When it comes to maintaining outdoor spaces, having the right equipment is essential. The functionality of certain tools relies heavily on the precise arrangement and interaction of their individual elements. Recognizing the key components that make up these machines allows for better upkeep and troubleshooting, ensuring they operate efficiently over time.

In this guide, we will explore the primary segments that form the core of a robust gardening device. From essential mechanical parts to small but critical elements, each piece plays a role in the overall performance. Gaining insight into how these components fit and work together helps in understanding the machine’s operation and in identifying potential issues when they arise.

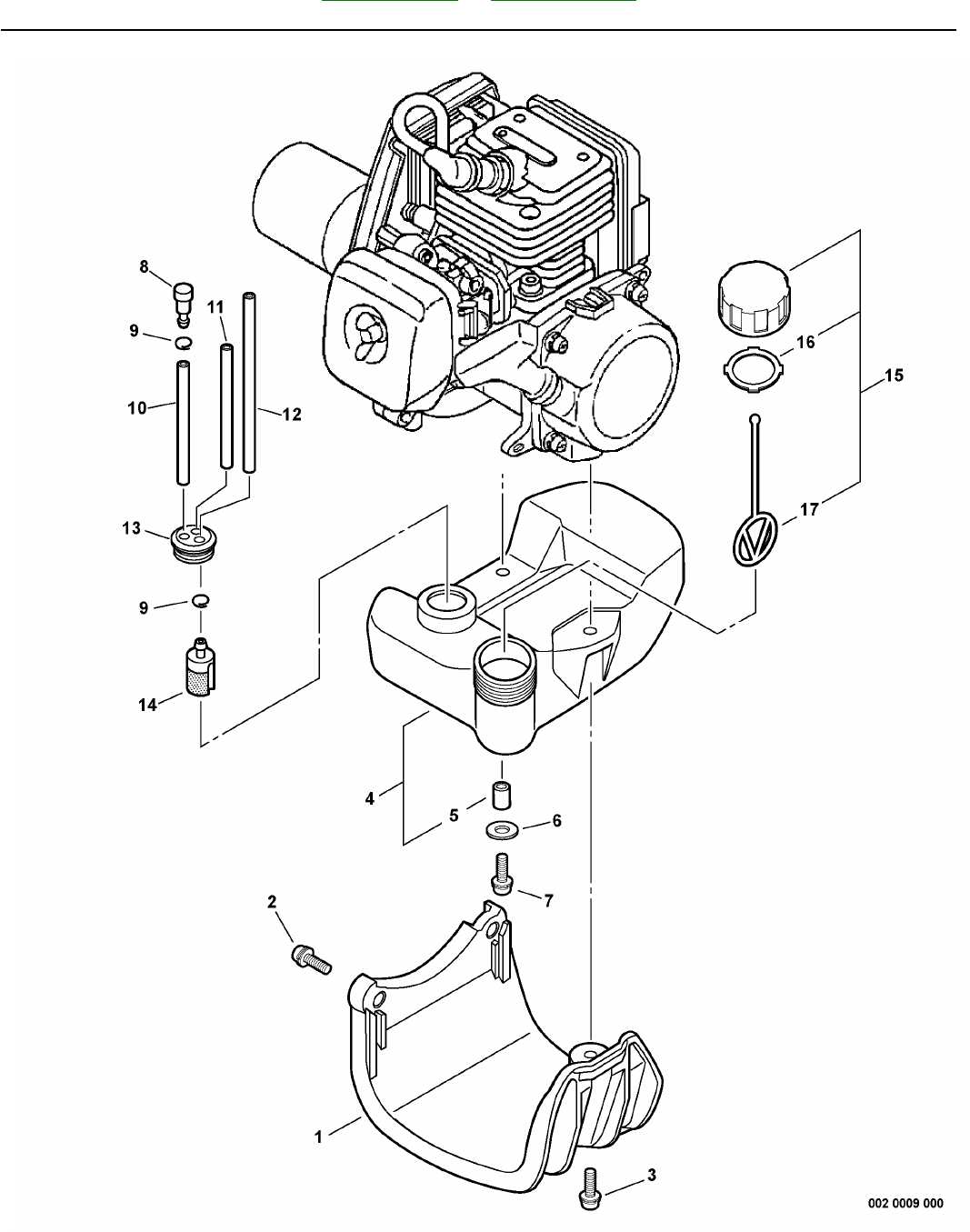

Overview of the Echo PAS 230

The versatile system offers users a flexible and efficient solution for a wide range of tasks. This model is designed to provide both durability and performance, ensuring that users can rely on it for heavy-duty applications in various environments. Its modular nature allows for easy attachment of different tools, making it an all-in-one solution for professionals and homeowners alike.

| Key Features | Benefits |

|---|---|

| Interchangeable attachments | Allows for a variety of uses, reducing the need for multiple tools |

| Durable engine | Reliable performance even in tough conditions |

| Ergonomic design | Provides comfort during prolonged use |

| Compact build | Easy to store and transport |

| Step | Action |

|---|---|

| 1 | Turn off the equipment and disconnect the spark plug for safety. |

| 2 | Remove the air filter cover using the appropriate tools. |

| 3 | Take out the old filter and inspect the housing for dirt or damage. |

| 4 | Install the new air filter securely into the housing. |

| 5 | Reattach the air filter cover and ensure it is fastened properly. |

| 6 | Reconnect the spark plug and start the equipment to check for proper operation. |

By adhering to these practices, you can significantly enhance the efficiency and longevity of your machinery. Regular maintenance not only saves you from potential costly repairs but also ensures your equipment runs at its best.

Exploring the Ignition System Layout

The ignition mechanism plays a vital role in the functionality of a two-stroke engine, ensuring the combustion process occurs at the correct moment. This section delves into the organization and components of this essential system, providing insights into its structure and operation.

Understanding the ignition system layout involves familiarizing oneself with various elements that contribute to the engine’s performance. Below are key components typically found within this setup:

- Ignition Coil: This component transforms low voltage from the battery into high voltage needed to create a spark.

- Spark Plug: The device that ignites the fuel-air mixture by producing a spark when high voltage is applied.

- Flywheel: Often equipped with magnets, it generates electrical energy as it rotates, supplying power to the ignition coil.

- Timing Mechanism: This ensures the spark occurs at the right moment during the engine cycle for optimal performance.

Proper maintenance and understanding of each component can significantly enhance the reliability and efficiency of the ignition system. Regular checks can prevent potential issues that may arise from wear or improper alignment.

Handle and Trigger Mechanism Overview

The handle and trigger assembly plays a crucial role in the operation of handheld equipment, serving as the primary interface for user interaction. This mechanism allows for effective control, enabling the operator to start, stop, and regulate the tool’s performance with precision. Understanding this assembly is essential for both maintenance and optimal functionality.

Components of the Handle and Trigger Mechanism

The key components involved in this mechanism include the handle itself, the trigger switch, and various connecting parts. Each element must work seamlessly to ensure reliability and safety during operation.

| Component | Description |

|---|---|

| Handle | Ergonomically designed for a secure grip, providing comfort during extended use. |

| Trigger Switch | Engages and disengages the tool’s operation, allowing for immediate response to user input. |

| Connecting Parts | Link the handle to the internal mechanisms, facilitating the transfer of force and motion. |

Functionality and Importance

Efficient operation of the handle and trigger assembly is vital for safety and performance. A well-designed mechanism enhances user experience by allowing intuitive control and reducing fatigue. Regular inspection and maintenance of these components can prevent malfunctions and ensure longevity.

Blade Attachment and Gearbox Details

The mechanism for connecting the cutting element to the drive system plays a crucial role in the efficiency and effectiveness of outdoor power tools. Understanding the intricacies of this assembly, including how the blade is affixed and the function of the gearbox, can enhance the performance of these machines.

Attachment Mechanism

The method of securing the cutting tool is vital for ensuring optimal operation. Several factors must be considered:

- Compatibility: The connection point should be suited to various attachments.

- Stability: A secure fit prevents vibrations during operation, leading to better performance.

- Ease of Replacement: A straightforward attachment process allows for quick changes to different cutting implements.

Gearbox Functionality

The gearbox serves as a critical component, translating the engine’s power into usable torque for the blade. Its design features include:

- Gear Ratios: Specific ratios determine the speed and power transferred to the cutting element.

- Durability: Robust materials are necessary to withstand the stress of operation.

- Maintenance: Regular inspection and lubrication of the gearbox can extend its lifespan and improve efficiency.

Throttle System Parts and Operation

The throttle system is a crucial component in controlling the speed and power output of outdoor power equipment. Understanding its functionality and the elements involved helps in maintaining optimal performance and ensuring safe operation. This section explores the various components that constitute the throttle mechanism and how they work together to regulate engine speed effectively.

Key Components of the Throttle Mechanism

The throttle system consists of several key elements that collaborate to manage airflow and fuel delivery. Each part plays a specific role in enhancing the responsiveness and efficiency of the equipment.

| Component | Description |

|---|---|

| Throttle Lever | A control device that allows the operator to adjust the engine speed manually. |

| Throttle Cable | A flexible conduit that connects the throttle lever to the carburetor, transmitting motion for speed adjustments. |

| Carburetor | A device that mixes air and fuel in the appropriate ratio for combustion. |

| Spring Mechanism | Provides resistance to the throttle lever, ensuring it returns to its original position when released. |

| Linkage Assembly | Connects various components, facilitating the movement needed to regulate airflow and fuel flow. |

Functionality of the Throttle System

The operation of the throttle mechanism is initiated when the operator manipulates the throttle lever. This action pulls the throttle cable, which in turn adjusts the carburetor’s position. As the carburetor opens, it allows more air to enter the engine, increasing the fuel flow and consequently enhancing engine speed. The spring mechanism ensures that the throttle returns to its default position when not engaged, promoting safety and control. Proper understanding and maintenance of these components ensure that the throttle system operates smoothly and effectively.

Troubleshooting Common Component Failures

When dealing with machinery, understanding how to diagnose and resolve frequent issues can greatly enhance performance and longevity. Identifying malfunctioning elements is essential for maintaining efficiency and preventing more significant problems down the line. A systematic approach can help users quickly address concerns, ensuring optimal operation.

Begin by observing any unusual sounds, vibrations, or performance inconsistencies. Such symptoms often indicate underlying issues. Next, inspect electrical connections and wiring for signs of wear or damage, as these can lead to intermittent failures or complete breakdowns. Always check for loose connections, which are common culprits in malfunctioning systems.

Fuel or power delivery problems can also disrupt functionality. Ensure that the fuel supply is clean and free from contaminants, and verify that the filters are not clogged. If applicable, test the power source to ensure it meets the required specifications. An inadequate supply can lead to poor performance or starting issues.

Finally, if components appear worn or damaged upon inspection, replacement may be necessary. Keep a log of the issues encountered and solutions implemented. This documentation will assist in future troubleshooting efforts and help identify recurring problems, allowing for proactive maintenance strategies.

Finding Compatible Replacement Parts

When maintaining or repairing outdoor equipment, ensuring that you acquire the right components is crucial for optimal performance. This section outlines strategies to help you identify suitable substitutes, thereby prolonging the lifespan of your machine and enhancing its functionality.

Researching Options

Understanding the specifications and requirements of your device is the first step. Consider the following approaches:

- Consult the manufacturer’s guidelines for recommended components.

- Utilize online forums and communities for insights from other users.

- Look for reputable retailers specializing in outdoor machinery.

Evaluating Compatibility

Once you have a list of potential substitutes, it’s important to assess their compatibility. Here are key factors to consider:

- Verify the dimensions and weight of the component.

- Ensure that the material quality meets or exceeds the original specifications.

- Check for warranties or return policies from the supplier.

By carefully researching and evaluating available options, you can confidently select components that will effectively serve your needs.