Understanding the intricate connections and elements of mechanical systems is essential for anyone involved in maintenance or repair. Each part plays a critical role, and knowing how they interact helps ensure smooth functionality and prevent malfunctions. This guide aims to provide a clear and detailed view of these crucial components without getting lost in technical jargon.

By exploring the layout and functions of various mechanical elements, you will gain valuable insights into how they fit together and work in harmony. Whether for routine upkeep or troubleshooting, this knowledge empowers you to address issues more effectively and efficiently.

We will dive into the specific structures and their purposes, offering a step-by-step overview. From connecting frameworks to moving mechanisms, every aspect will be covered to enhance your understanding and skills in maintaining and repairing these systems.

B&S Engine Parts Overview

The following section provides a concise guide on the key components found in small mechanical systems. Understanding the essential elements helps in maintaining and optimizing performance. This breakdown ensures proper care and functionality over time.

- Fuel System: A vital component responsible for the distribution of the fuel mixture, ensuring smooth operation.

- Ignition Assembly: This element triggers the combustion process, sparking life into the system.

- Cooling Mechanism: Critical for regulating temperature and preventing overheating during prolonged use.

- Lubrication System: Ensures all moving parts function efficiently by reducing friction and wear.

- Exhaust Setup: Helps in expelling unwanted gases, maintaining efficiency and safety.

These

Identifying Key Engine Components

Understanding the core elements of a machine’s internal mechanism is essential for proper maintenance and repair. By recognizing the function and placement of various components, it becomes easier to troubleshoot issues and ensure the overall efficiency of the system.

Recognizing Major Sections

The mechanical system is typically divided into distinct sections, each with its own role. These parts work in harmony to deliver power and regulate the entire operation. Familiarizing yourself with their arrangement and how they interact is key to keeping everything running smoothly.

Examining Specific Components

Each individual part has a unique function that contributes to the machine’s performance. Key mechanical elements can often be identified by their structure and location within the assembly. Learning to distinguish these components not only aids in maintenance but also

Understanding the Function of Engine Parts

Mechanical systems rely on a variety of components working together to ensure efficient performance. Each individual element plays a critical role in maintaining the system’s operation, contributing to everything from energy generation to motion control. Understanding how these components interact is key to diagnosing issues and improving performance.

- Power Generation: The core of the system focuses on converting fuel into usable energy, driving various processes.

- Cooling Mechanism: Proper temperature regulation is crucial to prevent overheating and ensure longevity of the entire assembly.

- Lubrication System: Smooth movement of all elements is supported by proper lubrication, reducing wear and tear.

- Air and Fuel Mixing: A balanced intake of air and fuel is vital for optimal combustion and energy efficiency.

- Exhaust Removal: The system efficiently expels waste gases

Common Parts in B&S Engines

When working with small power equipment, certain components are found across various models. These essential elements ensure smooth functionality and are often the key to maintaining optimal performance.

Ignition System Components

The ignition setup plays a critical role in starting and running the machinery. It typically includes a spark device, wiring, and other elements responsible for generating the necessary spark to ignite fuel. Regular inspection of these elements is crucial for reliability.

Fuel Delivery Mechanisms

To ensure efficient operation, the fuel is delivered through a well-coordinated system. This network includes valves, a fuel pump, and a filter, all working together to control the mixture of air and fuel. Proper maintenance of this mechanism is key to preventing performance issues.

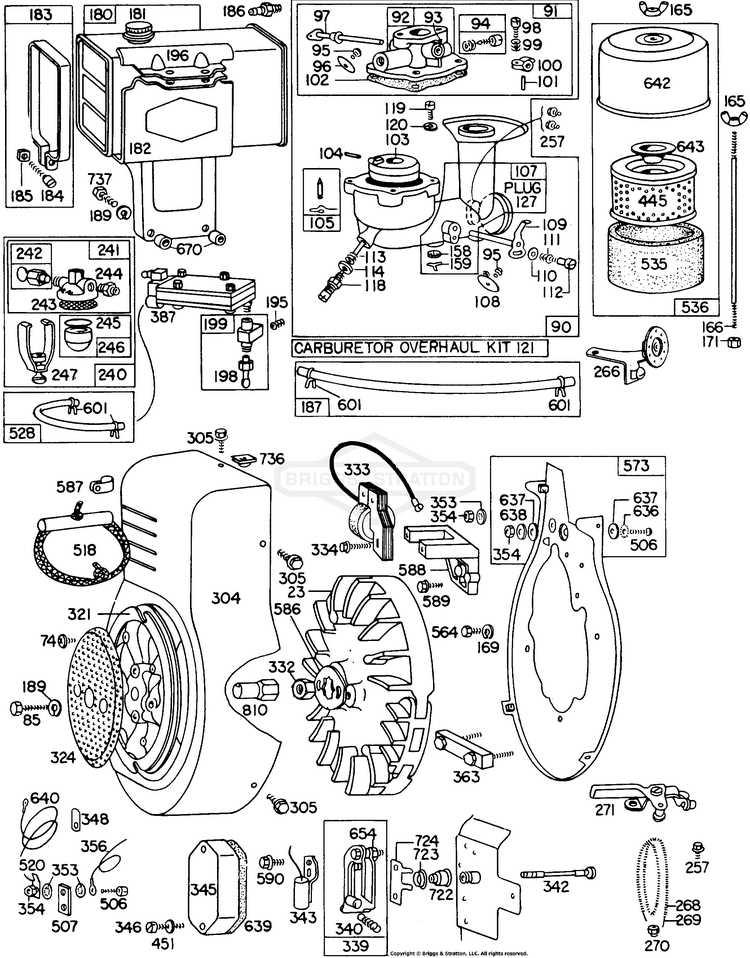

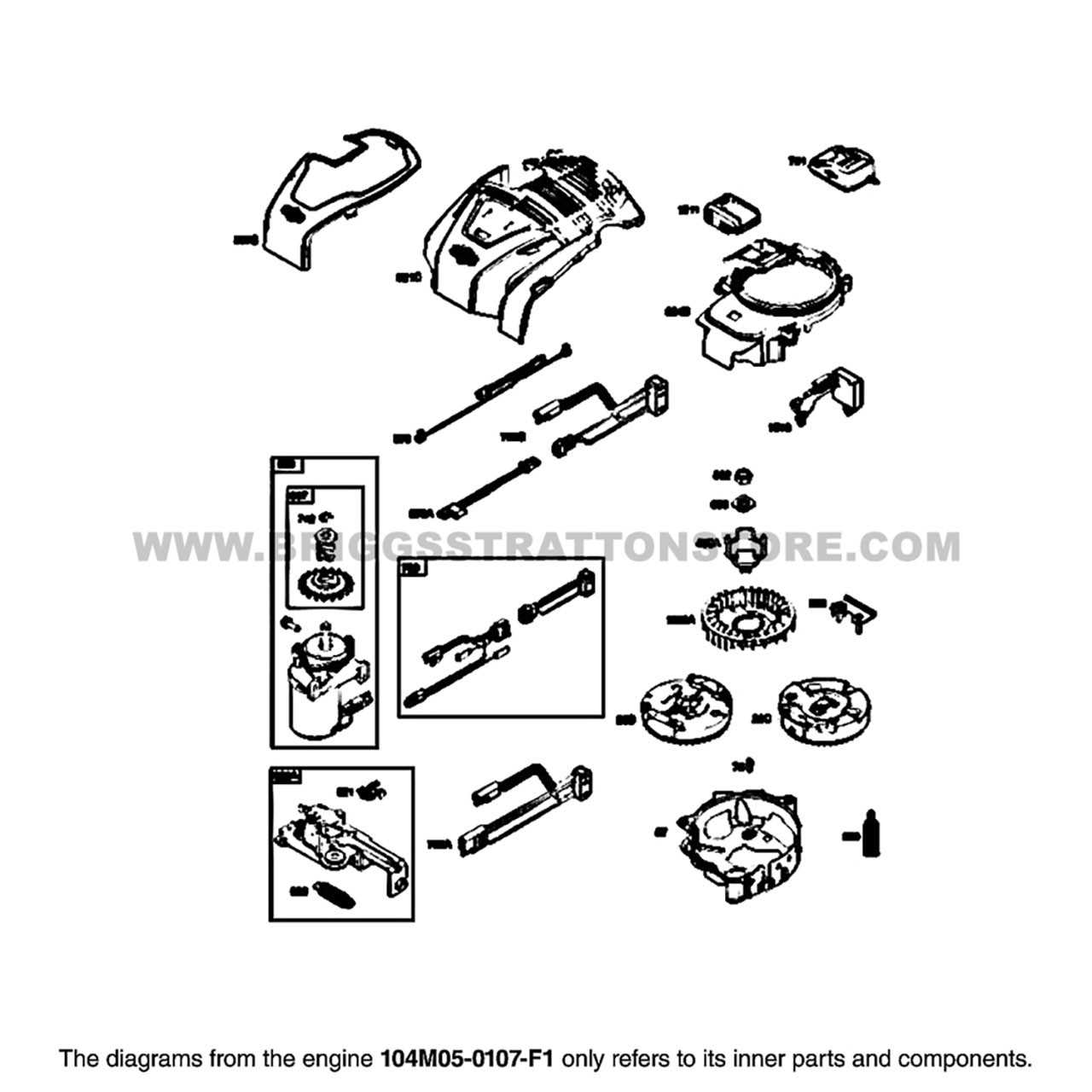

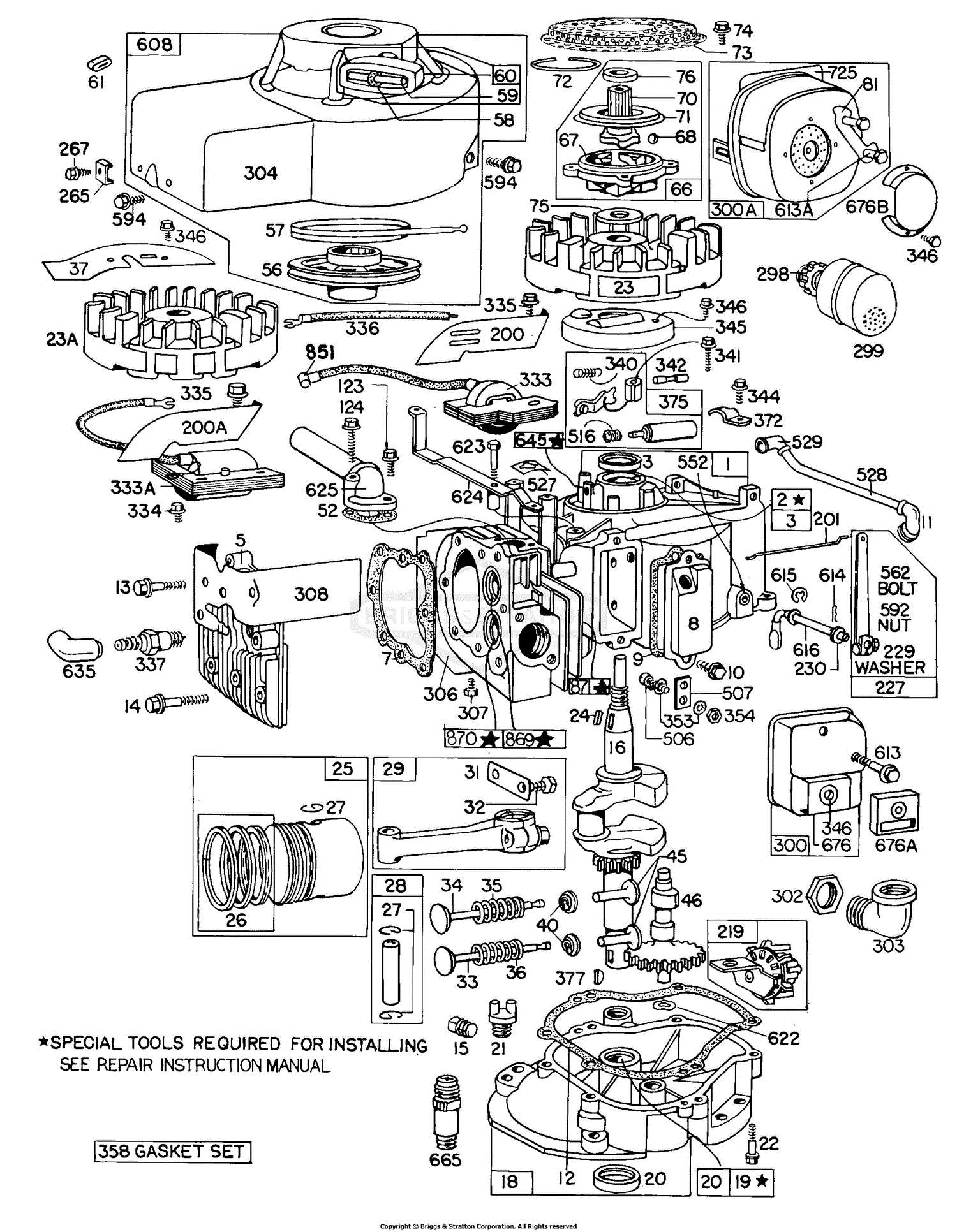

How to Read a B&S Parts Diagram

Understanding the layout of a component schematic is essential for identifying individual elements and ensuring proper assembly or maintenance. These schematics provide a clear visual guide to the various elements of machinery, allowing users to quickly locate specific components without confusion.

To interpret the drawing effectively, start by identifying the numbered labels that correspond to specific parts in the accompanying list. Each label indicates a unique element, guiding the user in understanding how different parts fit together.

Step Description 1 Locate the reference numbers on the schematic and cross-check them with the list to find the relevant component. 2 Signs of Wear in Engine Components Identifying deterioration in mechanical elements is crucial for maintaining optimal performance and extending the lifespan of any machinery. Over time, various factors can contribute to the decline of these components, leading to decreased efficiency and potential failure. Recognizing the signs of wear early can help prevent more extensive damage and costly repairs.

Common Indicators of Deterioration

- Unusual Noises: Uncharacteristic sounds, such as knocking or grinding, often signal that parts are no longer functioning smoothly.

- Excessive Vibration: Noticeable shaking during operation may indicate imbalances or loose connections within the system.

- Oil Leaks: Visible fluid leaks can suggest that seals or gaskets have become compromised, leading to potential lubrication issues.

- Overheating: Elevated temperatures during operation may indicate friction due to worn components, potentially resulting in catastrophic failure.

Visual Inspection Techniques

- Check for cracks or fractures on visible surfaces, which may indicate stress or fatigue.

- Look for discoloration or changes in texture that may suggest overheating or chemical damage.

- Assess the alignment and fit of parts to ensure they are not misaligned or improperly seated.

By being vigilant and proactive in monitoring these signs, one can effectively mitigate risks and ensure the longevity of crucial machinery.

Replacing Worn Out Engine Parts

Over time, various components within a mechanical system can experience wear and tear, leading to diminished performance and efficiency. Recognizing the signs of deterioration is crucial for maintaining optimal functionality. Timely replacement of these worn components can prevent more significant issues and extend the lifespan of the entire system.

Identifying Signs of Wear is essential for effective maintenance. Look for indicators such as unusual noises, reduced power output, or frequent overheating. These symptoms often signal that certain elements need to be assessed and potentially replaced. Regular inspections can help pinpoint the areas that require attention.

Choosing Quality Replacements is another critical aspect of this process. It is advisable to select components that meet or exceed the original specifications. This ensures compatibility and reliability, which can enhance overall performance. Researching trusted manufacturers and seeking recommendations can guide you in making informed choices.

Once suitable replacements have been sourced, the installation process should be approached with care. Following proper procedures and utilizing the right tools is essential to ensure that the new components are fitted correctly. If necessary, consult a professional for assistance to avoid potential complications.

Engine Maintenance and Part Inspection

Regular upkeep and assessment of machinery components are vital for optimal performance and longevity. By conducting thorough evaluations, one can identify potential issues before they escalate, ensuring smooth operation and preventing unexpected failures.

Importance of Routine Checks

Scheduled inspections allow for the early detection of wear and tear, which can significantly reduce the risk of costly repairs. Focusing on critical elements not only extends the lifespan of equipment but also enhances overall efficiency.

Best Practices for Assessment

When examining machinery, it is crucial to follow a systematic approach. Visual inspections should be conducted regularly, checking for signs of damage, leaks, or unusual wear. Additionally, keeping records of maintenance activities helps track the condition over time and facilitates informed decisions regarding replacements and repairs.

Choosing the Right Replacement Parts

When it comes to maintaining machinery, selecting appropriate components is crucial for ensuring optimal performance and longevity. Making informed decisions can significantly impact the efficiency of your equipment, leading to improved reliability and reduced downtime.

Compatibility is a key factor in the selection process. Always verify that the substitute items match the specifications of your existing system to avoid any complications during installation. This ensures a seamless integration and functionality.

Additionally, consider the quality of the components you choose. Opt for high-grade materials that provide durability and resilience. While lower-priced options may seem appealing, investing in quality replacements will save money in the long run by minimizing frequent repairs and replacements.

Furthermore, it’s wise to research reputable suppliers who offer a warranty on their products. This not only assures you of the item’s reliability but also provides peace of mind should any issues arise after installation. Always prioritize suppliers with positive feedback and a proven track record.

Ultimately, making thoughtful choices regarding replacements will enhance the overall functionality and safety of your machinery, ensuring it operates at its best for years to come.

Engine Assembly Tips and Tricks

When working on machinery reassembly, it is essential to approach the task with careful planning and methodical execution. A thorough understanding of the components and their interactions can significantly enhance the efficiency and longevity of the assembly. Here are some valuable insights and methods to ensure a successful assembly process.

Preparation is Key

Before diving into the assembly, gather all necessary tools and components. Having everything organized will save time and prevent frustration during the process. Create a checklist of items needed for the assembly to ensure nothing is overlooked.

Follow a Systematic Approach

Adopting a systematic approach can streamline the assembly process. Start by arranging components in the order they will be assembled. This organization helps visualize the entire process and reduces the likelihood of mistakes.

Tip Description Label Components Use labels to mark parts for easy identification during assembly. Use a Torque Wrench Ensure bolts are tightened to the manufacturer’s specifications to avoid damage. Keep a Clean Workspace A clutter-free area minimizes distractions and potential errors. Double-Check Your Work Regularly verify that each component is correctly positioned and secured. Tools Needed for Part Installation

When undertaking a task that involves the assembly or replacement of components, having the right tools is essential for ensuring efficiency and effectiveness. The proper instruments not only facilitate the process but also contribute to the longevity and functionality of the items being installed.

Essential tools may include wrenches, screwdrivers, and pliers, each serving a specific purpose to secure or loosen various fittings. Additionally, having a torque wrench on hand ensures that connections are made with the correct pressure, which is crucial for optimal performance. Other helpful items such as a socket set and adjustable pliers can aid in tackling different sizes of fittings with ease.

Furthermore, using protective gear like gloves and goggles enhances safety during the installation process. By equipping yourself with these necessary tools, you set the stage for a successful and hassle-free assembly experience.