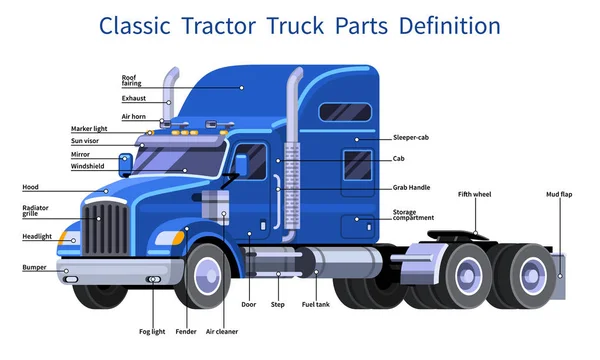

Every vehicle relies on a variety of essential elements to ensure smooth access and functionality. These components play a crucial role in providing security, convenience, and ease of use. By examining these intricate mechanisms, one can appreciate the engineering and design that goes into creating an efficient and reliable system.

Each element serves its purpose, contributing to the overall operation and safety of the vehicle. From locking mechanisms to hinges, understanding these components allows for better maintenance and troubleshooting. Moreover, gaining insights into their configuration can aid in making informed decisions when repairs or replacements are necessary.

In this section, we will explore the various components involved in facilitating access to the vehicle’s interior. By familiarizing ourselves with these elements, we can enhance our knowledge of their functions and improve our interaction with them. This understanding ultimately leads to a more informed approach to vehicle care and maintenance.

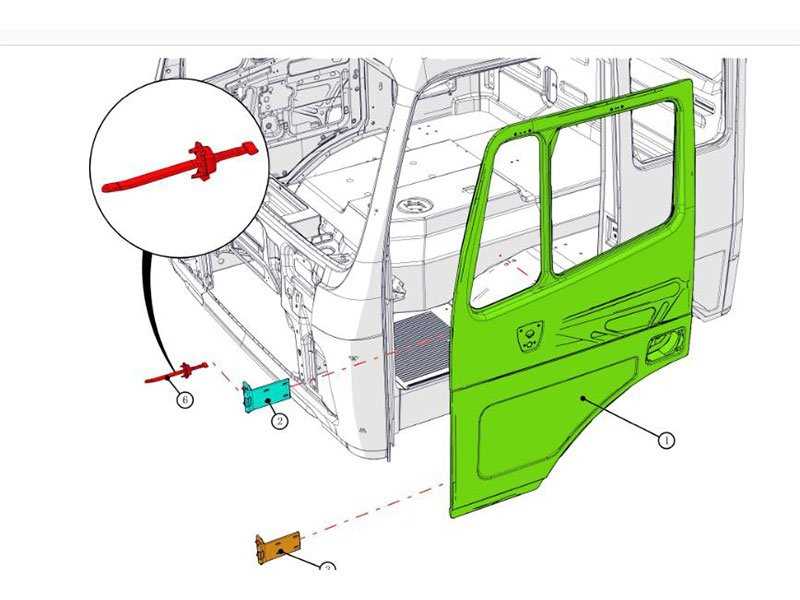

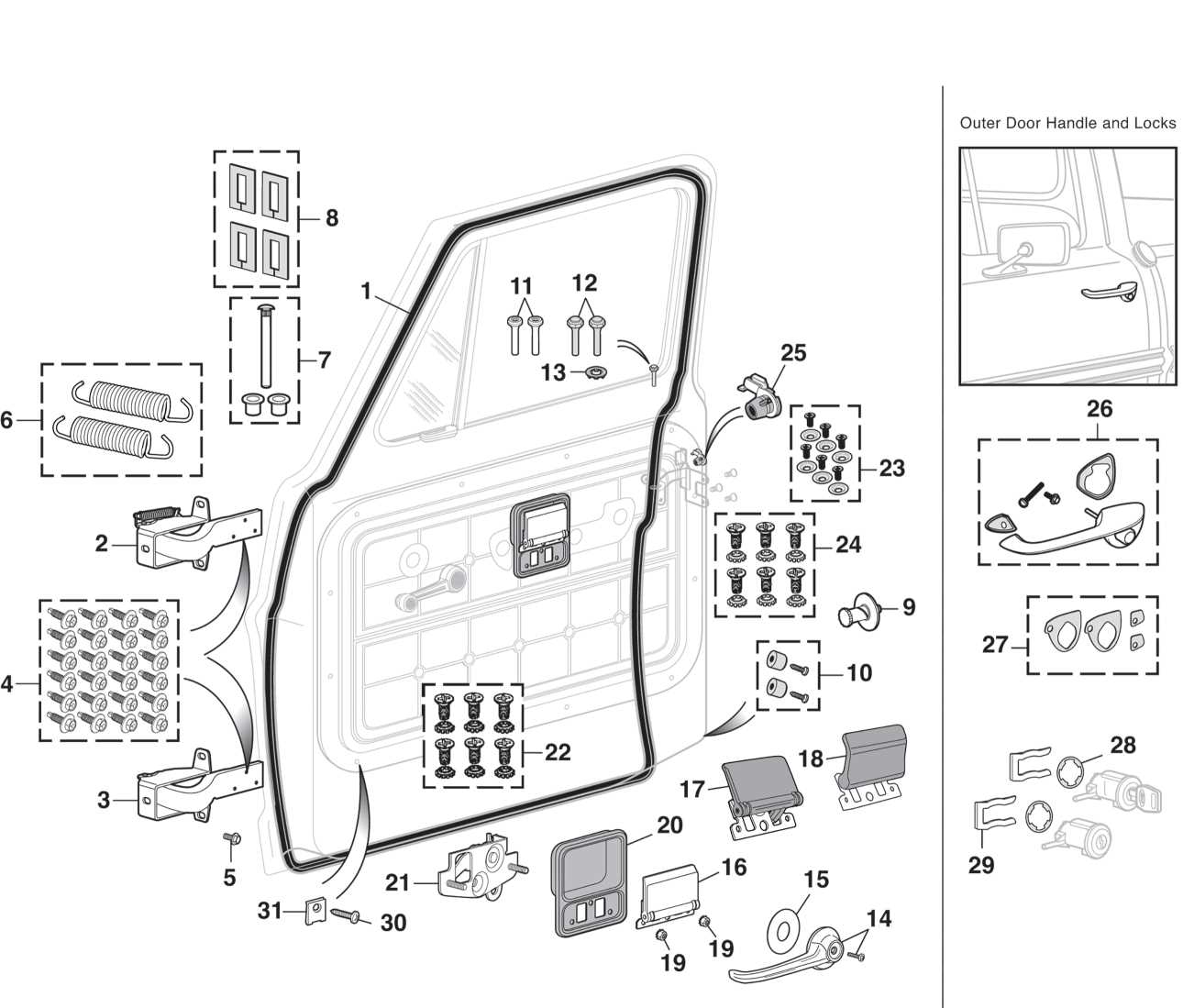

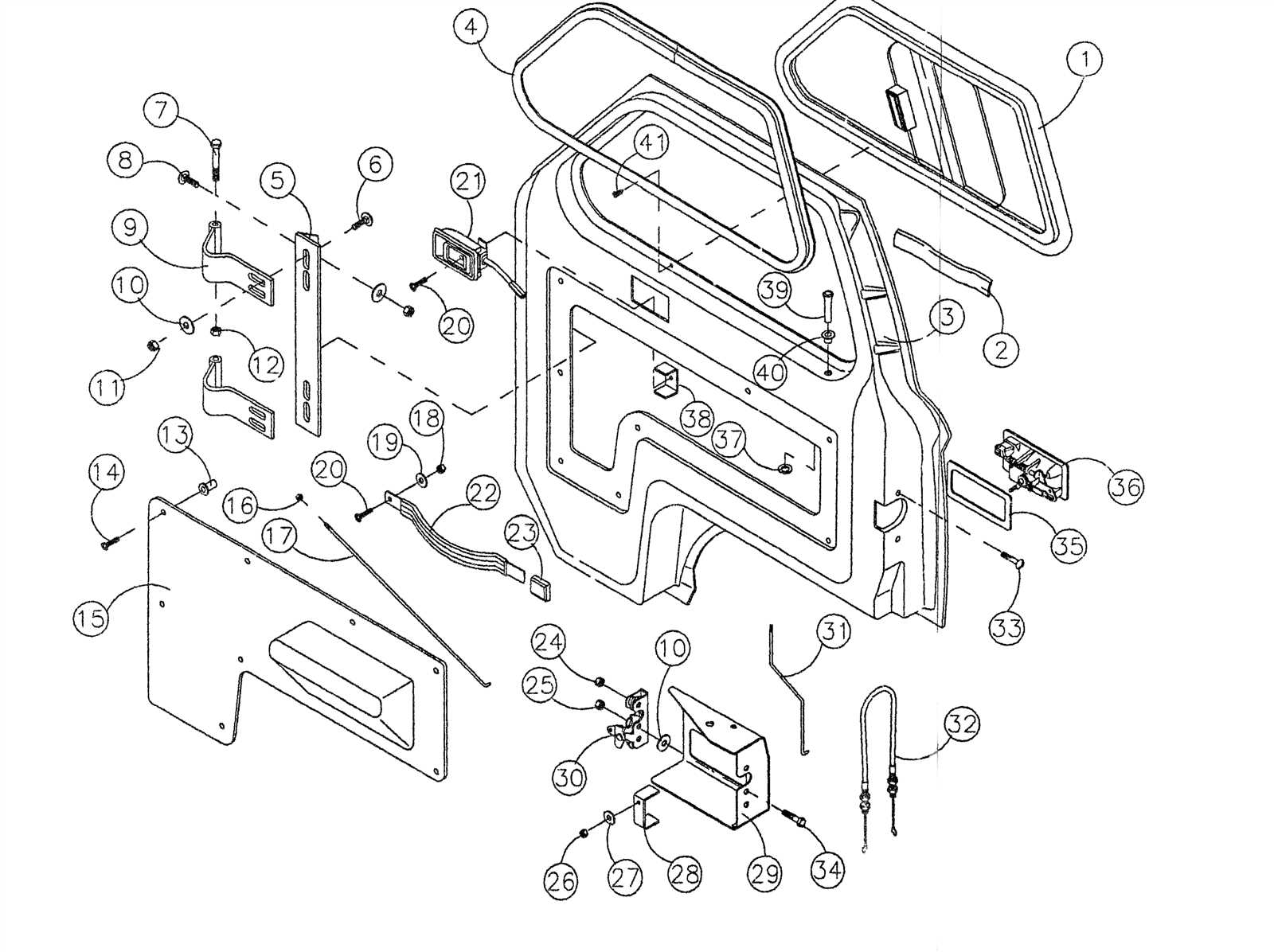

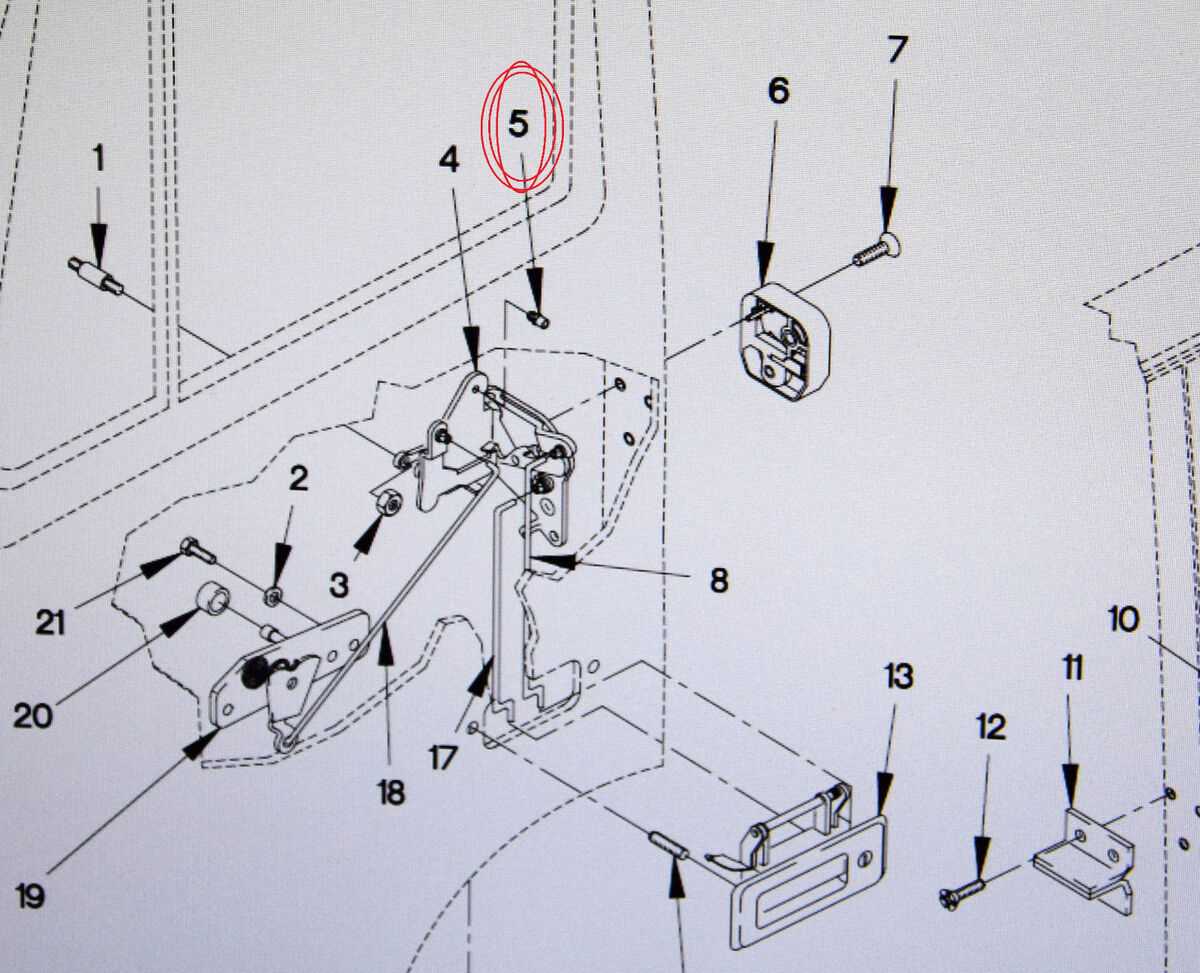

This section delves into the fundamental elements that contribute to the functionality and integrity of vehicle entryways. Understanding these components is crucial for effective maintenance and repair, ensuring smooth operation and safety.

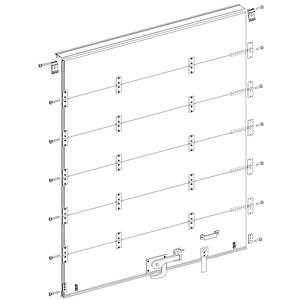

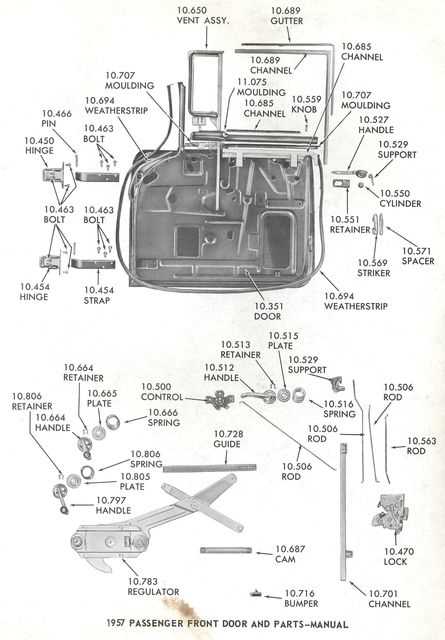

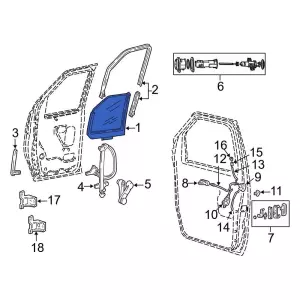

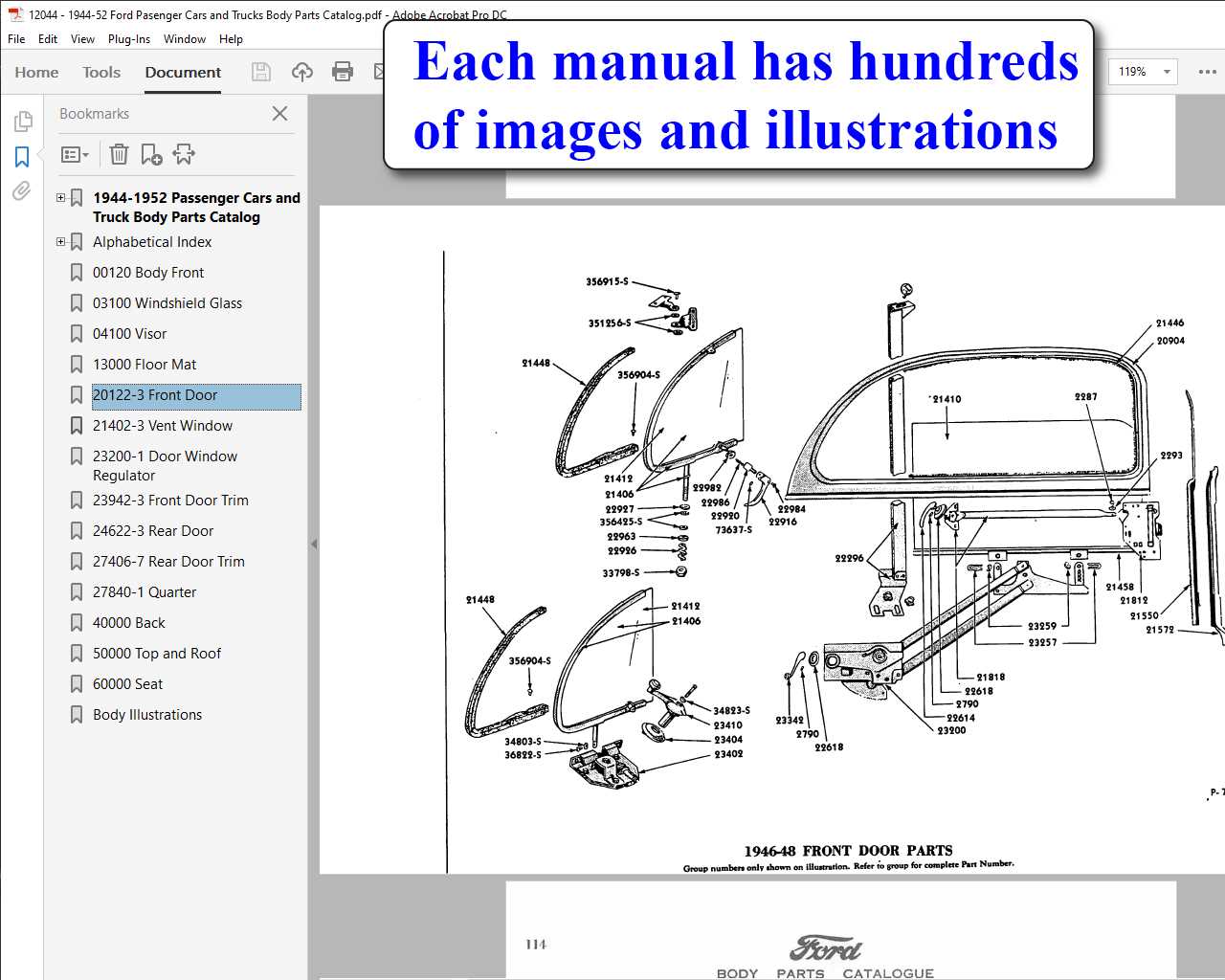

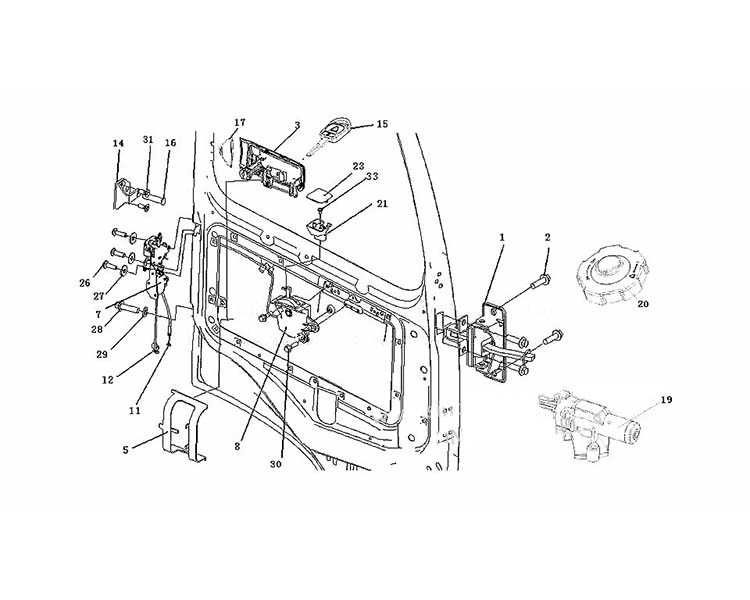

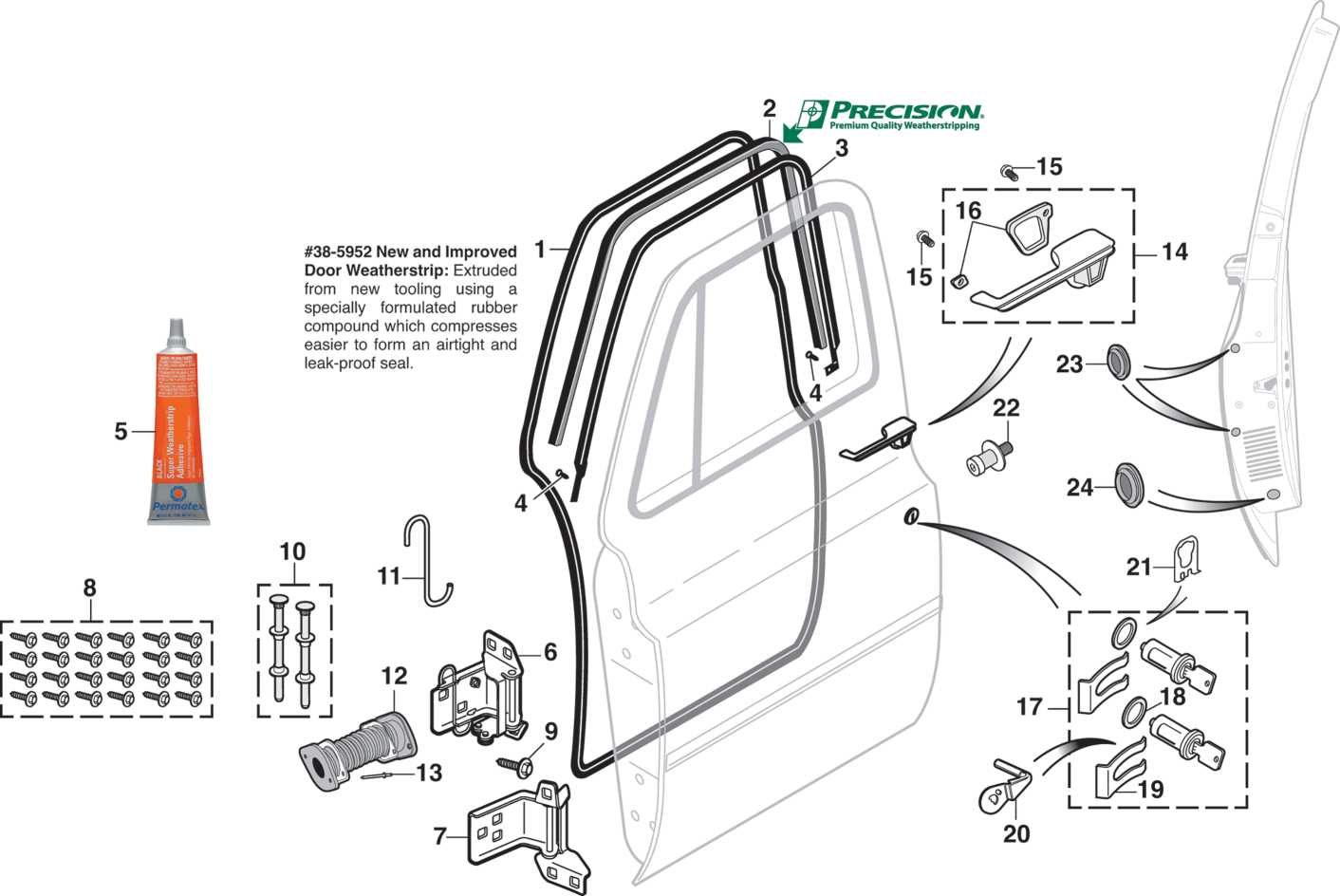

- Frame: The sturdy structure that supports the entire assembly, providing strength and stability.

- Seals: These components play a vital role in weatherproofing, preventing moisture and debris from entering the cabin.

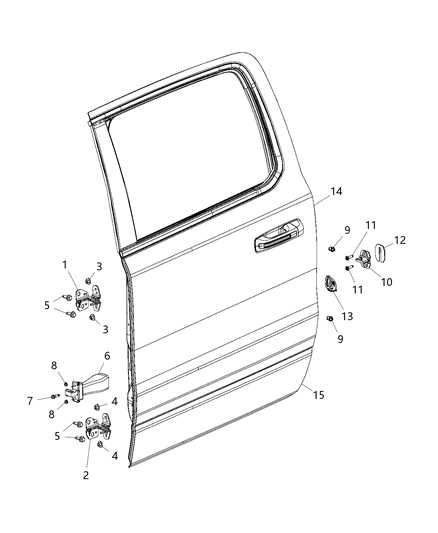

- Handles: Essential for opening and closing, handles must be durable and ergonomic for user convenience.

- Hinges: Allow for smooth movement, hinges must be robust to withstand repeated use without failure.

- Locks: Security features that ensure safety, they require reliable mechanisms to function effectively.

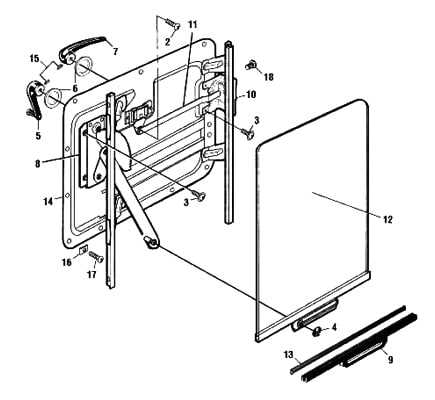

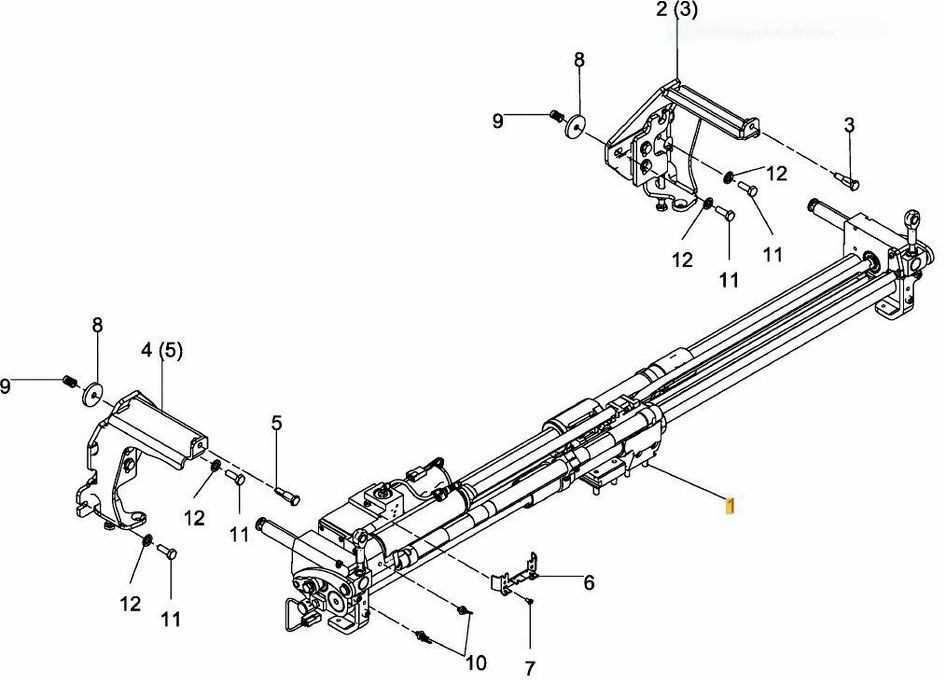

- Window Mechanism: This includes all components that allow for window operation, contributing to ventilation and visibility.

Each of these elements serves a specific purpose and, when functioning correctly, contributes to the overall performance and reliability of the vehicle’s entryway.

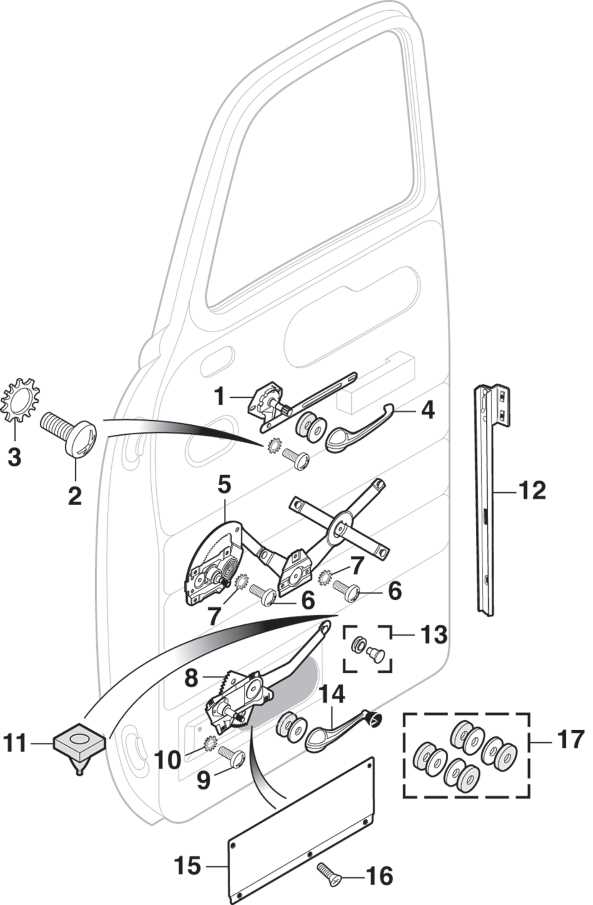

Understanding Truck Door Mechanisms

Grasping the functioning of entryway systems in vehicles reveals the intricate engineering that allows for seamless operation. These assemblies are vital for ensuring security, accessibility, and convenience for users.

The mechanisms involved can be broadly categorized into several components that contribute to the overall performance. Each part plays a specific role, working in harmony to achieve efficient functionality.

- Locking Systems: Essential for securing the entry, these systems utilize various technologies to ensure safety.

- Hinges: These pivotal connections allow for smooth opening and closing motions, facilitating access.

- Handles: Often the primary interface for users, handles are designed for comfort and ease of use.

- Weather Seals: Critical for protecting the interior from elements, these seals help maintain a comfortable environment.

Understanding these components provides insight into how different elements interact, enhancing the overall utility and performance of vehicle entry systems.

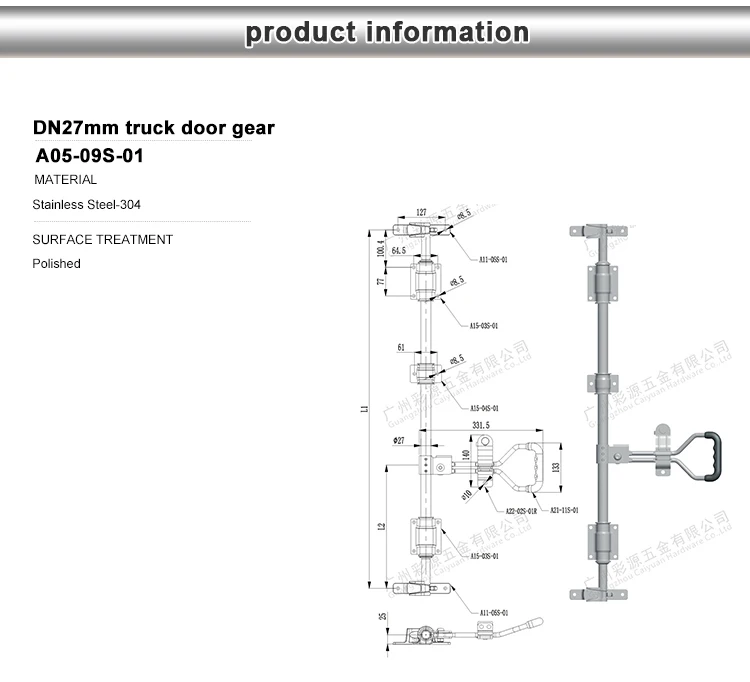

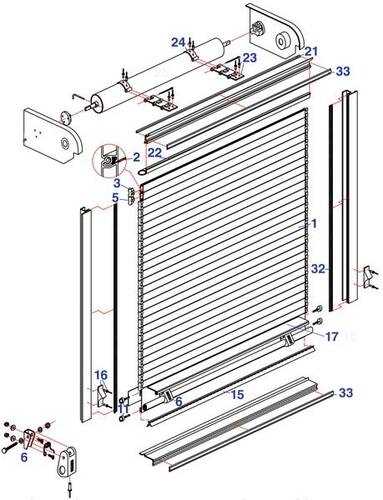

Types of Truck Door Hinges

When it comes to the mechanics of vehicle access, the connectors play a crucial role in ensuring smooth operation and durability. These components come in various styles, each designed to meet specific requirements and performance standards.

- Pivot Hinges: These are commonly utilized in many designs, allowing the panel to rotate around a central point. They are ideal for lightweight applications.

- Continuous Hinges: Also known as piano hinges, they extend the full length of the opening. This type offers superior strength and stability, making it suitable for larger or heavier structures.

- Friction Hinges: These provide a controlled resistance, allowing the access point to hold in any position without needing additional support. This feature is beneficial for convenience and safety.

- Spring Hinges: These incorporate a spring mechanism to ensure the access point automatically returns to a closed position. They are often used in scenarios where automatic closure is essential.

- Offset Hinges: This type allows the frame to be set back from the opening, creating more space when the access point is opened. It is advantageous in situations where clearance is a concern.

Each type of connector serves a distinct purpose, contributing to the overall functionality and reliability of the vehicle’s structure. Understanding the differences can aid in selecting the most suitable option for specific needs.

Common Locking Systems in Trucks

The security of a vehicle’s entry points is crucial for protecting its contents and ensuring the safety of passengers. Various mechanisms are employed to secure these access points, each with unique features and functionalities. Understanding these systems can help users make informed decisions when it comes to safety enhancements.

Among the prevalent mechanisms are electronic locks, which utilize electrical current to engage or disengage the locking mechanism. These systems often come with keyless entry options, providing convenience and ease of use. Mechanical locks, on the other hand, rely on physical keys and intricate internal structures to secure the access points, offering a traditional yet reliable solution.

Another noteworthy option is the deadbolt system, designed to offer additional security by requiring a higher level of force to open. This mechanism is particularly effective in preventing unauthorized access. Furthermore, central locking systems enable simultaneous locking or unlocking of all access points, streamlining the process for users.

In addition to these standard options, smart locks are gaining popularity, integrating technology to allow remote access and monitoring via smartphones or other devices. These innovative solutions offer enhanced security and convenience, adapting to the evolving needs of users.

Each locking mechanism has its advantages and is suited to different requirements. Familiarity with these systems can significantly contribute to maintaining security and ensuring peace of mind.

Window Features in Truck Doors

Windows play a vital role in enhancing the functionality and aesthetics of vehicle access panels. These openings not only provide visibility but also contribute to the overall comfort and safety of the occupants. Understanding the various features associated with these glass elements can help improve their performance and longevity.

One significant aspect of these openings is their ability to provide ventilation while maintaining security. Additionally, the mechanisms that control the operation of these glass sections are essential for user convenience and efficiency. Below is a summary of some key features:

| Feature | Description |

|---|---|

| Power Operation | Automated systems allowing effortless opening and closing of glass panels. |

| Tinted Glass | Darkened surfaces reducing glare and providing privacy for occupants. |

| Safety Glass | Specially treated surfaces designed to resist shattering and enhance protection. |

| Insulation | Features that minimize heat transfer, contributing to a comfortable interior climate. |

Seals and Gaskets Explained

In various mechanical applications, components are often subjected to harsh environments, necessitating the use of effective sealing solutions. These elements play a crucial role in preventing the ingress of contaminants and the egress of fluids, thereby ensuring optimal performance and longevity of the assembly.

Understanding the significance of these sealing mechanisms is essential for maintaining efficiency and reliability. Here are some key aspects to consider:

- Functionality: Seals and gaskets create a barrier that stops unwanted substances from entering or escaping the system.

- Materials: Common materials used include rubber, silicone, and cork, each chosen for its unique properties suited to specific applications.

- Types: Various designs exist, including flat gaskets, O-rings, and lip seals, each serving distinct purposes based on the mechanical requirements.

When selecting appropriate sealing solutions, it’s vital to consider factors such as temperature, pressure, and chemical compatibility. These elements will directly influence the performance and durability of the seals and gaskets in use.

In conclusion, a thorough understanding of sealing technologies is imperative for anyone involved in maintenance or assembly processes. Proper application of these components can significantly enhance the efficiency and lifespan of machinery.

Replacing Damaged Door Panels

When faced with unsightly or malfunctioning coverings on vehicle access points, addressing the issue promptly is crucial for both aesthetics and functionality. Outdated or compromised coverings can detract from the overall appearance and potentially hinder access. This section will guide you through the process of replacing these elements, ensuring a seamless transition to a fresh and appealing finish.

Assessment and Preparation

Begin by carefully examining the existing coverings to determine the extent of the damage. Look for signs of wear, such as cracks, tears, or discoloration. Once you’ve identified the affected areas, gather the necessary tools and replacement materials. Having everything on hand before starting will streamline the process and minimize interruptions.

Installation Process

Start by removing any fasteners or clips securing the old coverings in place. Gently pull them away from the frame, being cautious not to damage adjacent components. Once the old coverings are detached, clean the area thoroughly to ensure proper adhesion of the new material. Finally, align the new coverings carefully and secure them using the appropriate fasteners, ensuring a snug fit for durability.

Wiring and Electrical Connections

Understanding the layout and interaction of electrical components is crucial for maintaining functionality. This section focuses on the essential connections that facilitate proper operation, ensuring that every element works harmoniously within the system.

At the core of these connections are various wires and terminals that establish communication between components. The integrity of these links directly affects performance and reliability. Regular checks and maintenance can help identify potential issues before they escalate.

- Identify the primary wiring harnesses and their roles in the system.

- Check for wear and tear on insulation to prevent shorts.

- Ensure all connectors are secure and free of corrosion.

- Utilize a multimeter to test voltage and continuity at critical points.

In addition to the primary connections, understanding the importance of grounding is vital. A solid ground connection is necessary to avoid electrical noise and ensure stability in operations.

- Locate grounding points in the system.

- Inspect for corrosion or loose connections.

- Clean and tighten any compromised points to enhance electrical flow.

By focusing on these elements, one can ensure a reliable electrical system, which is essential for optimal performance and safety.

Paint and Finish Considerations

When it comes to enhancing the appearance and durability of exterior vehicle elements, selecting the appropriate coating and finishing techniques is essential. This aspect not only influences the aesthetic appeal but also provides protection against environmental factors such as rust, UV radiation, and physical damage. A well-executed finish can significantly extend the lifespan of these components.

Choosing the Right Coating

Different types of coatings are available, each with unique properties suited for various applications. Understanding these options helps in making an informed choice that meets both functional and visual requirements.

| Coating Type | Advantages | Best Use |

|---|---|---|

| Acrylic | Excellent color retention, quick drying | General applications |

| Polyurethane | Durable, resistant to chemicals | High-wear areas |

| Epoxy | Strong adhesion, ideal for protection | Undercoating and priming |

Finishing Techniques

In addition to selecting the right coating, employing proper finishing techniques is crucial for achieving a flawless look. Techniques such as sanding, polishing, and applying clear coats can enhance the overall finish and durability of the surface.

Maintenance Tips for Door Parts

Regular upkeep of components related to vehicle entryways is crucial for ensuring longevity and optimal functionality. By adhering to a few straightforward practices, you can significantly enhance the performance and reliability of these elements, minimizing potential issues down the line.

Routine Inspections

Conducting frequent evaluations of all associated components can help identify wear and tear early. Look for signs of corrosion, misalignment, or loose fittings, which can compromise functionality and safety.

Lubrication Practices

Applying appropriate lubricants to hinges and mechanisms is essential for smooth operation. Ensure that you use products designed for automotive applications to avoid damaging any surfaces.

| Component | Maintenance Tip |

|---|---|

| Hinges | Apply lubricant regularly to prevent squeaking and ensure smooth movement. |

| Locks | Use graphite powder to lubricate for enhanced security and ease of use. |

| Weather Stripping | Inspect for cracks and replace to maintain a proper seal and insulation. |

| Handle Mechanisms | Tighten screws and check for any wear to prevent malfunction. |

Safety Features in Truck Door Design

Ensuring the well-being of passengers and drivers is a critical aspect of vehicle construction. The integration of protective elements within the structure contributes to overall safety and functionality. This section highlights essential features designed to enhance security and resilience during operation.

- Reinforced Frames: Stronger materials and structures provide additional protection against impacts, enhancing the integrity of the vehicle.

- Locking Mechanisms: Advanced locking systems prevent unauthorized access, safeguarding both the vehicle and its occupants.

- Weather Seals: Effective sealing prevents moisture and debris from entering, ensuring a safer and more comfortable interior environment.

- Impact Absorption: Design strategies that absorb and dissipate energy during collisions significantly reduce injury risk.

- Visibility Enhancements: Features like larger windows or strategically placed mirrors improve the driver’s view, reducing blind spots and promoting safer navigation.

Incorporating these elements not only adheres to safety standards but also instills confidence in users, making every journey more secure. Continuous innovation in design practices ensures that protection remains a top priority in modern vehicle development.