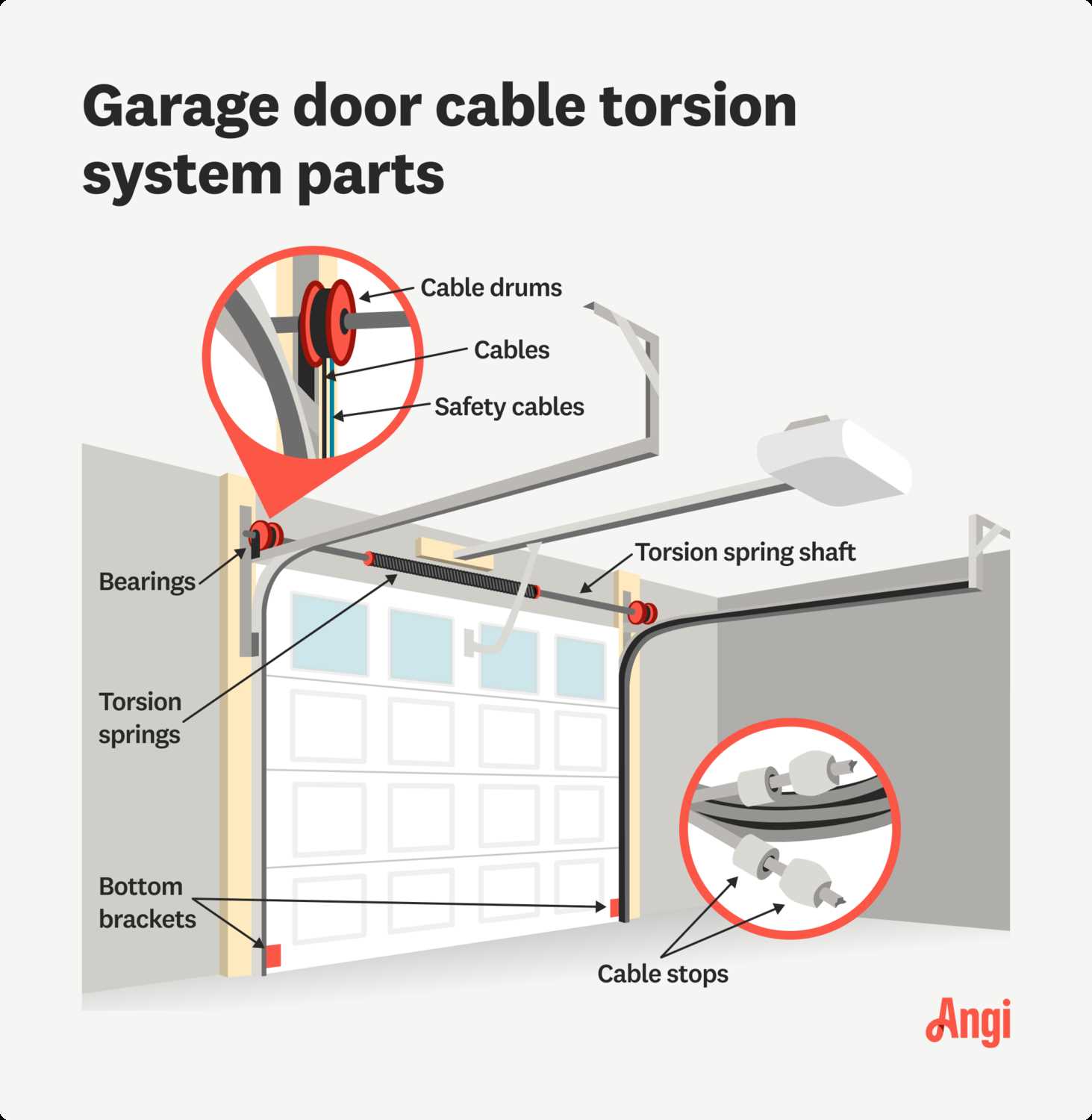

Track and Roller System

This system plays a crucial role in the smooth operation of the mechanism, facilitating the movement of the panel along a designated pathway. It ensures stability and efficiency, allowing for seamless transitions during opening and closing actions.

Components and Functionality

The framework comprises two primary elements: the track and the rollers. The track is a continuous rail that guides the rollers as they move. Rollers, typically made of durable materials, fit into the track and provide the necessary support and guidance. This combination minimizes friction and wear, enhancing longevity.

Maintenance Tips

Regular upkeep is essential to ensure optimal performance. Cleaning the track to remove debris and lubricating the rollers can prevent operational issues. Additionally, inspecting for any misalignments or damage can help maintain the integrity of the entire system.

Maintenance of Openers

Regular upkeep of mechanisms responsible for entryway access ensures smooth operation and longevity. Implementing a consistent maintenance routine helps identify potential issues before they escalate, enhancing the overall performance and reliability of these devices.

Inspection: Routine checks are crucial for detecting wear or damage. Look for signs of deterioration in moving elements and connections.

Lubrication: Keeping components adequately lubricated minimizes friction and reduces the likelihood of malfunctions. Utilize a suitable lubricant for optimal results.

Adjustment: Periodic adjustments may be necessary to maintain correct alignment and functionality. Ensure that all settings are in accordance with manufacturer specifications.

Cleaning: Regularly cleaning surrounding areas and components prevents debris accumulation, which can hinder performance. A clean environment promotes efficient operation.

By prioritizing these maintenance tasks, one can significantly extend the lifespan of the mechanism and enhance its efficiency, ensuring dependable access at all times.

Common Issues and Solutions

Every mechanism can encounter challenges over time. Understanding these common difficulties and their resolutions can enhance functionality and prolong the lifespan of the system.

-

Unresponsive Mechanism:

If the unit does not respond when activated, check the power source. Ensure that the connection is secure and that the fuse or circuit breaker has not tripped.

-

Noisy Operation:

Excessive noise during function may indicate a need for lubrication. Apply a silicone-based lubricant to the moving components to reduce friction.

-

Incomplete Opening or Closing:

If the unit does not fully open or close, check the sensors for obstruction or misalignment. Ensure they are clean and positioned correctly.

-

Remote Control Issues:

When the remote fails to operate, replace the batteries and confirm that there are no obstructions between the remote and the receiver.

-

Frequent Reversing:

If the system reverses unexpectedly, inspect the safety sensors for dirt or misalignment. Clear any debris and adjust their position as needed.

Upgrading Garage Door Openers

Enhancing the functionality of a residential access mechanism can significantly improve convenience and security. Modern advancements in technology have made it easier to replace older systems with innovative solutions that offer better performance, safety features, and user-friendly interfaces.

Benefits of Modernization

Upgrading to the latest models provides numerous advantages, including enhanced security features, quieter operation, and improved energy efficiency. Newer systems often include smart technology, allowing remote access and monitoring through mobile devices. This connectivity ensures that users can manage their access points from virtually anywhere.

Installation Considerations

When considering an upgrade, it’s crucial to assess the current setup and ensure compatibility with new equipment. Professional installation is recommended to guarantee that all components function seamlessly together. Additionally, evaluating the overall structure and condition of the access point is essential for a successful upgrade.