In the realm of outdoor machinery, comprehending the intricate arrangements of various elements is crucial for effective maintenance and operation. This section aims to provide a thorough exploration of the essential components that make up these powerful tools.

Grasping the configuration of each segment not only enhances user experience but also empowers owners to troubleshoot and repair with confidence. By dissecting the structure, enthusiasts and professionals alike can ensure optimal performance.

Moreover, delving into the specifics of each element allows for a better understanding of how they interact, ultimately leading to informed decisions regarding upgrades or replacements. This knowledge serves as a foundation for anyone seeking to maximize the longevity and efficiency of their equipment.

Understanding the Echo CS 590 Model

This section explores the essential features and components of a specific model known for its reliability and efficiency in various tasks. By examining its structure and functionality, users can gain a better understanding of how to maintain and utilize the equipment effectively.

The model is designed with a focus on user-friendliness and optimal performance. Key elements work in harmony to ensure smooth operation, making it suitable for both professionals and hobbyists alike.

| Component | Description |

|---|---|

| Engine | Powerful and efficient engine that provides the necessary force for cutting tasks. |

| Bar and Chain | High-quality cutting bar and chain designed for durability and precision in cuts. |

| Fuel System | Advanced fuel system for optimal combustion and reduced emissions. |

| Air Filter | Efficient air filtration system that ensures clean airflow to the engine. |

| Safety Features | Incorporates various safety mechanisms to protect the user during operation. |

Understanding these components is crucial for effective maintenance and operation. Familiarity with the structure not only enhances performance but also prolongs the lifespan of the equipment.

Key Features of the Chainsaw

Chainsaws are powerful tools designed for cutting through wood efficiently and effectively. Their design incorporates various features that enhance usability, performance, and safety, making them essential for both professional and recreational users.

Performance and Efficiency

High-performance models offer impressive cutting speed and power, allowing for swift and clean cuts in various types of wood. These machines often feature adjustable settings to optimize efficiency based on the task at hand.

Safety Features

Safety is paramount when operating a cutting device. Modern chainsaws include several safety mechanisms, such as chain brakes, hand guards, and automatic oilers, to minimize the risk of accidents and ensure a safer working environment.

| Feature | Description |

|---|---|

| Power Source | Available in gas, electric, and battery-operated versions for various applications. |

| Guide Bar Length | Varies to accommodate different cutting needs, from small limbs to large trees. |

| Weight | Designed for balance and maneuverability, allowing for prolonged use without fatigue. |

| Chain Type | Different chains are available for specialized cutting, such as ripping or carving. |

Common Issues and Solutions

In the realm of outdoor power equipment, users often encounter various challenges that can hinder performance. Understanding these common problems and their remedies is essential for maintaining efficiency and prolonging the lifespan of the equipment.

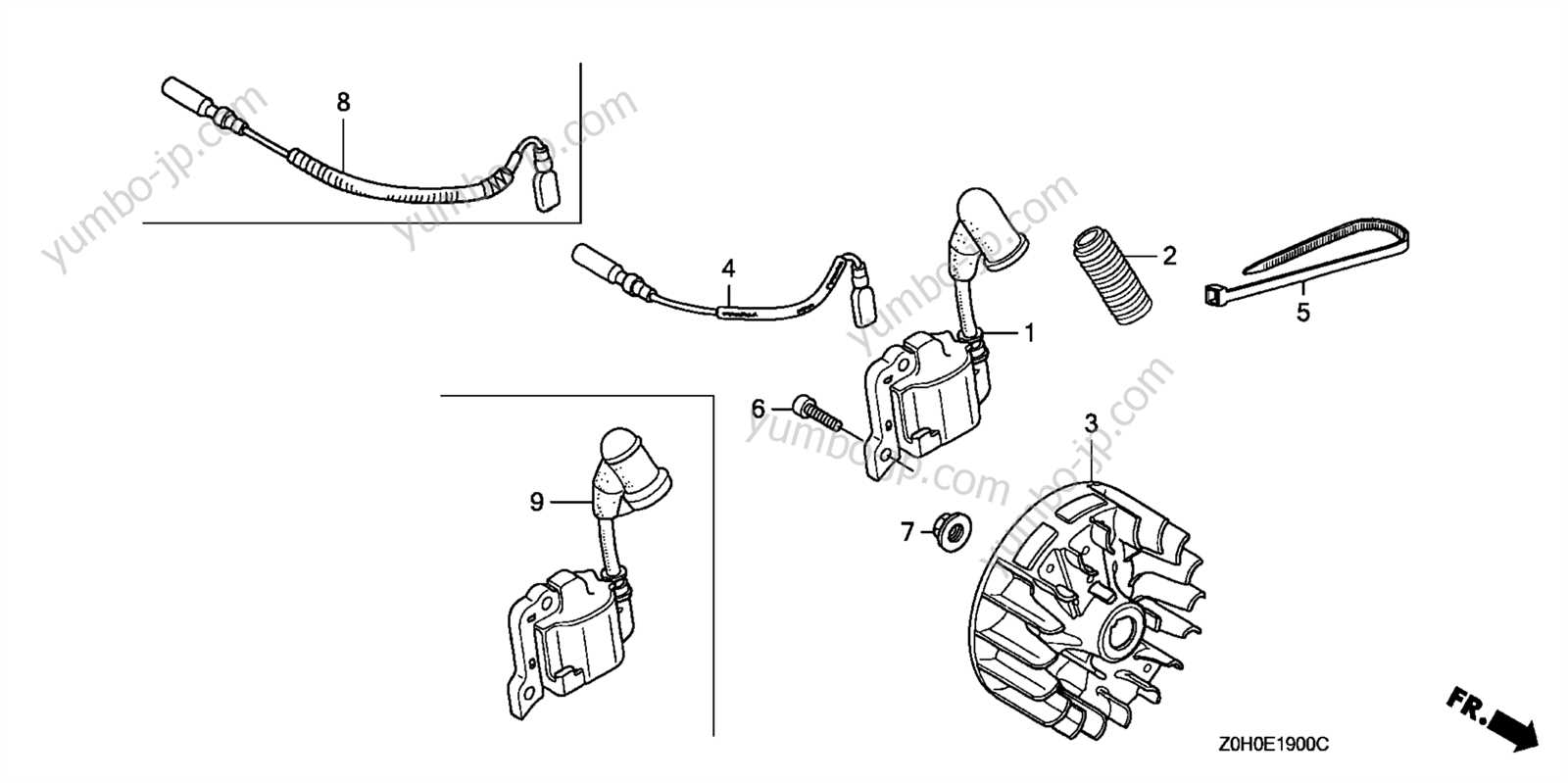

Issue 1: Difficulty starting the engine. This can stem from fuel issues or a weak spark. Solution: Ensure fresh fuel is used and check the spark plug for damage or wear.

Issue 2: Poor cutting performance. This is frequently caused by dull blades or improper height settings. Solution: Regularly sharpen blades and adjust the cutting height as needed.

Issue 3: Overheating. This can occur due to debris blocking ventilation or low oil levels. Solution: Keep the equipment clean and regularly check oil levels to prevent overheating.

Issue 4: Unusual vibrations. This may indicate loose parts or imbalance. Solution: Inspect and tighten all components, ensuring everything is balanced.

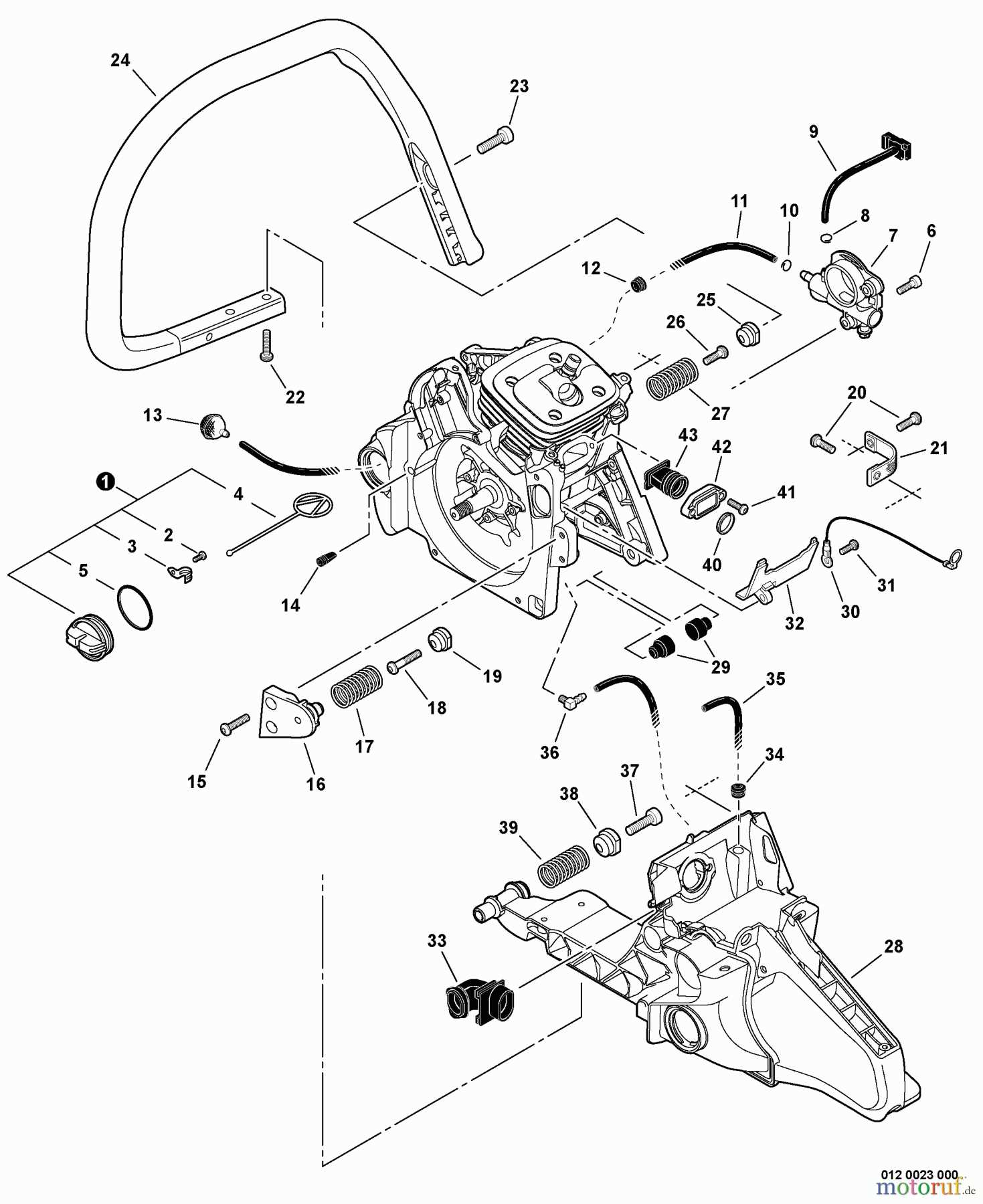

Parts Overview for Maintenance

This section provides an essential guide for keeping your equipment in optimal condition. Understanding the various components and their functions is crucial for effective upkeep and troubleshooting.

Regular maintenance is key to ensuring longevity and performance. Below are the main elements to focus on:

- Engine Assembly: Vital for powering the unit efficiently.

- Fuel System: Ensures proper fuel delivery and combustion.

- Air Filter: Essential for maintaining airflow and preventing debris from entering.

- Cutting Mechanism: Critical for achieving desired performance during operation.

- Starter System: Important for reliable ignition and startup.

By delving into each component, users can identify wear and tear, perform necessary replacements, and ultimately enhance the overall functionality of their equipment.

How to Use the Parts Diagram

Understanding the layout of components is crucial for efficient maintenance and repair. By familiarizing yourself with the visual representation of each element, you can easily identify what needs attention or replacement, ensuring optimal performance of your equipment.

Identifying Components

Start by locating the specific section related to the issue you’re facing. Each segment typically includes labels and numbers that correspond to individual items, allowing you to pinpoint exactly what you need.

Ordering Replacements

Once you have identified the necessary elements, use the reference numbers to order replacements. This streamlined process saves time and minimizes errors when sourcing new parts, making your repair efforts more efficient.

Identifying Replacement Components

Understanding the essential elements of your equipment is crucial for effective maintenance and repair. Recognizing the various components allows users to ensure optimal functionality and prolong the lifespan of their tools. This section aims to guide you in pinpointing the specific pieces that may require replacement, enhancing your overall experience.

Start by examining the user manual, which typically contains valuable information about each component’s role and specifications. Familiarizing yourself with these details will empower you to identify worn or damaged parts quickly.

Visual aids, such as exploded views or labeled diagrams, can be incredibly helpful. These resources provide a clear representation of the assembly, making it easier to locate and assess the condition of individual elements. By cross-referencing these visuals with your equipment, you can effectively determine which components need attention.

Moreover, keeping an inventory of common wear items can streamline your maintenance process. Regular checks and timely replacements can prevent larger issues from arising, ultimately saving you time and money.

Essential Tools for Repairs

When tackling maintenance or restoration tasks, having the right instruments is crucial for achieving optimal results. The appropriate tools not only streamline the process but also enhance safety and efficiency. Understanding which items are indispensable can make all the difference in executing successful repairs.

Basic Hand Tools

Among the most essential instruments are hand tools, including screwdrivers, wrenches, and pliers. These items enable users to manipulate and secure components effectively. Investing in a quality set ensures reliability and durability during frequent use.

Power Tools and Accessories

In addition to hand tools, power tools play a significant role in modern repair work. Devices such as drills and saws can dramatically reduce the time required for tasks. Equipping yourself with the right accessories further enhances functionality, allowing for more precise and efficient repairs.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial for both personal well-being and the proper functioning of equipment. By adhering to certain guidelines, individuals can minimize risks associated with repairs and create a secure work environment.

- Personal Protective Equipment (PPE): Always wear appropriate gear, such as gloves, safety goggles, and sturdy footwear, to protect against potential hazards.

- Work Area Preparation: Keep the workspace clean and organized. Remove any unnecessary tools or materials that could cause accidents.

- Disconnect Power Sources: Before starting any repair, ensure that all power sources are disconnected to prevent accidental activation.

- Use Proper Tools: Utilize the correct tools for each task to avoid damaging components and ensure efficient work.

- Read Instructions: Familiarize yourself with the manufacturer’s guidelines and safety instructions before beginning repairs.

By following these precautions, individuals can significantly reduce the likelihood of accidents and ensure a smooth repair process. Always prioritize safety to protect yourself and the equipment you are working on.

Where to Find Genuine Parts

Locating authentic components for your equipment is crucial for ensuring optimal performance and longevity. Reliable sources not only guarantee quality but also provide peace of mind when making replacements. Understanding where to seek these original items can enhance your maintenance routine significantly.

| Source | Description |

|---|---|

| Authorized Dealers | Official retailers often carry a comprehensive selection of authentic components. |

| Manufacturer’s Website | Direct purchases from the manufacturer’s site ensure you receive original items. |

| Reputable Online Retailers | Well-known e-commerce platforms may offer genuine products with customer reviews. |

| Local Repair Shops | Professionals can sometimes provide access to authentic parts and installation services. |

Comparing Models: Echo vs Competitors

This section explores the characteristics and features of a popular brand in the outdoor power equipment sector and how it measures up against other notable manufacturers. By analyzing performance, durability, and user satisfaction, we aim to provide insights into what sets these products apart.

| Feature | Brand A | Brand B | Brand C |

|---|---|---|---|

| Engine Power | 25 cc | 30 cc | 28 cc |

| Weight | 10 lbs | 12 lbs | 11 lbs |

| Fuel Efficiency | 50 mpg | 45 mpg | 48 mpg |

| Noise Level | 75 dB | 80 dB | 78 dB |

| Warranty | 2 years | 3 years | 2 years |

By comparing these specifications, users can better understand the advantages and disadvantages of each option, allowing for an informed decision based on personal needs and preferences.

Upgrading Your Chainsaw Performance

Enhancing the efficiency of your cutting tool can significantly improve your overall experience and productivity. By focusing on various aspects such as power, handling, and maintenance, you can achieve remarkable results. This section explores practical modifications and adjustments that can elevate your device to new heights.

Power Enhancements

One of the most effective ways to boost performance is by upgrading the engine components. Consider replacing the carburetor with a high-performance model to improve fuel efficiency and throttle response. Additionally, installing an aftermarket exhaust system can enhance airflow, allowing the engine to operate more effectively under load.

Improving Handling and Comfort

Equipping your tool with better grips and anti-vibration systems can lead to a more comfortable cutting experience. Look for options that reduce fatigue during prolonged use. A lighter weight bar can also contribute to better maneuverability, making tasks easier and more enjoyable.

Tips for Long-lasting Use

Ensuring durability and efficiency in your equipment requires attention to maintenance and proper handling. Following a few key practices can significantly enhance performance and lifespan.

- Regularly inspect components for wear and tear.

- Keep the equipment clean to prevent debris buildup.

- Use high-quality fuel and lubricants to optimize functionality.

Additionally, consider the following:

- Store in a dry, cool place to avoid corrosion.

- Follow manufacturer guidelines for usage and maintenance schedules.

- Address any issues immediately to prevent further damage.