In the world of marine engineering, precision and efficiency are crucial for achieving optimal performance on the water. Central to this is the understanding of how various components come together to form the mechanisms that power boats. This system is a complex arrangement of mechanical elements, each working in harmony to ensure smooth operation and control.

These mechanisms are responsible for converting engine power into thrust, allowing vessels to glide through water effortlessly. Knowing the layout of these components is essential for maintenance, repairs, or upgrades, as each part plays a vital role in the overall functionality.

In this guide, we’ll explore the intricate design of propulsion units, breaking down the individual elements that contribute to their reliable operation. By the end, you’ll gain a deeper appreciation for the craftsmanship involved in

Key Components of Mercury Outdrive Systems

In propulsion systems, several crucial elements work in tandem to ensure smooth and efficient performance. These components are responsible for delivering power, optimizing handling, and ensuring long-term durability under various conditions.

Propeller and Drive Shaft

The propeller is vital for transforming the rotational force into forward motion. It is directly connected to the drive shaft, which transmits power from the engine to the propeller, ensuring effective propulsion. The size and design of the propeller play a crucial role in determining speed and control.

- Propeller Blades: Responsible for slicing through water to generate thrust.

- Drive Shaft: A strong, durable link between the engine and the propeller, ensuring consistent power transmission.

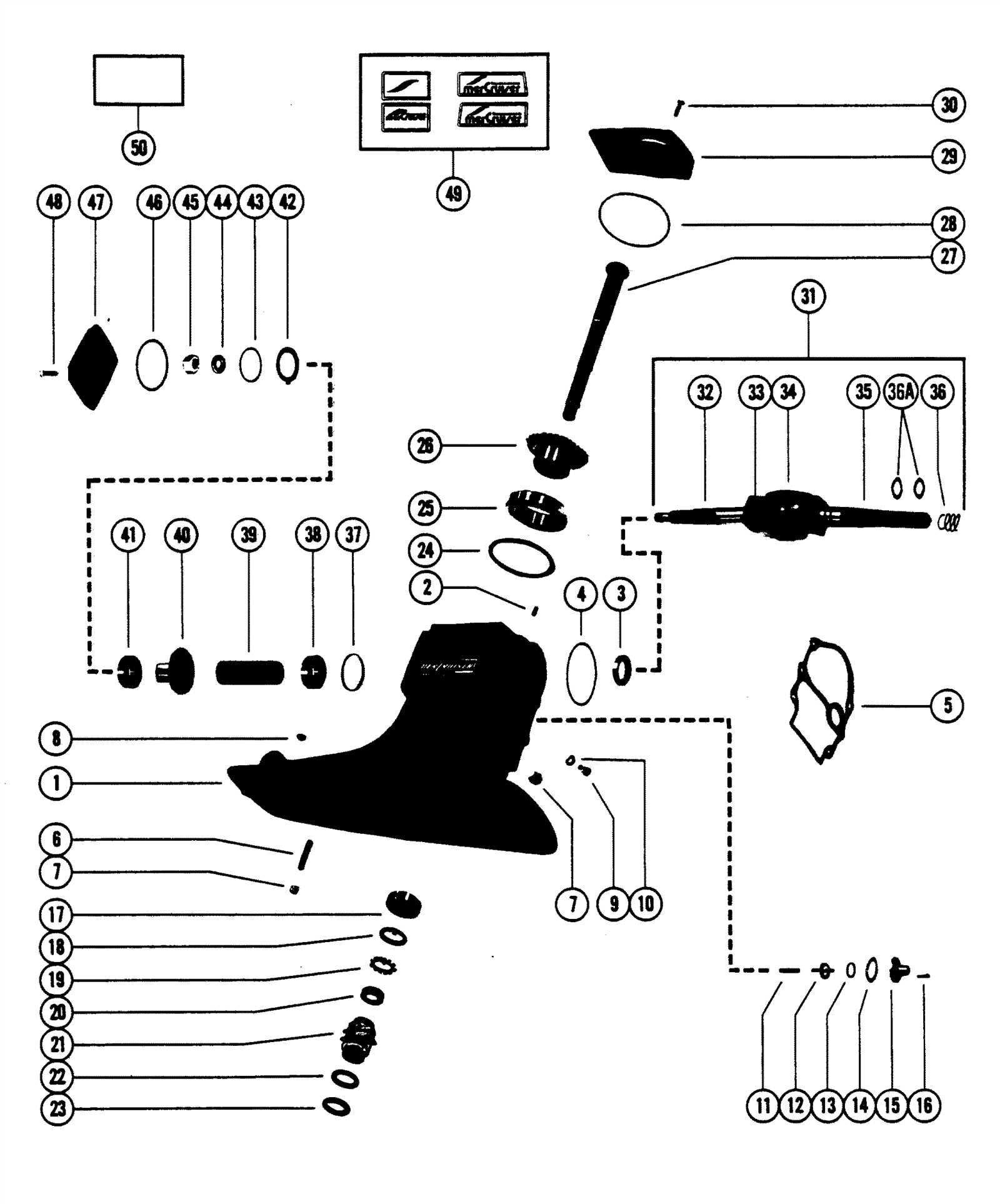

- O-rings: Versatile and widely used, these are designed to prevent fluid leakage in both static and dynamic applications.

- Oil seals: Often used in rotating components, they ensure oil containment and prevent dirt ingress.

- Gasket seals: Found in stationary applications,

Maintaining the U-Joint and Gimbal Bearings

Proper care of critical components is essential for ensuring smooth operation and preventing long-term damage. Regular maintenance helps extend the lifespan of these key mechanical parts, which play a pivotal role in the overall performance of your system. Attention to lubrication, alignment, and wear monitoring can significantly enhance efficiency and prevent costly repairs.

Lubrication and Inspection

Routine lubrication is vital to reduce friction and wear. Checking the seals around the joint and bearings is equally important, as any sign of cracking or deterioration can lead to leakage and corrosion. It’s advisable to inspect these elements at regular intervals to avoid any potential failure.

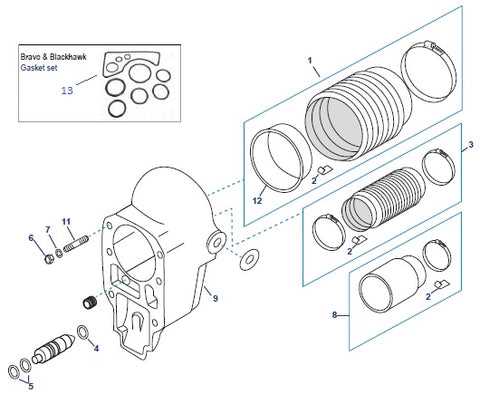

Examining the Water Pump Assembly

The water pump assembly is a crucial component in marine propulsion systems, playing a vital role in cooling and maintaining optimal operating temperatures. Understanding its structure and functionality can enhance maintenance and ensure longevity.

This assembly typically consists of several key elements, each contributing to the overall performance:

- Housing: This outer shell encases the internal mechanisms and helps direct water flow.

- Impeller: A rotating component that moves water through the system, critical for generating pressure.

- Seal: Essential for preventing leaks and ensuring that water flows efficiently through the pump.

- Wear Plate: Provides a protective surface against wear caused by water flow, prolonging the lifespan of the assembly.

Regular inspection and maintenance of the water pump assembly can prevent overheating and potential damage. Here are some recommended practices:

- Check for leaks around the housing and seals.

- Inspect the impeller for wear or damage.

- Ensure that the wear plate is intact and shows no significant signs of deterioration.

- Clean any debris from the intake and discharge areas to promote optimal water flow.

By paying attention to these components and conducting routine checks, boat owners can maintain the efficiency and reliability of their marine engines.

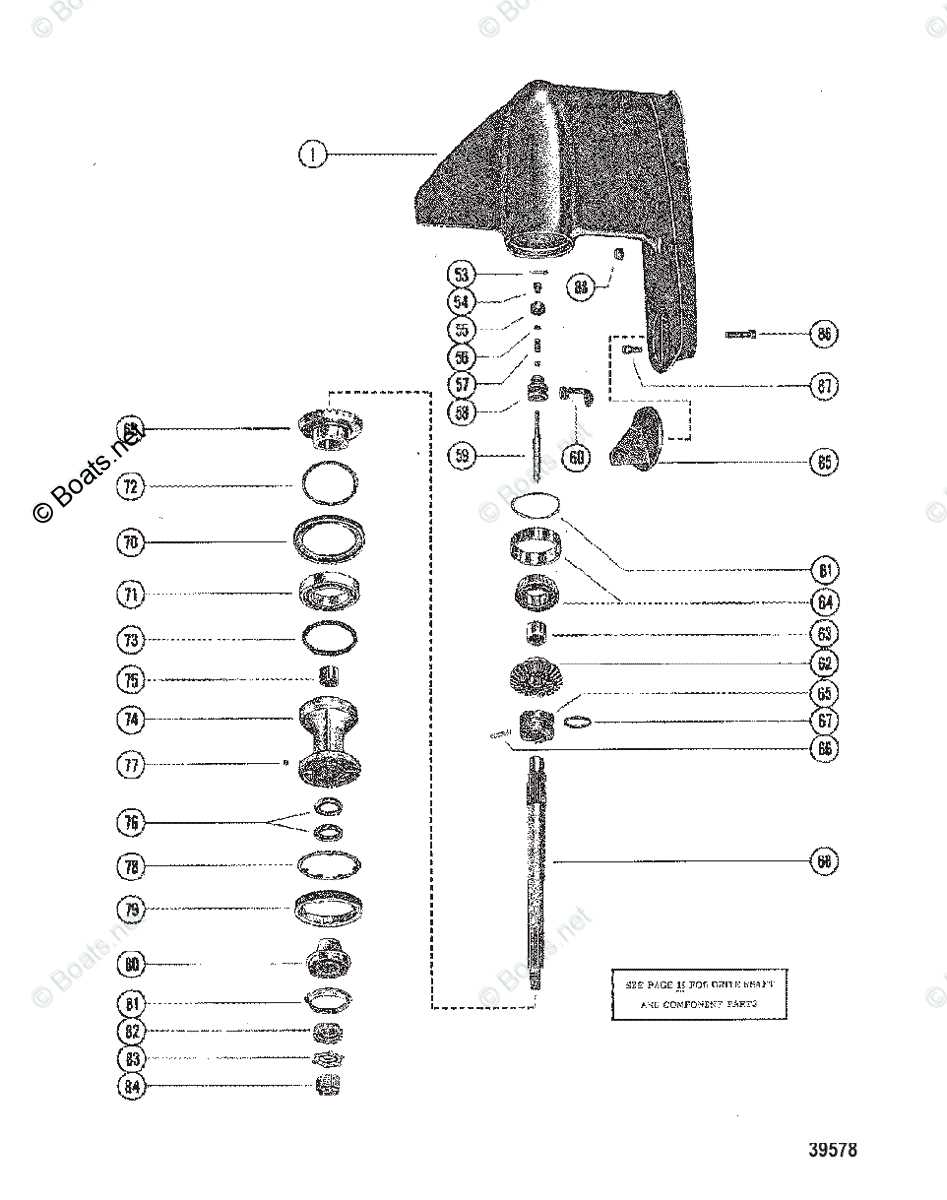

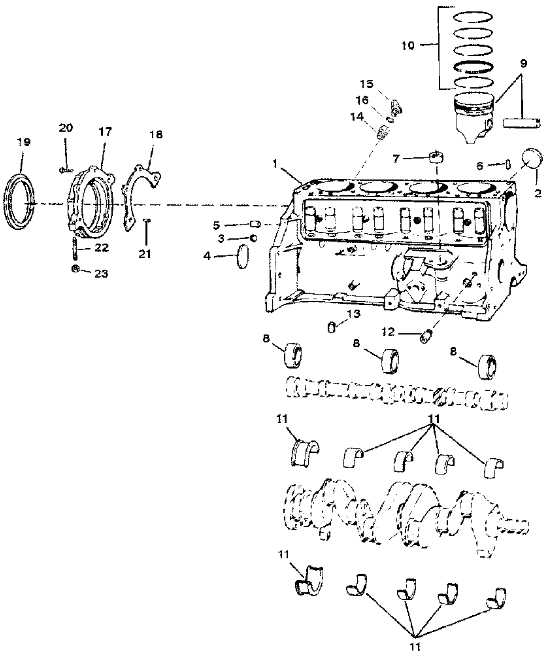

Inspecting the Driveshaft and Associated Parts

Thorough examination of the driveshaft and its related components is crucial for maintaining optimal performance and ensuring safe operation of your vessel. This process involves checking for wear, damage, and proper alignment to prevent potential issues during use. Understanding how each component interacts can significantly enhance your maintenance efforts and extend the lifespan of the system.

Key Components to Examine

- Universal Joints: Inspect for rust, wear, and proper lubrication.

- Yokes: Look for cracks or signs of excessive wear.

- Bearings: Ensure they are functioning smoothly without any unusual noises.

- Couplings: Check for secure connections and signs of deterioration.

Inspection Steps

- Begin by visually inspecting the entire assembly for obvious signs of damage.

- Rotate the driveshaft manually to feel for any irregularities or binding.

- Use a torque wrench to ensure all fasteners are tightened to the manufacturer’s specifications.

- Check alignment by measuring the distance between the driveshaft and the housing at multiple points.

- Lubricate all moving parts as necessary to ensure smooth operation.

The Importance of Trim Cylinder Operation

The trim cylinder is a crucial component in marine propulsion systems, playing a significant role in the overall performance and handling of watercraft. Its primary function is to adjust the angle of the drive unit, allowing for optimal positioning in various water conditions. This adjustment enhances maneuverability, fuel efficiency, and the overall safety of the vessel.

Benefits of Proper Trim Cylinder Functionality

- Improved Performance: Correctly functioning trim cylinders ensure that the drive unit maintains the ideal angle, promoting better speed and acceleration.

- Enhanced Fuel Efficiency: By optimizing the angle, the engine operates more efficiently, reducing fuel consumption during travel.

- Increased Stability: Proper trim adjustments help maintain stability and control, especially in rough water, contributing to a safer boating experience.

Maintenance Considerations

- Regularly inspect the trim cylinder for signs of wear or damage.

- Ensure hydraulic fluid levels are adequate to allow for smooth operation.

- Check for any leaks or corrosion that could affect functionality.

Proper Lubrication Techniques for Outdrive Parts

Ensuring optimal performance of marine propulsion systems requires diligent attention to lubrication. Adequate lubrication minimizes friction, reduces wear, and extends the lifespan of essential components. Understanding effective techniques can significantly enhance the reliability and functionality of these systems.

Key Considerations for Lubrication

- Type of Lubricant: Selecting the appropriate lubricant is crucial. Use high-quality marine-grade products designed for underwater applications.

- Application Frequency: Regularly scheduled maintenance checks should dictate how often lubrication is applied. Consistency is key.

- Environmental Conditions: Consider the operating environment, including water temperature and salinity, as they can affect lubricant performance.

Steps for Effective Lubrication

- Identify all necessary lubrication points based on manufacturer recommendations.

- Clean the areas thoroughly to remove any debris or old lubricant before applying new material.

- Apply the lubricant evenly, ensuring complete coverage of moving parts.

- Monitor for leaks or any signs of wear after lubrication, and adjust maintenance schedules as needed.

By adhering to these techniques, marine enthusiasts can maintain their propulsion systems efficiently, ensuring smooth operation and longevity.

Common Signs of Outdrive Wear and Tear

Regular maintenance and vigilance are essential to ensure the longevity of your vessel’s propulsion system. Over time, various indicators may suggest that components have begun to deteriorate, impacting performance and reliability. Recognizing these signs early can help prevent further damage and costly repairs.

Indicator Description Unusual Noises Grinding, whining, or clunking sounds during operation may indicate mechanical issues or worn parts. Vibration Excessive shaking or vibrations while the engine is running could signal misalignment or imbalance in the system. Oil Leaks Any signs of fluid leakage around seals or gaskets should be addressed promptly to prevent internal damage. Decreased Performance Notable drops in speed, acceleration, or responsiveness may suggest wear and could impact maneuverability. Corrosion Visible rust or deterioration on metal surfaces can compromise structural integrity and efficiency. Upgrading Key Components for Better Performance

Enhancing the efficiency and functionality of your marine propulsion system can significantly improve your overall experience on the water. Focusing on crucial elements can lead to notable advancements in speed, handling, and fuel economy. This section will delve into some vital upgrades that can transform your vessel’s performance, making it more responsive and enjoyable to operate.

Choosing the Right Propeller

One of the most impactful modifications involves selecting an appropriate propeller. Upgrading to a propeller that matches your specific boating needs can enhance thrust and reduce drag, resulting in improved acceleration and top speed. Factors such as pitch, diameter, and material play critical roles in determining the optimal propeller for your setup.

Improving the Trim System

Another essential upgrade is enhancing the trim mechanism. A more advanced trim system allows for finer adjustments, optimizing the angle of the drive unit relative to the water. This optimization not only boosts speed but also enhances fuel efficiency and overall handling, providing a smoother ride in various conditions.

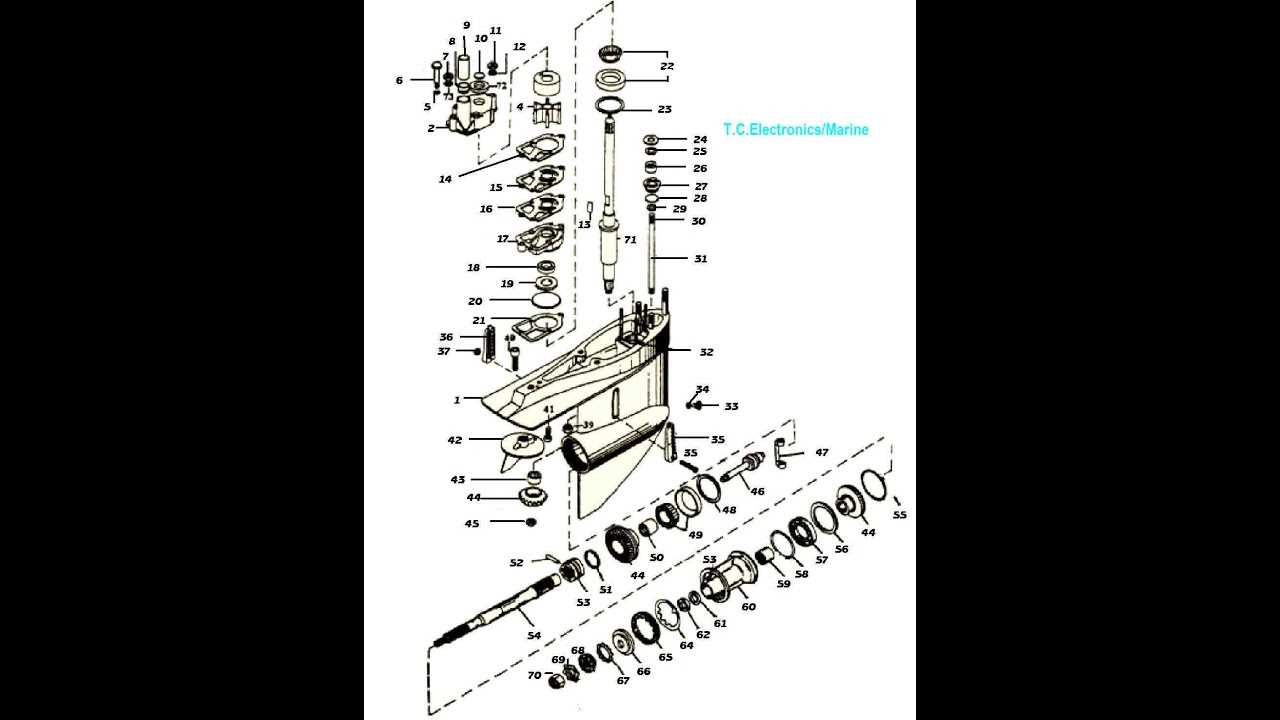

Exploring the Function of Propeller Assembly

The propeller system plays a crucial role in ensuring the movement and efficiency of the entire vessel. It transforms the rotational force into thrust, allowing for smooth navigation across various water conditions. The design and mechanics behind this assembly directly impact the overall performance, making it a critical element in marine operations.

Key Components Involved in Propeller Mechanism

The propeller mechanism consists of multiple integrated parts that work in unison. From the blades to the central hub, each component is engineered to maximize speed and stability. The blade shape, in particular, influences the flow of water and the resulting thrust, which in turn affects maneuverability and fuel efficiency.

Enhancing Performance through Proper Maintenance

To ensure optimal functionality, regular maintenance

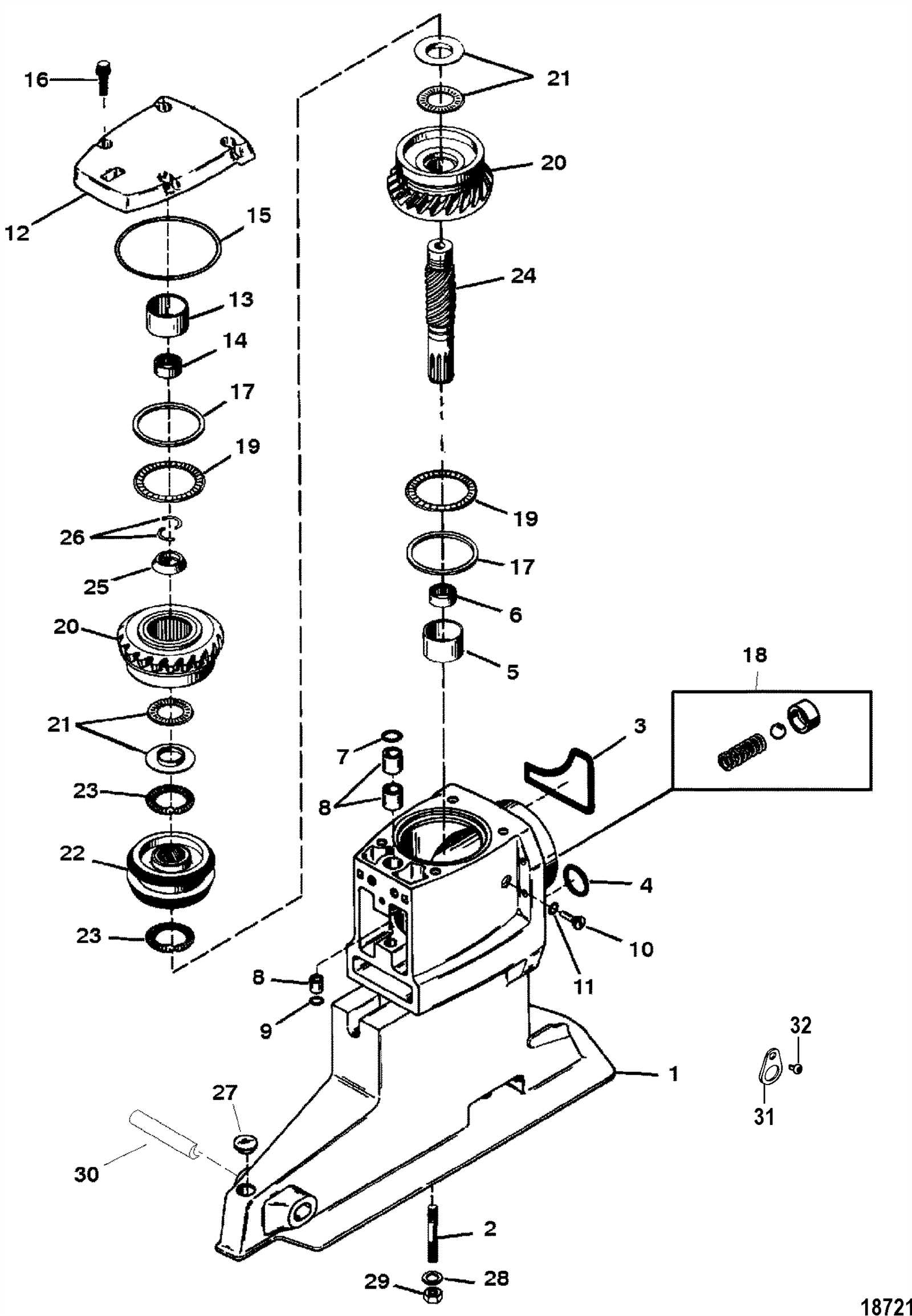

Understanding the Role of Gearcase Housing

The gearcase housing serves as a critical component in the operation of any propulsion system, providing a protective enclosure for the intricate mechanical elements within. Its primary function is to maintain the structural integrity of the system while safeguarding internal parts from environmental factors such as water and debris.

Protecting Internal Components

The housing acts as a shield, ensuring that crucial moving mechanisms remain unaffected by harsh external conditions. This protection is vital for the system’s durability and long-term performance, as exposure to water and contaminants can cause premature wear and damage.

Ensuring Proper Alignment

Another essential role of the gearcase housing is to guarantee the correct alignment of rotating parts. Misalignment can lead to inefficiencies and increased strain on mechanical components, ultimately reducing the overall efficiency and lifespan of the system.

Identifying Critical Seals and Gaskets

Seals and gaskets play a vital role in ensuring the proper functioning of mechanical systems. These components prevent leakage, maintain pressure, and protect internal parts from external contaminants. Identifying the right seals and gaskets is essential for maintaining system efficiency and avoiding costly repairs.