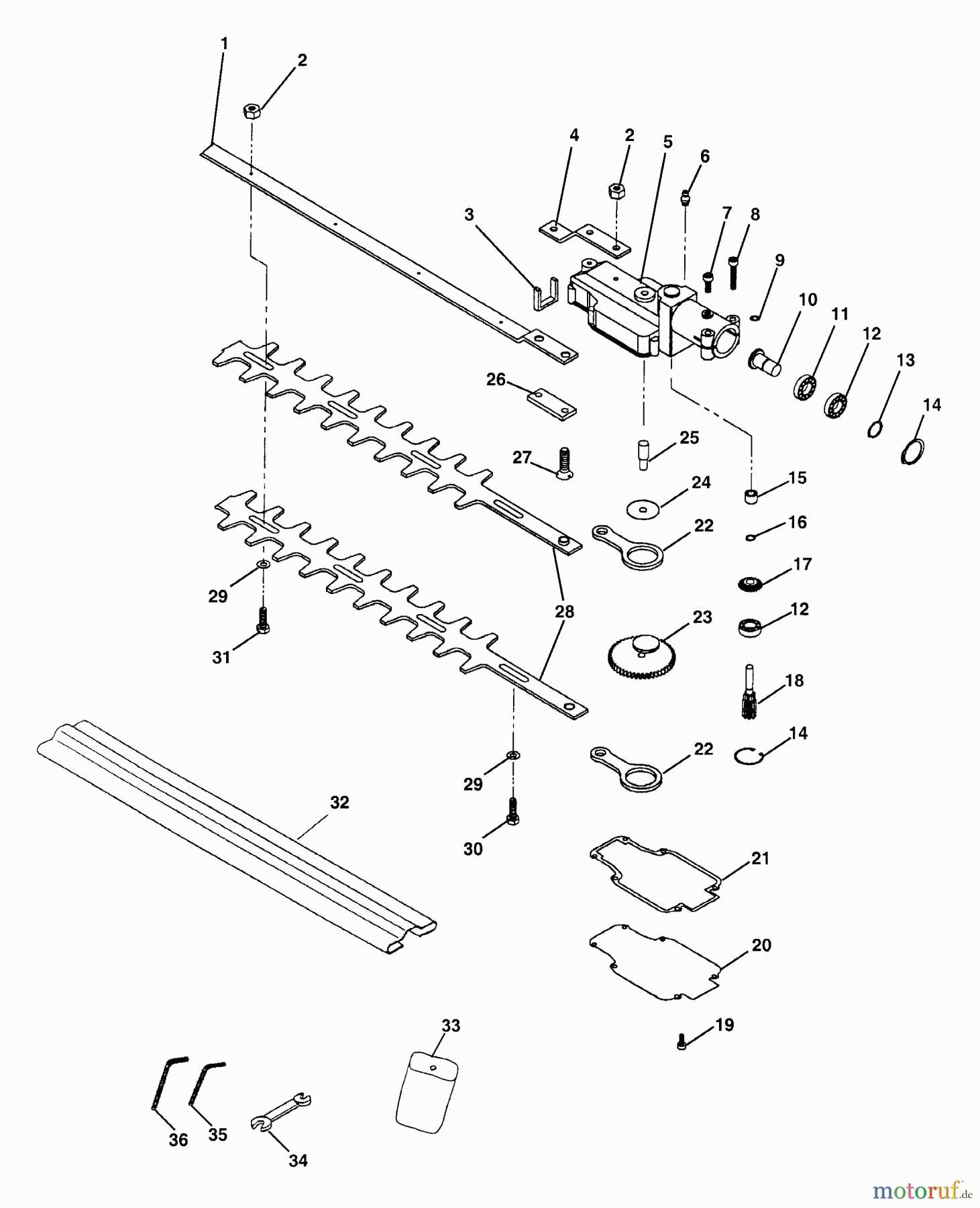

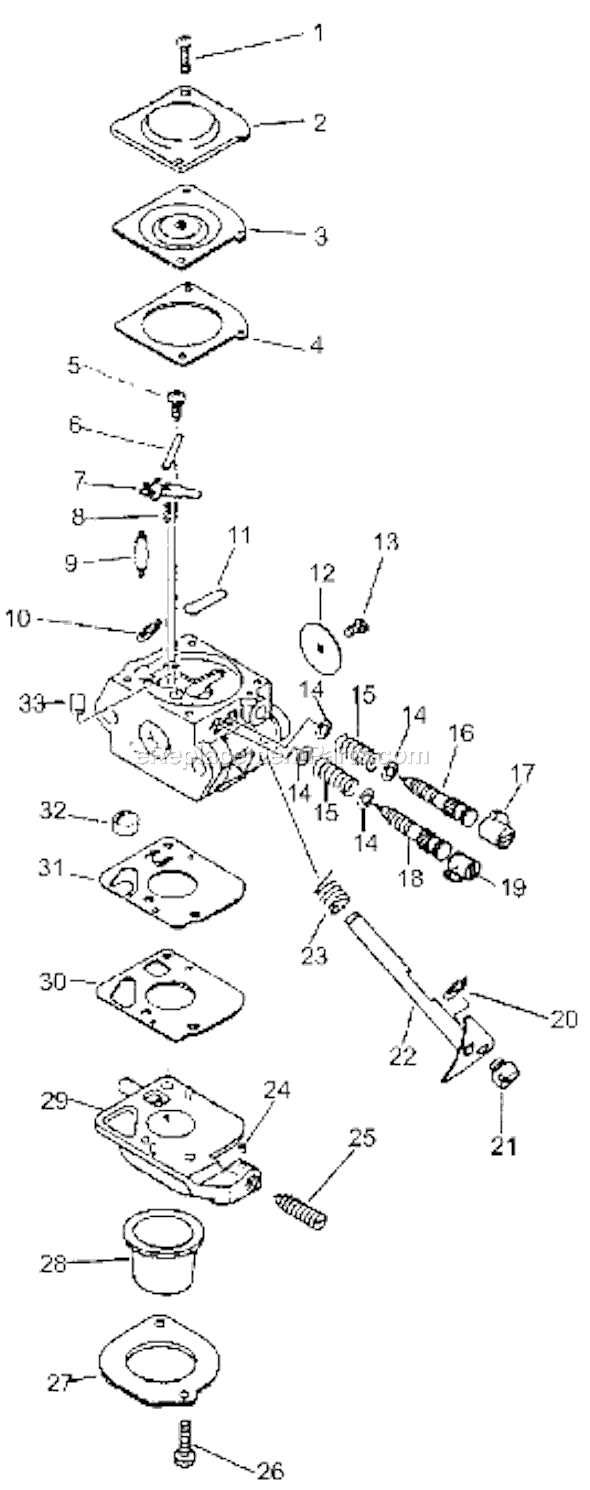

In any mechanical system, the interplay of various elements determines the overall efficiency and longevity of the equipment. When approaching maintenance or troubleshooting tasks, having a clear overview of each element’s role is crucial. Proper identification and understanding of each element allow for a smoother workflow and more accurate decision-making when it comes to replacements or repairs.

Every intricate system is designed with precision, where each section contributes to the machine’s functionality. Knowing how to assess individual components ensures that the system operates at its full potential. It also enables more effective management of the equipment, leading to fewer interruptions and an extended lifespan.

This guide provides a detailed breakdown, offering insights into the distinct sections of the system. By familiarizing yourself with their functions, you can gain a deeper understanding of how the system works in harmony, ensuring optimal performance and minimal downtime.

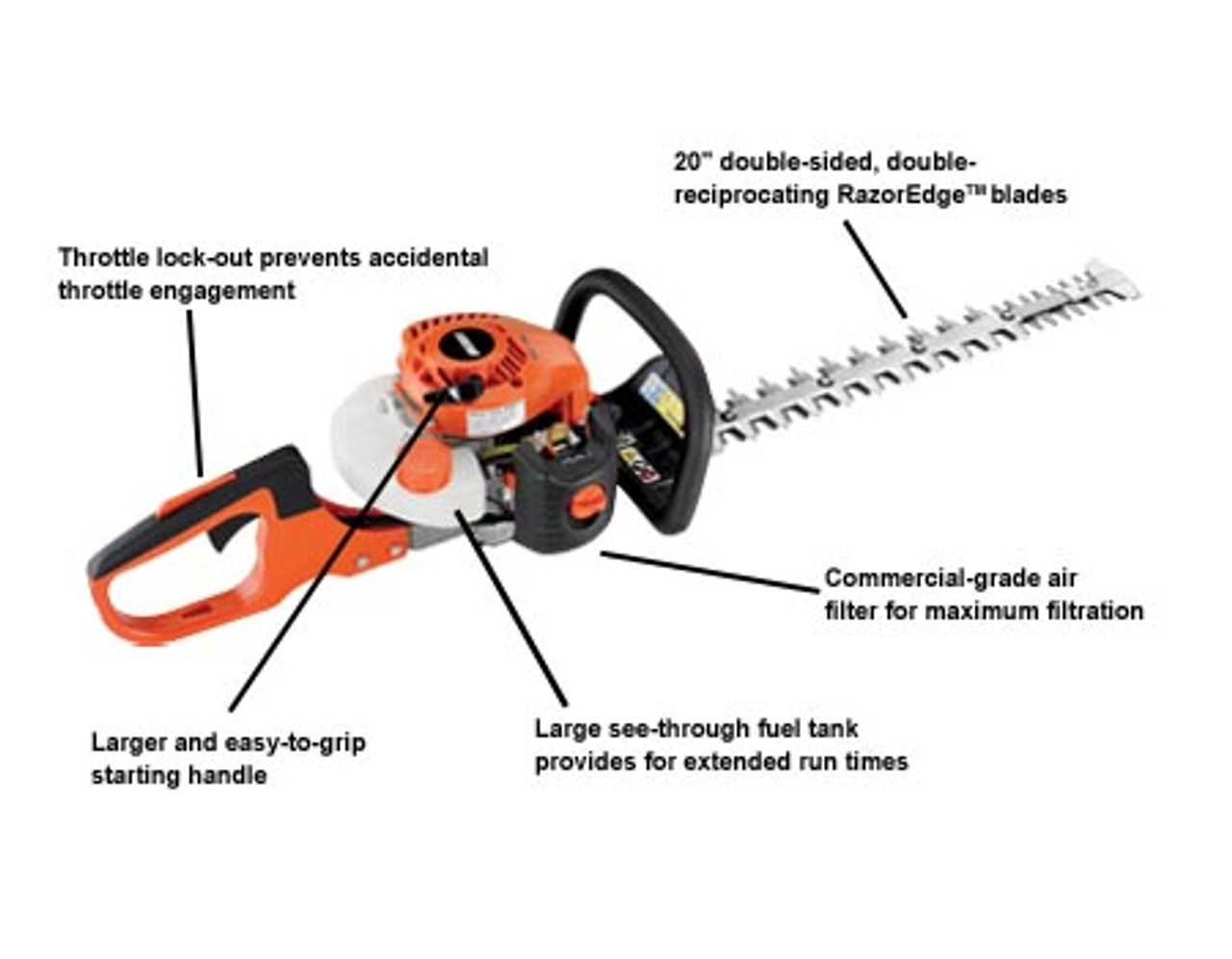

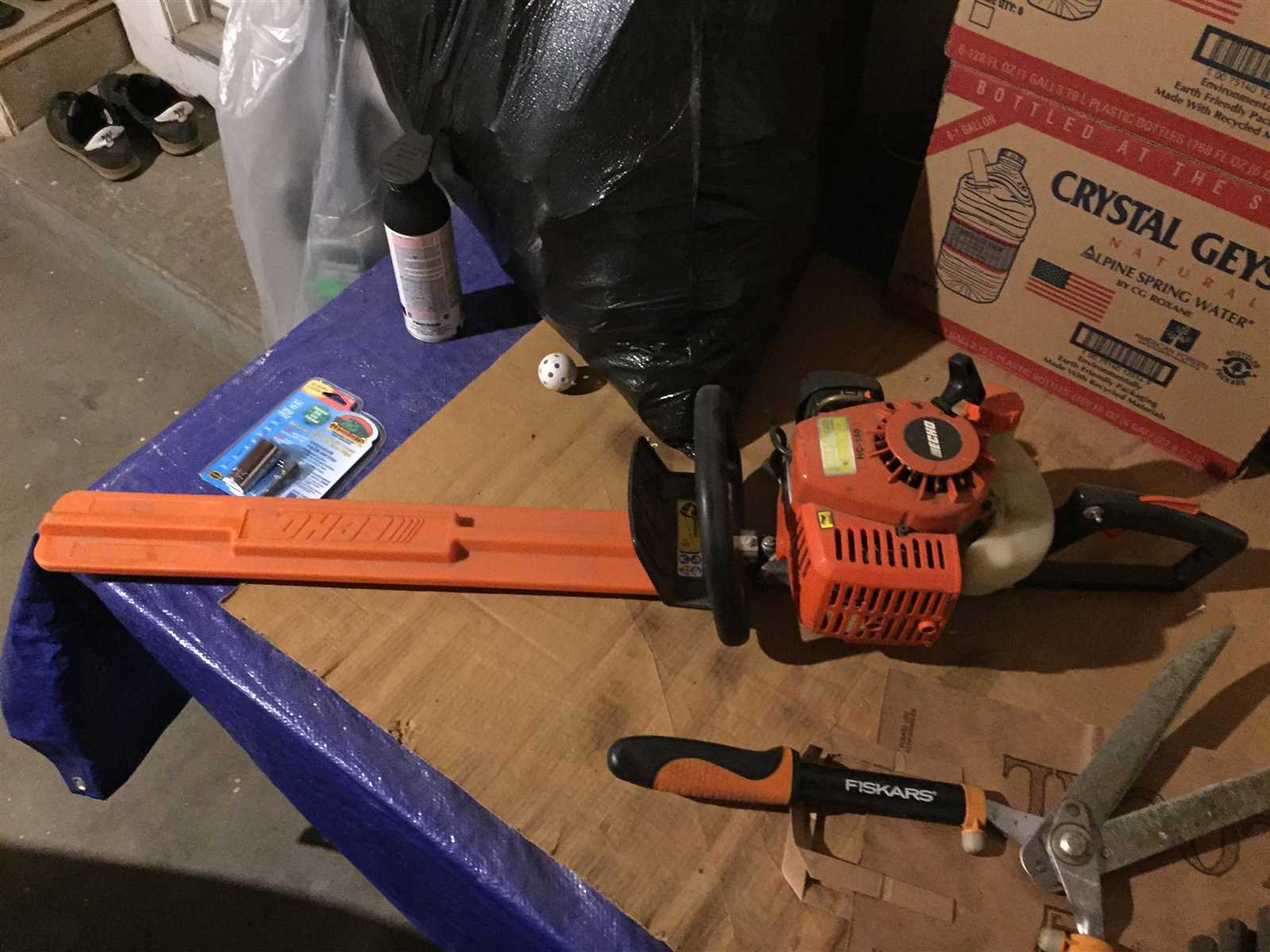

Understanding the Main Components of the Echo HC-150

The primary elements of this trimming device play a crucial role in its overall performance and functionality. Each piece is meticulously designed to work together, ensuring efficiency, durability, and ease of use during various landscaping tasks. This section explores the key functional components that contribute to its reliability and user-friendly operation.

| Component | Function | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Engine Assembly | Provides the power required for cutting and trimming operations, ensuring consistent performance during extended use. | ||||||||

| Cutter Blades | Responsible for precision cutting, these blades ensure clean and sharp results, making them ideal for shaping and trimming hedges. | ||||||||

| Feature | Benefit |

|---|---|

| Ergonomic Shape | Reduces wrist strain |

| Non-Slip Material | Improves grip security |

| Adjustable Length | Accommodates different users |

| Weight Distribution | Enhances control and reduces fatigue |

Maintenance of the Exhaust System

The exhaust system plays a crucial role in ensuring optimal performance and longevity of the equipment. Regular upkeep is essential to prevent issues such as blockages and deterioration, which can lead to inefficiencies and potential damage. By adhering to a consistent maintenance schedule, users can enhance the overall functionality and reliability of their machinery.

Inspection Procedures

Regular inspections should focus on identifying any signs of wear, corrosion, or damage within the exhaust components. Check for loose connections and ensure that all seals are intact to prevent leaks. Cleaning the exhaust system periodically can also help remove carbon deposits that accumulate over time, maintaining smooth operation.

Replacement of Components

When inspecting the exhaust system, it is important to replace any worn or damaged parts promptly. Components such as gaskets, mufflers, and pipes should be evaluated for integrity. Upgrading to higher quality materials can improve durability and efficiency, ultimately enhancing the machine’s performance and reducing the need for frequent repairs.

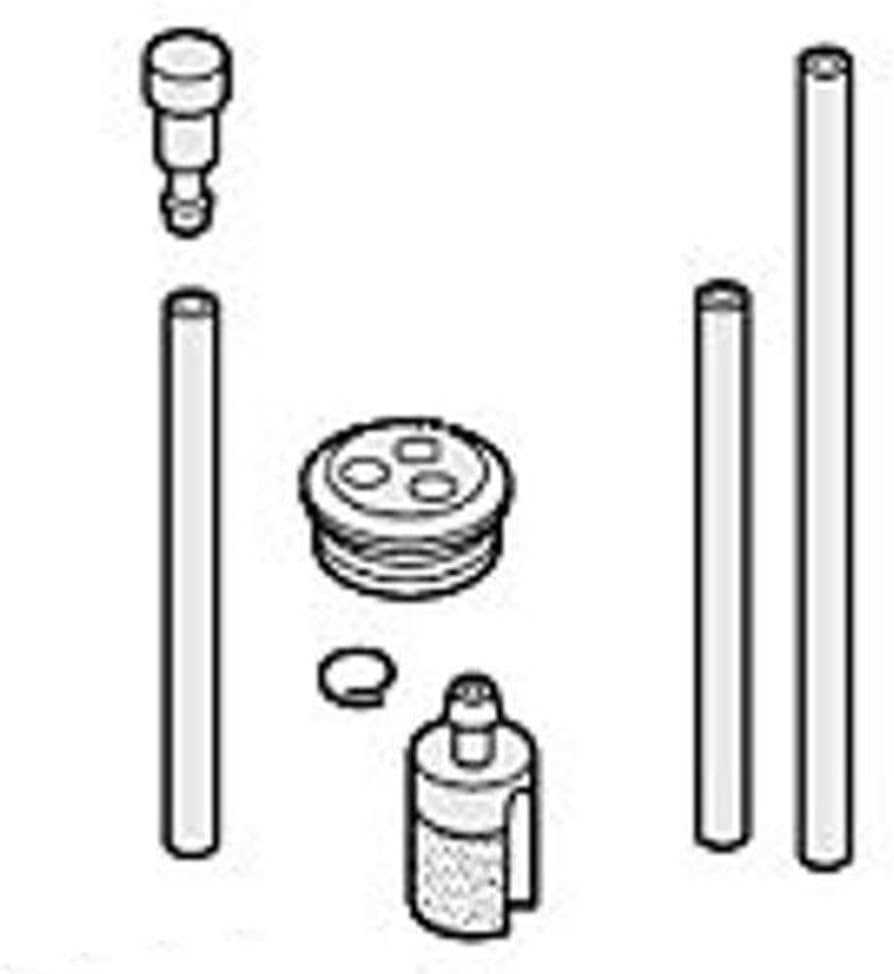

Fuel Tank Structure and Features

The design of a fuel reservoir plays a crucial role in the overall efficiency and functionality of outdoor power equipment. Its construction is meticulously engineered to ensure optimal storage, safe handling, and effective fuel delivery during operation. Understanding the intricacies of this component can greatly enhance performance and longevity.

Material Composition

Typically, these tanks are made from durable materials that resist corrosion and withstand harsh environmental conditions. Common choices include high-density polyethylene and specialized alloys, which provide strength while remaining lightweight.

Capacity and Shape

The size and contour of the fuel reservoir are designed to maximize storage while fitting seamlessly within the overall machinery layout. A larger capacity allows for extended usage periods, reducing the need for frequent refueling. Moreover, the shape is often optimized to facilitate easy installation and maintenance.

Fuel Delivery System

A well-engineered fuel delivery mechanism is vital for maintaining consistent performance. This system typically includes a fuel line, filter, and sometimes a primer bulb to ensure that fuel flows smoothly to the engine. These features work in unison to prevent clogs and ensure reliability during operation.

Ventilation Features

Proper ventilation is essential for maintaining pressure within the tank, allowing fuel to flow freely without creating a vacuum. Many designs incorporate vents that not only facilitate air exchange but also prevent spillage and evaporation, enhancing safety and efficiency.

Safety Considerations

Incorporating safety features such as anti-spill designs and secure caps ensures that fuel remains contained during transportation and usage. These aspects are critical for preventing leaks and minimizing environmental impact, contributing to responsible operation.

In conclusion, the structure and features of a fuel storage unit are integral to the performance and safety of outdoor equipment. By focusing on material quality, design, and safety elements, manufacturers aim to create a reliable and efficient component that meets user needs effectively.

Throttle Control and Its Operation

The mechanism responsible for regulating the speed and power output of a machine plays a crucial role in its overall functionality. By adjusting the airflow and fuel mixture, this system allows for precise control, enabling operators to optimize performance for various tasks. Understanding its components and operation is essential for effective usage and maintenance.

Components of Throttle Control

The throttle control system comprises several key elements that work together seamlessly. A lever or pedal is typically used to engage the throttle, providing the operator with the ability to increase or decrease engine speed. Connective cables or linkages transmit the operator’s input to the throttle body, where the airflow is adjusted accordingly. Sensors may also be integrated to monitor the position and performance, ensuring efficient operation.

Operation Mechanism

When the operator adjusts the throttle, the connected components respond by modifying the engine’s airflow. This change in airflow influences the combustion process, directly affecting power output and efficiency. A well-tuned throttle control allows for smooth acceleration and deceleration, enhancing the user experience and prolonging the life of the equipment. Regular inspection and maintenance of this system are vital to ensure reliable performance and prevent mechanical issues.