The intricate layout of mechanical systems is essential for understanding how various elements work together. Each section plays a critical role, and their arrangement impacts the overall functionality. By exploring the structure and interconnections, you gain a clearer picture of how these elements collaborate to ensure smooth operation.

In this detailed guide, we will walk through the key sections and highlight their placement within the broader framework. This approach will help you appreciate the significance of each individual piece, its positioning, and how it influences performance.

With a focus on clarity and precision, we aim to provide a thorough insight into this layout, allowing for better understanding and potential troubleshooting when needed.

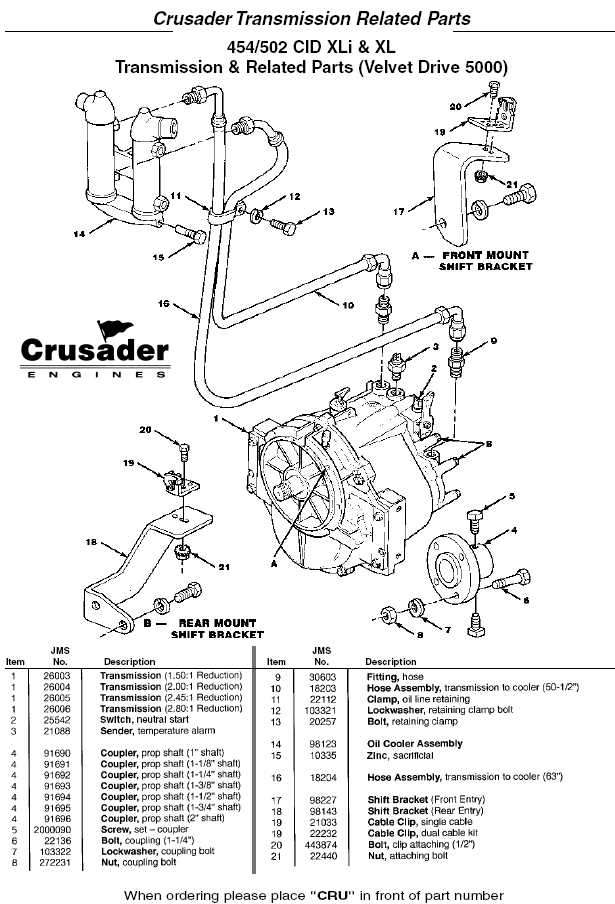

Understanding the 454 Engine Layout

The layout of this specific powertrain is designed to provide efficient performance and reliability. It consists of several interconnected systems working together to ensure smooth operation. Each component plays a key role in maintaining the functionality, contributing to the overall balance and power output. By understanding the arrangement of these elements, you can better grasp how each section contributes to the entire system.

Key Components and Their Functions

The system incorporates various essential elements that handle different tasks, from managing fuel flow to ensuring proper airflow. For instance, one set of components controls combustion efficiency, while another governs the temperature regulation, helping prevent overheating. The careful coordination between these sections ensures that the machine operates effectively under a variety of conditions.

How the Layout Impacts Performance

The structure and placement of the various systems greatly influence the performance. The alignment allows for optimized energy distribution, ensuring maximum output with minimal loss. This layout not only enhances power but also contributes to durability and longevity. Proper understanding of how these elements interact can lead to better maintenance and tuning for those looking to maximize efficiency.

Main Components of the 454 Engine

This section focuses on the fundamental elements that make up the core of this high-performance power unit. Understanding these primary components is crucial for maintaining the overall system and ensuring its proper functioning. Each part plays a vital role in delivering optimal performance and durability.

Key Structural Elements

- Cylinder block – the foundation of the entire mechanism, housing crucial moving parts.

- Cylinder heads – responsible for controlling the flow of air and fuel, playing a key role in combustion.

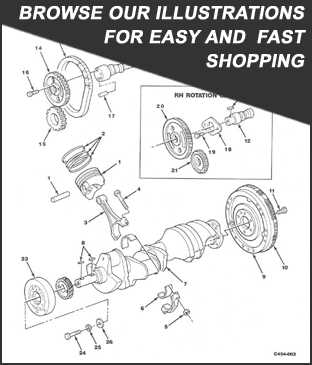

- Pistons – convert pressure into mechanical energy, working in sync with the crankshaft.

- Crankshaft – ensures smooth power delivery by converting reciprocating motion into rotational force.

- Reduces harmful vibrations

- Enhances system stability

- Improves longevity of connected components

Role of Pistons in Power Generation

The movement of pistons plays a crucial role in the overall process of converting energy into motion. As these components move within the cylinder, they interact with various elements, creating the necessary force to drive the system. Their motion is central to harnessing potential energy and turning it into kinetic output, which is essential for mechanical performance.

Pistons are responsible for transforming energy through a cyclical process of compression and expansion. During each cycle, they move up and down, helping to compress the mixture and, later, release the energy stored. This action generates the required momentum, which is transferred to other components for further use in power creation.

Furthermore, the efficiency of this process largely depends on the design and condition of the pistons. High-performance systems rely on the seamless movement and durability of these parts, ensuring

Exhaust System Overview for 454 Engine

The exhaust framework plays a vital role in the overall performance and efficiency of a vehicle. This assembly is responsible for channeling gases produced during combustion away from the combustion chamber, ensuring optimal operation and minimizing harmful emissions. Understanding the components and their functions is essential for maintaining and enhancing the overall functionality of the powertrain.

Key Components: The exhaust system comprises several critical elements that work together seamlessly. The exhaust manifold collects gases from multiple cylinders and directs them into a single outlet. Following this, the catalytic converter plays a crucial role in reducing harmful pollutants before the gases flow through the muffler, which dampens noise, providing a smoother and quieter operation.

Performance Considerations: Upgrading or modifying the exhaust system can lead to significant performance improvements. Enhanced airflow can result in increased horsepower and torque, contributing to a more responsive driving experience. Additionally, careful selection of materials and designs can improve durability and longevity, ensuring that the assembly withstands the rigors of high-performance applications.

Regular inspections and maintenance of the exhaust framework are essential to prevent leaks and ensure optimal functionality. By prioritizing these aspects, vehicle owners can enjoy a more efficient and powerful driving experience.

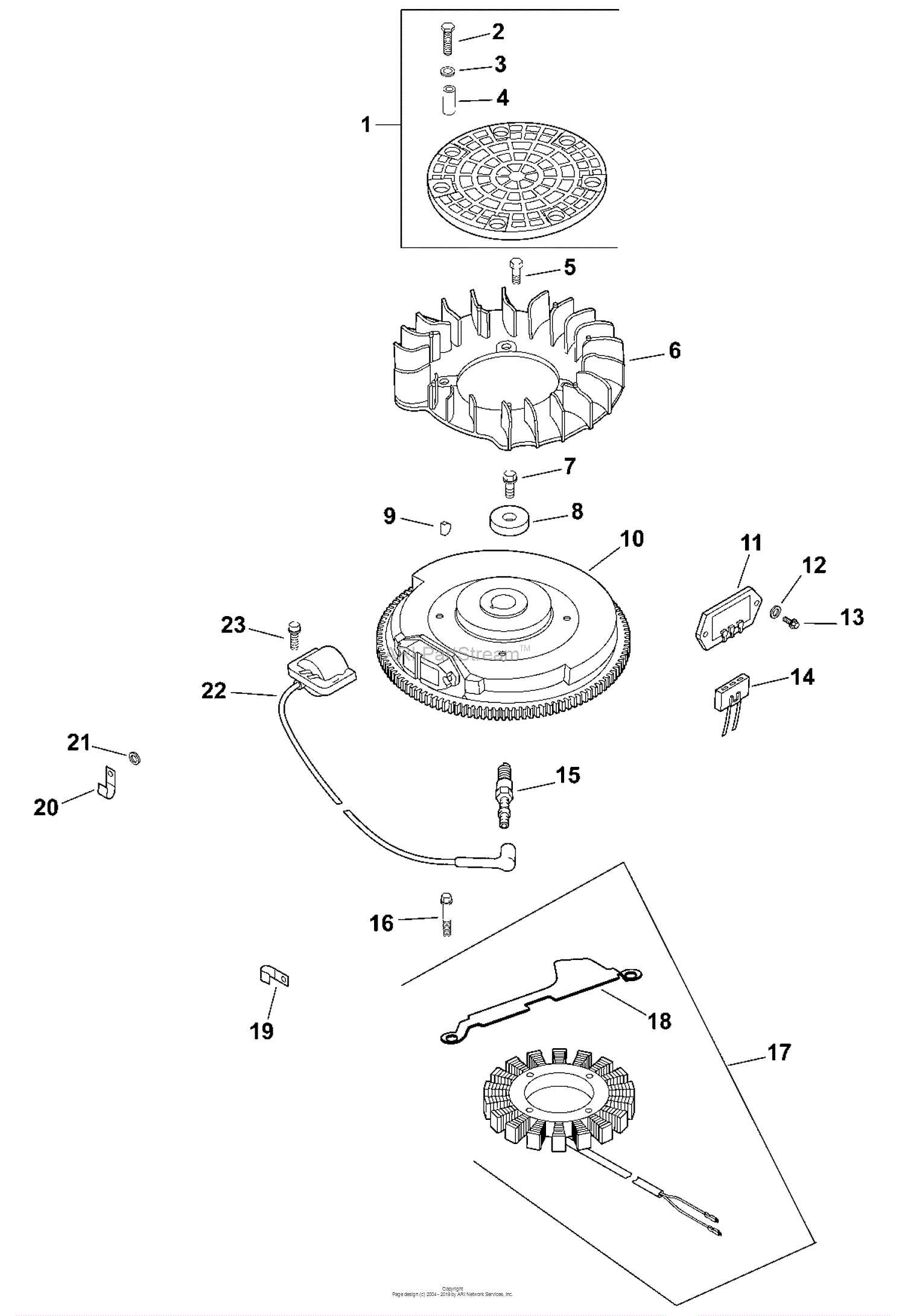

Key Parts of the Ignition System

The ignition system plays a crucial role in the overall functionality of a vehicle’s propulsion system. It is responsible for generating the necessary spark to ignite the air-fuel mixture within the combustion chamber, ensuring optimal performance and efficiency. Understanding the fundamental components of this system is essential for effective maintenance and troubleshooting.

Primary Components

Several key elements work together within the ignition system to ensure reliable operation. Each component contributes to the process of producing and delivering the ignition spark. Below is a brief overview of these essential elements:

Component Function Spark Plug Generates the electrical spark that ignites the air-fuel mixture. Ignition Coil Transforms low voltage from the battery into high voltage needed to create the spark. Distributor Distributes the high voltage from the ignition coil to the correct spark plug at the right time. Ignition Switch Controls the power flow to the ignition system, allowing the engine to start. Supporting Elements

In addition to the primary components, several auxiliary elements enhance the performance and reliability of the ignition mechanism. These include various sensors, wiring harnesses, and connectors that facilitate seamless communication between different parts of the system.

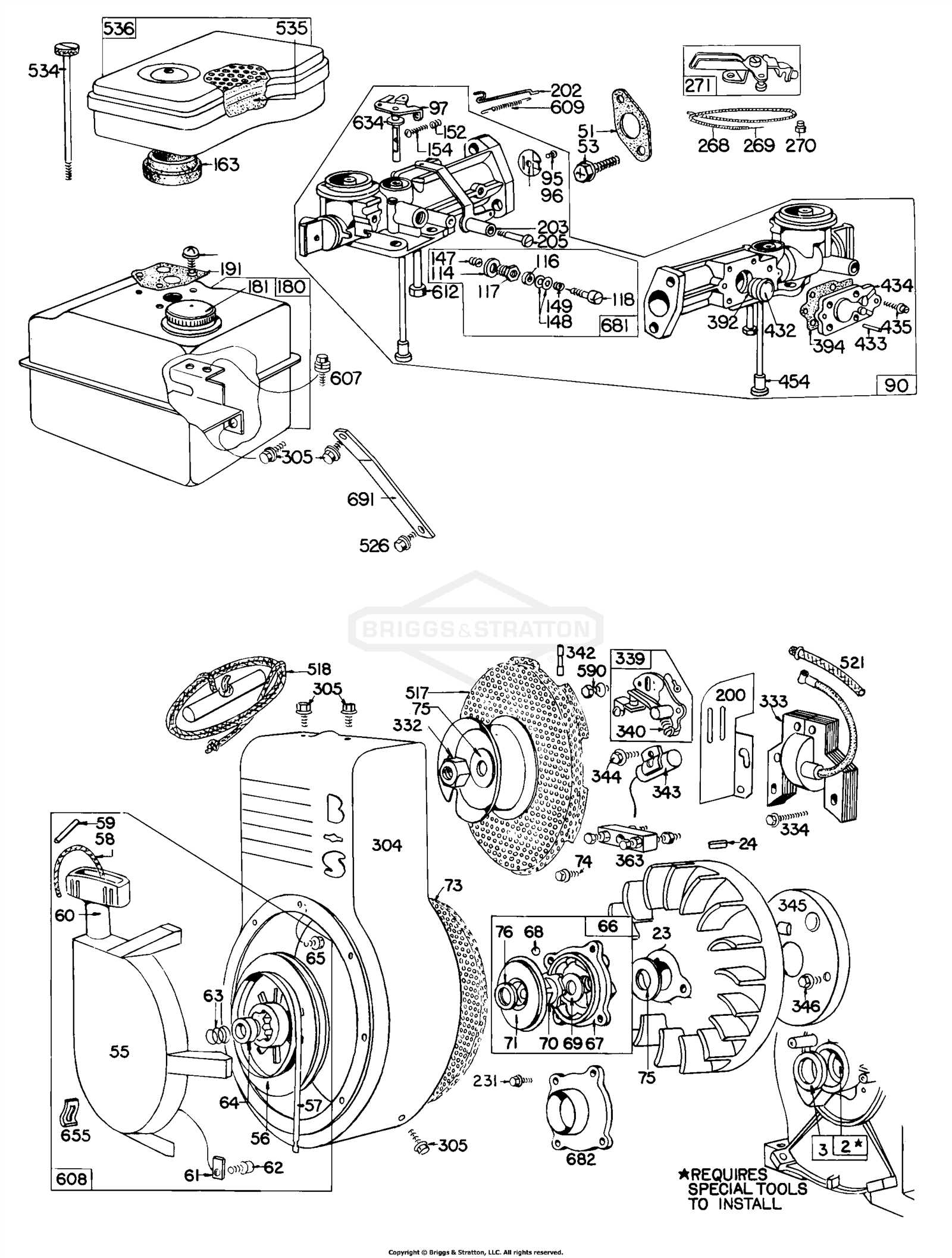

Fuel Delivery Mechanism in the 454 Engine

The fuel delivery system is crucial for ensuring optimal performance and efficiency in high-capacity internal combustion systems. This mechanism is responsible for transporting fuel from the tank to the combustion chambers, where it mixes with air for ignition. Understanding the components and functioning of this system can significantly enhance maintenance and troubleshooting efforts.

Key components of the fuel delivery mechanism include:

- Fuel Pump: This device draws fuel from the tank and pumps it through the system, maintaining adequate pressure for efficient flow.

- Fuel Filter: This component removes impurities and contaminants from the fuel, protecting the injectors and other parts from damage.

- Fuel Injectors: These are responsible for atomizing the fuel and delivering it into the combustion chamber in a precise manner.

- Fuel Lines: These pathways transport the fuel from one component to another, requiring proper routing to prevent leaks.

Moreover, regular maintenance of these elements is vital for smooth operation. Issues such as clogging or wear can lead to inefficient combustion and power loss. Periodic checks and replacements ensure the longevity and reliability of the entire system.

In summary, the efficient functioning of the fuel delivery mechanism directly impacts performance, fuel efficiency, and overall engine health. Proper understanding and upkeep of this system are essential for any high-capacity motor application.

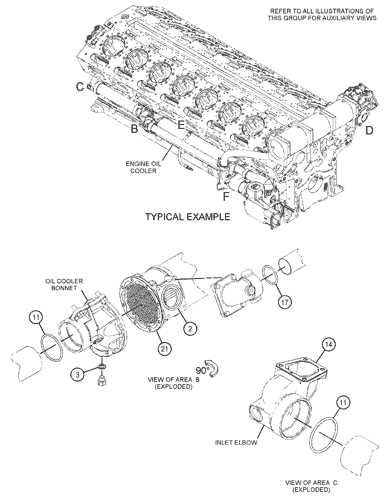

Cooling System Parts and Operation

The cooling system plays a vital role in maintaining optimal temperatures within a vehicle’s machinery. Its efficient functioning is crucial for preventing overheating, ensuring the longevity and reliability of the overall mechanism. Understanding the components and their interactions can greatly enhance performance and reduce potential issues.

Key elements involved in this system include:

- Radiator: A key component responsible for dissipating heat from the coolant.

- Water Pump: Circulates coolant throughout the system, ensuring effective heat transfer.

- Thermostat: Regulates the temperature by controlling the flow of coolant to maintain ideal operating conditions.

- Coolant Reservoir: Holds excess coolant and helps to maintain the system’s pressure.

- Hoses: Flexible conduits that transport coolant between various components.

These components work together in a coordinated manner. The water pump draws coolant from the reservoir, sending it through the radiator where it is cooled by airflow. The thermostat monitors temperature changes, adjusting coolant flow to maintain the appropriate level. This cycle continues, ensuring that the internal workings remain within safe temperature limits.

Regular maintenance of these elements is essential for optimal performance. Checking for leaks, ensuring proper fluid levels, and inspecting for wear can help prevent costly repairs and maintain efficiency. Understanding how each component functions allows for better decision-making regarding maintenance and troubleshooting.

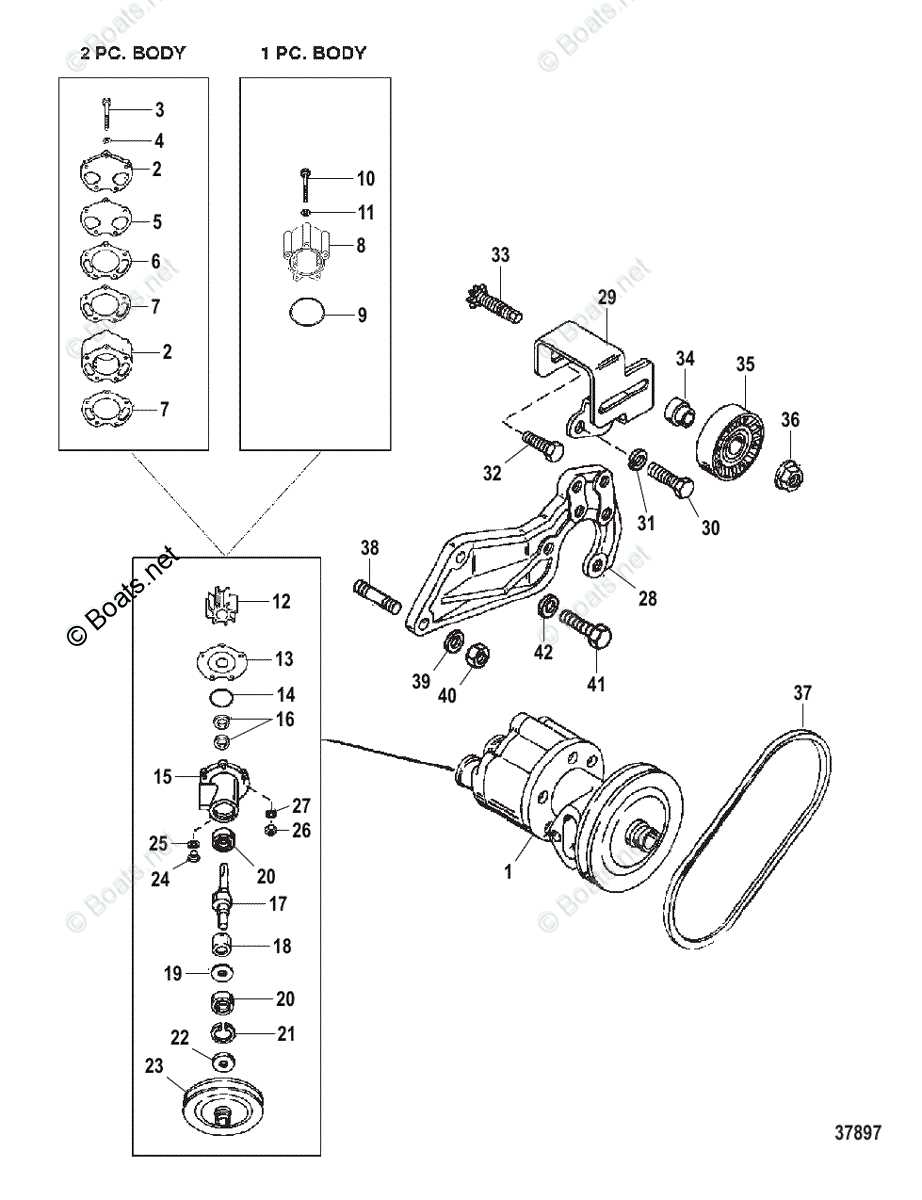

Oil Pump and Lubrication System

The functionality of a power unit heavily relies on its ability to maintain proper lubrication throughout its components. A robust lubrication system is essential for reducing friction, dissipating heat, and ensuring the longevity of mechanical elements. The oil pump plays a crucial role in this system by circulating lubricant to various areas where it is needed most, providing protection and optimal performance.

Functionality of the Lubrication Mechanism

This mechanism ensures that vital areas receive adequate amounts of lubricant, preventing wear and tear that could lead to costly repairs. The circulation of oil helps to create a protective barrier between moving parts, thereby minimizing contact and enhancing efficiency. Moreover, a well-maintained lubrication system contributes to improved thermal management, allowing the unit to operate within its designed temperature range.

Importance of Regular Maintenance

Consistent maintenance of the lubrication system is paramount for sustaining peak performance. Regular checks of oil levels and the condition of the pump can prevent potential failures. Additionally, using the appropriate type of lubricant ensures that the system functions effectively, further prolonging the life of the mechanical assembly.

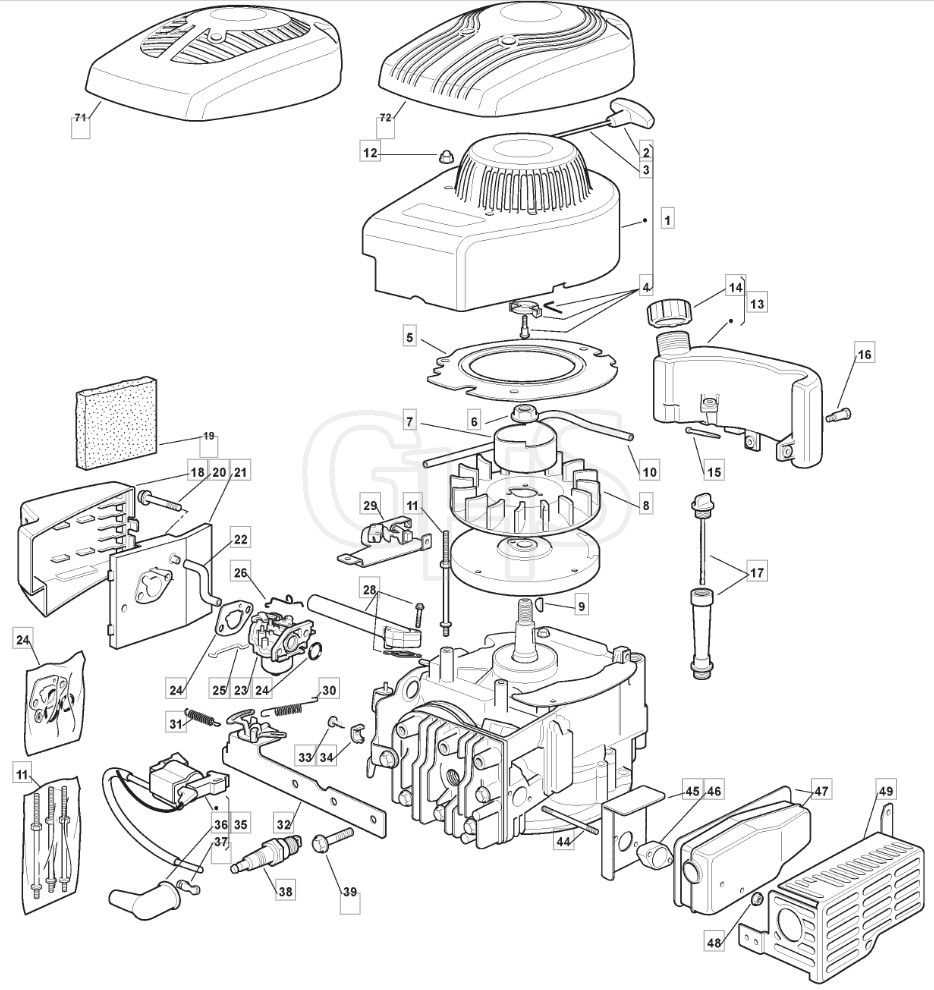

Valvetrain Components and Their Function

The valvetrain is a crucial assembly in any internal combustion system, responsible for managing airflow into and out of the combustion chamber. This intricate network ensures optimal performance by controlling the timing and movement of various elements that regulate valve action. Understanding these components is essential for anyone interested in enhancing efficiency and power output.

Key Elements of the Valvetrain

Among the primary components are the camshaft, pushrods, and rocker arms. The camshaft plays a pivotal role in dictating when valves open and close, while pushrods transfer the motion generated by the camshaft to the rocker arms. These rocker arms then manipulate the valves themselves, allowing air and fuel to enter while enabling exhaust gases to exit. Each part is meticulously designed to work in harmony, contributing to the overall functionality of the system.

Importance of Proper Functioning

A well-functioning valvetrain significantly impacts the efficiency and performance of the entire mechanism. If any of the components fail or wear out, it can lead to a decrease in power, increased emissions, and potential damage to the assembly. Regular maintenance and timely replacements of worn elements are essential to ensure that the system operates smoothly, ultimately enhancing the longevity and effectiveness of the whole setup.

Performance Upgrades for 454 Engine Parts

Enhancing the capabilities of a high-displacement motor can significantly elevate driving experience and overall performance. By incorporating specialized modifications and high-quality components, enthusiasts can achieve greater power output, improved efficiency, and a more responsive driving sensation. This section outlines various strategies to optimize such a robust power unit.

Upgrade Type Description Benefits High-Performance Camshaft Installing a camshaft designed for higher lift and duration can improve airflow and combustion efficiency. Increased horsepower and torque across a broader RPM range. Intake Manifold Swapping out the factory intake for a performance-oriented manifold enhances air delivery to the cylinders. Better throttle response and higher peak power output. Exhaust System Upgrade A free-flowing exhaust system reduces back pressure, allowing gases to exit more efficiently. Improved horsepower, torque, and engine sound. Fuel System Enhancements Upgrading injectors and fuel pumps ensures adequate fuel delivery for increased air flow. Consistent power delivery and improved performance under load. Forced Induction Adding a supercharger or turbocharger significantly boosts air intake, leading to substantial power gains. Significantly higher power levels with improved torque characteristics.

Functionality of the Cylinder Block

The cylinder block plays a crucial role in the overall operation, serving as the core foundation for various mechanical processes. It provides structural support and alignment for other essential components, ensuring smooth coordination within the system. Its design is engineered to endure significant stresses while maintaining efficiency and reliability.

Structural Integrity and Heat Management

The robust construction of the block ensures it can withstand high pressures and temperatures generated during operation. By dissipating heat effectively, it helps maintain optimal performance levels and prevents overheating, which could lead to potential failures.

Support for Moving Elements

Within this framework, several key moving elements are housed and guided, allowing them to function seamlessly. The precise design of the block enables smooth movement, reducing wear and tear, and extending the longevity of the entire mechanism.

Importance of the Crankshaft Design

The design of the crankshaft plays a pivotal role in the overall functionality and efficiency of a vehicle’s power system. This key component is responsible for transforming motion into a usable form, ensuring smooth operation and reliable performance. A well-constructed crankshaft directly impacts the durability and balance of the entire mechanism, making it essential for both longevity and optimal power output.

Balance and Stability

A properly designed crankshaft contributes to the overall balance of the system. It minimizes unwanted vibrations, reducing wear on other parts. This ensures that the mechanical forces are distributed evenly, leading to greater stability and smoother operation.