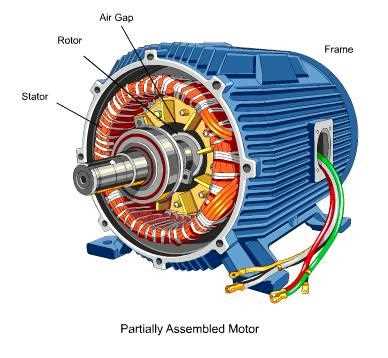

When it comes to mechanical cooling devices, their efficiency depends on several crucial elements working in harmony. These devices, designed to move air and regulate temperature, require a well-structured configuration to operate effectively. This guide focuses on the main components that make up such systems, outlining how they interact to ensure consistent airflow and performance.

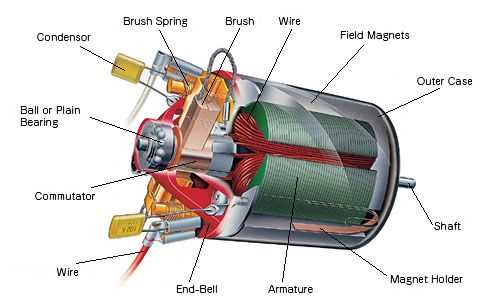

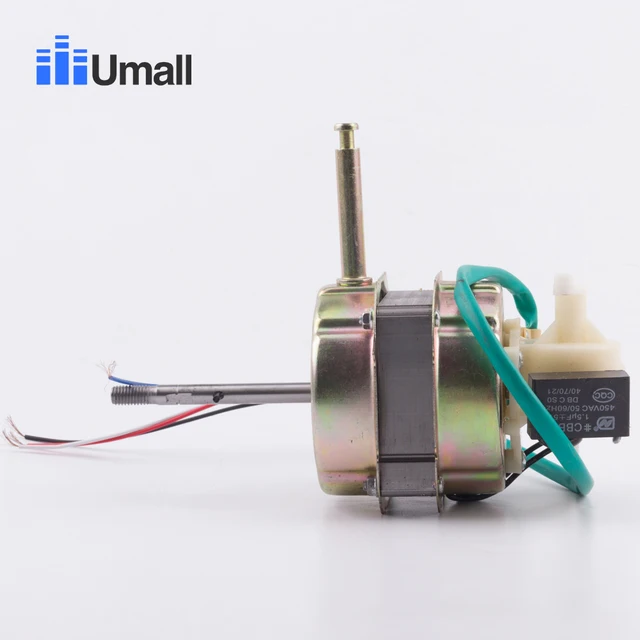

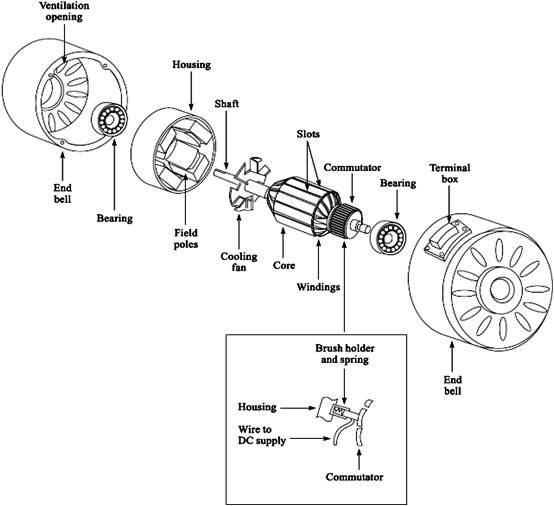

The central mechanism of these systems relies on a combination of rotating and stationary elements, which convert electrical energy into mechanical movement. These components are meticulously designed to achieve balance, durability, and precision in performance. Understanding their function and relationship is essential for maintenance and troubleshooting.

From the dynamic core that drives the system to the connections and supports that stabilize it, each element plays a vital role. Identifying and understanding these key sections not only aids in repairs but also in enhancing overall efficiency and longevity of the device.

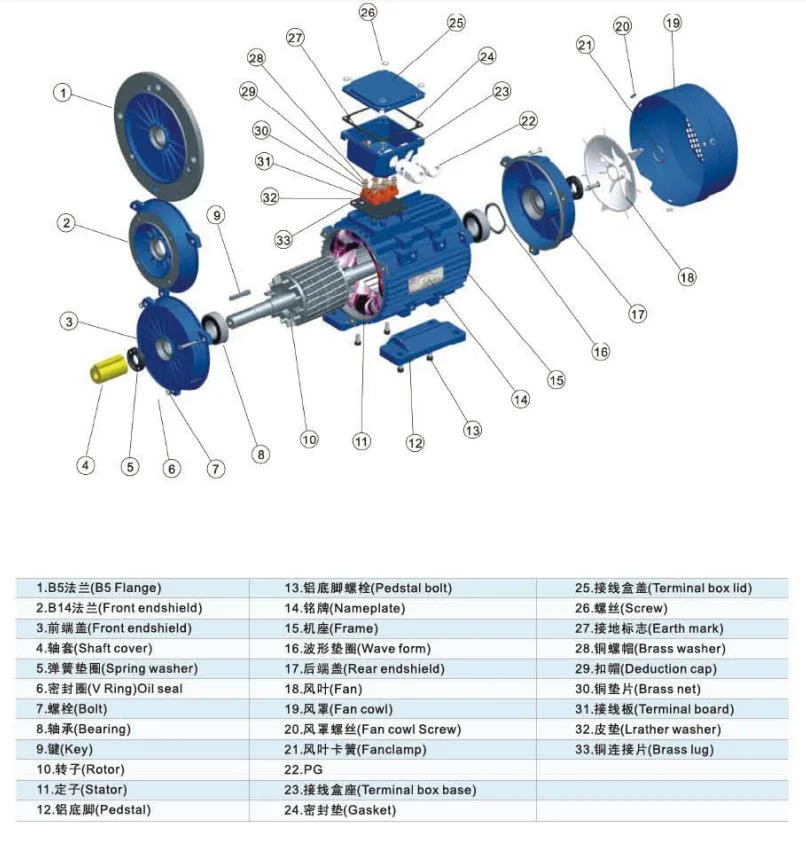

Electric Fan Motor Components Overview

Understanding the internal makeup of rotating airflow devices is key to ensuring optimal performance and longevity. These machines rely on various interconnected elements, each playing a crucial role in converting electrical energy into mechanical motion.

| Component | Function | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rotor | Converts electrical input into rotational motion. | ||||||||||||||||||

| Stator | Produces the magnetic field that interacts with the rotor. | ||||||||||||||||||

| Function | Description |

|---|---|

| Magnetic Field Generation | Produces a rotating field that drives motion. |

| Induction | Enables neighboring components to initiate rotation. |

| Stability | Maintains consistent performance during operation. |

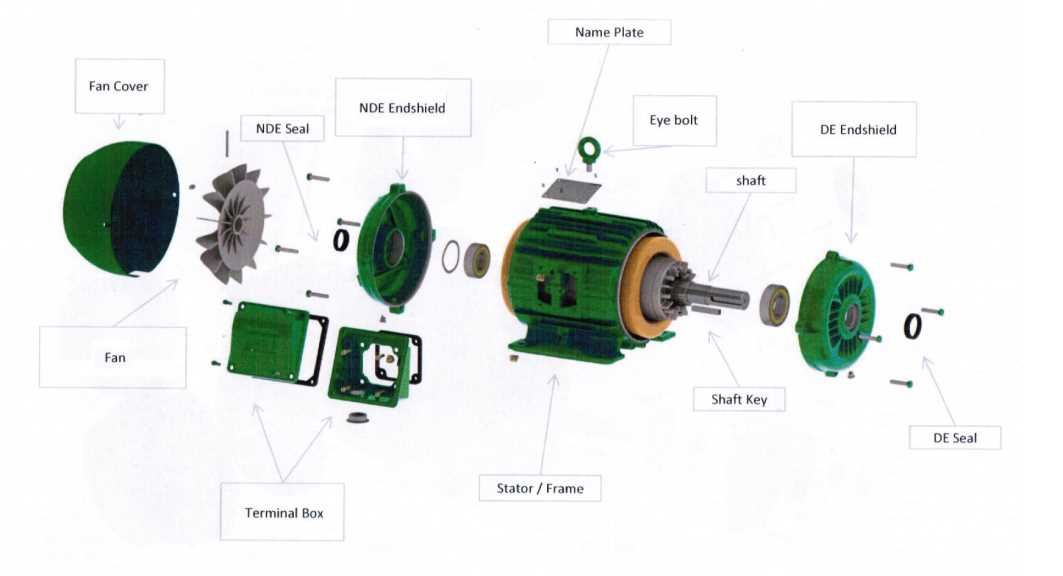

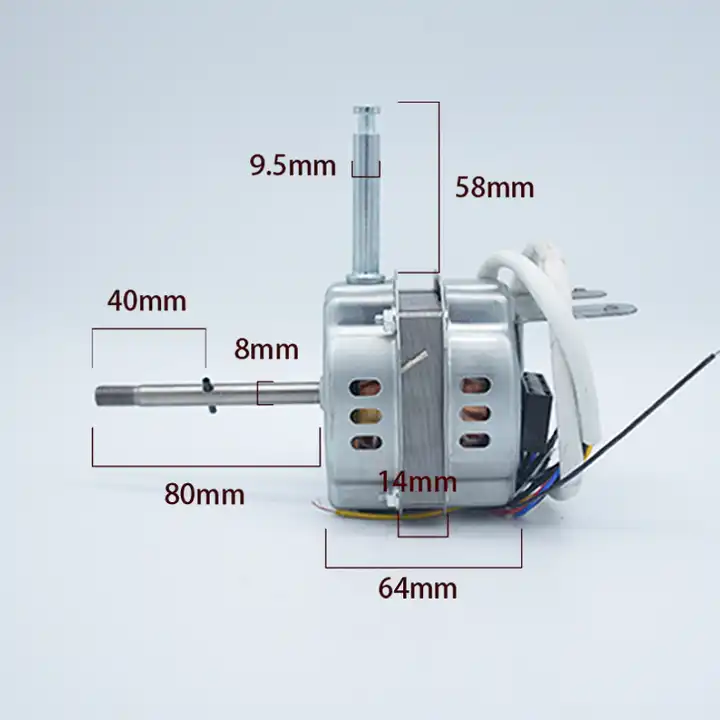

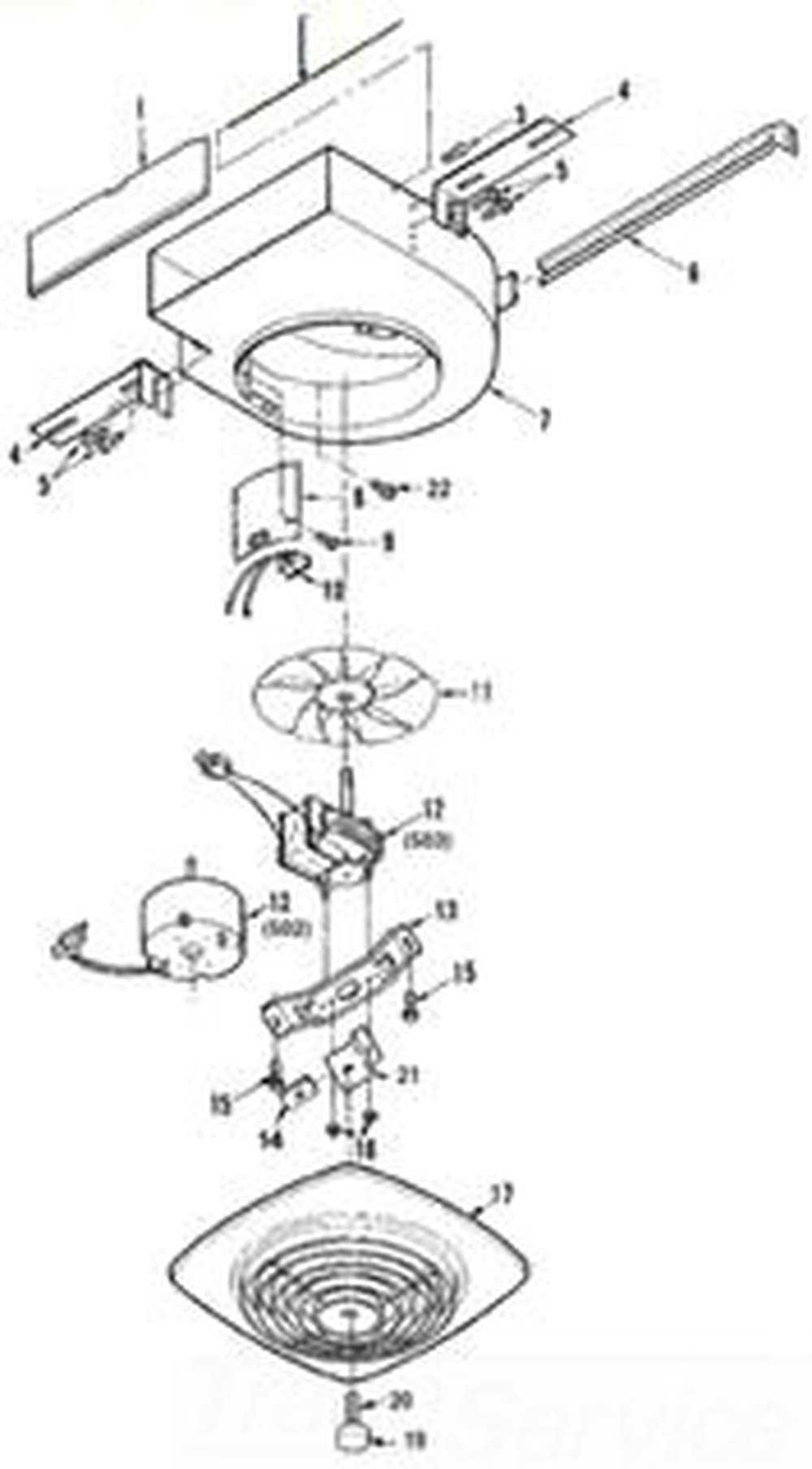

Fan Blade Connection to Motor Assembly

The integration of a rotating element with a driving mechanism is a crucial aspect of various appliances. This section explores how the blades are securely linked to the central unit, ensuring optimal performance and efficiency. A proper connection allows for the effective transfer of energy, contributing to the overall functionality of the device.

Understanding the Connection Mechanism

Establishing a robust connection involves specific components that facilitate the attachment and rotation of the blades. Typically, these elements include a hub, screws, and locking mechanisms, which together maintain stability during operation. The arrangement not only influences performance but also impacts the durability of the assembly.

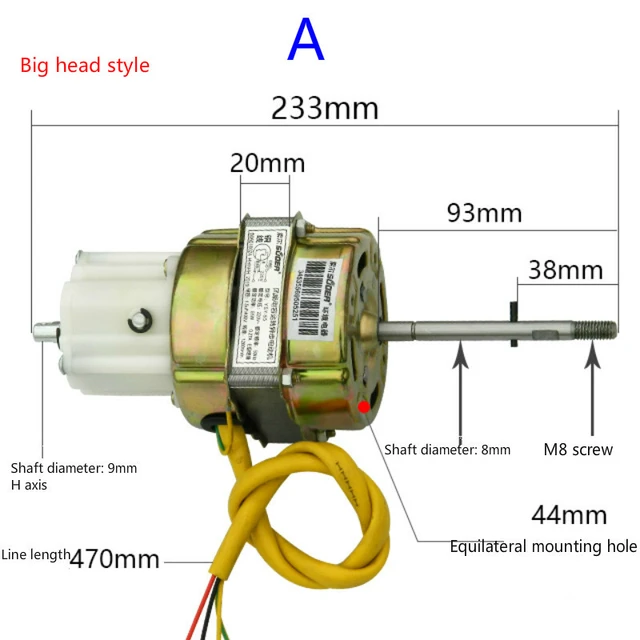

Connection Types and Specifications

Different types of connections can be utilized depending on the design and purpose of the appliance. Here’s a table summarizing common connection types and their specifications:

| Connection Type | Description | Application |

|---|---|---|

| Screw Connection | Utilizes screws for secure attachment. | Common in household units. |

| Snap Fit | Components snap together for ease of assembly. | Ideal for lightweight designs. |

| Interlocking Mechanism | Features interlocking parts to enhance stability. | Used in industrial models. |

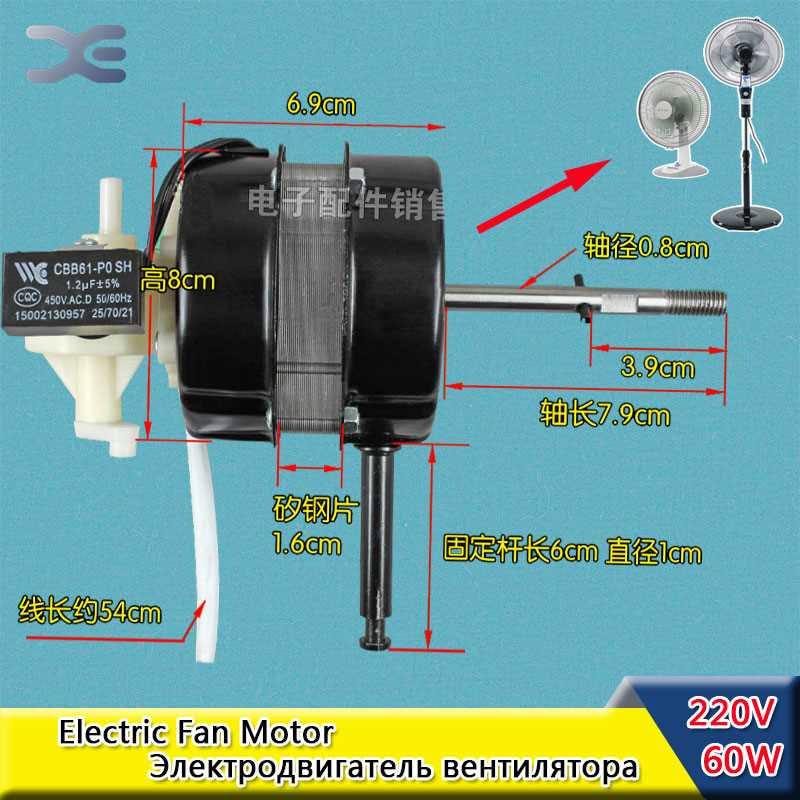

Impact of Housing on Motor Efficiency

The outer structure of a rotating device plays a crucial role in determining its overall performance and energy consumption. By providing protection and stability, this component can significantly influence how effectively the internal mechanisms operate. The design and materials used in constructing this enclosure can enhance thermal management and airflow, ultimately affecting the system’s efficiency.

A well-engineered casing minimizes vibrations and noise, contributing to a smoother operation. Additionally, the shape and size of the housing can affect the cooling characteristics of the unit. Adequate ventilation allows for better heat dissipation, preventing overheating and ensuring that the device maintains optimal performance levels over time. Thus, the right choice of housing is essential for maximizing efficiency and longevity.

Troubleshooting Common Motor Component Issues

When dealing with issues related to the functionality of rotational devices, understanding the common problems that may arise is essential for effective resolution. This section explores typical challenges encountered with essential elements and provides guidance on identifying and addressing these complications.

One frequent concern is overheating, which can result from excessive load or inadequate ventilation. To resolve this, ensure that the assembly is not obstructed and that the airflow is unobstructed. Additionally, verify that the specifications of the current draw do not exceed the recommended limits.

Another common problem involves unusual noises, which may indicate wear or misalignment of key components. Inspect the configuration for any signs of looseness and replace any worn-out elements to restore smooth operation. Regular maintenance and checks can prevent such issues from escalating.

Finally, a lack of response or failure to initiate is often attributed to electrical faults or control system failures. Check connections and ensure that the supply voltage matches the required specifications. If issues persist, consider examining the control mechanisms for potential faults.