In the realm of machinery, the precise arrangement of elements plays a crucial role in ensuring optimal performance and reliability. Familiarity with these configurations enables technicians and enthusiasts to diagnose issues more effectively and conduct maintenance with greater ease. By delving into the intricate relationships between various components, one can gain insights into the overall functionality of the system.

Technical illustrations serve as invaluable resources, providing clear visual representations that simplify the understanding of complex assemblies. These depictions highlight not only the individual pieces but also their interactions and connections within the broader mechanical framework. With an emphasis on clarity and detail, such resources facilitate better comprehension of the mechanisms at play.

Whether one is an experienced professional or a curious learner, having access to accurate schematics enhances the ability to troubleshoot and repair machinery. By engaging with these visual aids, individuals can cultivate a deeper appreciation for the engineering principles that underpin successful designs and operations. The importance of understanding these configurations cannot be overstated, as they are fundamental to achieving lasting functionality.

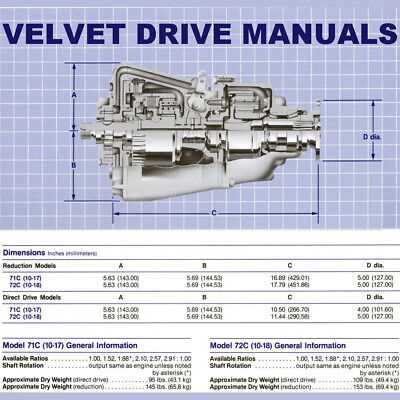

Overview of Velvet Drive 71C

This section delves into a specialized mechanism commonly utilized in marine applications, known for its reliable performance and efficiency. Designed to facilitate seamless power transfer, this unit is essential for enhancing the operation of various watercraft.

Key Features

- Durable construction materials for longevity

- Compact design that maximizes space

- Efficient torque management for optimal performance

- Versatile compatibility with multiple engine types

Applications

- Yachts and recreational boats

- Commercial vessels requiring robust transmission systems

- Sport fishing boats that demand reliable operation

- Workboats used in various industrial applications

This mechanism plays a vital role in ensuring smooth operation and enhancing overall vessel performance, making it a preferred choice among marine professionals.

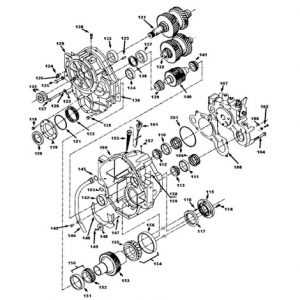

Key Components of the Transmission

The transmission system plays a crucial role in the overall functionality of a vehicle, ensuring that power generated by the engine is effectively converted and transferred to the wheels. Understanding the essential elements that make up this intricate system is vital for maintenance and performance optimization.

Main Gears and Shafts

At the heart of the transmission, the main gears and shafts are responsible for controlling the gear ratios, allowing the vehicle to accelerate smoothly and maintain speed. These components work together to manage the torque and speed delivered to the wheels, ensuring optimal performance across various driving conditions.

Clutch Mechanism

The clutch mechanism serves as a critical interface between the engine and the transmission. It allows for smooth engagement and disengagement, enabling the driver to change gears without jarring transitions. A well-functioning clutch is essential for maintaining seamless operation and enhancing the overall driving experience.

In summary, a solid grasp of these key components not only aids in troubleshooting but also enhances one’s ability to appreciate the engineering marvels of automotive technology.

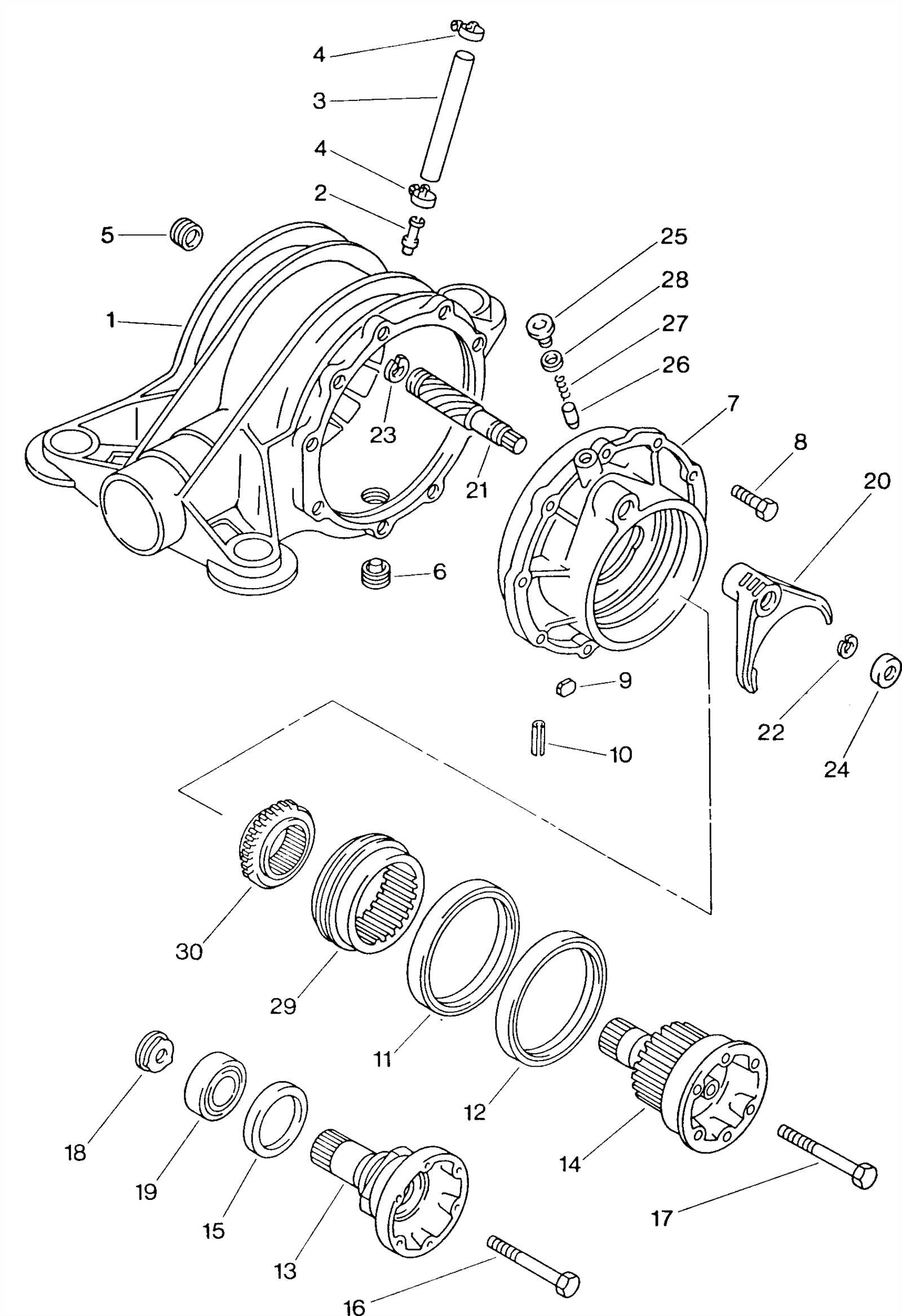

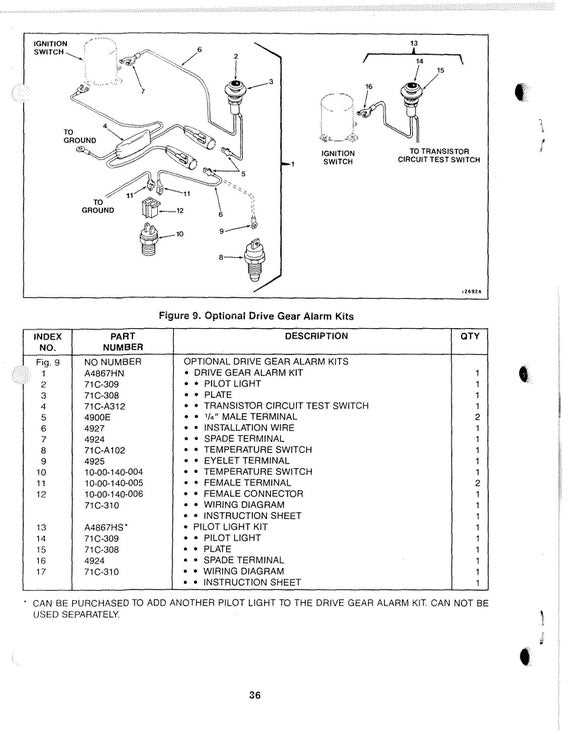

Understanding the Parts Diagram

Grasping the layout of mechanical components is crucial for effective maintenance and repair. This visual representation serves as a guide, illustrating the relationships and functions of each element within a system. By comprehending this overview, one can identify specific pieces and their roles, facilitating a smoother troubleshooting process.

Components Overview

Each segment of the illustration is labeled to indicate its corresponding function. This allows users to quickly locate the necessary parts when undertaking repairs or replacements. Familiarity with these labels can significantly enhance one’s ability to communicate issues effectively with professionals.

| Component Name | Description | Function |

|---|---|---|

| Element A | Main structure supporting the assembly | Provides stability and alignment |

| Element B | Connecting piece between components | Facilitates movement and energy transfer |

| Element C | Control mechanism | Regulates operation and performance |

Importance of Familiarization

Understanding the configuration not only aids in repairs but also enhances overall efficiency in operation. A clear grasp of how each piece interacts with others ensures that any adjustments or replacements can be made with confidence, minimizing downtime and improving functionality.

Common Issues with 71C Parts

When dealing with marine transmission components, users often encounter a variety of challenges that can affect performance and reliability. Understanding these common complications can help in maintaining and troubleshooting effectively.

- Seal Leaks: One of the most prevalent issues is the failure of seals, leading to fluid leaks. This can result in reduced lubrication and eventual damage to internal mechanisms.

- Worn Gears: Over time, gears can become worn due to friction and heat, affecting overall efficiency and functionality. Regular inspections can help identify wear early.

- Corrosion: Exposure to saltwater can lead to rust and corrosion of metal components. Using protective coatings can mitigate this problem.

- Alignment Issues: Improper alignment during installation can cause undue stress on components, leading to premature wear and failures.

Addressing these concerns proactively can extend the lifespan of the system and enhance overall performance. Regular maintenance and inspections are key to preventing these issues from escalating.

Maintenance Tips for Velvet Drive

Ensuring the longevity and efficiency of your transmission system requires regular upkeep and attention. Implementing a solid maintenance routine can prevent costly repairs and enhance performance. Below are some essential practices to keep your equipment in optimal condition.

Regular Fluid Checks

Monitoring fluid levels is crucial for maintaining proper operation. Ensure that the lubrication is at the recommended levels, and replace it according to the manufacturer’s guidelines. Contaminated or old fluid can lead to overheating and accelerated wear, so be vigilant in checking for discoloration or debris.

Visual Inspections

Conduct periodic visual inspections to identify any signs of wear or damage. Look for leaks, cracks, or unusual wear patterns on components. Early detection of issues can prevent more significant problems down the line. Additionally, inspect hoses and connections to ensure they are secure and in good condition.

By following these tips and maintaining a proactive approach, you can extend the life of your transmission and enhance its overall performance.

How to Identify Genuine Parts

Ensuring the authenticity of components is crucial for optimal performance and longevity of your equipment. Knowing how to distinguish original items from counterfeit or inferior substitutes can save you time and resources while enhancing the reliability of your machinery. This section outlines key factors to consider when assessing the authenticity of replacements.

When evaluating components, keep an eye out for specific indicators that signify quality and legitimacy. The following table summarizes essential features to help you in this process:

| Feature | What to Look For |

|---|---|

| Brand Markings | Check for clear and precise logos, trademarks, and serial numbers. |

| Packaging | Original items typically come in high-quality, tamper-proof packaging with consistent branding. |

| Material Quality | Examine the material for durability and finish; genuine components use superior materials. |

| Documentation | Reputable manufacturers provide manuals, warranties, and certifications for their products. |

| Supplier Reputation | Purchase from authorized dealers or well-known distributors with positive reviews. |

By familiarizing yourself with these characteristics, you can confidently navigate the market and ensure you acquire components that meet the highest standards of quality and performance.

Replacement Parts and Compatibility

When it comes to maintaining and repairing marine propulsion systems, understanding the components involved is essential for ensuring longevity and performance. Knowing which elements can be substituted and how they relate to one another can save time and money while enhancing operational efficiency.

Here are some key points to consider regarding compatibility and replacement:

- Original Equipment Manufacturer (OEM) vs. Aftermarket: OEM components are designed specifically for the system, while aftermarket options may offer cost savings but could vary in quality and fit.

- Interchangeability: Some components may be interchangeable with similar models or brands, but it’s crucial to verify specifications to avoid mismatches.

- Performance Implications: Using non-compatible components may affect overall performance, leading to potential mechanical issues or inefficiencies.

- Warranty Considerations: Replacing parts with non-OEM options may void warranties, so it’s important to review warranty conditions before making substitutions.

In summary, careful consideration of the components used in marine systems will facilitate informed decisions regarding replacements, ultimately contributing to the system’s reliability and efficiency.

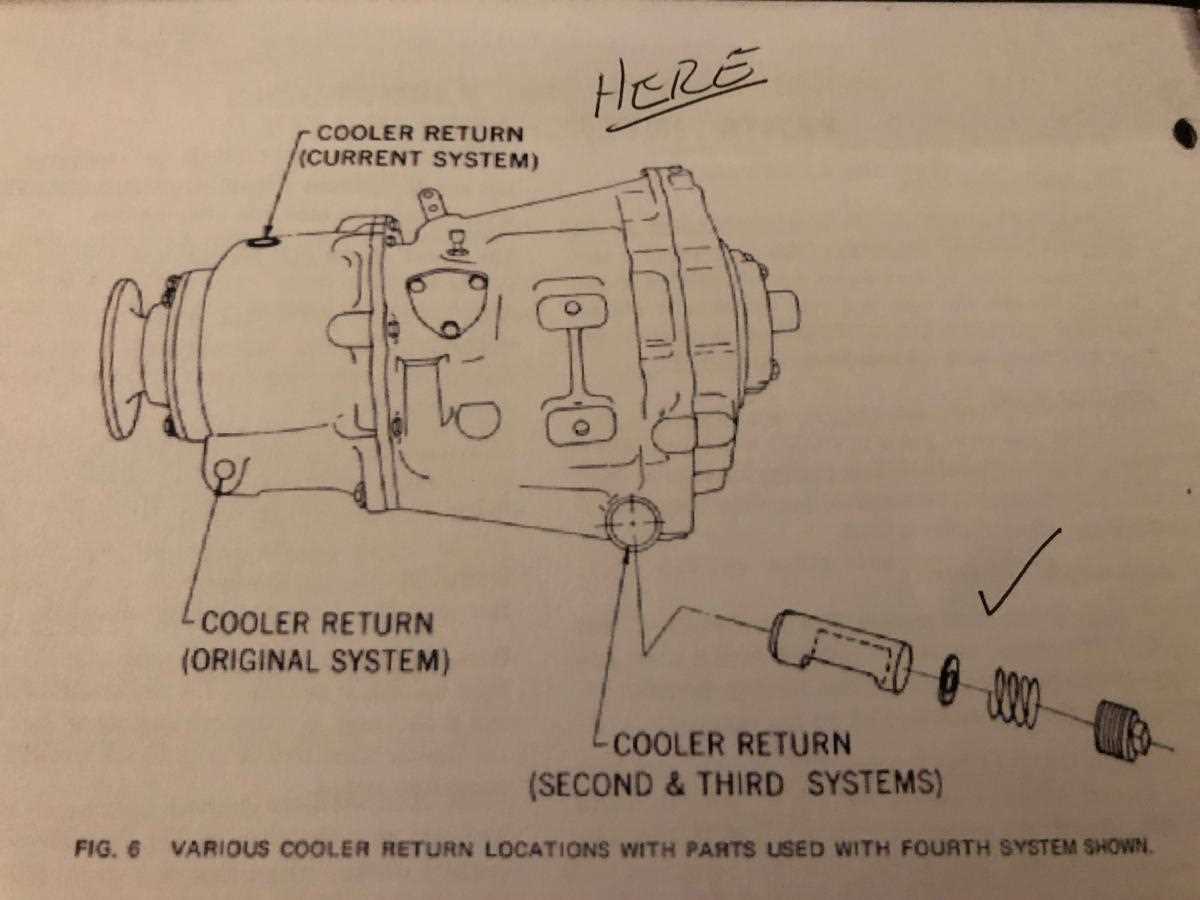

Visual Representation of the Assembly

This section provides an insightful look into the components and their arrangement within a specific mechanical system. Understanding the visual layout aids in comprehending how each element interacts and contributes to the overall functionality.

Illustrating the Configuration: A clear depiction of the assembly is essential for both novice and experienced users. It allows for easier identification of individual elements and highlights their relationships within the entire structure.

Component Breakdown: By examining each segment through a visual format, users can more effectively troubleshoot issues, perform maintenance, and optimize performance. A well-organized illustration simplifies the complexities of assembly, fostering better understanding and operational efficiency.

Tools Needed for Repair Work

When undertaking any maintenance task, having the right tools at your disposal is essential for ensuring efficiency and effectiveness. The proper equipment not only facilitates a smoother workflow but also minimizes the risk of damage to components. This section outlines the essential instruments required for successful repair endeavors.

Essential Hand Tools

Hand tools form the backbone of any repair project. A comprehensive set should include wrenches, screwdrivers, and pliers, allowing for versatile handling of various fasteners and connections. Additionally, a sturdy hammer and a precision measuring tool are invaluable for adjustments and alignment tasks.

Power Tools and Safety Equipment

For more extensive repairs, power tools such as drills and grinders can significantly expedite the process. Safety gear, including gloves and goggles, is critical to protect against potential hazards during work. Ensuring that you have both reliable tools and appropriate safety equipment will enhance not only your productivity but also your overall safety during repair activities.

Performance Enhancements for 71C

Improving the functionality of marine propulsion systems can lead to significant gains in efficiency and responsiveness. By focusing on specific components and making targeted upgrades, enthusiasts can elevate their vessels’ performance to new heights. This section explores effective modifications and enhancements that can optimize overall operation.

Upgrade the Transmission Fluid: Using high-quality fluids can improve lubrication and reduce friction, leading to smoother shifts and prolonged component life. Consider synthetic options designed for high-performance applications.

Enhance Cooling Systems: Maintaining optimal temperatures is crucial for performance. Upgrading cooling systems or adding additional cooling components can prevent overheating and ensure consistent operation under demanding conditions.

Install High-Performance Filters: Replacing standard filters with high-flow alternatives can enhance the intake process, allowing for better airflow and improved combustion efficiency, ultimately boosting overall performance.

Adjust Gear Ratios: Modifying gear ratios can significantly impact acceleration and top speed. Tailoring these ratios to specific applications or conditions can help achieve desired performance characteristics.

Routine Maintenance: Regular inspection and maintenance of critical components cannot be overlooked. Ensuring that parts are clean and in good condition will maximize efficiency and prevent potential issues during operation.

By implementing these enhancements, enthusiasts can experience a noticeable improvement in their marine propulsion systems, ensuring both reliability and performance on the water.

Frequently Asked Questions about 71C

This section addresses common inquiries regarding a specific transmission model. We aim to provide clear and concise answers to enhance your understanding and assist with maintenance or troubleshooting.

What type of fluids should be used with this transmission?

It is crucial to utilize the recommended lubricants to ensure optimal performance and longevity. Always refer to the manufacturer’s guidelines for the appropriate specifications.

How often should maintenance be performed?

Regular upkeep is essential for the efficient operation of your unit. It is advisable to check fluid levels and conduct inspections periodically, typically every few months or as indicated in the service manual.

What are the signs of potential issues?

Common indicators of problems include unusual noises, fluid leaks, or erratic shifting. If you notice any of these symptoms, it is wise to consult a professional for a thorough examination.

Can I perform repairs myself?

While some minor adjustments can be made by knowledgeable individuals, it is generally recommended to seek assistance from certified technicians for complex repairs to avoid further complications.

Where can I find replacement components?

Replacement parts can typically be sourced from authorized dealers, online retailers, or specialized marine supply stores. Ensure that the components meet the specifications required for your specific model.

Where to Buy Velvet Drive Parts

Finding components for your marine transmission can be a straightforward process if you know where to look. Various retailers, both online and brick-and-mortar, specialize in marine equipment and accessories, ensuring you have access to quality items to keep your system running smoothly. Whether you’re looking for specific fittings, replacement items, or maintenance tools, the right sources can make all the difference.

Online Retailers

Numerous websites offer a wide selection of marine equipment. Major e-commerce platforms frequently stock a variety of components, allowing for easy comparison of prices and availability. Always check customer reviews and ratings to ensure you’re purchasing from reputable sellers. Additionally, specialized marine supply websites can provide detailed catalogs and expert advice.

Local Marine Supply Stores

Visiting a local marine supply store can be beneficial for hands-on assistance. Knowledgeable staff can help identify the exact components you need and may even offer insights into maintenance or installation. Furthermore, purchasing in person allows you to inspect items before buying, ensuring you get the right fit for your system.