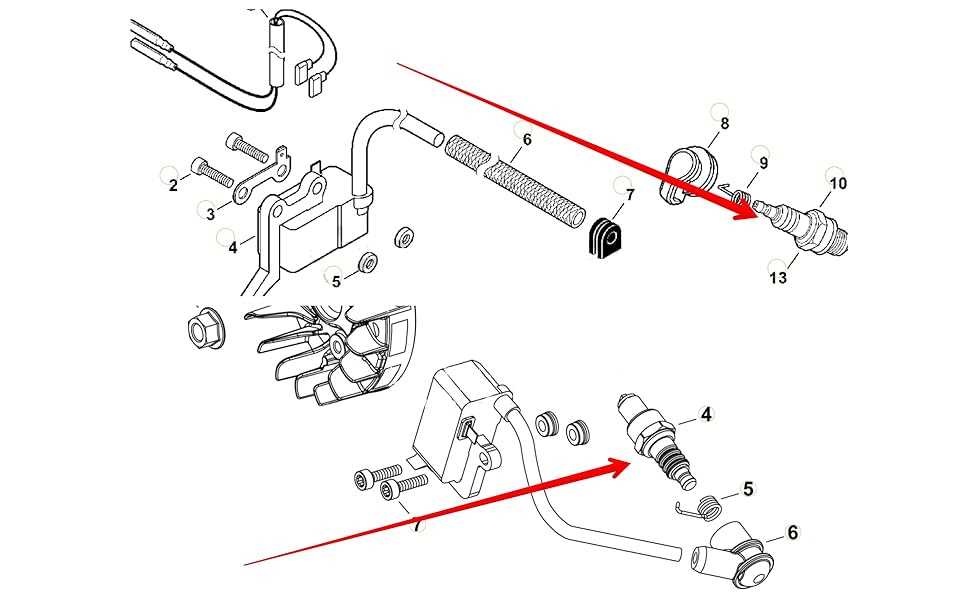

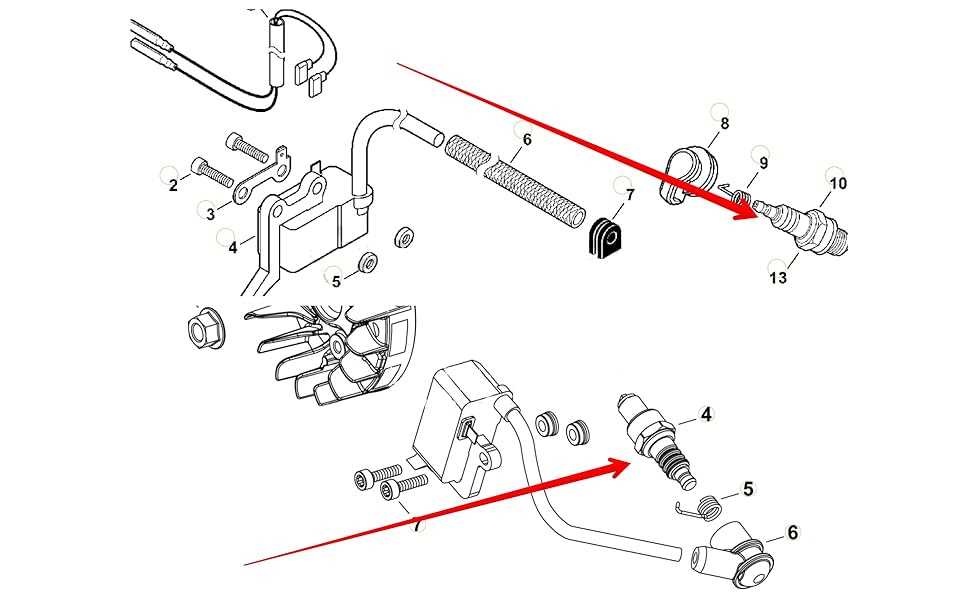

| Spark Plug |

Rece

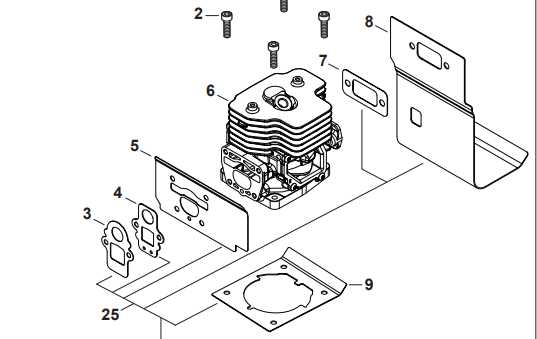

Air Filter and Maintenance Tips

Proper air filtration is crucial for maintaining optimal performance and longevity of your equipment. Regular maintenance of the air filter ensures efficient airflow, preventing debris from entering the engine and causing potential damage.

Regularly inspecting and cleaning the air filter is essential. Ensure it is free from dirt, dust, and other particles that could obstruct airflow. Use a gentle brush or compressed air to clean the filter gently, avoiding damage to the delicate filter material.

Additionally, replacing the air filter according to the manufacturer’s recommendations is key to maintaining peak performance. This proactive approach prevents engine wear and improves fuel efficiency, ensuring your equipment operates reliably.

Remember, a well-maintained air filter not only protects your equipment but also enhances its overall performance, ensuring it remains in top condition for all your outdoor tasks.

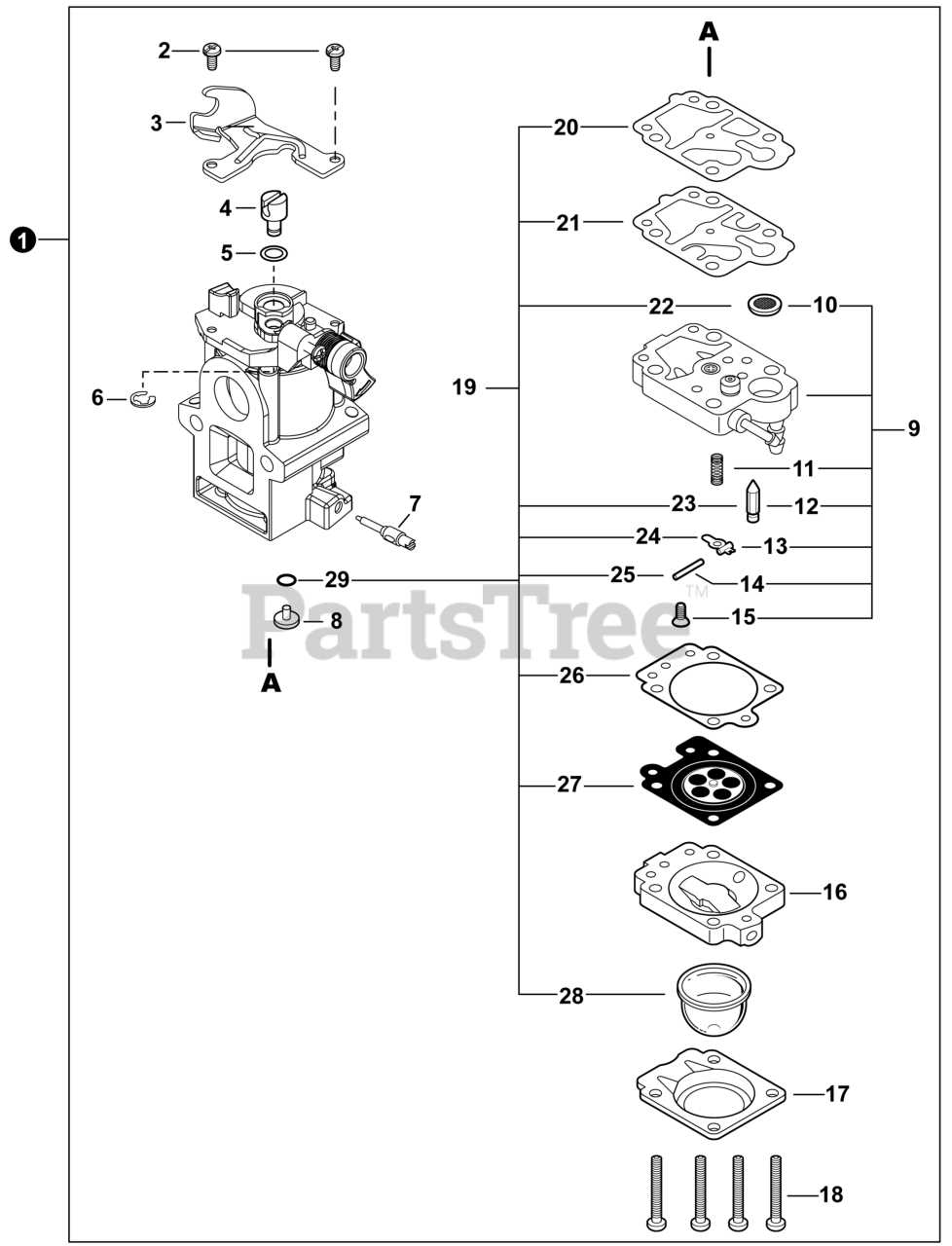

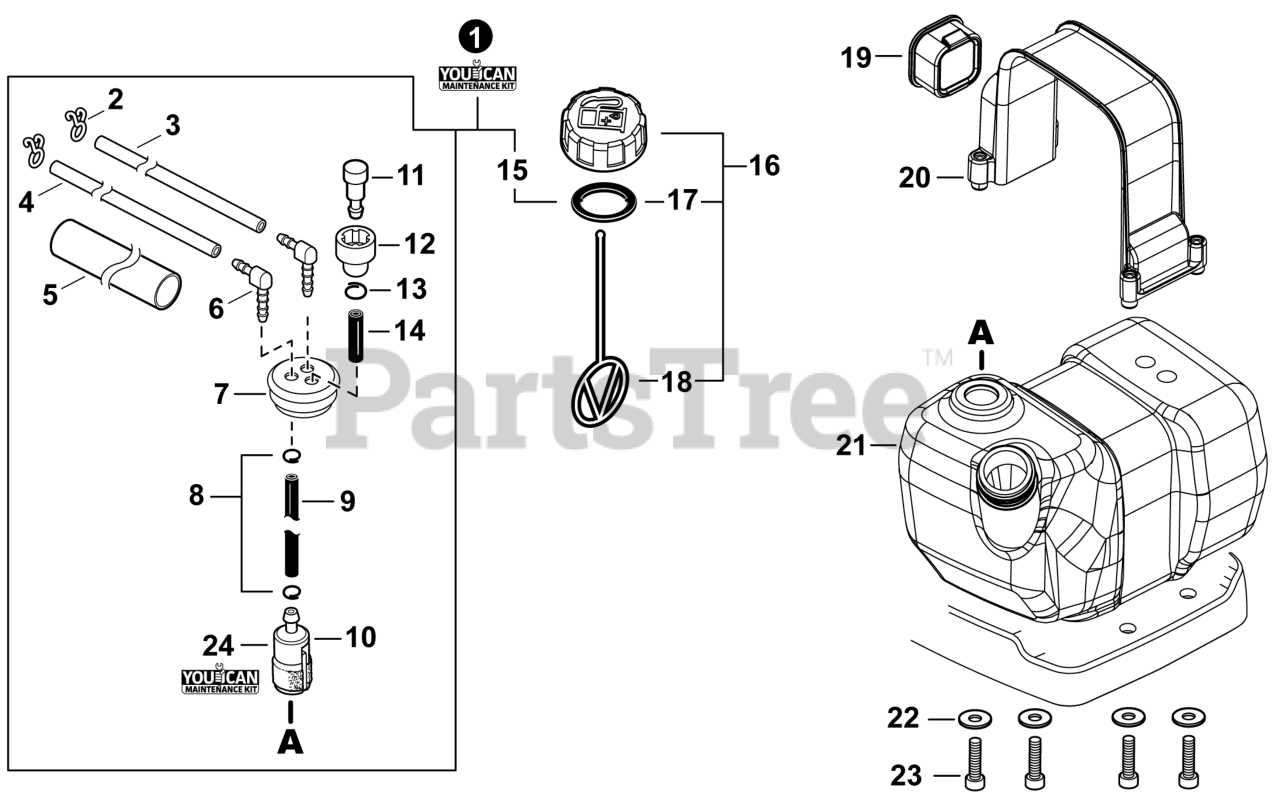

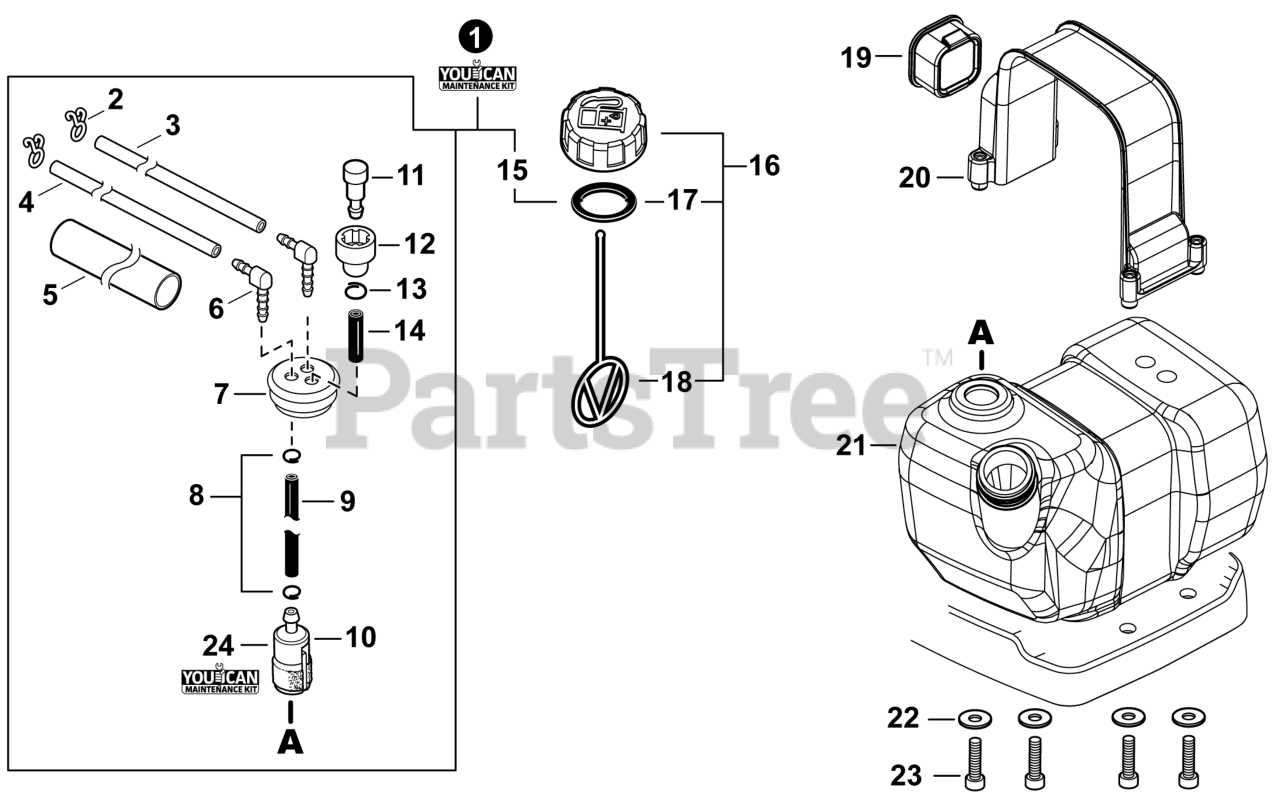

Fuel System Breakdown

The fuel delivery system plays a crucial role in the overall functionality of any equipment powered by a combustion engine. Its primary purpose is to ensure a consistent flow of fuel to the engine, enabling efficient operation. Understanding the components involved in this system is essential for effective maintenance and troubleshooting.

Key Components

This system typically consists of several vital elements, including the fuel tank, pump, filters, and lines. Each component works in harmony to transport the fuel from the storage tank to the engine. Regular inspection of these parts can prevent potential issues that may hinder performance.

Common Issues

Common problems within the fuel delivery system may include clogs in the filters, leaks in the lines, or failures in the pump. Identifying these issues early can save time and resources during repairs, ensuring optimal performance of the equipment.

Blower Tube and Housing Details

The blower tube and its housing play a vital role in ensuring efficient air movement and overall performance. These components are designed to guide and control the airflow, allowing the machine to operate at optimal efficiency. Proper understanding of the tube’s structure and the housing setup can significantly improve the equipment’s usage.

| Component |

Description |

| Blower Tube |

A long, cylindrical part that directs airflow for

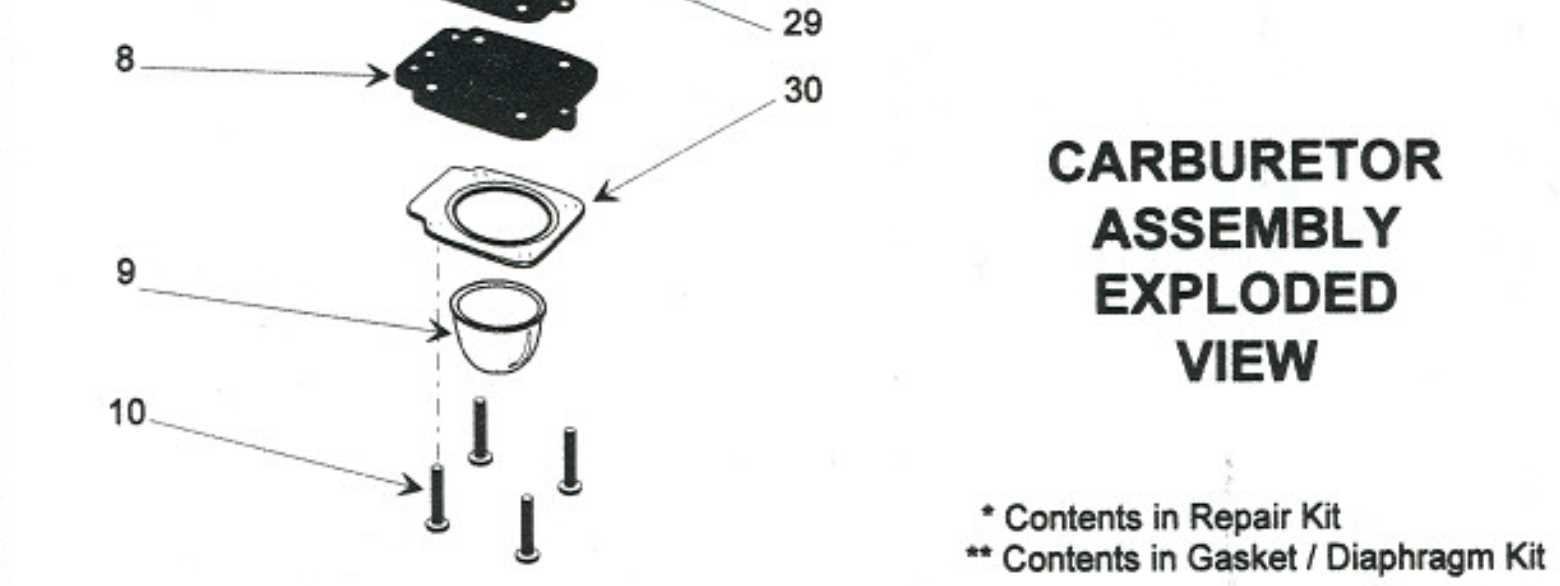

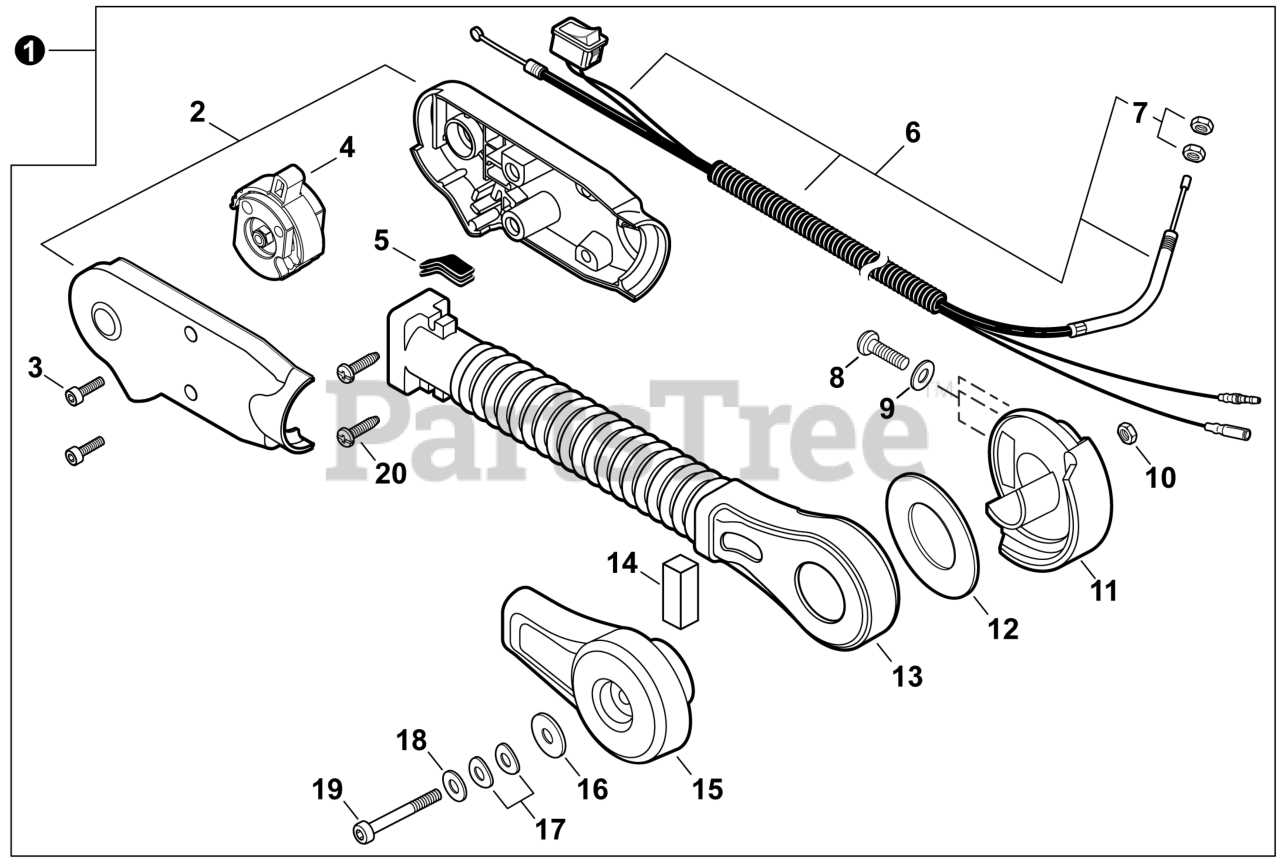

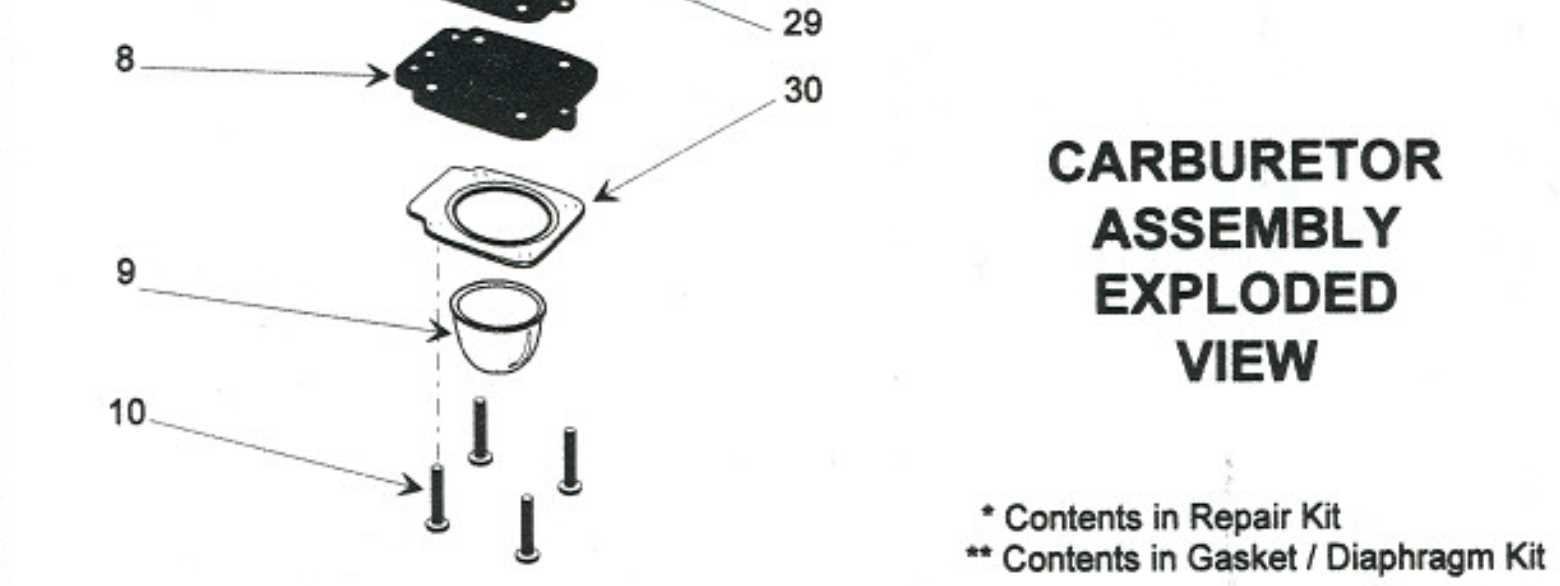

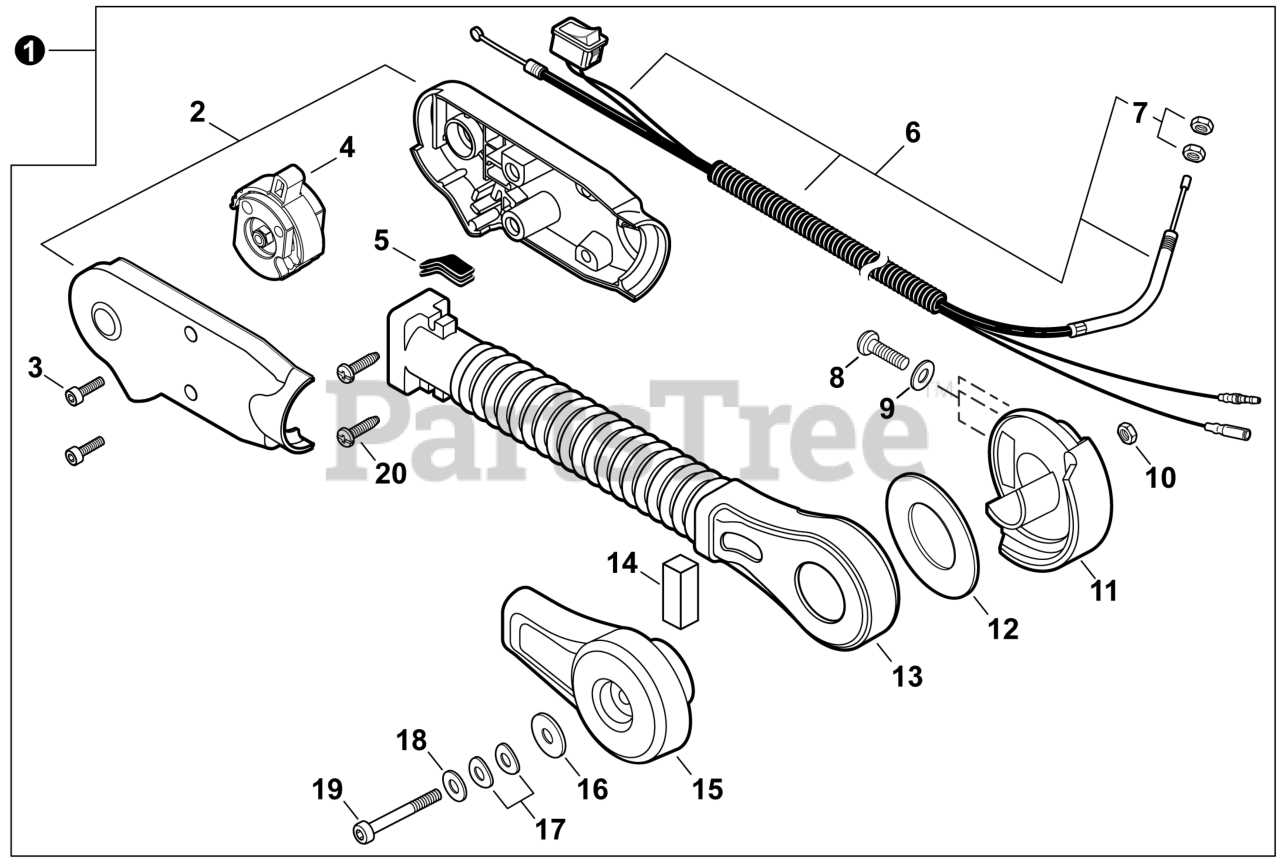

Throttle Controls and Mechanism

The throttle system plays a critical role in regulating the engine’s speed, ensuring smooth and efficient operation. It allows the user to adjust power output by controlling airflow to the engine, which directly influences performance during use. Understanding the components involved in this system and how they function together is key to maintaining optimal functionality.

- Throttle Lever: The lever is used to manually adjust the engine speed. By moving the lever, the user can increase or decrease the power, enabling better control during operation.

- Throttle Cable: This flexible connection transfers the lever’s motion to the carburetor. The integrity of the cable is crucial for maintaining a direct and responsive connection between the user’s input and the engine’s behavior.

- Carburetor Linkage: The linkage mechanism is responsible for translating throttle adjustments into engine changes, ensuring the correct amount of fuel and air is mixed for combustion.

- Return Spring: This component ensures the throttle returns to a neutral or idle position when released, preventing unintended acceleration and enhancing safety.

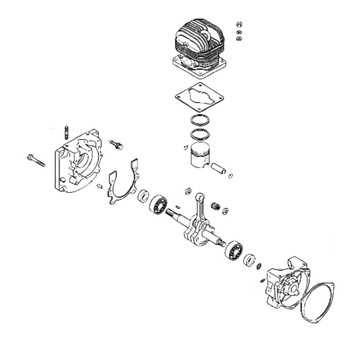

Examining the Recoil Starter Assembly

The recoil starter mechanism is a vital component in many outdoor power equipment devices, enabling easy ignition of the engine. This assembly consists of several key elements that work in unison to ensure reliable starting and optimal performance. Understanding the structure and function of this mechanism can aid in effective maintenance and troubleshooting.

Key Components of the Recoil Starter

The recoil starter assembly typically includes a few essential parts, each contributing to its functionality. Below is a breakdown of these components:

| Component |

Description |

| Starter Rope |

A durable cord that is pulled to engage the starting process. |

| Starter Handle |

The grip used to pull the starter rope, providing leverage for starting. |

| Spring |

Stores tension, enabling the recoil action after the rope is released. |

| Guide Pulley |

Ensures smooth operation of the rope and helps redirect the force during the start. |

| Mounting Bracket |

Secures the assembly to the engine casing, providing stability during operation. |

Maintenance Tips

To keep the recoil starter functioning optimally, regular maintenance is essential. Ensure that the starter rope is free from frays and kinks, and periodically inspect the spring for any signs of wear. Lubricating the moving parts can also enhance performance and prolong the lifespan of the assembly.

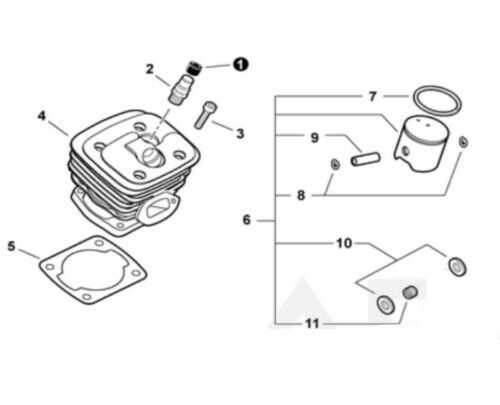

Vibration Dampening System Overview

The vibration dampening mechanism plays a crucial role in enhancing the overall performance and comfort of equipment. This system is designed to minimize the transmission of vibrations generated during operation, thereby reducing operator fatigue and increasing control over the device. By effectively absorbing and dissipating oscillations, this feature contributes to a smoother user experience and improved operational efficiency.

At its core, the dampening system typically incorporates various components that work in unison to mitigate vibrations. These may include specialized mounts, pads, and other absorptive elements that are strategically positioned to target specific vibration frequencies. The implementation of such technology not only prolongs the lifespan of the equipment but also ensures optimal functionality across a range of operating conditions.

Understanding the significance of vibration dampening can greatly enhance the usability and reliability of tools and machinery. Operators are encouraged to familiarize themselves with the characteristics of this system to fully leverage its benefits, ensuring a seamless integration into their workflow.

Muffler and Exhaust System Parts

The muffler and exhaust assembly play a crucial role in the performance and efficiency of a machine. This section highlights the essential components involved in managing exhaust flow, reducing noise, and ensuring optimal operation.

Key Components

- Muffler: Responsible for dampening sound produced during operation, enhancing user comfort.

- Exhaust Pipe: Directs exhaust gases away from the engine, preventing back pressure and ensuring smooth operation.

- Heat Shield: Protects surrounding components from excessive heat generated by exhaust gases.

- Gaskets and Seals: Provide a secure fit between parts, preventing leaks and ensuring efficient exhaust flow.

Maintenance Tips

- Regularly inspect the exhaust system for signs of wear or damage.

- Replace any worn gaskets or seals to prevent exhaust leaks.

- Keep the exterior of the muffler and pipes clean to avoid corrosion.

- Listen for unusual noises that may indicate issues with the muffler or exhaust flow.

Handle and Support Frame Structure

The handle and support frame is a crucial component of outdoor equipment, providing stability and control during operation. This structure is designed to withstand various forces while ensuring comfort and ease of use for the operator. Its ergonomic design plays a significant role in facilitating efficient handling, contributing to overall performance and user satisfaction.

In the context of maintenance and repair, understanding the intricacies of this framework is essential. The support frame not only houses essential mechanisms but also protects them from external elements. The handle’s design influences the operator’s grip, allowing for extended use without discomfort. Ensuring that these components are in optimal condition is vital for safe and effective operation.

Regular inspections can help identify wear and tear, enabling timely replacements or adjustments. Additionally, reinforcing connections and securing joints will enhance the durability of the handle and support frame structure, prolonging the lifespan of the equipment. Proper care and attention to this area will lead to improved performance and reliability in various working conditions.

|

|