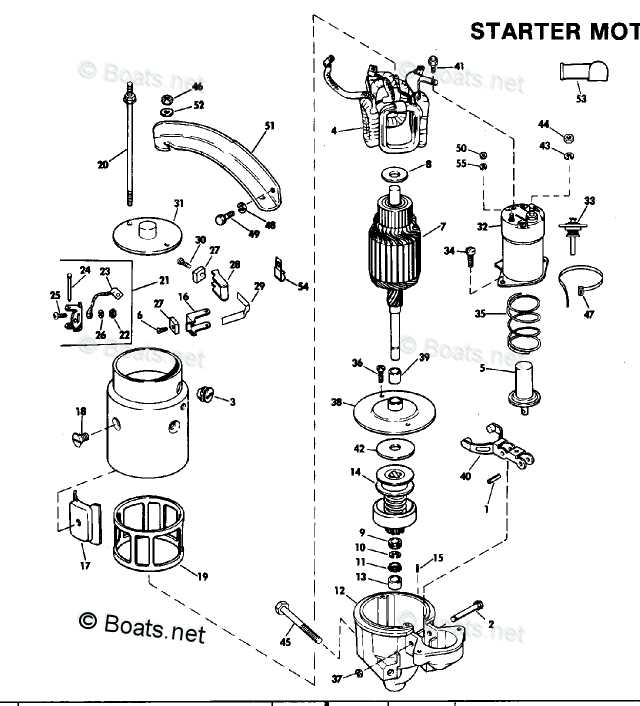

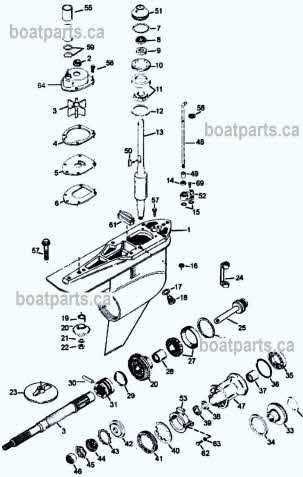

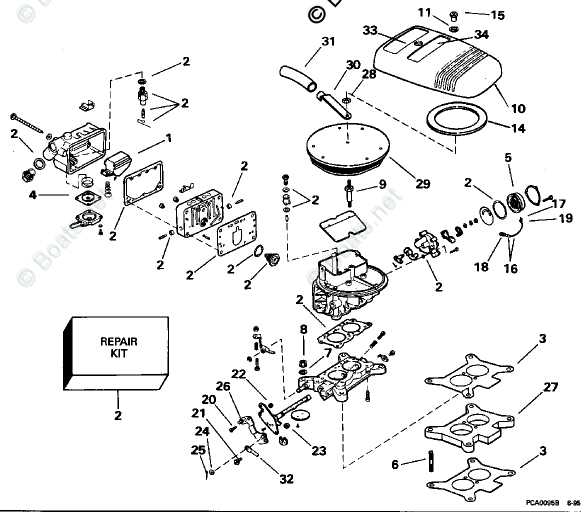

In the world of maritime mechanics, having a clear visual representation of various engine elements is crucial for maintenance and repair. This section delves into the intricacies of these components, allowing enthusiasts and professionals alike to grasp the connections and functions that drive performance on the water.

By exploring a detailed schematic, individuals can better appreciate how each part works in unison. This not only aids in troubleshooting but also enhances overall understanding of the engine’s operational capabilities. A comprehensive overview empowers users to identify potential issues and facilitates effective interventions when necessary.

Whether you are an experienced technician or a boating novice, familiarity with these illustrations can significantly improve your ability to manage and optimize your marine engine. Gaining insights into the arrangement and purpose of each element will enhance your confidence in handling various tasks related to engine upkeep.

Key Components of Omc Sterndrive

This section will delve into the essential elements that play a vital role in the operation of the marine propulsion system. Understanding these crucial components can enhance performance and maintenance of your vessel.

- Engine Coupling: This component connects the engine to the drive unit, ensuring smooth power transfer.

- Drive Shaft: A critical part that transmits rotational force from the engine to the propeller.

- Gear Housing: Houses the gears that facilitate speed and torque adjustments for optimal navigation.

- Propeller: The rotating blade that propels the vessel through water by converting engine power into thrust.

- Trim Tabs: Adjustable surfaces that help stabilize and control the boat’s orientation in the water.

Each of these components works in harmony to ensure effective operation, making it crucial to understand their functions and maintenance requirements.

How to Read Parts Diagrams

Understanding assembly illustrations is essential for effective maintenance and repair of mechanical systems. These visuals provide a detailed representation of components and their arrangement, enabling users to identify specific elements and comprehend how they fit together. Mastering the interpretation of these illustrations will enhance your ability to troubleshoot and procure necessary items efficiently.

Identifying Components

The first step in decoding these visuals is to familiarize yourself with the symbols and labels used to represent various elements. Each part will typically be numbered or marked in some way, corresponding to a legend or list that describes its function and specifications. Pay attention to any notes or annotations that may provide additional context or highlight important details about assembly or installation.

Understanding Relationships

Next, observe how the components interact with one another. Many illustrations will depict connections, such as how one piece attaches to another, which can be crucial for reassembly. Look for arrows or lines that indicate movement or flow, as these can help clarify the operational dynamics of the system. This understanding is vital for ensuring that repairs or modifications are made accurately.

Common Issues with Sterndrive Parts

Many boat owners encounter various challenges related to the mechanical components of their vessels. Understanding these common problems can lead to better maintenance and improved performance. Below are some prevalent issues faced by users of these marine systems.

- Overheating: Excessive heat can cause severe damage, often resulting from inadequate coolant flow or blocked passages.

- Vibration: Unusual vibrations may indicate misalignment or wear in the drive assembly, leading to potential failures if not addressed.

- Leakage: Fluid leaks from seals or gaskets can compromise performance and safety, necessitating prompt attention.

- Gear Failure: Worn or damaged gears can lead to reduced power transfer, affecting the overall efficiency of the vessel.

- Corrosion: Exposure to saltwater can result in corrosion of various components, emphasizing the importance of regular inspections and protective measures.

Addressing these common challenges promptly can help extend the lifespan of the mechanical system and ensure a safer boating experience.

Maintenance Tips for Longevity

Ensuring the durability of your watercraft requires consistent care and attention. Proper maintenance not only enhances performance but also extends the lifespan of various components. Below are key practices to follow for optimal upkeep.

Regular Inspections

- Check all fluid levels periodically, including oil and coolant.

- Inspect for any signs of wear or damage on essential parts.

- Ensure that all connections and fittings are secure and free from corrosion.

Seasonal Preparations

- Before storing, thoroughly clean the vessel to prevent debris buildup.

- Consider winterizing systems to protect against freezing conditions.

- Run the engine briefly after maintenance to circulate fluids.

Identifying Replacement Parts Easily

When it comes to maintaining marine equipment, recognizing the right components for replacement can be a straightforward process with the right approach. A comprehensive understanding of the machinery involved, along with effective resources, can simplify the task of locating and identifying necessary substitutes.

Utilizing Visual References

One of the most effective methods to identify needed components is by consulting visual references. Diagrams and charts that illustrate various elements can provide clarity and help in quickly locating specific items. By having a visual guide, it becomes easier to understand how parts fit together and which ones may require attention.

Leveraging Online Resources

The internet is a treasure trove of information that can assist in pinpointing required replacements. Numerous websites and forums dedicated to marine equipment offer insights, reviews, and advice on component identification. Engaging with these online communities can also provide valuable tips from experienced users who have faced similar challenges.

Understanding Sterndrive Functionality

The mechanism that connects a vessel’s engine to its propulsion system plays a crucial role in marine navigation. This system allows for efficient power transfer, enabling the craft to move smoothly through the water. Understanding how this assembly operates is essential for both maintenance and performance enhancement.

Key Components

At the heart of this assembly are various components that work in unison to facilitate movement. The engine generates power, which is transmitted to a drive unit that adjusts the angle and thrust of the propulsion device. This configuration is vital for maneuverability, especially in challenging aquatic environments.

Maintenance Considerations

Regular upkeep of this system is imperative for optimal functioning. It involves inspecting and replacing essential elements to prevent wear and tear. A well-maintained system not only enhances performance but also prolongs the lifespan of the entire assembly.

Understanding the intricacies of this propulsion system contributes to better operational knowledge and improved safety on the water.

Best Practices for Installation

Ensuring a smooth and effective setup process is crucial for optimal performance and longevity of marine equipment. Following established guidelines can significantly reduce the likelihood of issues arising post-installation.

Before beginning the installation, gather all necessary tools and components. This preparation will help streamline the process and minimize interruptions. It is also advisable to read through any accompanying manuals to familiarize yourself with specific requirements and recommendations.

During installation, pay close attention to alignment and securing methods. Properly aligning components can prevent misfits and enhance functionality. Additionally, ensure all fasteners are tightened to the recommended torque specifications to avoid any potential loosening during operation.

Once the setup is complete, conduct thorough checks to verify everything is in place and functioning correctly. Testing the system before full deployment can help identify any issues that need addressing, ensuring a safe and efficient experience on the water.

Essential Tools for Repairs

When it comes to maintaining and fixing marine propulsion systems, having the right set of instruments is crucial. These tools not only streamline the repair process but also ensure that each task is performed efficiently and effectively. A well-equipped toolkit can make the difference between a smooth repair job and a frustrating experience.

Start with basic hand tools such as wrenches, screwdrivers, and pliers. These items are fundamental for loosening or tightening components. Additionally, a reliable socket set can provide the versatility needed for various bolt sizes, while a torque wrench ensures that fasteners are secured to the manufacturer’s specifications.

Power tools, like drills and impact wrenches, can significantly reduce the time spent on repairs. They are particularly helpful when dealing with stubborn or rusted bolts. Furthermore, a quality multimeter is essential for diagnosing electrical issues, allowing for precise troubleshooting of wiring and connectivity problems.

Safety equipment should not be overlooked. Gloves, goggles, and masks protect you from potential hazards during repairs, ensuring a safe working environment. By investing in these essential tools, you will be well-prepared to tackle any maintenance challenge that comes your way.

Where to Find Quality Parts

When seeking reliable components for your marine propulsion system, it’s essential to explore various sources to ensure quality and compatibility. A well-informed choice can significantly enhance the performance and longevity of your vessel.

Trusted Retailers

Reputable dealers often provide a wide range of options, along with expert advice. Here are some advantages of purchasing from established retailers:

- Access to original equipment manufacturer (OEM) parts.

- Knowledgeable staff to assist with inquiries.

- Warranty offerings on products.

Online Marketplaces

The internet provides a plethora of platforms for sourcing components. Consider the following tips when shopping online:

- Check user reviews and ratings to gauge seller reliability.

- Look for return policies to ensure satisfaction with your purchase.

- Compare prices across different websites for the best deals.

Comparing Omc to Other Systems

This section delves into the differences and similarities between various marine propulsion systems, focusing on their design, functionality, and performance characteristics. Understanding these distinctions can help boat owners make informed decisions when selecting the right system for their needs.

Design Features

Different propulsion systems exhibit unique design elements that can significantly affect performance and maintenance requirements. For instance, some systems may feature integrated components that simplify installation and reduce potential failure points, while others may prioritize modular designs for easier repairs and upgrades.

Performance Comparison

The performance of various marine systems can vary widely based on their engineering and intended use. Factors such as fuel efficiency, speed, and torque delivery play crucial roles in determining which system best suits specific boating activities. Below is a comparison table highlighting key performance metrics across different systems.

| System Type | Fuel Efficiency | Maximum Speed | Torque Delivery |

|---|---|---|---|

| Type A | 30% better | 45 knots | High |

| Type B | 20% better | 40 knots | Medium |

| Type C | 15% better | 35 knots | Low |