Understanding the layout and function of various mechanical elements within a vehicle is crucial for efficient maintenance and repairs. Each component plays a vital role in ensuring smooth operation, and knowing where they are positioned can save time when troubleshooting issues or performing regular upkeep.

In this section, we will explore the key structural elements that contribute to the overall performance of the system. By identifying the proper placement and function of these elements, it becomes easier to address potential problems and optimize vehicle functionality.

Whether you are performing routine maintenance or addressing more complex issues, having a clear understanding of the spatial arrangement and purpose of these essential components will provide you with valuable insights.

A3 Engine Component Overview

The layout of the vehicle’s core power system is intricate, consisting of multiple interconnected elements that work in harmony to deliver optimal performance. Each component plays a crucial role in ensuring smooth operation, enhancing efficiency, and maintaining reliability. Understanding the key elements of this system provides valuable insight into how the vehicle operates and can assist in identifying potential issues or areas for improvement.

Main Functional Units

- Power Generation: Converts fuel into energy through combustion, driving the core mechanisms.

- Transmission System: Transfers the energy generated to the drivetrain, enabling movement.

- Cooling Mechanism: Regulates the temperature, preventing overheating and maintaining performance.

Supporting Systems

- Lubrication: Ensures that all moving parts work smoothly by reducing friction.

- Air Intake: Supplies oxygen necessary for the combustion process.

- Exhaust: Removes waste gases produced during en

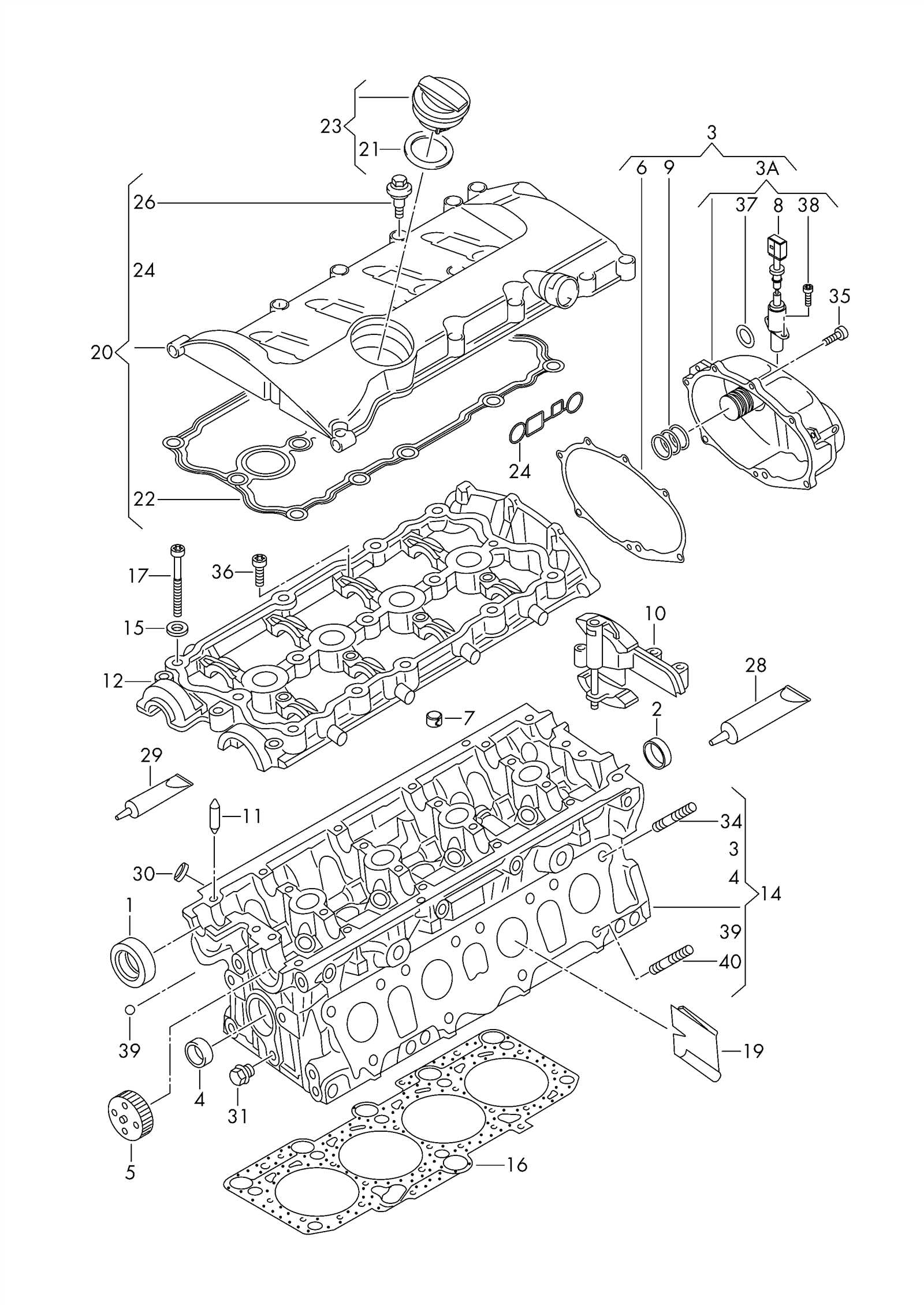

Main Parts of the Audi A3 Engine

The heart of any vehicle relies on a collection of critical components working together. These elements ensure smooth performance, durability, and efficiency. Below is a breakdown of the most essential elements that play a key role in the operation of the vehicle’s power system.

- Cylinder Block: The foundation of the system, housing the main working sections where power generation occurs.

- Cylinder Head: Situated above the main block, this section controls air and fuel intake, as well as the release of exhaust gases.

- Crankshaft: A crucial rotating part responsible for converting linear motion into rotational energy that propels the vehicle forward.

- Pistons: Moving up and down within the cylinders, these parts help compress fuel and air mixtures to generate power.

- Timing Belt: Ensures that various components are synchronized, enabling the smooth operation of the entire system.

- Fuel Injector: Delive

Key Systems in Audi A3 Motor

The motor of this vehicle integrates several crucial mechanisms that ensure smooth performance and optimal functionality. These systems work in harmony to provide power, control, and efficiency while driving, making the vehicle reliable and responsive in various conditions. Below, we outline some of the most essential subsystems that contribute to the motor’s overall operation.

- Ignition System – Responsible for igniting the fuel-air mixture within the cylinders, this mechanism plays a vital role in starting and maintaining the motor’s operation.

- Fuel Delivery – This system controls the precise amount of fuel injected into the combustion chambers, ensuring efficient use of fuel and balanced performance.

- Cooling Mechanism – Prevents the motor from overheating by circulating coolant through various channels, maintaining a stable temperature during operation.

- Exhaust Pathway – Safely directs gases produced during combustion out of the vehicle, contributing to reduce

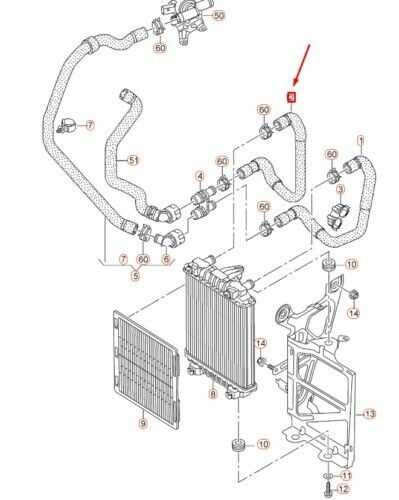

Cooling System Elements in Audi A3

The cooling system is a crucial component in maintaining the optimal temperature of a vehicle’s internal mechanisms, ensuring that they do not overheat during operation. This system is responsible for regulating heat and dispersing it efficiently to maintain performance and longevity of various mechanical elements. Understanding the main components involved in this system provides insight into how heat is managed and controlled under varying driving conditions.

Key Components

Several elements work together to ensure the cooling process functions smoothly. Among them, the radiator plays a central role, helping to transfer heat away from the system by utilizing a coolant. In conjunction, the thermostat ensures that the coolant flow is properly regulated, opening and closing based on the required temperature levels.

Fluid Circulation

The coolant pump ensures continuous circulation of the fluid through the system. It is designed to push the coolant through hoses and passages to absorb excess heat, which is then released through the radiator. Proper maintenance of these components is essential for preventing overheating and ensuring smooth vehicle operation.

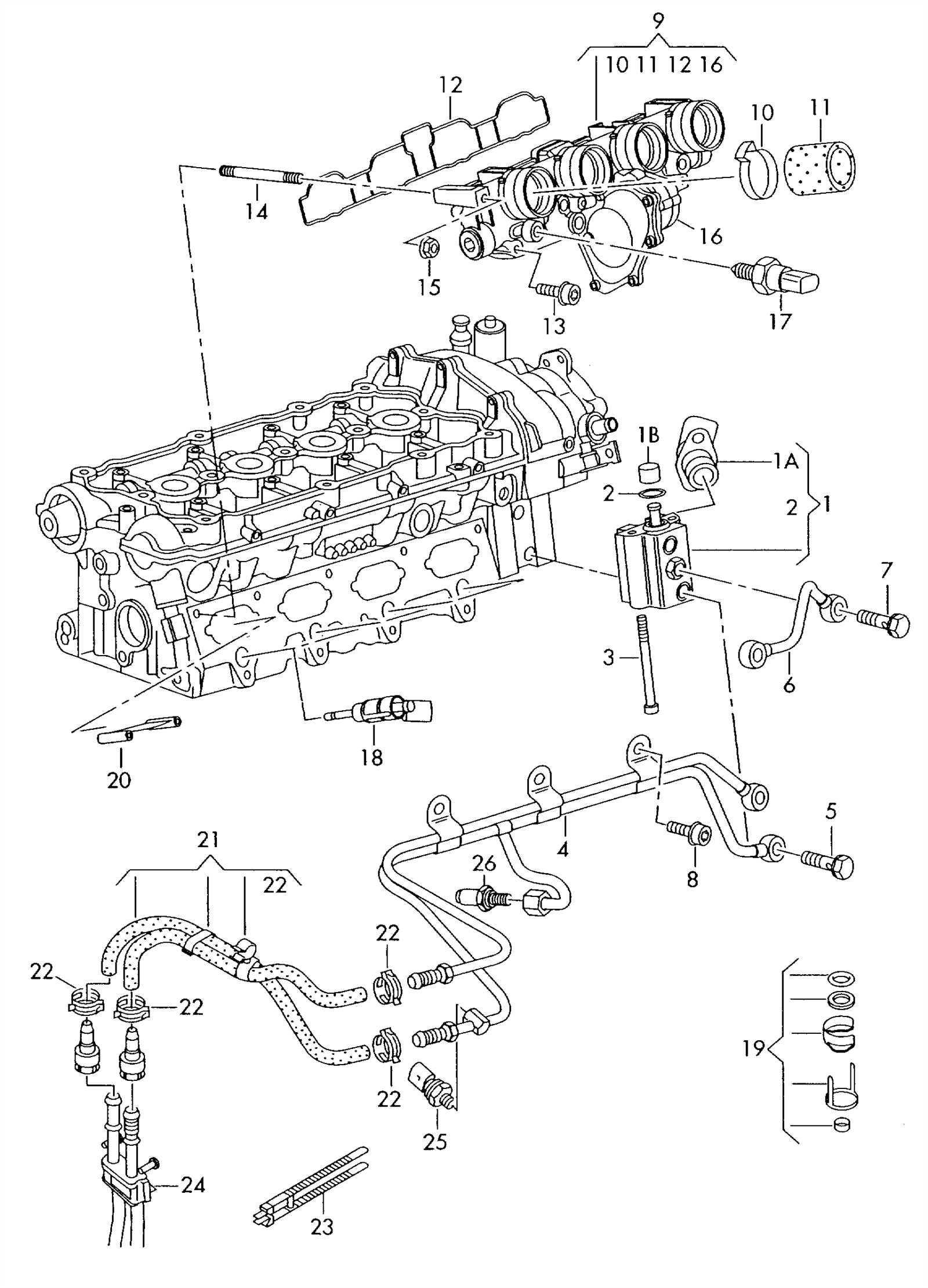

Ignition Mechanism and Components

The ignition system plays a critical role in starting and maintaining the performance of any internal combustion setup. It ensures that the necessary spark is generated at the right moment, allowing smooth operation and fuel efficiency. A reliable ignition process not only enhances power output but also helps prevent misfires and other operational issues.

Key Elements of the Ignition System

The ignition mechanism consists of several interconnected components. These include the spark plugs, which are responsible for delivering the electrical charge to ignite the fuel mixture. Additionally, ignition coils convert the lower voltage from the battery into the high voltage needed to create a spark. Other essential elements include the distributor and ignition control module, both of which regulate timing and voltage distribution to the plugs.

Maintenance and Troubleshooting

Proper upkeep of the ignition components is crucial for optimal performance. Regular inspections and replacements of spark plugs and coils ensure consistent firing and prevent potential problems such as stalling or rough running. Monitoring the sy

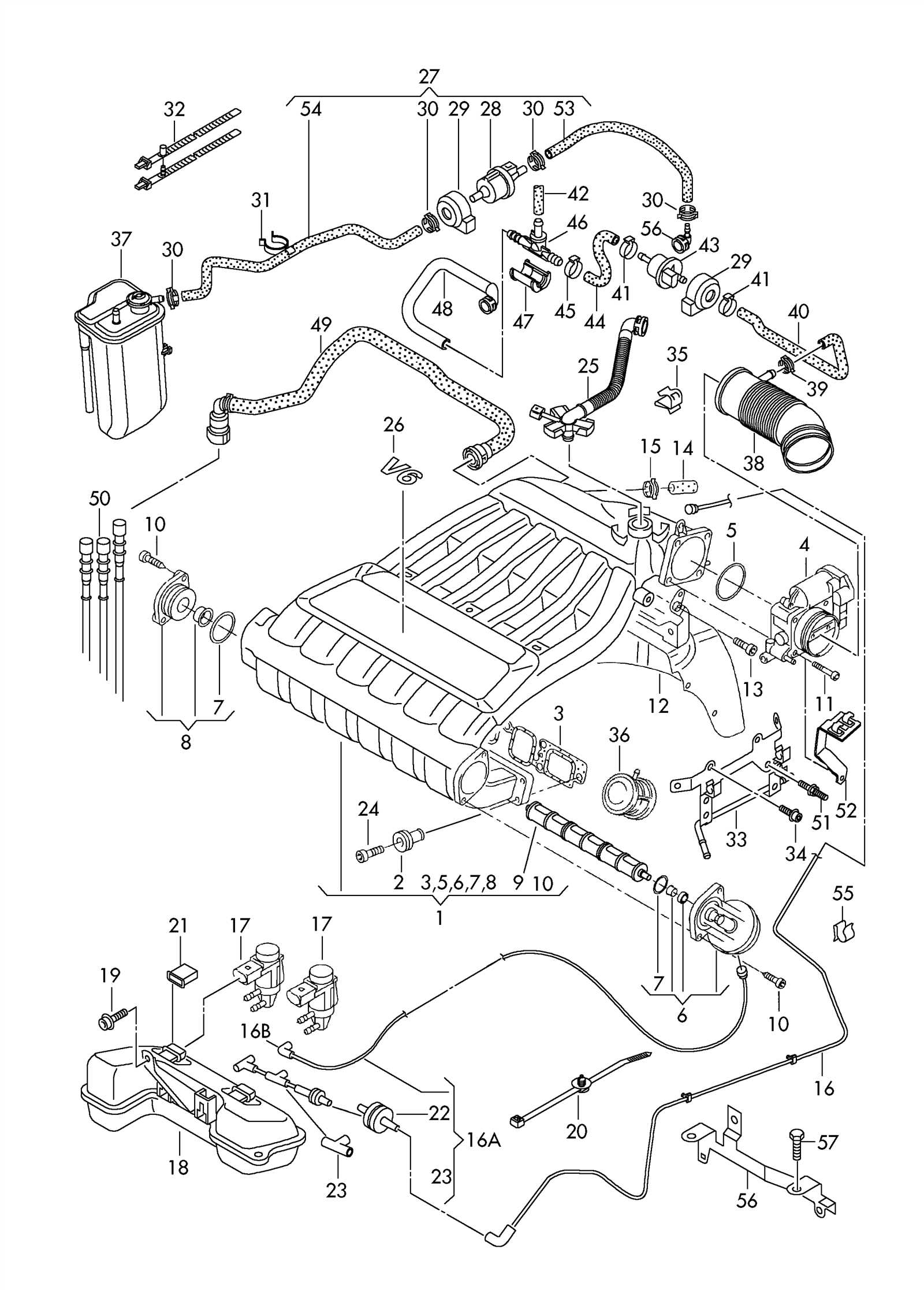

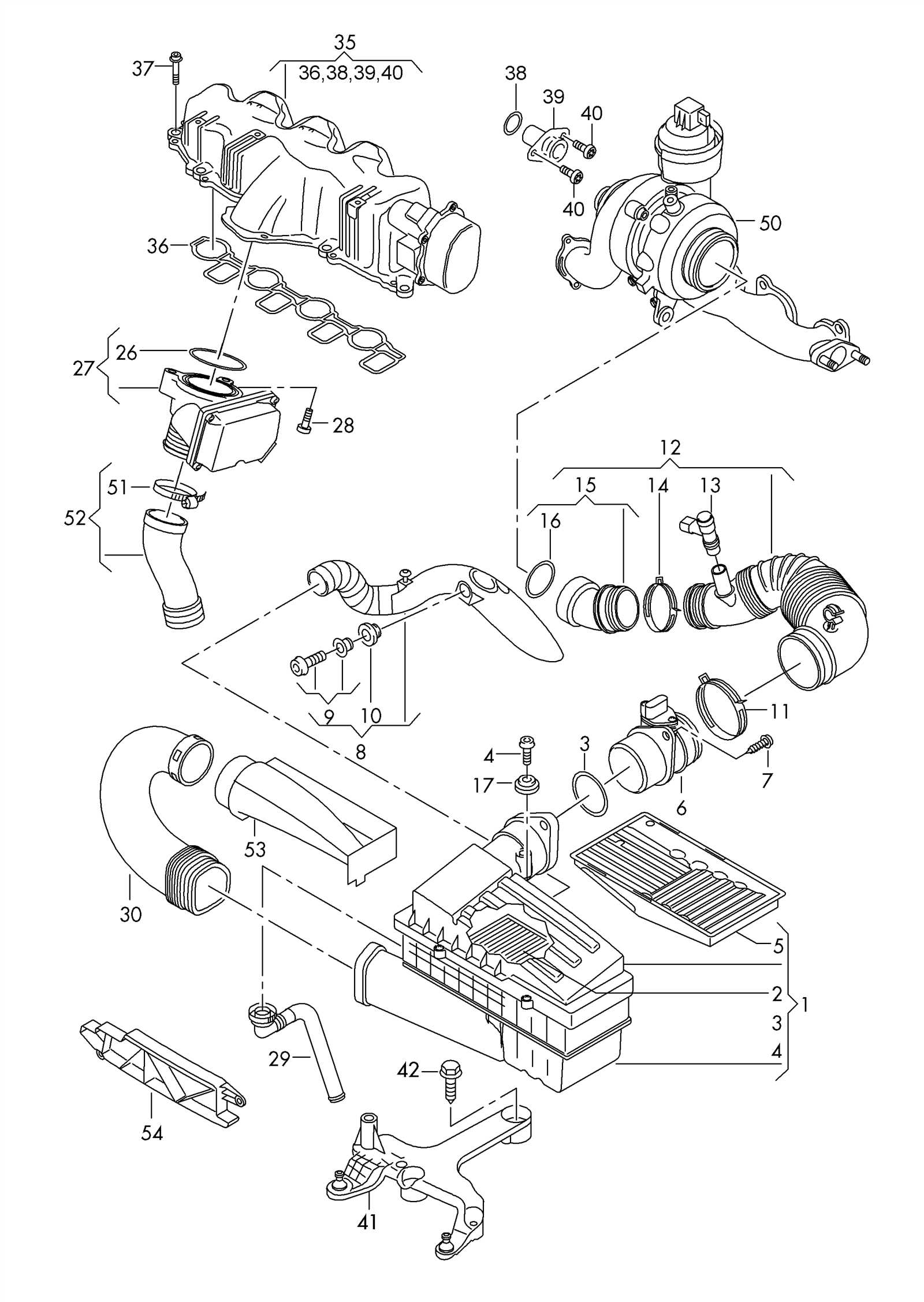

Air Intake and Fuel System Design

The efficiency of any vehicle’s operation relies heavily on the design and functionality of its air intake and fuel delivery mechanisms. These systems work in tandem to ensure optimal performance, providing the necessary mixture of air and fuel for combustion. Proper engineering in these areas can significantly enhance power output, fuel efficiency, and overall responsiveness of the vehicle.

In an effective setup, the air intake system is designed to facilitate a smooth flow of air into the combustion chamber. This process often involves various components such as air filters, intake manifolds, and throttle bodies, each playing a crucial role in regulating airflow. The quality of air entering the system can directly influence performance and emissions, making its design a key factor in achieving high efficiency.

Similarly, the fuel delivery system must be meticulously designed to ensure that the right amount of fuel reaches the combustion chamber at the correct pressure. This involves a series of components including fuel pumps, injectors, and lines that must be calibrated for precise operation. The synchronization between fuel and air delivery is essential for achieving a balanced mixture, which is vital for optimal engine performance.

Overall, a well-engineered air intake and fuel delivery system can significantly impact a vehicle’s acceleration, fuel consumption, and emissions. Continuous advancements in technology enable manufacturers to enhance these systems, leading to more efficient and powerful performance.

Exhaust System Layout in Audi A3

The exhaust system plays a crucial role in managing the flow of gases produced during combustion. It not only directs these gases away from the vehicle but also contributes to overall performance and emissions control. Understanding the configuration of this system can provide valuable insights into its functionality and maintenance.

Typically, the layout consists of several key components that work together seamlessly:

- Manifold: Collects exhaust gases from the combustion chambers.

- Catalytic Converter: Reduces harmful emissions by converting them into less harmful substances.

- Muffler: Lowers noise produced by the exhaust gases.

- Pipes: Directs gases through the system to the rear of the vehicle.

- Tips: Finishing ends of the exhaust system, often designed for aesthetic appeal.

Each element of the layout is engineered to enhance efficiency and reduce environmental impact. Regular inspection and maintenance of these components can ensure optimal performance and longevity.

Timing Belt and Related Parts

The timing belt plays a crucial role in the smooth operation of various mechanisms, ensuring that different components work in harmony. This vital element, along with its associated elements, requires proper maintenance and timely replacement to prevent potential issues that could affect overall performance.

Components of the Timing Mechanism

- Timing Belt

- Idler Pulley

- Tensioner

- Water Pump

Importance of Regular Maintenance

Regular inspections and timely replacements of the timing belt and its associated components can significantly extend the lifespan of the mechanism. Neglecting maintenance can lead to serious damage and costly repairs. It is advisable to follow the manufacturer’s recommendations for replacement intervals and to seek professional assistance for any concerns.

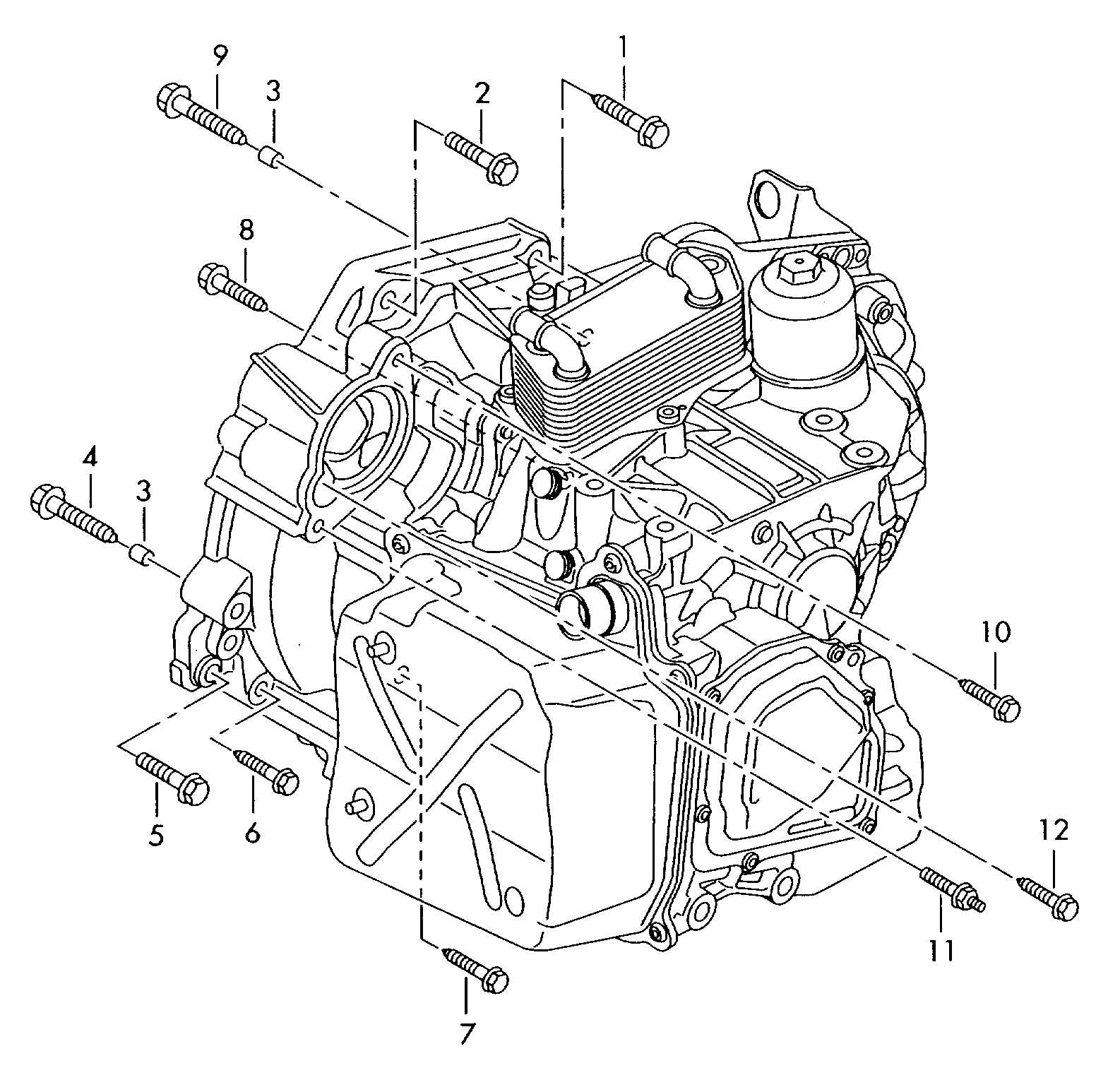

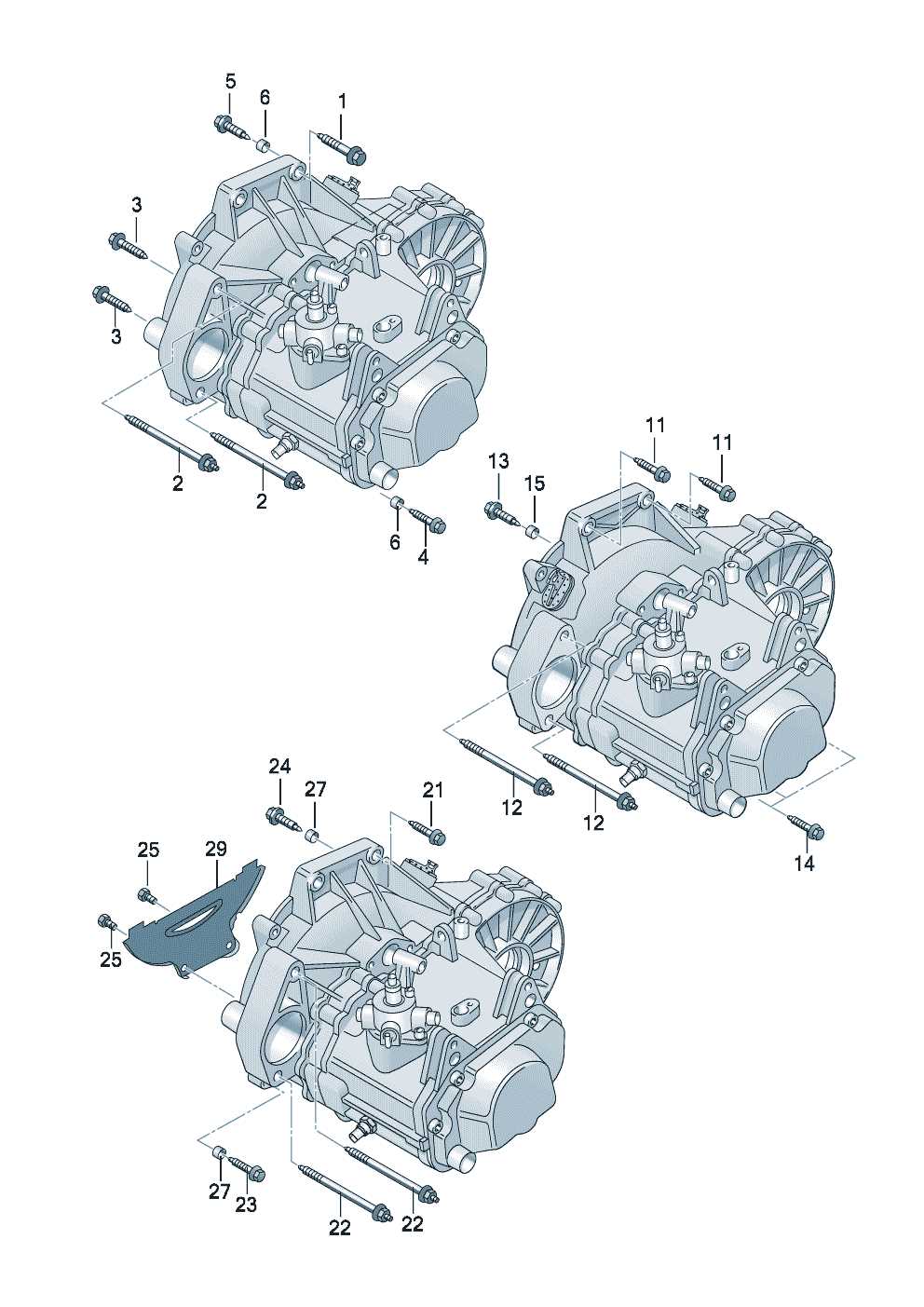

Engine Block Structural Features

The foundation of a vehicle’s powertrain is crucial for its overall performance and durability. This component serves as the central structure that houses various essential mechanisms, contributing to the engine’s efficiency and reliability. Understanding its structural characteristics is vital for comprehending how it interacts with other components within the system.

Material Composition

The selection of materials significantly impacts the strength and weight of the block. Typically, high-grade aluminum or cast iron is used, providing a balance between durability and lightweight design. Aluminum is often favored for its superior heat dissipation properties, while cast iron offers enhanced rigidity and resistance to wear.

Design Considerations

Several factors influence the design of this critical structure. Cooling channels are strategically integrated to manage temperature, preventing overheating during operation. Additionally, reinforcement in specific areas enhances strength, allowing the block to withstand high pressures and stresses generated during combustion.

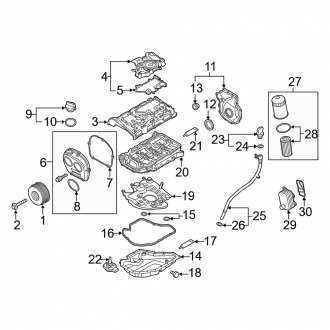

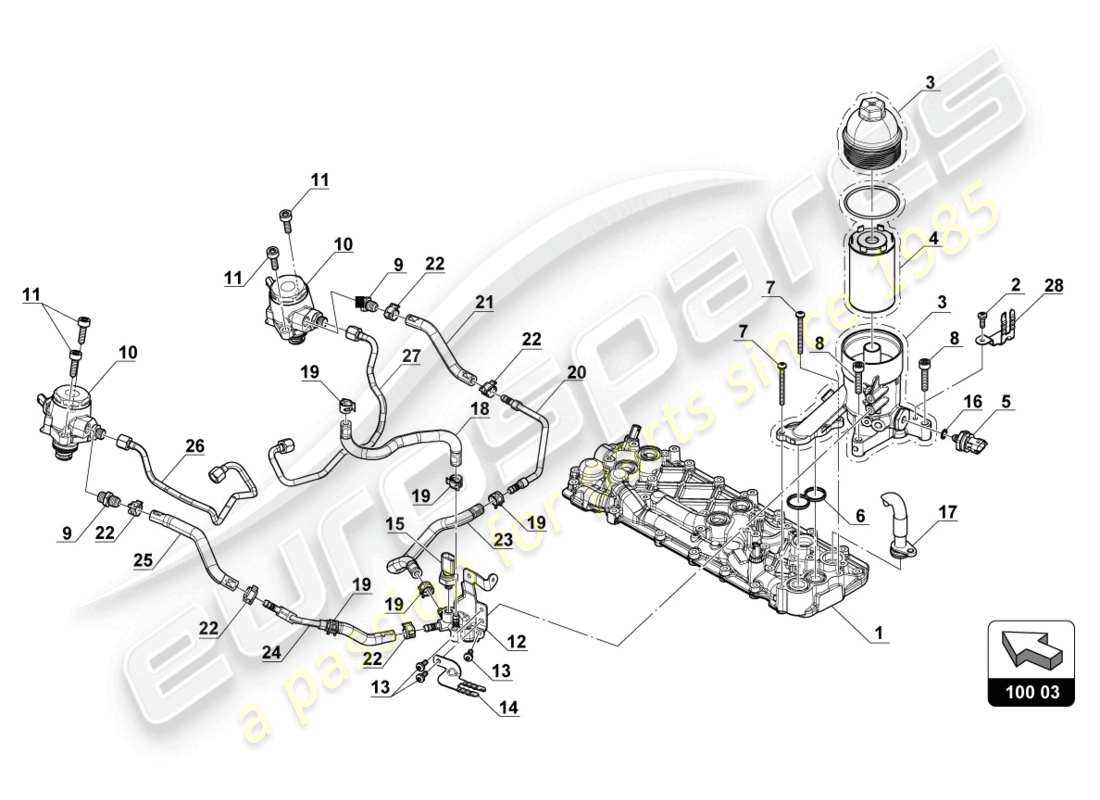

Lubrication System Parts and Function

The lubrication system plays a crucial role in ensuring the smooth operation of various components within a vehicle. This system is designed to reduce friction, dissipate heat, and prevent wear and tear, thus enhancing the overall performance and longevity of the machinery.

At the core of this system is the oil pump, which circulates lubricant throughout the assembly. The oil travels through various channels and reaches critical areas, ensuring that all moving elements are adequately coated. Additionally, filters are integrated into the setup to remove contaminants, maintaining the cleanliness and efficiency of the lubricant.

Another vital component is the oil cooler, which regulates the temperature of the lubricant. By dissipating excess heat, it ensures that the fluid remains at optimal viscosity, promoting effective lubrication. Moreover, pressure relief valves are included to maintain the appropriate pressure levels within the system, preventing damage due to over-pressurization.

Overall, the effective functioning of the lubrication system is essential for minimizing friction and heat, thereby safeguarding the integrity of the machinery.

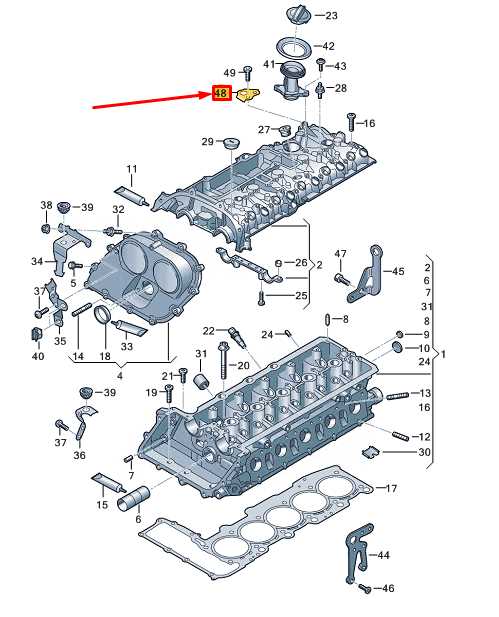

Valve Train Mechanism and Setup

The valve train system is a crucial component of the internal combustion process, responsible for regulating the intake and exhaust of gases within the combustion chamber. This mechanism ensures that air-fuel mixtures enter the chamber at the appropriate time while allowing exhaust gases to exit efficiently. A precise setup is essential for optimal engine performance and efficiency.

Components of the Valve Train

This system consists of various elements, including the camshaft, lifters, pushrods, rocker arms, and valves. Each part plays a specific role in facilitating the opening and closing of the valves at the right intervals. The camshaft’s rotation activates the lifters, which, in turn, move the pushrods and rocker arms to manipulate the valves effectively.

Adjustment and Maintenance

Proper adjustment and regular maintenance of the valve train are vital for sustaining performance. Misalignment or wear in any component can lead to inefficient gas exchange and diminished engine functionality. Regular inspections and timely replacements help maintain the integrity of this essential mechanism, ensuring smooth operation and longevity.

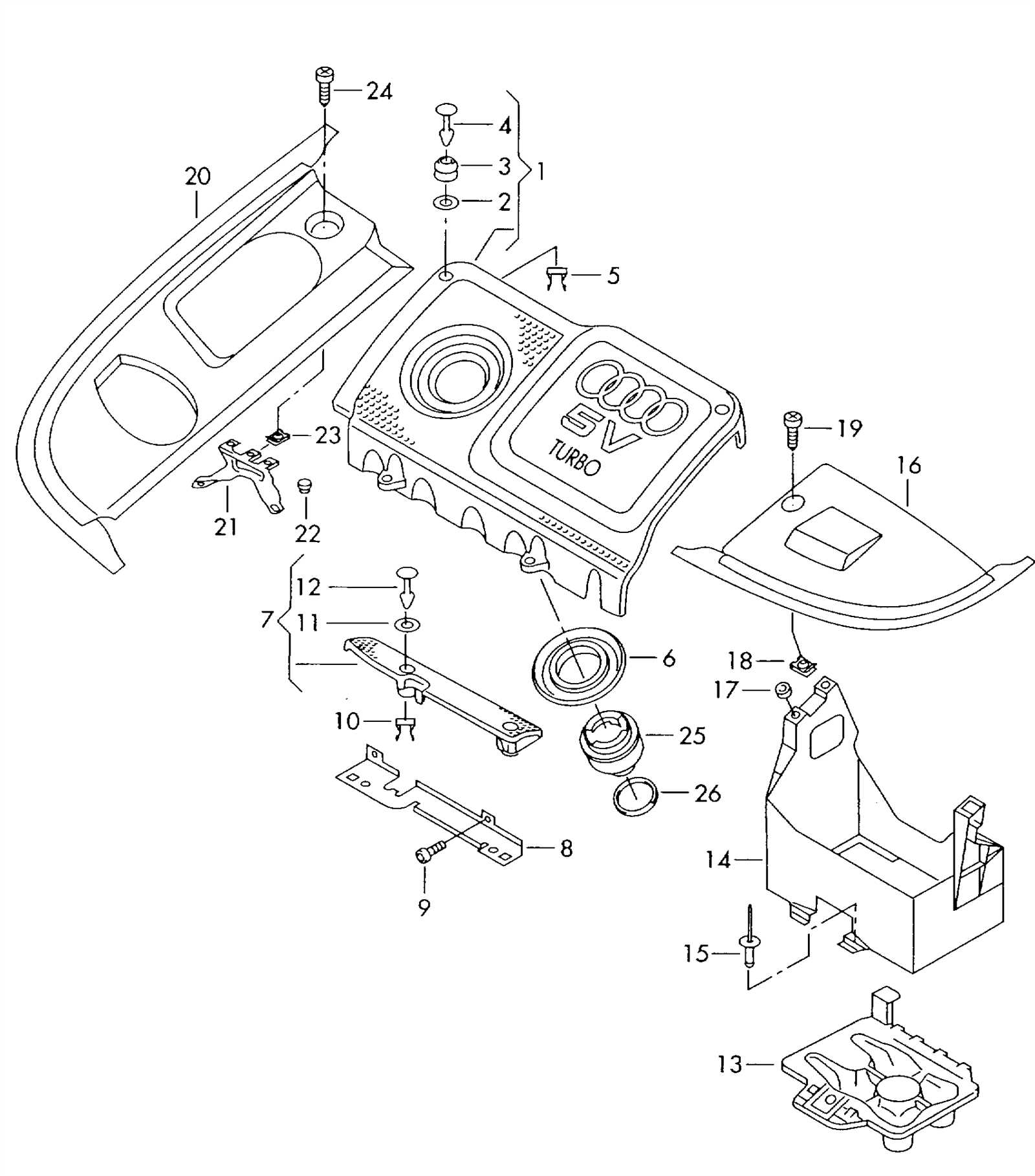

Turbocharger Components in Audi A3

The turbocharger plays a vital role in enhancing performance by increasing the amount of air entering the combustion chamber, resulting in greater power output. This sophisticated device consists of several key components that work in harmony to optimize engine efficiency and responsiveness.

At the core of the turbocharger is the turbine, which harnesses exhaust gases to spin the impeller. This rotation compresses incoming air, allowing for a denser mixture of fuel and air. Additionally, the wastegate regulates exhaust flow, preventing excessive boost pressure that could lead to engine damage. The intercooler is another essential element, cooling the compressed air before it enters the combustion chamber, further improving performance.

Supporting these components are various housings and bearings, designed to withstand extreme temperatures and pressures. Each part contributes to the overall effectiveness of the turbocharger, ensuring optimal functionality and longevity.

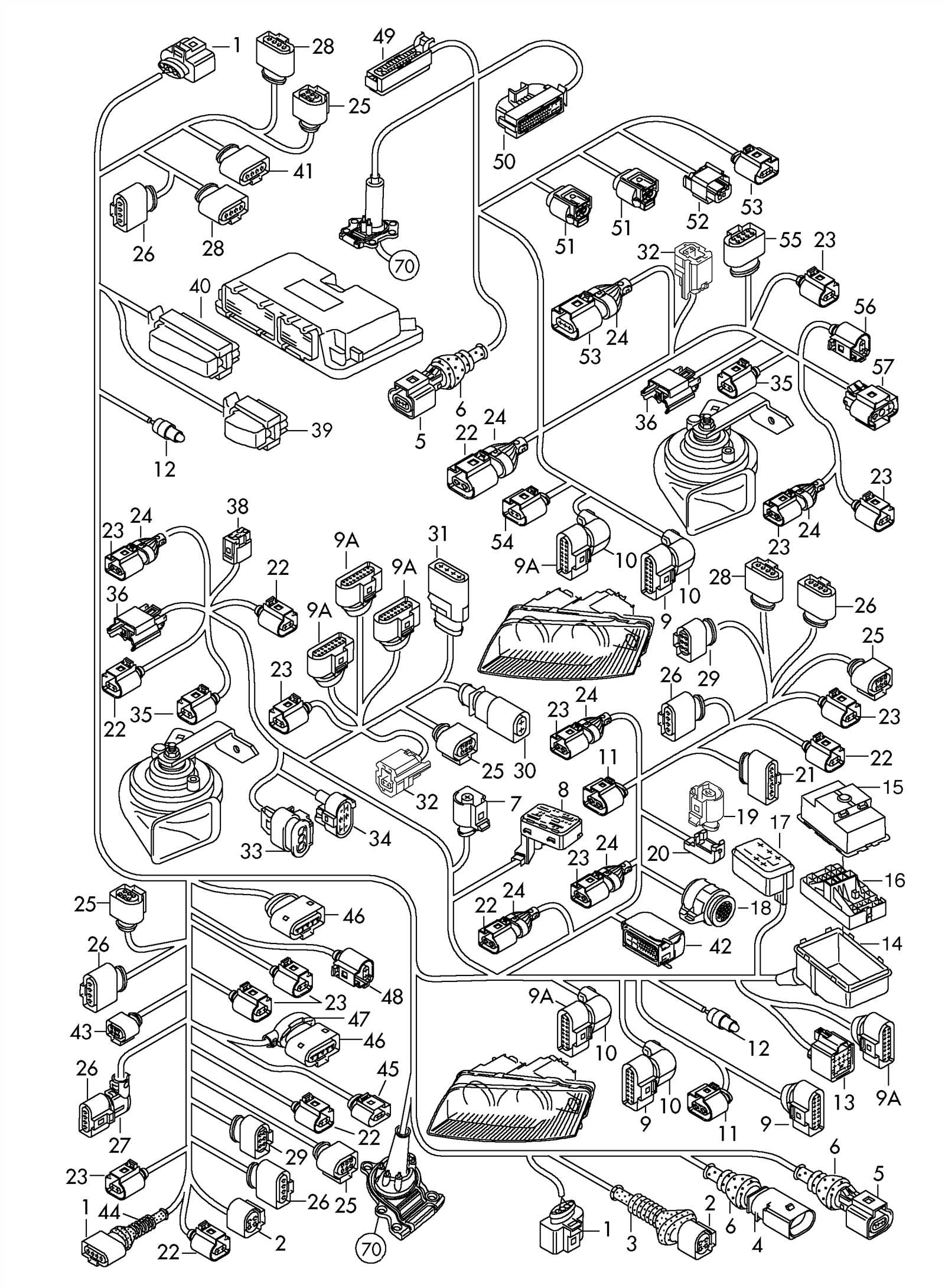

Electrical Wiring and Engine Sensors

The electrical system plays a crucial role in the overall functionality of a vehicle’s performance. It consists of various components that work in tandem to ensure that vital information is transmitted efficiently. This section delves into the intricate wiring and the array of sensors that monitor essential parameters, contributing to optimal operation.

Wiring System Overview

The wiring network connects various electronic units, facilitating communication between sensors and control modules. Each wire is meticulously designed to handle specific voltages and currents, ensuring reliable operation. Understanding the layout of these connections is vital for diagnosing potential issues and ensuring proper maintenance.

Functionality of Sensors

Sensors serve as the eyes and ears of the system, constantly gathering data about different aspects of performance. They monitor variables such as temperature, pressure, and air quality, sending this information to the control unit for analysis. The accuracy of these sensors directly impacts the efficiency and effectiveness of the entire system.

Sensor Type Function Location Temperature Sensor Monitors coolant temperature Near the engine block Pressure Sensor Measures oil pressure Oil filter area Oxygen Sensor Detects exhaust gas composition Exhaust manifold Mass Airflow Sensor Measures air intake Between air filter and intake manifold