The internal workings of a vehicle’s power system are a fascinating blend of precision engineering and advanced technology. A detailed look at the mechanisms under the hood reveals a complex network of interconnected systems that work together to deliver optimal performance and reliability. Understanding these mechanisms is crucial for both enthusiasts and those interested in maintaining their vehicle’s performance.

Beneath the surface, a variety of components play specific roles in ensuring that the power system operates smoothly. From the elements responsible for combustion to the units that regulate and control various functions, every piece is designed with precision. Knowing how these elements fit and function together can provide deeper insights into vehicle maintenance and enhancements.

This section will explore the primary elements that drive the power system, offering a closer look at their roles and how they contribute to the overall functioning of the vehicle. By understanding these elements, you can gain a greater appreciation of the intricacies involved in automotive performance.

Audi A4 Engine Components Overview

In this section, we explore the various mechanical elements that contribute to the smooth operation of the vehicle’s core system. Each part plays a crucial role in maintaining efficiency and ensuring optimal performance. Understanding the layout and function of these components can help identify potential areas for maintenance and troubleshooting.

Main Mechanical Units

The powertrain is composed of several key units, each responsible for a specific function. The cylinder block serves as the foundation, housing critical moving parts. Alongside it, the cylinder head contains vital elements such as valves and camshafts, which are essential for regulating the intake and exhaust processes.

Supporting Systems

Other crucial systems support the core function of the powertrain. These include the cooling system, responsible for maintaining a stable temperature, and the lubrication system, which ensures that all moving parts operate smoothly without excess friction. Proper maintenance of these systems is vital for the longevity of the mechanical components.

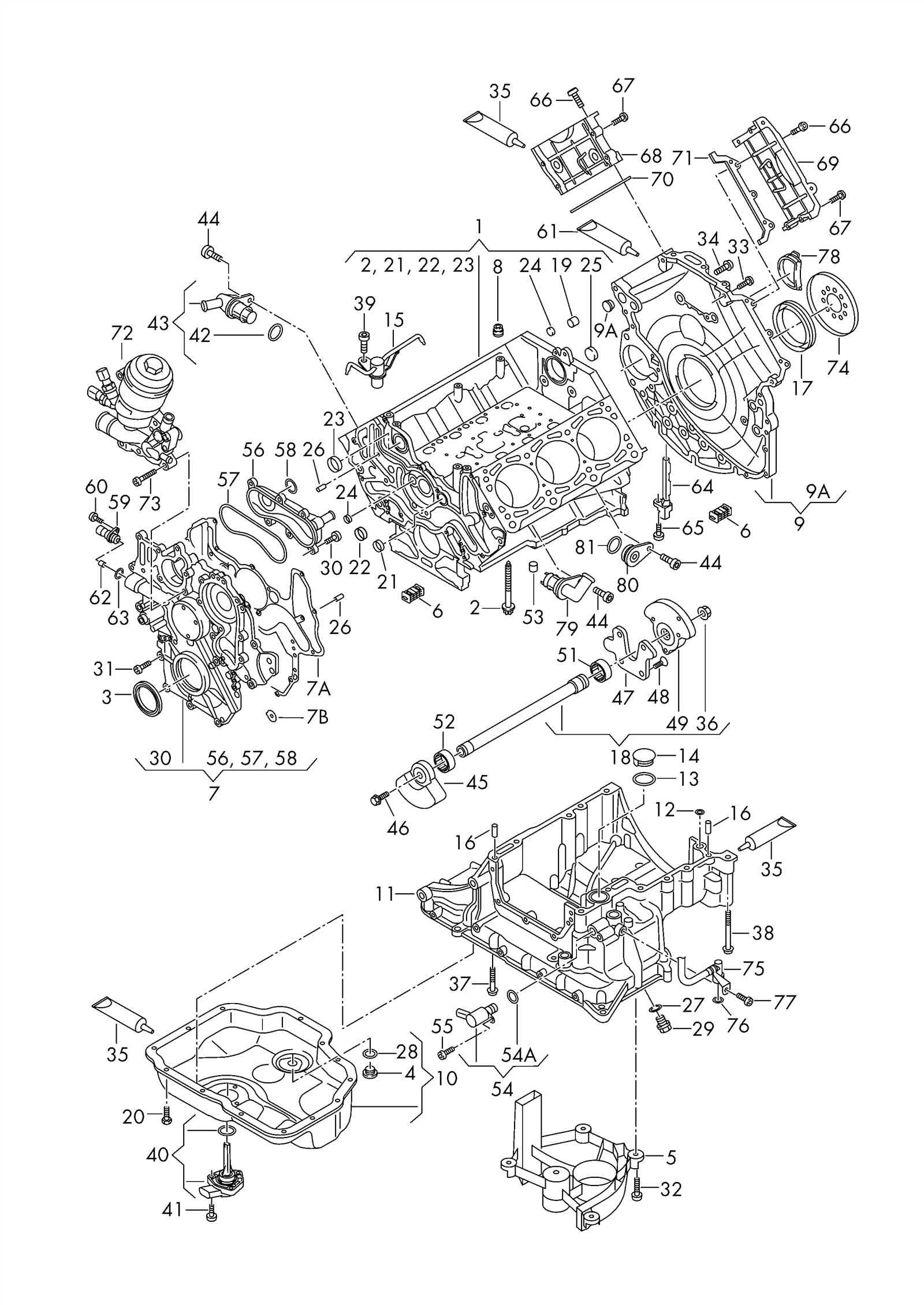

Main Block Structure and Functionality

The core component of a vehicle’s power unit plays a crucial role in housing and supporting various mechanical systems responsible for converting fuel into motion. This section is designed to provide a solid foundation for key mechanisms, ensuring stability and efficient operation during high-performance activities.

The structure consists of a robust assembly that includes chambers, channels, and mounting points to integrate other essential systems. These elements work together to facilitate proper fluid movement, temperature regulation, and overall mechanical coordination, vital for smooth performance.

Functionality is centered around maintaining internal alignment and supporting rotational forces generated during operation. The durability of this central section is crucial to withstand extreme conditions and pressures while keeping connected systems functioning as intended.

Crankshaft Position and Role in Operation

The positioning of the crankshaft is a crucial element in ensuring the correct sequence of mechanical motions. It influences how other components align and interact, playing a fundamental role in maintaining overall functionality. The balance of rotational forces and synchronization with related systems depends on precise movement and orientation.

Here are key aspects of its function:

- Synchronization: The crankshaft coordinates with various mechanisms to maintain consistent performance.

- Energy Transfer: It converts linear motion into rotational force, essential for powering further actions.

- Timing: Precise timing of its rotation is critical for efficient operation and smooth functioning of related components.

The exact position and movement are monitored continuously, ensuring that all systems stay in sync and operate as intended.

Cylinder Heads: Layout and Importance

The cylinder head is a vital component in the operation of any internal combustion system. It serves as a closure for the upper section, playing a key role in the overall performance and efficiency. The design and placement of the cylinder head directly influence factors such as fuel combustion, airflow, and heat dissipation, making it an essential element in maintaining proper functionality.

The layout of the cylinder head includes complex channels and passages that manage both intake and exhaust gases. These pathways are meticulously engineered to optimize the flow, ensuring that the combustion process occurs efficiently. Additionally, the head houses crucial mechanisms like valves and spark plugs, which are responsible for controlling the entry and exit of gases and initiating combustion.

Beyond its structural function, the cylinder head also plays a critical role in thermal management. It helps dissipate the heat generated during combustion, preventing overheating and ensuring the system operates within optimal temperature ranges. This combination of structural integrity, precise airflow control, and heat management underscores the importance of the cylinder head in the overall functionality of the power system.

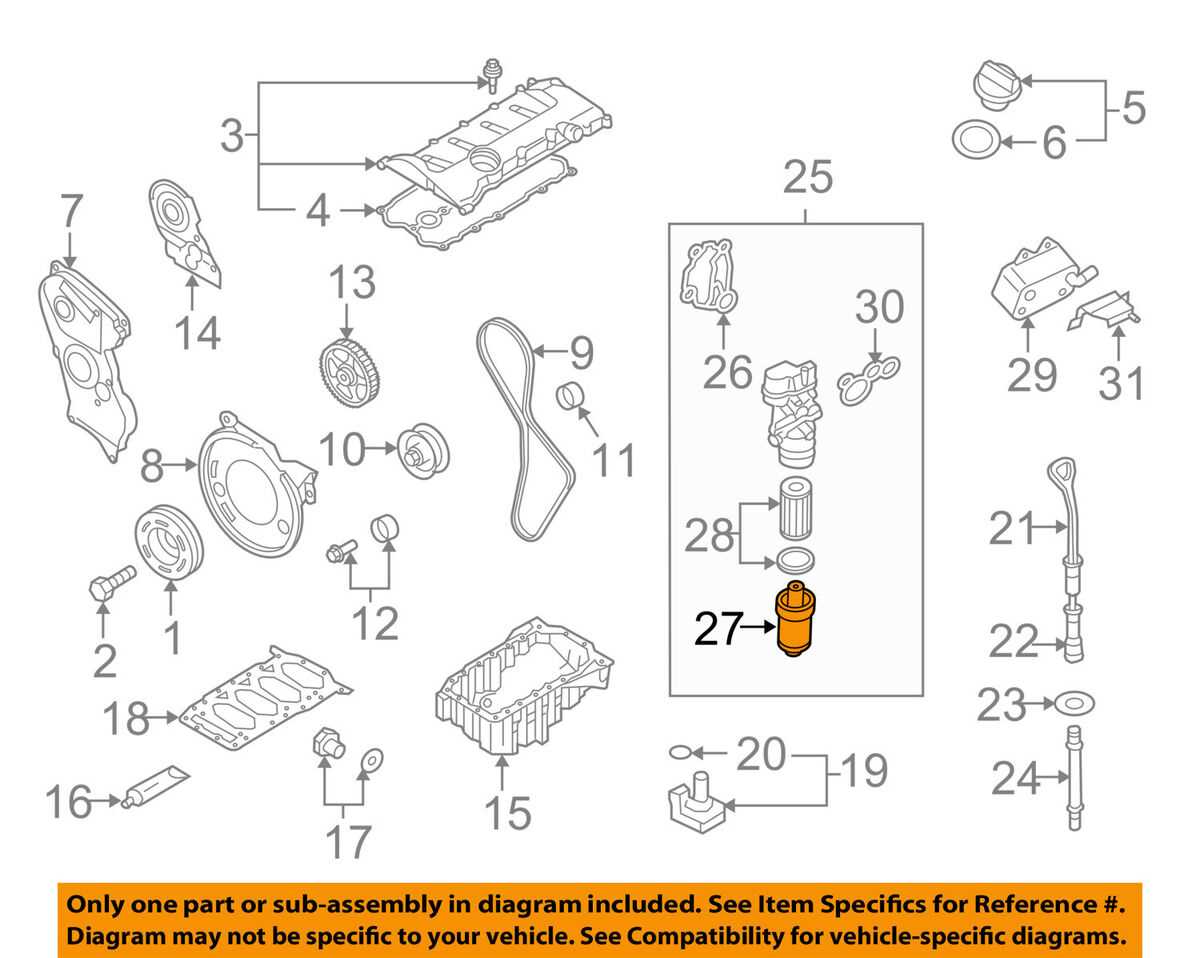

Oil Pump Assembly and Lubrication System

The lubrication system plays a critical role in ensuring smooth operation and long-term reliability of the vehicle’s components. Proper oil distribution minimizes friction and prevents excessive heat build-up, ensuring the overall health of the mechanical elements.

Structure and Function

The pump is responsible for maintaining consistent circulation of oil throughout the entire system. It draws oil from the reservoir and distributes it to various moving parts. This process helps reduce wear, ensuring that surfaces remain coated and friction is kept to a minimum.

Flow Control and Pressure Regulation

One of the essential tasks of the system is maintaining the correct pressure. A properly regulated flow ensures that all components receive adequate lubrication without overloading or under-supplying any section. The pressure is typically adjusted through built-in relief valves, which prevent any damage from excessive pressure build-up.

Timing Chain and Belt Configurations

The timing mechanism plays a crucial role in the performance and efficiency of a vehicle’s propulsion system. It ensures that various components operate in harmony, maintaining precise synchronization between the crankshaft and the camshaft. This coordination is essential for optimal performance and longevity.

There are primarily two types of configurations used: timing chains and timing belts. Chains are typically made of metal, providing durability and longevity, often requiring minimal maintenance. On the other hand, belts are usually composed of reinforced rubber, which can be quieter during operation but may need periodic replacement due to wear and tear.

Each configuration presents its advantages and disadvantages. Timing chains can withstand higher loads and have a longer lifespan, making them suitable for performance-oriented applications. Conversely, timing belts can offer a lighter alternative, which may contribute to improved fuel efficiency in some scenarios. Understanding these differences is vital for maintaining the overall functionality of the system.

Fuel Injection System Design

The design of the fuel injection system is crucial for optimizing the performance and efficiency of internal combustion systems. This intricate assembly is responsible for delivering the right amount of fuel to the combustion chamber at precisely the right moment. A well-engineered injection system enhances the overall functionality and responsiveness of the vehicle while minimizing emissions.

Components and Functionality

This system typically comprises various components, including injectors, fuel pumps, and control units. Each element plays a vital role in ensuring accurate fuel delivery. The injectors atomize the fuel, creating a fine mist that mixes seamlessly with air, promoting efficient combustion. Fuel pumps maintain the required pressure and flow, while electronic control units monitor and adjust the system to meet performance demands.

Technological Advancements

Recent advancements in fuel injection technology have led to the development of direct and multi-point systems. Direct injection improves fuel atomization and combustion efficiency, while multi-point injection provides better throttle response and drivability. These innovations contribute to reduced fuel consumption and lower emissions, aligning with modern environmental standards.

Exhaust Manifold and Emission Control

The exhaust manifold plays a crucial role in directing the gases produced during combustion away from the combustion chamber. This component is essential for maintaining optimal performance and reducing harmful emissions, contributing to a cleaner environment and better overall efficiency of the vehicle.

Functionality of the Exhaust Manifold

The primary function of the manifold is to collect exhaust gases from multiple cylinders and channel them into a single outlet. This process is vital for minimizing backpressure and ensuring that the flow of gases is smooth, which can enhance the overall functionality of the vehicle. A well-designed manifold helps to improve engine efficiency by optimizing the expulsion of exhaust gases.

Emission Control Technologies

Modern vehicles incorporate various technologies to manage emissions effectively. Components such as catalytic converters and oxygen sensors work in tandem with the manifold to reduce pollutants before they are released into the atmosphere. These systems not only comply with environmental regulations but also enhance fuel economy by ensuring that the combustion process is as complete as possible. Effective emission control is essential for reducing the environmental impact of vehicles and improving air quality.

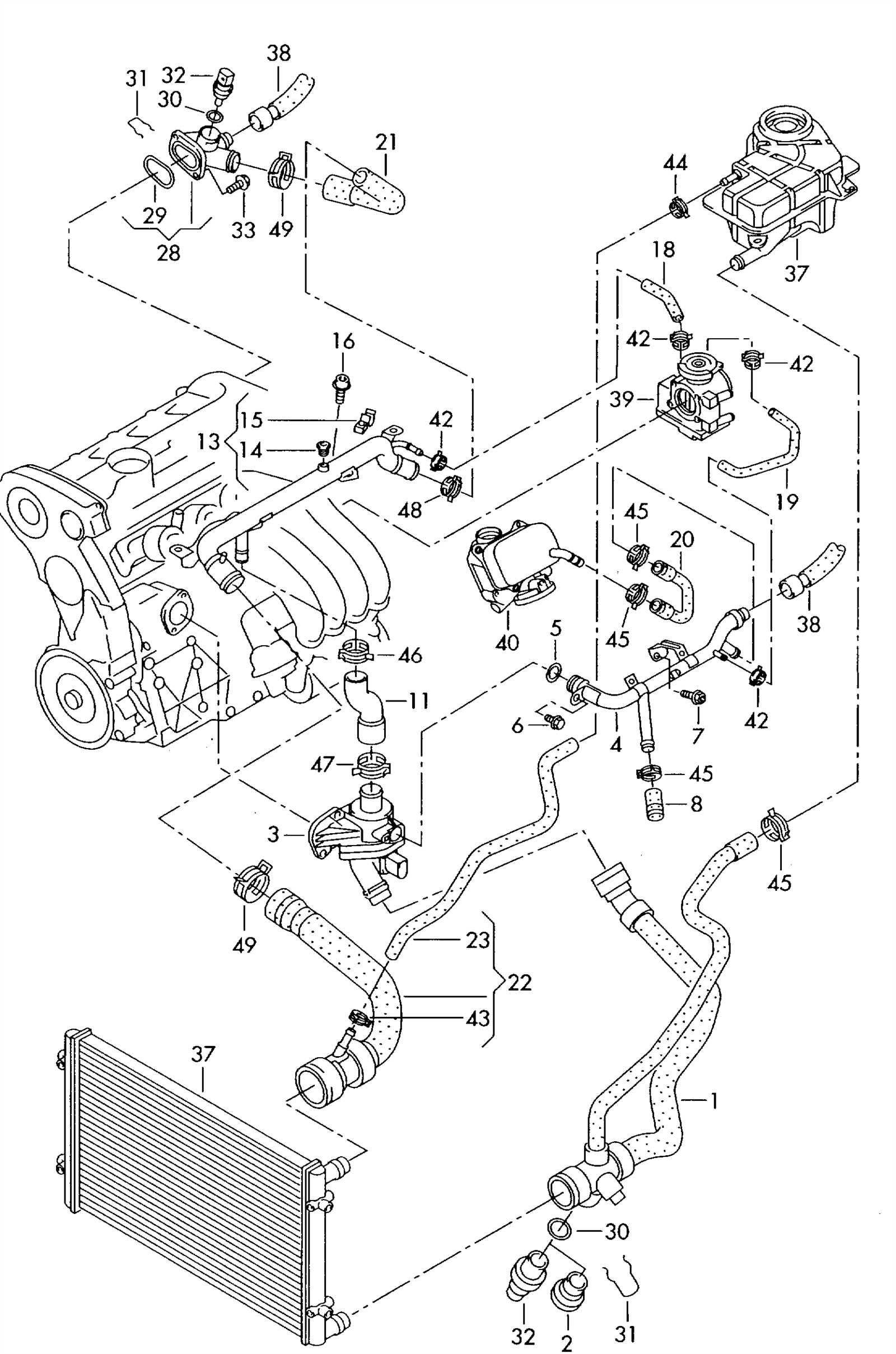

Cooling System Components and Flow

The cooling system plays a crucial role in maintaining optimal operating temperatures within a vehicle. It consists of several interconnected elements that work together to dissipate heat generated during operation. Understanding the flow of coolant through these components is essential for efficient thermal management and overall performance.

The flow of coolant begins at the water pump, which circulates the fluid through the entire system. As the coolant absorbs heat, it travels through various channels and components, including the radiator, thermostat, and hoses. Each component is designed to facilitate heat exchange, ensuring that the system functions effectively.

| Component | Function |

|---|---|

| Water Pump | Circulates coolant through the system. |

| Radiator | Dissipates heat from the coolant to the outside air. |

| Thermostat | Regulates coolant flow based on temperature. |

| Hoses | Transport coolant between components. |

Efficient operation of the cooling system is vital for preventing overheating and ensuring longevity of the mechanical components. Regular maintenance and inspection of these elements can help identify potential issues before they escalate, contributing to the reliability of the entire system.

Turbine and Supercharger Placement

The arrangement of the turbine and supercharger significantly influences the performance characteristics of a vehicle. Optimal positioning can enhance airflow dynamics, reduce lag, and improve overall efficiency. This section delves into how these components interact and their strategic placement within the system.

Importance of Positioning

Proper placement is crucial for maximizing the effectiveness of forced induction systems. A well-positioned turbine can facilitate quicker spool times, allowing for immediate power delivery. Conversely, the supercharger must be strategically located to ensure it provides a steady airflow under various operating conditions, enhancing responsiveness and acceleration.

Challenges and Considerations

When determining the layout, several factors must be considered, including space constraints, heat management, and exhaust routing. Engineers must strike a balance between performance and practicality, ensuring that the components do not interfere with other systems while maintaining optimal thermal efficiency. Effective cooling solutions are also essential to prevent overheating and ensure sustained performance under demanding conditions.

Electrical Connections and Sensor Integration

In modern vehicles, the interaction between various electronic components is crucial for optimal performance. This section delves into the significance of electrical linkages and the role of sensors in enhancing vehicle functionality. Understanding these connections is vital for diagnosing issues and ensuring efficient operation.

Importance of Electrical Linkages

Electrical linkages facilitate communication between different systems, allowing for seamless operation. They are essential for transferring signals and power to various modules, ensuring that components respond accurately to inputs. Regular inspection and maintenance of these connections can prevent malfunctions and enhance reliability.

Role of Sensors

Sensors play a pivotal role in gathering data from the environment and the vehicle itself. They monitor parameters such as temperature, pressure, and position, providing real-time feedback to the control units. This information is essential for making adjustments and maintaining optimal performance, contributing to overall efficiency and safety.

Air Intake and Filtration Mechanism

The process of air intake and filtration plays a vital role in ensuring optimal performance and efficiency of a vehicle’s internal combustion system. This mechanism is responsible for delivering clean, filtered air to the combustion chamber, allowing for a precise mix of fuel and air, which is essential for effective operation.

At the core of this system lies the air filter, which serves as the first line of defense against contaminants. It captures dust, debris, and other particulates, preventing them from entering the combustion process. A high-quality filter is crucial for maintaining airflow while ensuring that harmful particles do not affect performance.

The air intake assembly channels ambient air through various ducts and pathways. This assembly often includes components such as the intake manifold, throttle body, and various sensors that monitor air quality and flow rate. Each element works in unison to create an efficient airflow system that enhances combustion efficiency and overall power output.

Regular maintenance of the air intake and filtration system is essential for sustaining optimal functionality. Replacing the filter and inspecting the intake components can prevent potential issues related to airflow restrictions and engine performance, ultimately leading to better fuel efficiency and reduced emissions.