In modern heating solutions, the intricate interplay of various elements is crucial for optimal performance. Each component plays a significant role in ensuring efficiency and reliability, contributing to the overall functionality of the system. A clear comprehension of these mechanisms can enhance both maintenance and troubleshooting efforts.

By exploring the relationship between these critical elements, one can gain insights into how they work together to generate warmth. Understanding their roles not only simplifies the repair process but also elevates the effectiveness of the entire heating setup. Knowledge in this area ultimately leads to better energy management and prolonged system lifespan.

Moreover, a thorough examination reveals how each segment can impact performance, energy consumption, and safety. By delving into this subject, users can make informed decisions about their heating solutions, ensuring a comfortable environment throughout the year.

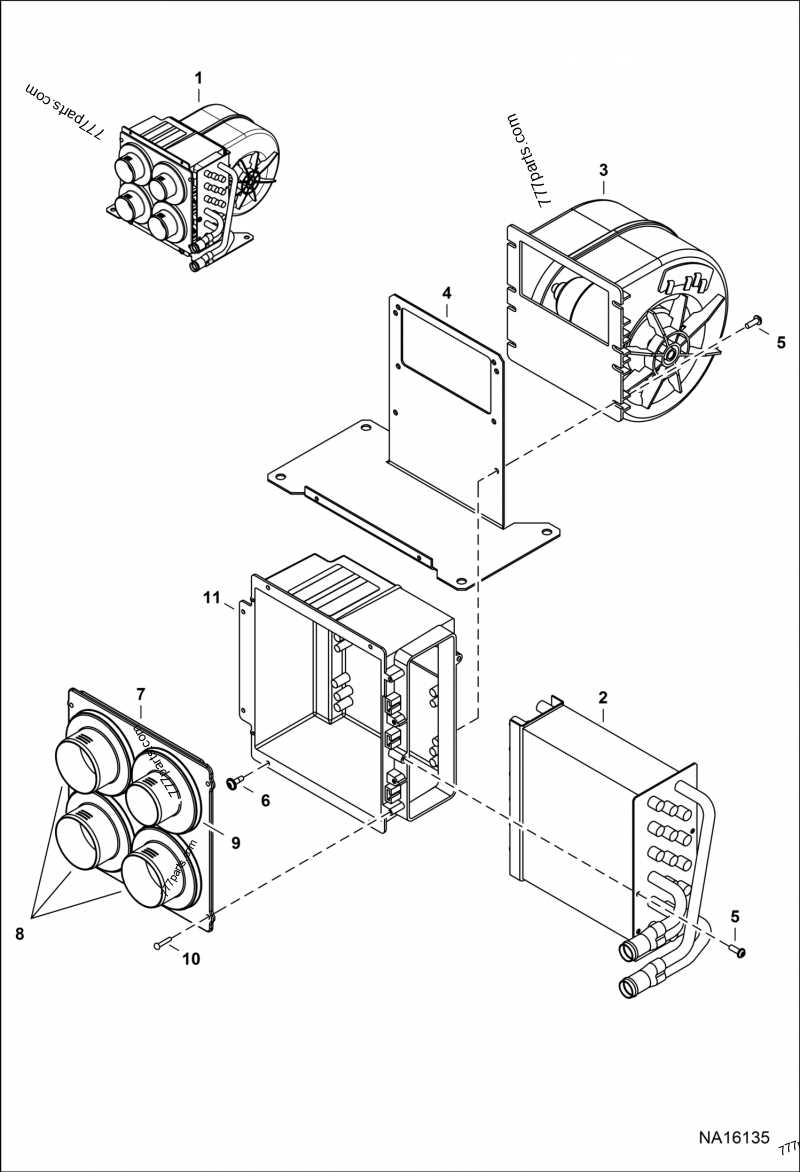

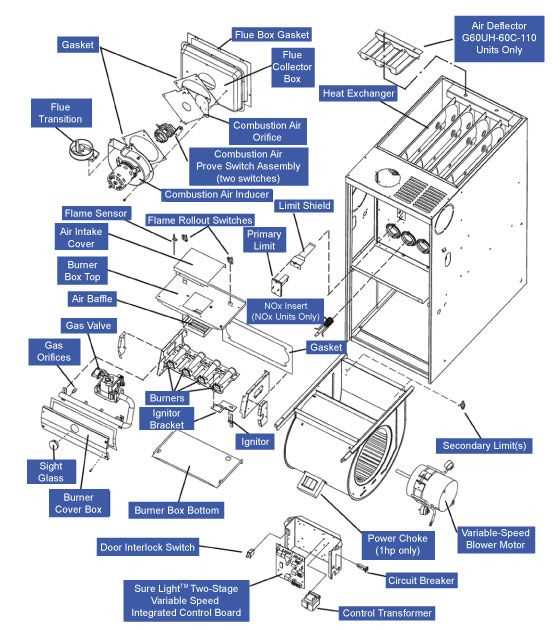

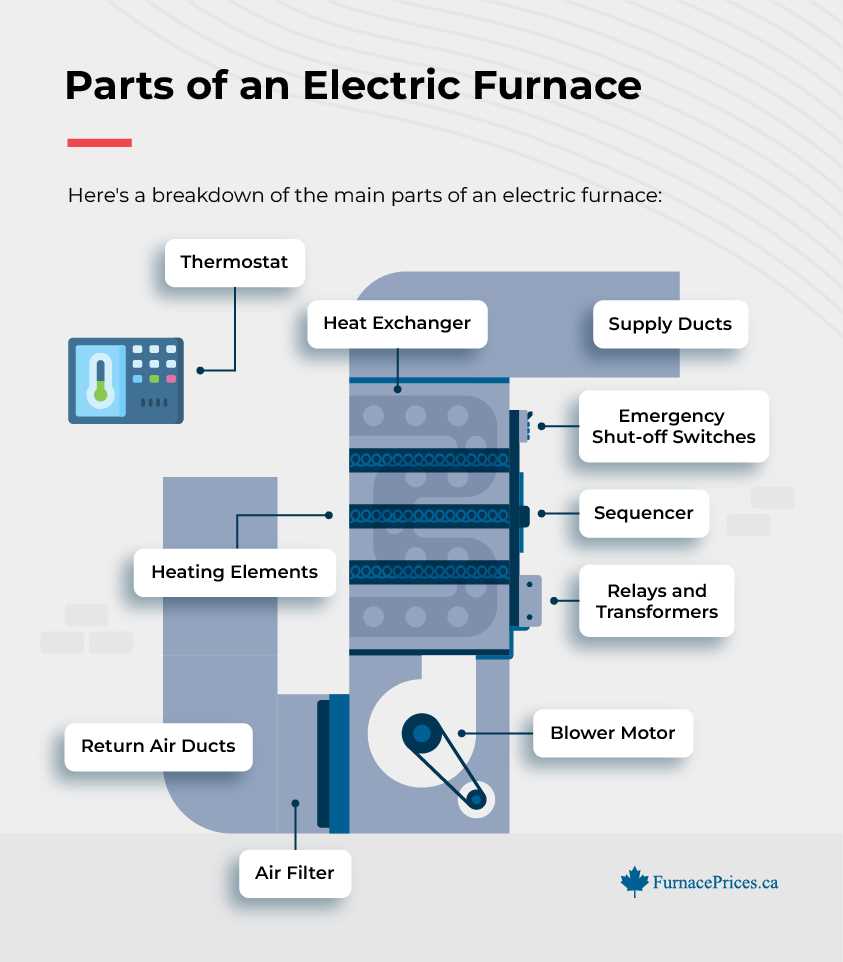

Understanding Electric Furnace Components

The efficient operation of a heating unit relies on a variety of interconnected elements, each playing a crucial role in its functionality. Recognizing these components helps in grasping how they work together to deliver warmth and comfort in living spaces.

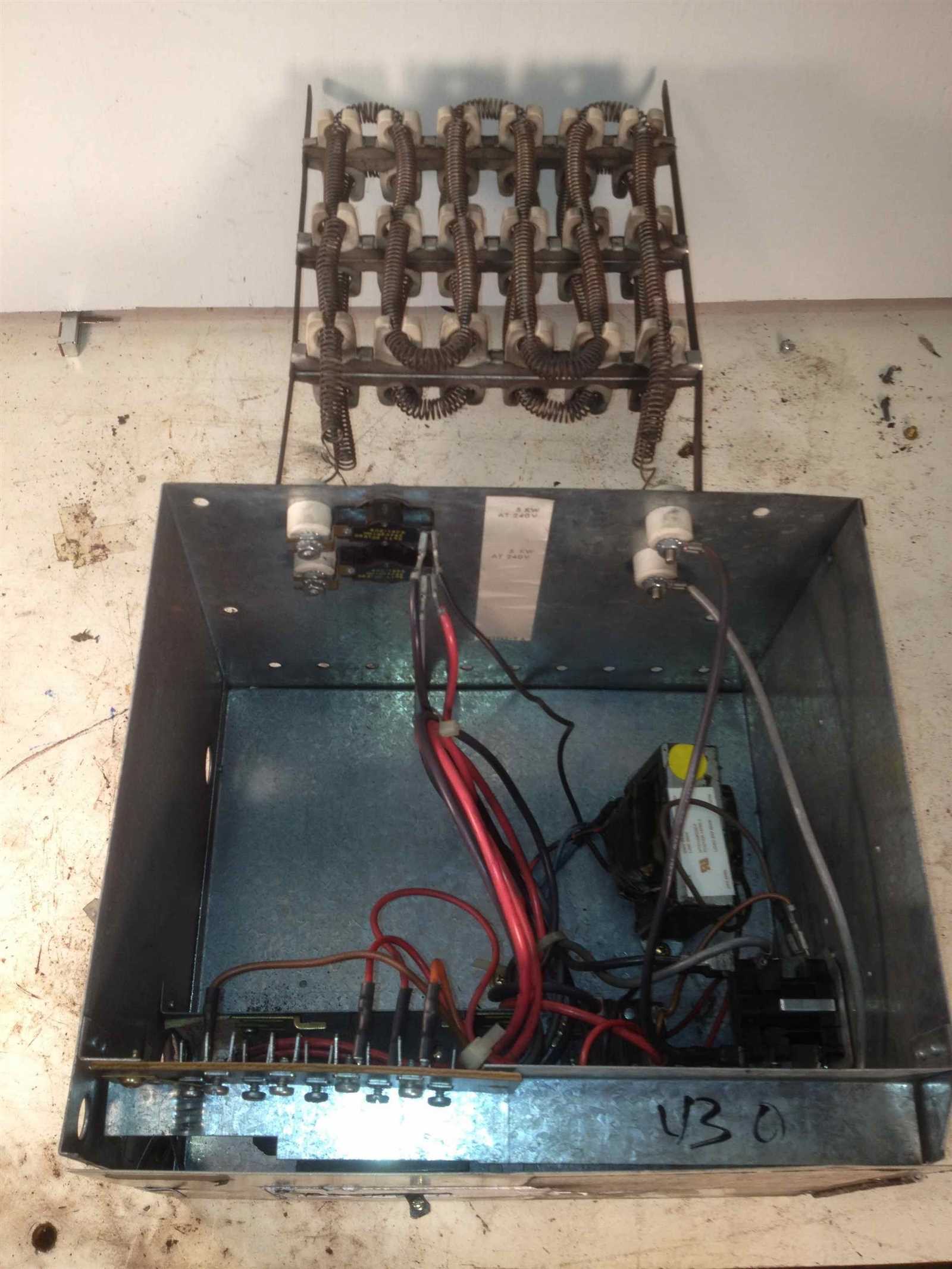

Heating Element: This core component generates warmth by converting electrical energy into heat. Its material and design significantly influence efficiency and performance.

Thermostat: Serving as the control center, this device monitors the ambient temperature and regulates the heating cycle, ensuring consistent comfort levels.

Blower Motor: Responsible for circulating heated air throughout the area, the blower motor enhances the distribution of warmth, contributing to the overall effectiveness of the system.

Relay and Circuit Board: These electronic components facilitate communication between the thermostat and the heating element, ensuring seamless operation and responsiveness to user settings.

Safety Features: Various mechanisms, such as limit switches and fuses, are integrated to prevent overheating and potential hazards, emphasizing the importance of safety in design.

Understanding these integral components allows users to appreciate their roles in creating a reliable and efficient heating system.

Key Parts of Electric Furnaces

The effective operation of heating systems relies on several essential components that work together to ensure optimal performance and efficiency. Understanding these elements is crucial for maintenance and troubleshooting, as each plays a significant role in the overall functionality.

| Component | Description |

|---|---|

| Heating Element | This is responsible for generating heat through electrical resistance, converting electrical energy into thermal energy. |

| Thermostat | A device that regulates temperature by monitoring and controlling the heat output based on the desired setting. |

| Blower Motor | This component circulates heated air throughout the space, ensuring even distribution and comfort. |

| Control Board | A central hub that manages the operation of various elements, coordinating their functions for effective heating. |

| Safety Switch | This feature prevents overheating and ensures safe operation by shutting down the system if temperatures exceed safe levels. |

| Filter | A crucial element that removes dust and debris from the air before it is heated and circulated, improving air quality. |

Functionality of Heating Elements

Heating components play a crucial role in generating warmth through various methods. Their design and operation significantly influence efficiency and performance in diverse applications.

Types of Heating Elements

- Resistive Heating Elements

- Infrared Heaters

- Induction Heaters

Key Functions

- Conversion of Electrical Energy to Thermal Energy

- Temperature Regulation and Control

- Durability and Resistance to Wear

Importance of Temperature Sensors

Temperature sensors play a crucial role in various heating systems, ensuring optimal performance and safety. They monitor thermal conditions and provide real-time data that aids in maintaining desired levels of heat, which is essential for efficiency and reliability.

Key Functions of Temperature Sensors

- Monitoring: Continuous tracking of thermal levels for precise control.

- Safety: Preventing overheating and potential hazards.

- Efficiency: Optimizing energy consumption by regulating heat output.

Benefits of Accurate Temperature Measurement

- Enhanced System Longevity: Reduces wear and tear on components.

- Improved Performance: Ensures consistent operation and product quality.

- Cost Savings: Minimizes energy waste and lowers operational expenses.

Role of Control Panels Explained

Control panels serve as the nerve center for managing and monitoring thermal systems, ensuring optimal functionality and safety. They provide users with the ability to oversee operations, making adjustments as necessary to maintain efficiency and performance.

These panels typically include various components that contribute to their effectiveness. Below is a summary of their key functions:

| Function | Description |

|---|---|

| Monitoring | Allows users to track operational parameters and conditions in real-time. |

| Control | Facilitates adjustments to settings for improved performance and energy savings. |

| Safety | Incorporates alarms and automatic shutdown features to prevent hazardous situations. |

| Data Logging | Records operational data for analysis and troubleshooting purposes. |

Ultimately, these control mechanisms enhance the overall reliability and safety of thermal systems, making them indispensable in modern applications.

Electrical Connections and Wiring Basics

This section explores fundamental principles that govern the establishment of safe and effective connections within heating appliances. Understanding these basics is essential for ensuring reliable operation and preventing potential hazards.

Understanding Voltage and Current

Voltage represents the electrical force that drives current through a circuit, while current is the flow of electric charge. Recognizing the relationship between these elements is crucial for making informed decisions about wiring and ensuring compatibility with components.

Safety Precautions

Prioritize safety when working with any electrical system. Always ensure power is disconnected before making adjustments. Utilizing proper insulation and circuit protection devices can prevent accidents and maintain optimal performance.

Safety Features in Electric Furnaces

Ensuring secure operation is crucial in any heating device. Various mechanisms are implemented to minimize risks and enhance user protection. These features not only prevent accidents but also contribute to the longevity and efficiency of the system.

One key aspect is the integration of thermal protection, which automatically shuts down the unit if it overheats. This function helps avoid potential fire hazards and equipment damage. Additionally, a robust electrical safety system is in place to prevent short circuits and overloads, safeguarding both the appliance and the surrounding environment.

Furthermore, the presence of proper insulation plays a vital role in maintaining safe surface temperatures, reducing the risk of burns. User-friendly controls and indicators allow for easy monitoring, ensuring that any irregularities are quickly addressed. Regular maintenance checks are also essential in upholding these safety standards, ensuring optimal performance over time.

Types of Insulation Materials Used

Insulation materials play a crucial role in maintaining temperature control and energy efficiency in various heating systems. These materials help to reduce heat loss or gain, ensuring optimal performance and safety. Different types of insulation are available, each offering unique properties suitable for specific applications.

| Material Type | Properties | Applications |

|---|---|---|

| Fiberglass | High thermal resistance, non-combustible | Residential and commercial heating systems |

| Mineral Wool | Excellent soundproofing, water-resistant | Industrial applications, sound-sensitive environments |

| Foam Board | Lightweight, high insulation value | Wall cavities, roofs, and floors |

| Cellulose | Eco-friendly, effective air barrier | Attics and wall insulation |

| Reflective or Radiant Barrier | Reduces radiant heat transfer | Roofs and attics in hot climates |

Choosing the right insulation material is essential for achieving the desired thermal performance and ensuring long-lasting efficiency in heating systems.

Maintenance of Furnace Parts

Regular upkeep of heating apparatus is essential for optimal performance and longevity. By ensuring each component operates efficiently, one can prevent malfunctions and enhance overall safety. This practice not only saves costs but also improves energy efficiency, leading to a more sustainable operation.

Routine Inspection

Conducting regular assessments helps identify wear and tear early. Checking connections, insulation, and heating elements ensures that any potential issues are addressed promptly, preventing larger problems down the line.

Cleaning Procedures

Maintaining cleanliness is crucial for the efficient functioning of heating systems. Removing dust and debris from components prevents overheating and promotes better airflow, thereby enhancing performance and safety.

Common Issues with Electric Furnaces

Many homeowners encounter a range of problems with their heating systems, leading to discomfort and increased energy costs. Understanding these frequent complications can help in identifying solutions and ensuring efficient operation throughout the colder months.

1. Insufficient Heat Production

One of the most common complaints is the inability of the system to generate adequate warmth. This issue may arise from various factors, including faulty thermostats or damaged heating elements. Ensuring proper calibration and regular maintenance can often mitigate this problem.

2. Frequent Cycling

Another prevalent concern is the system cycling on and off too frequently. This can lead to higher energy bills and wear on the components. Possible causes include incorrect thermostat settings, air leaks, or inadequate insulation. Addressing these factors is essential for optimal performance.

3. Unusual Noises

Strange sounds, such as rattling or buzzing, can indicate underlying issues. These noises may result from loose components or mechanical failures. Regular inspections can help identify and rectify these disturbances before they escalate into more significant problems.

4. Increased Energy Bills

A sudden spike in energy expenses may signal inefficiency in the heating system. This could stem from dirt accumulation on filters or internal components, leading to greater energy consumption. Regular cleaning and timely filter replacements are vital for maintaining efficiency.

5. Odors

Unpleasant smells emanating from the heating unit can be alarming. They may indicate burnt dust or, in worse cases, electrical issues. It’s crucial to address any unfamiliar odors promptly, as they could signify a potential hazard.

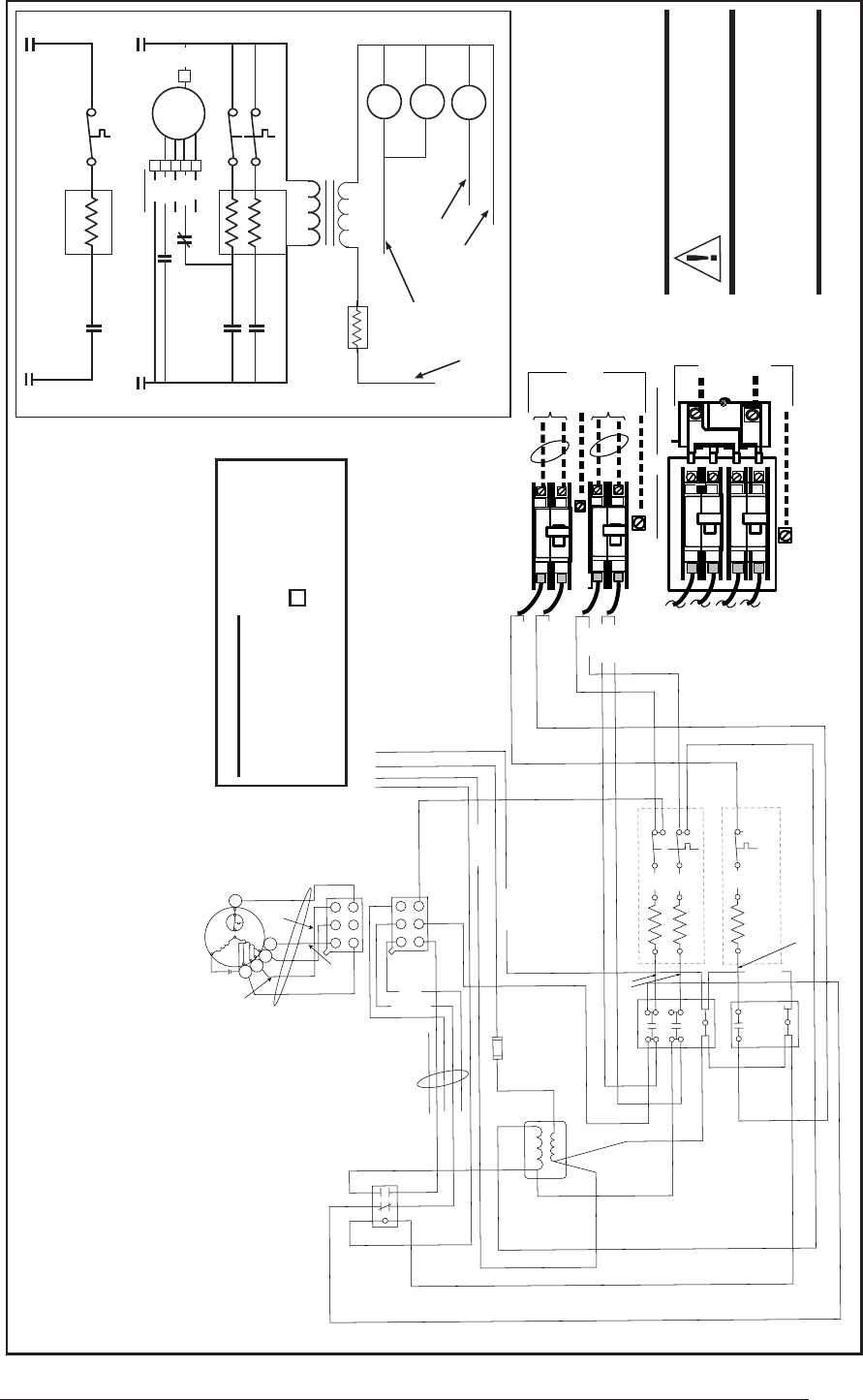

How to Read a Wiring Diagram

Understanding the layout of electrical connections is essential for troubleshooting and maintenance. A well-structured visual representation can simplify the process of identifying components and their interrelations. By familiarizing yourself with common symbols and conventions, you can efficiently navigate through the schematic.

Each element in the illustration serves a specific purpose, and recognizing these can aid in comprehending the overall system. Pay attention to the following key aspects:

| Element | Description |

|---|---|

| Symbols | Graphic representations indicating various components such as switches, connectors, and power sources. |

| Lines | Indicate the flow of electricity, showing how different parts are interconnected. |

| Labels | Text annotations that provide additional information about the components, including specifications and ratings. |

| Legend | A key that explains the symbols used, enhancing clarity and understanding. |

By following these guidelines, you can interpret the schematic effectively, leading to successful troubleshooting and repairs.

Choosing Replacement Parts Wisely

Selecting the right components for your heating unit is essential for maintaining optimal performance and longevity. Making informed choices can prevent future issues and enhance efficiency.

Key Considerations

- Compatibility: Ensure new components fit seamlessly with existing equipment.

- Quality: Opt for high-grade materials to reduce wear and tear.

- Manufacturer Reputation: Research brands known for reliability and customer support.

Steps to Take

- Consult the manual for specifications.

- Compare different suppliers for price and quality.

- Read reviews and testimonials from other users.