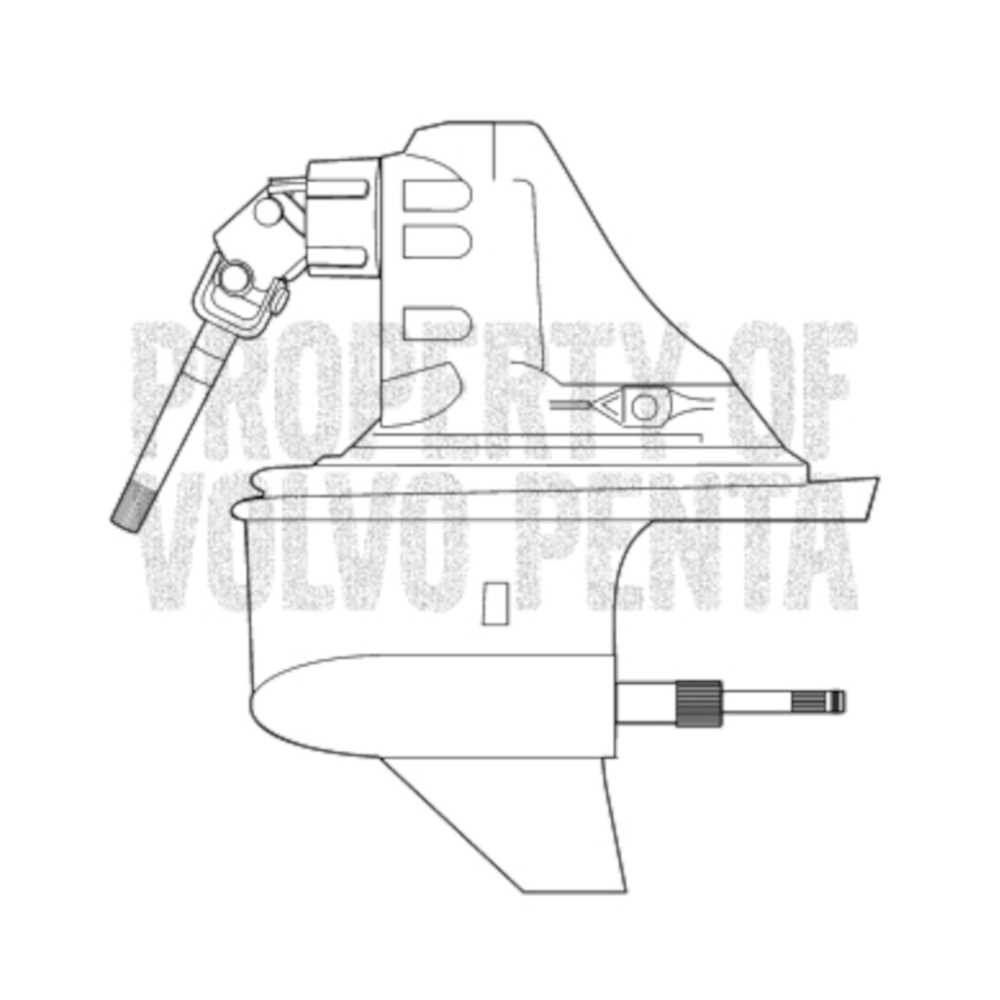

Exploring the intricacies of marine propulsion systems is essential for anyone involved in boating or marine engineering. These mechanisms play a crucial role in how vessels navigate through water, impacting performance and efficiency.

To effectively maintain and repair these systems, it is vital to have a comprehensive grasp of their various elements. Each component works in harmony, contributing to the overall functionality and reliability of the marine vessel.

In this section, we will delve into the essential components of drive systems, highlighting their configurations and interactions. Gaining insight into these assemblies can lead to improved maintenance practices and ultimately enhance the longevity of your marine craft.

Understanding Omc Outdrive Components

Grasping the essential elements of marine propulsion systems is crucial for effective maintenance and performance optimization. These mechanisms play a vital role in converting engine power into forward motion, ensuring smooth navigation across water. Familiarity with each component enhances troubleshooting and repair efficiency, ultimately prolonging the lifespan of the entire system.

Main Elements

Key components include the transmission unit, which facilitates gear shifting, and the housing that protects internal mechanisms from water intrusion. Additionally, seals and bearings are integral to reducing friction and ensuring durability under demanding conditions.

Understanding how these parts interact allows for better diagnostic skills and proactive upkeep. Regular inspections and timely replacements can prevent costly breakdowns, ensuring reliable operation and enhanced safety on the water.

Key Features of Omc Outdrive

This section highlights the essential characteristics of a marine propulsion system designed for enhanced performance and durability. Understanding these features can significantly influence maintenance and operational efficiency.

Durability and Reliability

- Corrosion-resistant materials for longevity.

- Robust construction to withstand harsh marine environments.

- Proven track record for reliability in various conditions.

Performance Enhancements

- Streamlined design for improved hydrodynamics.

- Efficient gear ratios for optimal speed and torque.

- Advanced cooling systems to prevent overheating.

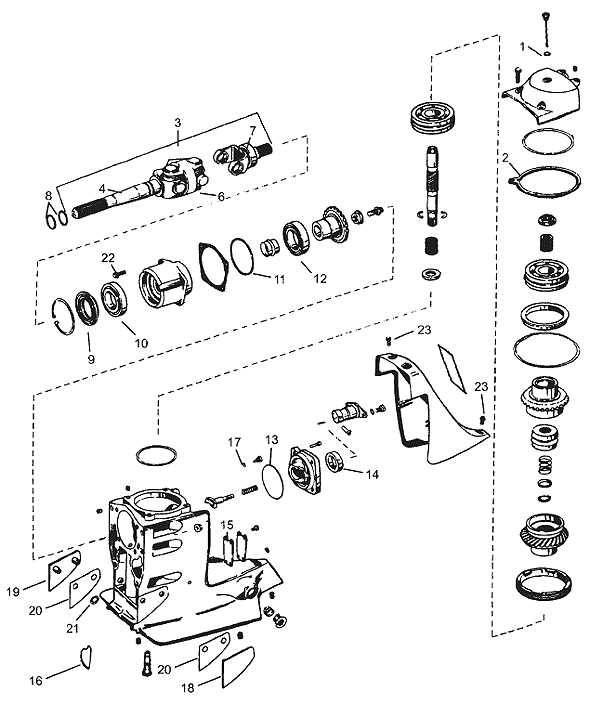

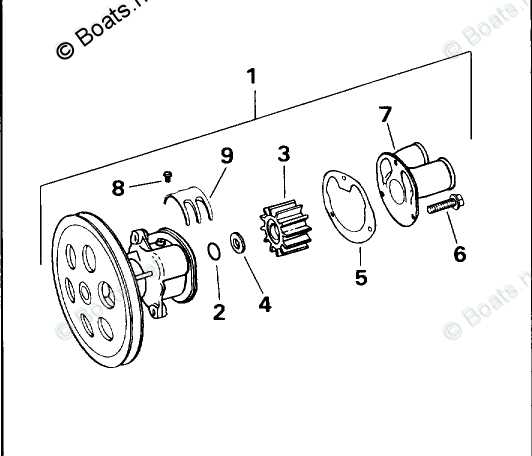

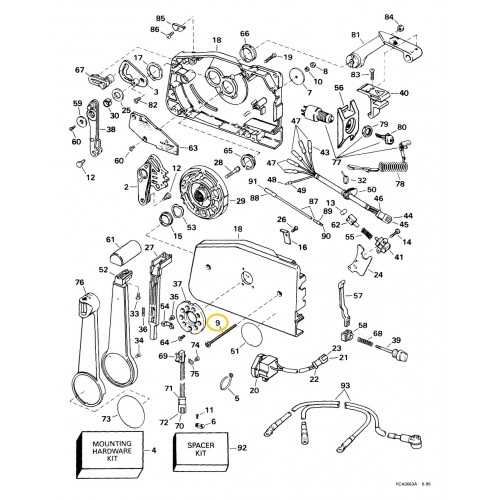

Importance of Accurate Parts Diagrams

Understanding the intricacies of mechanical components is crucial for effective maintenance and repair. Precise illustrations serve as vital resources, enabling users to identify each element and its function. Clarity in these representations helps in avoiding costly errors and ensuring seamless assembly.

Accurate visual guides not only facilitate a smoother workflow but also enhance the overall efficiency of repairs. When technicians have access to detailed depictions, they can delve into their tasks with confidence, reducing downtime and frustration. Furthermore, these representations are essential for sourcing the correct replacements, ensuring compatibility and longevity of the equipment.

Ultimately, reliable visual references play a key role in fostering a thorough understanding of mechanical systems, empowering users to tackle challenges with greater ease and precision. Investing time in familiarizing oneself with these tools can significantly impact the success of maintenance endeavors.

Common Issues with Outdrive Parts

Understanding the frequent challenges faced by marine propulsion systems can significantly enhance their performance and longevity. Identifying typical complications early can prevent costly repairs and ensure smooth operation.

Mechanical Failures

Mechanical issues often arise from wear and tear over time. These failures can lead to reduced efficiency and can impact overall handling. Regular inspections are crucial.

Corrosion and Damage

Exposure to saltwater can cause significant degradation. It’s essential to check for signs of rust or other forms of damage regularly to maintain optimal functionality.

| Issue | Symptoms | Solution |

|---|---|---|

| Wear on Components | Noisy operation, vibrations | Regular maintenance, replacement |

| Corrosion | Rust spots, flaking | Protective coatings, cleaning |

| Seal Failures | Leaks, reduced pressure | Seal replacement, inspection |

How to Read Outdrive Diagrams

Understanding technical illustrations related to marine propulsion systems can significantly enhance your maintenance and repair skills. These visuals provide crucial insights into the components and their interactions, enabling you to identify issues and carry out effective solutions. Grasping how to interpret these schematics is essential for anyone involved in marine mechanics.

Key Elements of Technical Illustrations

When examining a schematic, pay attention to the following features:

- Labels: Components are often labeled with specific names or numbers, which help in identifying parts accurately.

- Connections: Arrows or lines indicate how different elements are interconnected, revealing the flow of operations.

- Legends: Many illustrations include a legend that explains symbols used in the schematic, providing clarity on various components.

Steps to Analyze the Illustration

- Familiarize Yourself: Start by understanding the overall layout of the system. Identify major components and their general locations.

- Follow the Flow: Trace the connections from one part to another. This will help you understand how the system operates as a whole.

- Consult References: Use manufacturer manuals or online resources for detailed descriptions of each part and its function.

- Note Common Issues: Familiarize yourself with common problems associated with specific components, as depicted in the illustration.

By mastering these skills, you will enhance your ability to troubleshoot and maintain marine systems effectively, ensuring smoother operation and longevity of your vessel.

Essential Tools for Repairing Outdrives

When it comes to maintaining and fixing marine propulsion systems, having the right set of tools is crucial for ensuring efficiency and safety. Each component requires specific instruments to address various tasks, from disassembly to reassembly, making the selection of tools an essential part of the repair process.

Basic Hand Tools

Start with a reliable collection of hand tools. Wrenches and screwdrivers are indispensable for loosening and tightening bolts and screws. A torque wrench is also vital for applying the correct force, which prevents damage to sensitive components. Don’t forget about pliers and a hammer, as they can assist in a variety of tasks during repairs.

Specialized Equipment

In addition to standard tools, certain specialized equipment is necessary for comprehensive maintenance. A mechanical gauge helps in checking alignment and measuring various parameters accurately. For those intricate repairs, a lift or hoist can provide the necessary support and accessibility to work safely and effectively. Investing in quality tools will not only simplify the repair process but also enhance the longevity of your marine systems.

Step-by-Step Assembly Guide

This section provides a detailed guide to assembling the key components of a marine propulsion system. Each step is crucial for ensuring proper functionality and longevity. Follow the instructions carefully to achieve optimal results.

Preparation

Before starting the assembly, gather all necessary tools and components. A well-organized workspace will facilitate a smoother process.

- Gather all components required for assembly.

- Ensure that all tools are in good condition and easily accessible.

- Review the assembly instructions thoroughly.

Assembly Steps

- Assemble the main housing:

- Align the parts as indicated in the provided instructions.

- Secure the components using appropriate fasteners.

- Install the drive unit:

- Position the drive unit within the main housing.

- Ensure that all connections are tight and properly sealed.

- Attach the supporting structures:

- Carefully align and attach the necessary brackets and supports.

- Double-check all connections for stability.

- Final inspection:

- Review all components to ensure they are correctly installed.

- Perform a thorough check for any loose fittings or potential issues.

Once completed, the assembly should be functional and ready for testing. Follow any additional guidelines for operational checks to ensure everything performs as expected.

Maintenance Tips for Longevity

Ensuring the durability of your marine equipment requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of vital components. By following a few essential practices, you can safeguard your investment and enjoy smoother experiences on the water.

Start with routine inspections, checking for any signs of wear or corrosion. Cleanliness is paramount; remove debris and salt build-up to prevent damage. Lubrication of moving parts minimizes friction, enhancing efficiency. Additionally, adhere to the manufacturer’s guidelines regarding fluid changes and component replacements. Lastly, store equipment in a dry, protected environment during off-seasons to prevent deterioration.

Identifying Outdrive Part Numbers

Understanding component identifiers is essential for effective maintenance and repair. Each element within the propulsion system has a unique reference that simplifies sourcing and replacement. Familiarizing yourself with these identifiers can save time and ensure the right pieces are acquired.

Step 1: Begin by consulting the manufacturer’s documentation, which often contains a comprehensive list of identifiers alongside detailed descriptions.

Step 2: Visual inspections are crucial. Check for any labels or stamped numbers on the components, as these often reveal the specific identifiers needed.

Step 3: Online forums and support communities can be valuable resources. Engaging with fellow enthusiasts allows for the sharing of knowledge regarding identifier patterns and common issues.

Step 4: Always cross-reference numbers from different sources to ensure accuracy. A slight variation in the identifier can lead to acquiring the wrong component.

Upgrades for Omc Outdrive Efficiency

Enhancing the performance of your marine propulsion system can lead to significant improvements in speed and fuel consumption. By implementing targeted modifications, boaters can experience smoother operation and increased durability. This section explores several effective upgrades that can maximize the efficiency of your vessel’s drive mechanism.

Improved Propeller Design

Upgrading to a more advanced propeller can drastically enhance thrust and reduce drag. Consider options that feature better blade geometry for optimized water flow. This not only improves acceleration but also minimizes vibrations, resulting in a more enjoyable ride.

Maintenance and Lubrication

Regular upkeep and quality lubricants are crucial for maintaining optimal functionality. Implementing synthetic oils can decrease friction and heat buildup, ensuring smoother operation. Establish a consistent maintenance routine to monitor wear and replace components as necessary to prolong system life.

Comparing Outdrive Models and Designs

This section explores the various designs and configurations found in marine propulsion systems, highlighting their distinct characteristics and performance metrics. By examining different models, we can better understand how specific features impact overall efficiency, handling, and maintenance requirements.

Key Design Elements

When analyzing these systems, several fundamental elements emerge as crucial. Propeller alignment plays a significant role in performance, affecting speed and fuel consumption. Additionally, materials used in construction can influence durability and resistance to corrosion, which is vital for longevity in marine environments.

Performance Considerations

Different configurations offer unique advantages. For instance, some designs prioritize stability and maneuverability, making them ideal for smaller vessels, while others focus on speed and power, suitable for larger crafts. Understanding these differences enables boat owners to select the most suitable option for their specific needs.

Safety Precautions During Repairs

When undertaking maintenance or repairs on marine equipment, ensuring personal safety and the protection of the machinery is paramount. Following established safety protocols minimizes the risk of accidents and enhances the overall effectiveness of the repair process. It is essential to be aware of potential hazards and to implement measures that safeguard both the individual and the equipment involved.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) to shield yourself from potential injuries. This includes gloves, goggles, and steel-toed boots. These items help prevent cuts, chemical exposure, and injuries from falling objects. Furthermore, utilizing ear protection can be vital in noisy environments where loud machinery operates.

Workspace Safety

Maintaining a clean and organized workspace is crucial for safety. Ensure that tools and materials are stored properly to prevent tripping hazards. Adequate ventilation is also necessary, especially when working with chemicals or solvents. Regularly check for any signs of leaks or faulty equipment, and always have a fire extinguisher readily accessible.

Resources for Further Learning

To deepen your understanding of marine propulsion systems and their components, various resources are available that cater to different learning styles. Exploring these materials can enhance your knowledge and skills.

- Books: Seek out titles focused on marine engineering and maintenance.

- Online Courses: Platforms like Coursera and Udemy offer courses on boat mechanics and repair.

- Forums: Join online communities where enthusiasts share insights and troubleshooting tips.

- YouTube Channels: Follow channels dedicated to marine repairs and demonstrations for visual learning.

- Manufacturer Websites: Many companies provide manuals and technical documents for their products.

Utilizing these resources can provide valuable information and practical skills for anyone interested in this field.