The intricate systems that drive machinery are crucial to their overall functionality. Each component plays a vital role, contributing to the seamless operation of the entire assembly. A comprehensive exploration of these systems reveals how interconnected elements work together to produce the desired outcomes in various applications.

From the fundamental principles that govern movement to the specific roles of individual elements, grasping the nuances of these systems enhances our appreciation of engineering achievements. Delving into the structure and functionality of these mechanisms offers valuable insights into both historical advancements and contemporary innovations.

By examining the relationships between various elements, we can better understand the complexities involved in the design and operation of machinery. This exploration not only highlights the ingenuity of engineers but also showcases the importance of each element in achieving optimal performance.

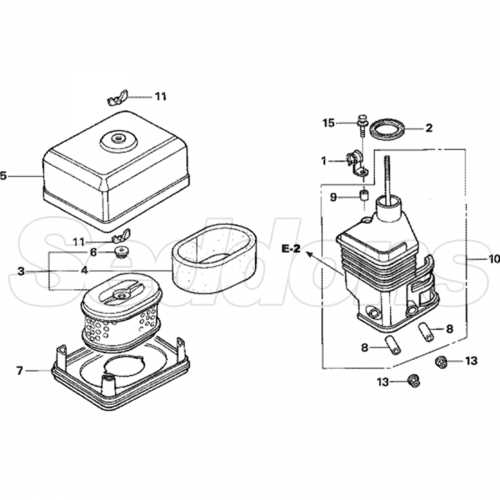

Various forms of power-generating mechanisms rely on the combustion of fuel to produce motion. Each design serves unique purposes and applications, showcasing diverse characteristics that influence performance, efficiency, and environmental impact. Understanding these variations is essential for those interested in the mechanics of transportation and machinery.

Classification Based on Cycle

- Two-Stroke: This design completes a power cycle with two strokes of the piston, providing a simpler construction and higher power-to-weight ratio.

- Four-Stroke: In this more common configuration, the cycle involves four strokes, leading to greater efficiency and lower emissions due to a complete combustion process.

Classification Based on Fuel Type

- Gasoline: Often used in light-duty vehicles, these systems rely on spark ignition for combustion.

- Diesel: Utilizing compression ignition, these types are prevalent in heavy-duty applications, known for their durability and fuel efficiency.

- Natural Gas: An alternative option that burns cleaner than gasoline and diesel, reducing harmful emissions.

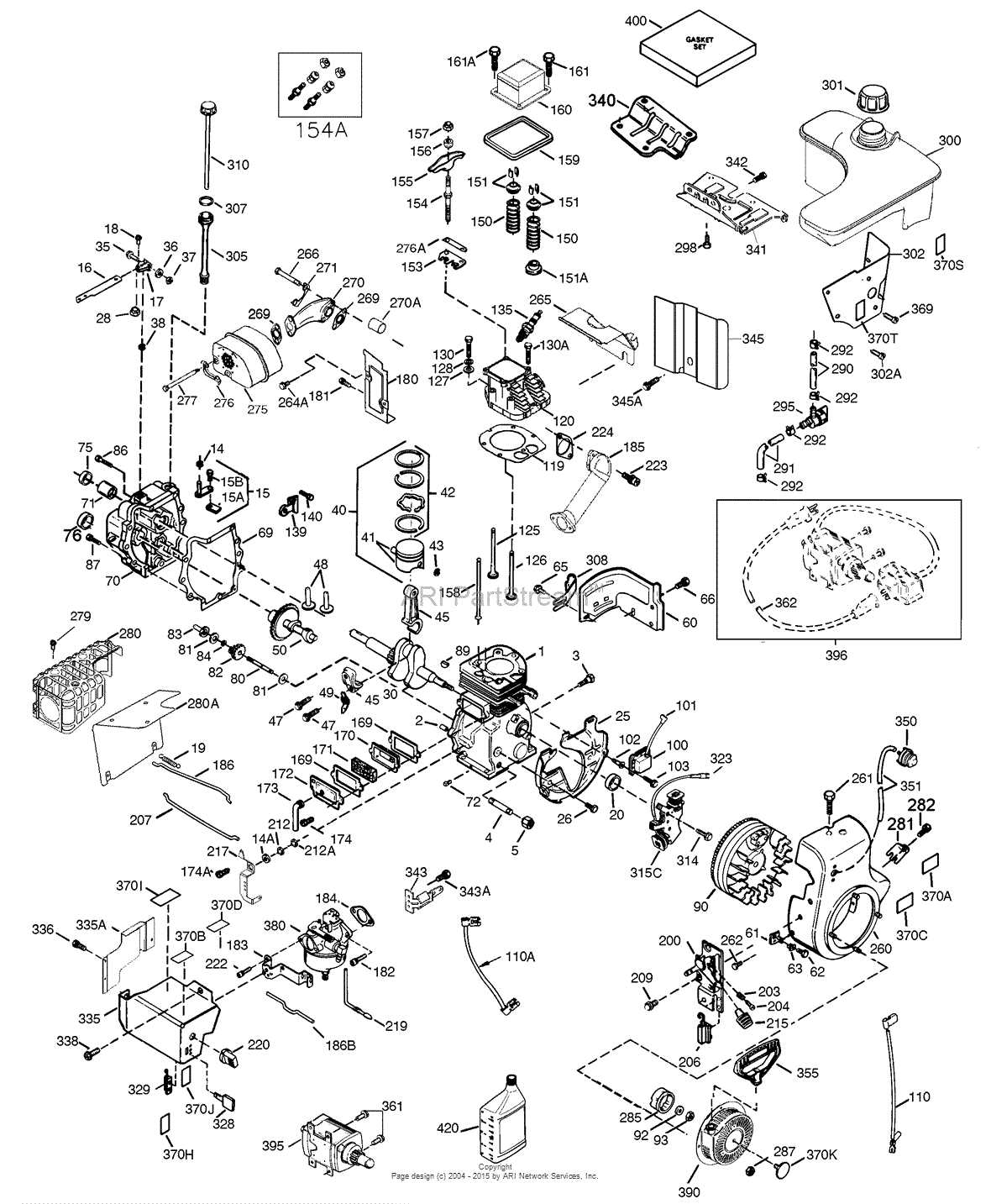

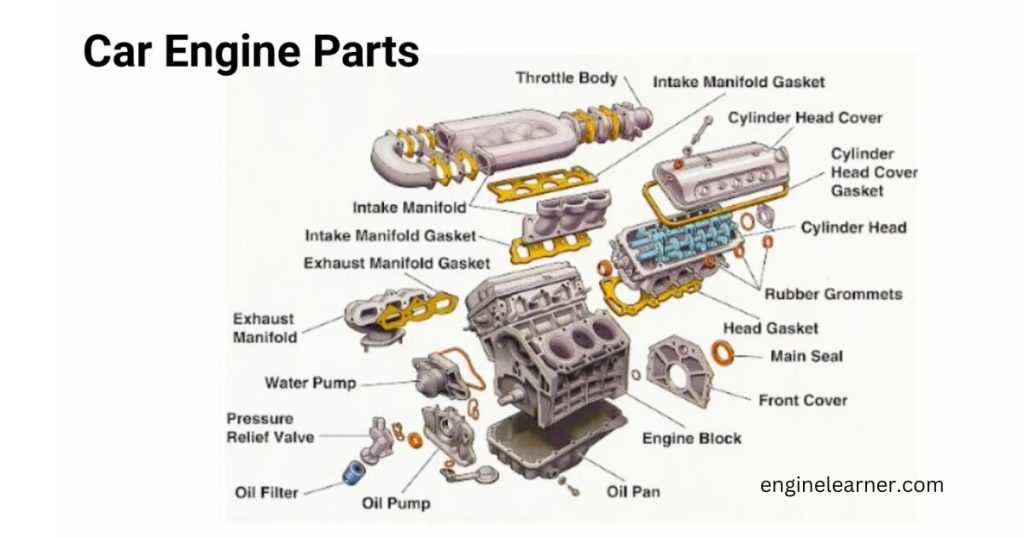

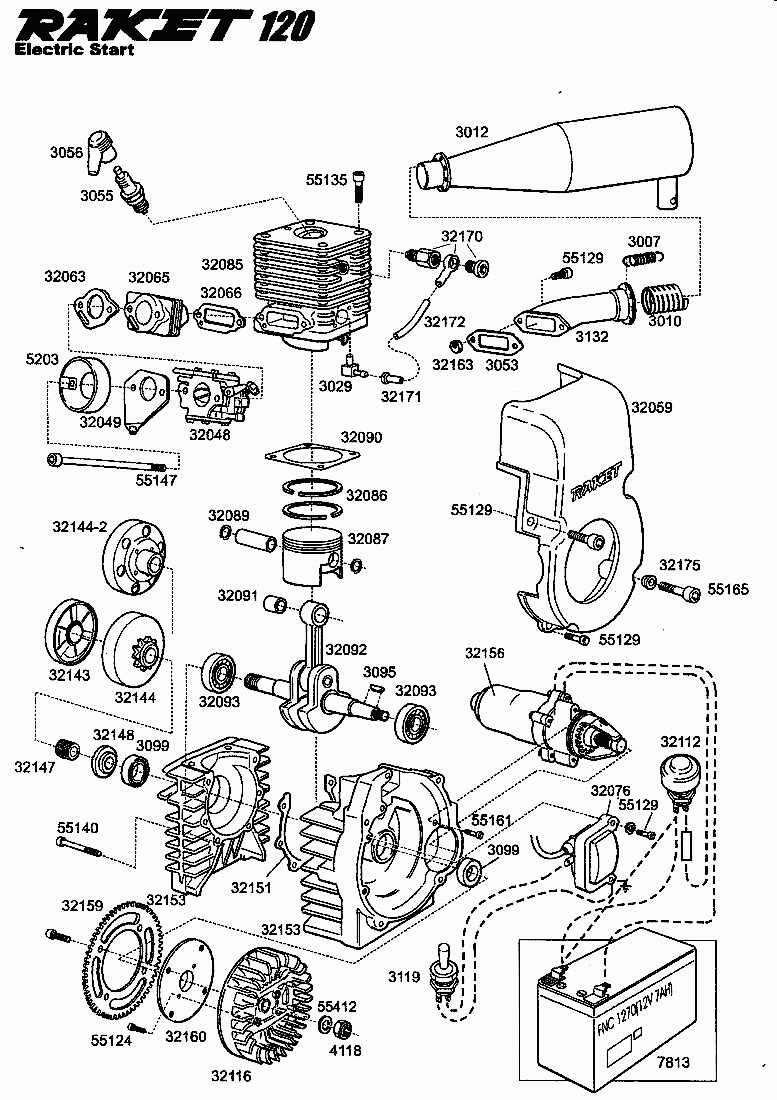

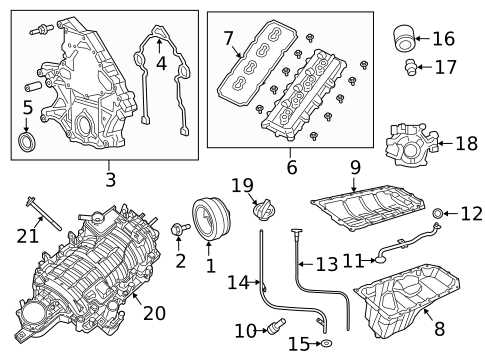

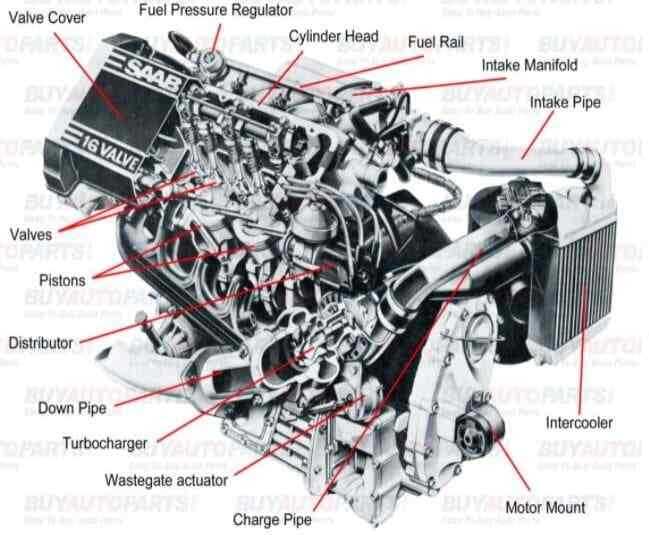

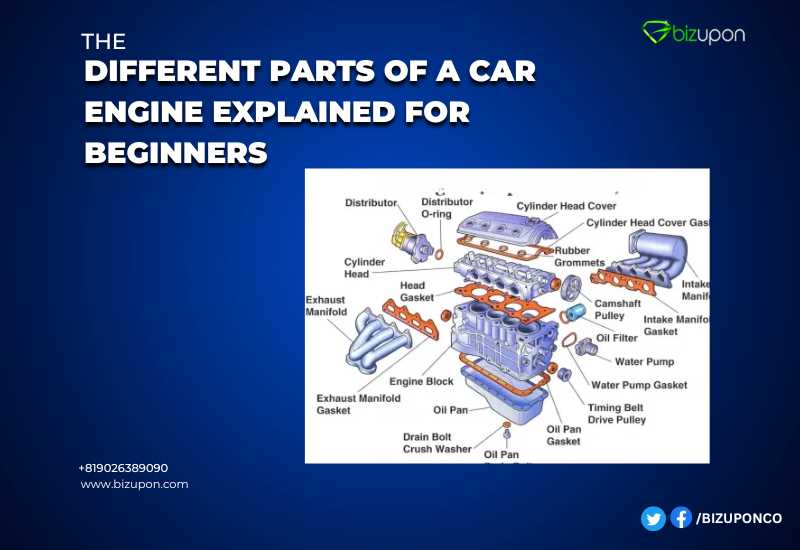

Key Components of Engine Systems

The functionality of a power unit relies on several essential elements that work in harmony to facilitate motion and efficiency. Each component plays a vital role in converting fuel into mechanical energy, ensuring smooth operation and performance. Understanding these crucial elements provides insight into the intricate design and engineering that underpins any machine’s operation.

Core Elements of Power Units

At the heart of every system are components that manage fuel delivery and combustion. These elements include systems that regulate the flow of fuel and air, optimizing the mixture for efficient burning. Furthermore, mechanisms responsible for igniting this mixture are essential for generating the energy needed to drive movement.

Supporting Mechanisms

In addition to the primary components, auxiliary systems enhance overall performance and reliability. These may include cooling systems that maintain optimal operating temperatures and lubrication systems that reduce friction between moving elements. Effective management of these supporting systems is crucial for longevity and efficiency.

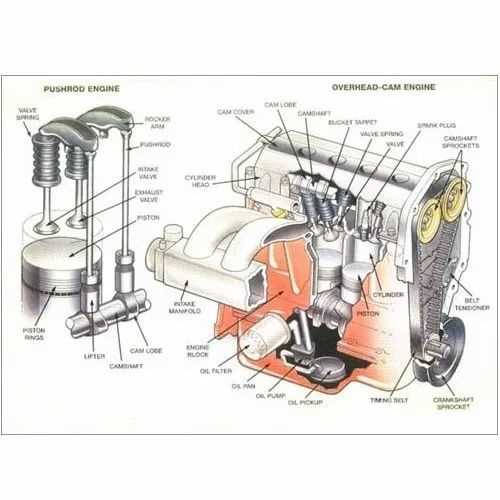

The Role of the Crankshaft

The crankshaft serves as a vital component in transforming linear motion into rotational movement, playing a critical role in the operation of various machines. This process is essential for the overall functionality of mechanical systems, enabling the conversion of power generated within a combustion chamber into usable energy.

Functionality and Importance

This crucial element is responsible for several key tasks, including:

- Converting the up-and-down motion of pistons into circular motion.

- Balancing the forces generated during combustion, ensuring smooth operation.

- Transmitting power to other components, such as the transmission or flywheel.

Design and Construction

The design of the crankshaft is engineered to withstand significant stresses and strains. Typically constructed from robust materials, its shape is finely tuned to optimize performance. Key features include:

- Journal bearings for smooth rotation.

- Counterweights to minimize vibration.

- Flanges for connecting to the powertrain.

In summary, the crankshaft is indispensable in ensuring that the motion produced by combustion is efficiently harnessed and utilized throughout the mechanical system, making it a cornerstone of performance and reliability.

Fuel Delivery Mechanisms Explained

Understanding the systems responsible for supplying combustible material to a combustion chamber is essential for comprehending overall performance and efficiency. These mechanisms play a crucial role in ensuring the proper mixture of air and fuel, directly influencing the effectiveness and power output of various types of machinery. This section delves into the various methods employed to transport fuel, highlighting their functions and importance.

Types of Fuel Delivery Systems

- Carbureted Systems:

Utilizing a carburetor, this method mixes fuel with air to form a combustible mixture before entering the combustion chamber. This design is commonly found in older models of vehicles and some small engines.

- Fuel Injection Systems:

Modern systems often employ fuel injectors, which deliver a precise amount of fuel directly into the combustion chamber or intake manifold. This technique enhances efficiency and performance.

Key Components of Fuel Delivery

- Fuel Pump: Responsible for transporting fuel from the tank to the delivery system, ensuring a consistent supply under various operational conditions.

- Fuel Filter: This component cleans the fuel before it enters the delivery system, preventing contaminants from causing damage or inefficiency.

- Fuel Lines: These tubes connect the tank, pump, and injectors, allowing for the unobstructed flow of fuel throughout the system.

Importance of Engine Cooling Systems

The management of temperature within a mechanical system is crucial for optimal performance and longevity. A well-functioning temperature regulation mechanism prevents overheating, ensuring that all components operate efficiently. Without this vital process, the risk of failure increases significantly, leading to potential damage and costly repairs.

The cooling mechanism plays a pivotal role in maintaining the appropriate thermal balance. It aids in dissipating excess heat generated during operation, safeguarding sensitive components from extreme conditions. By maintaining a stable operating temperature, the system enhances overall efficiency, contributing to better fuel consumption and reduced emissions.

Moreover, effective temperature control is essential for the durability of materials used in construction. Overheating can lead to thermal expansion, compromising structural integrity and leading to premature wear. A reliable cooling mechanism ensures that all elements remain within safe temperature limits, thus prolonging their lifespan.

In addition, efficient cooling systems contribute to the overall safety of the operation. By preventing overheating, they mitigate risks associated with critical failures, which could result in hazardous situations. Therefore, the significance of maintaining an effective temperature management system cannot be overstated, as it is integral to both performance and safety.

Overview of the Ignition System

The ignition system plays a crucial role in the overall functioning of a vehicle’s propulsion mechanism. It is responsible for initiating the combustion process, which ultimately powers the vehicle. Understanding its components and operation is essential for diagnosing issues and ensuring optimal performance.

Key Functions

- Ignition Timing: Determines the precise moment for the fuel-air mixture to ignite.

- Fuel Efficiency: Optimizes combustion for better energy output.

- Emissions Control: Reduces harmful exhaust gases by ensuring complete combustion.

Major Components

- Ignition Coil: Converts low voltage from the battery into the high voltage needed for sparking.

- Spark Plug: Produces a spark that ignites the fuel-air mixture.

- Distributor: Directs the high-voltage current to the correct cylinder at the right time.

- Ignition Module: Controls the timing and duration of the spark.

Each of these elements works in harmony to ensure that the ignition process occurs efficiently and reliably. Regular maintenance of the ignition system is vital for enhancing a vehicle’s performance and longevity.

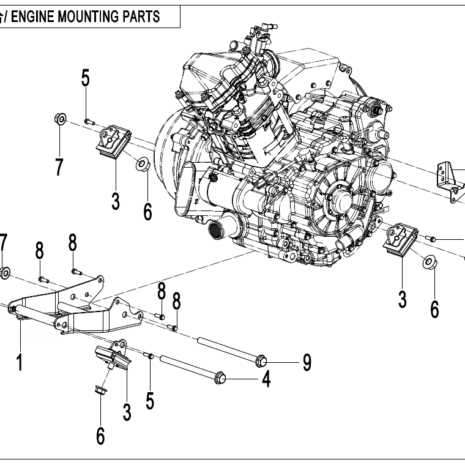

Transmission and Engine Interaction

The relationship between the propulsion unit and the system that transmits power is crucial for the overall performance of a vehicle. Understanding how these two components communicate and work together can enhance efficiency and driveability. A seamless interaction ensures that the vehicle responds optimally to the driver’s commands.

This interaction can be broken down into several key aspects:

- Power Transfer: The method by which rotational force from the propulsion unit is converted and sent to the wheels.

- Gear Ratios: The selection of different ratios that affect the balance between torque and speed, enabling the vehicle to adapt to varying driving conditions.

- Control Mechanisms: Systems that facilitate the engagement and disengagement of components to manage power flow effectively.

- Feedback Loops: Signals sent between systems to optimize performance, allowing for real-time adjustments during operation.

These elements work in tandem to ensure that the vehicle delivers a smooth and responsive driving experience. The efficiency of this interaction directly impacts fuel consumption and overall vehicle longevity.

For optimal performance, regular maintenance and checks are necessary to address any wear or inefficiencies that may arise over time. Understanding this connection empowers drivers and technicians alike to enhance the vehicle’s functionality.

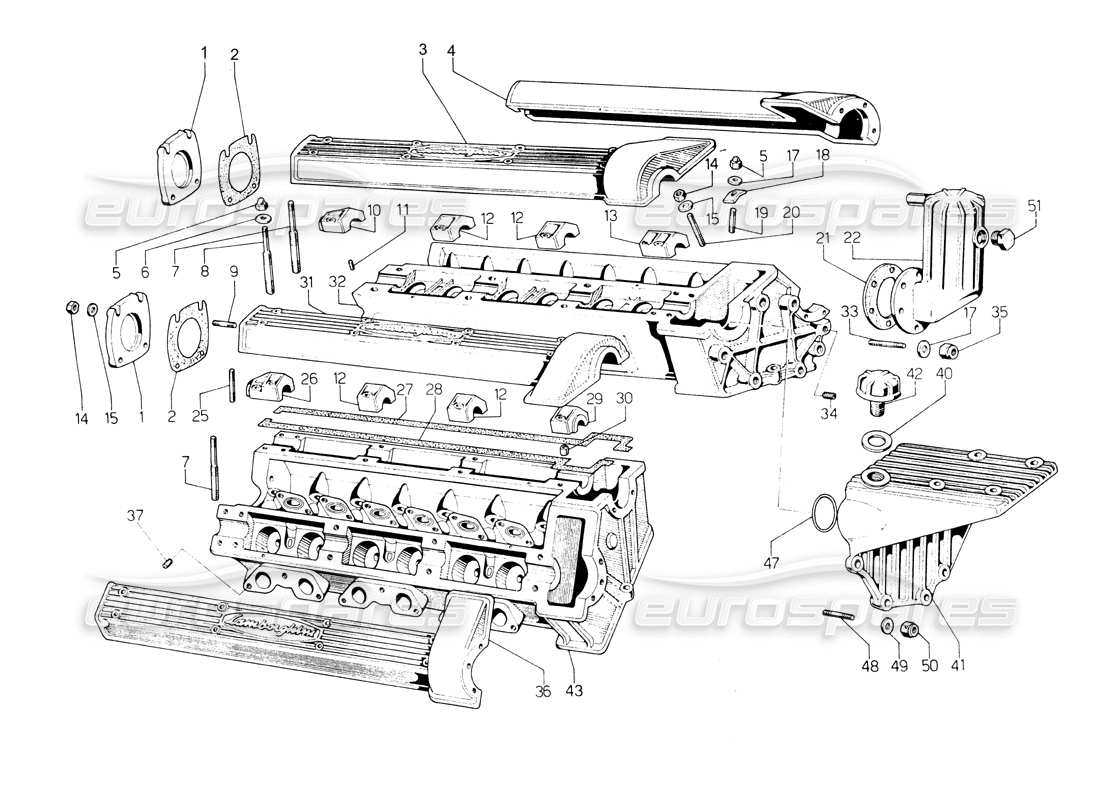

Understanding Valve Mechanisms

The function of controlling the flow of fluids within a mechanical system is crucial for its overall efficiency and performance. Various mechanisms serve this purpose, ensuring the appropriate timing and quantity of substances enter and exit different chambers. These systems are fundamental in optimizing operations, reducing emissions, and enhancing power output.

Types of Valve Mechanisms

Several configurations are commonly utilized in various applications, each tailored to specific operational requirements. For instance, pop-up mechanisms operate by lifting a disc or gate, allowing for a controlled passage of fluids. On the other hand, rotary types involve the rotation of a cylindrical component to achieve similar results. Understanding these differences is essential for selecting the right system for a given application.

Importance of Proper Functioning

Efficient functioning of these mechanisms is vital for maintaining optimal performance and longevity. Regular maintenance, including the inspection of seals and lubricants, can prevent malfunctions and ensure smooth operation. Additionally, advancements in technology have led to the development of more sophisticated designs that improve reliability and responsiveness.

How Exhaust Systems Work

The exhaust system plays a crucial role in the overall performance and efficiency of a vehicle. Its primary function is to channel harmful gases away from the combustion chamber and release them safely into the atmosphere. This process not only ensures the smooth operation of the vehicle but also minimizes harmful emissions that can contribute to environmental pollution.

Key Components and Their Functions

One of the most important components of this system is the manifold, which collects gases from multiple cylinders and directs them into the next phase of the exhaust flow. Following this, the catalytic converter transforms toxic pollutants into less harmful substances, significantly reducing emissions. The muffler then plays a vital role by dampening the noise produced during gas expulsion, ensuring a quieter ride.

Importance of Proper Functioning

Ensuring that each element of this assembly operates correctly is essential for optimal vehicle performance. A malfunctioning part can lead to increased emissions, decreased fuel efficiency, and louder engine noise. Regular maintenance and timely replacements are necessary to uphold the efficiency of the overall system, contributing not only to better performance but also to a cleaner environment.

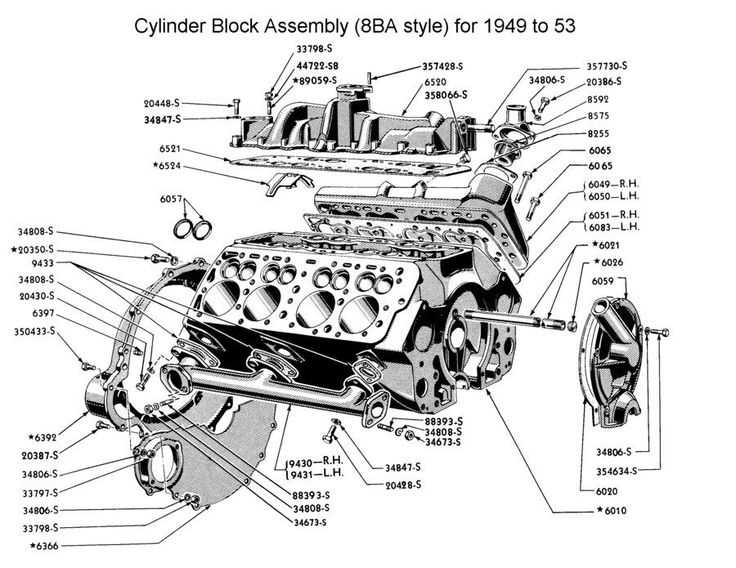

Engine Block: Its Structure and Purpose

The core of any power-generating system lies in the central component that houses various mechanisms, ensuring the conversion of fuel into energy. This essential unit provides the foundation for other key elements, supporting both internal motion and external stability.

Understanding its structure is vital to grasp how it operates. It is a solid and durable unit that supports several interconnected systems. Each section plays a critical role in distributing forces, managing heat, and maintaining the overall efficiency of the mechanism.

- Main Frame: The robust core designed to withstand immense pressures and high temperatures.

- Cylindrical Chambers: These sections serve as the area where controlled movements take place.

- Fluid Channels

Assessing Performance Metrics

Evaluating the overall functionality and efficiency of a mechanical system involves analyzing a variety of performance indicators. These factors help identify the strength, responsiveness, and reliability of the system under different conditions. By focusing on key metrics, it becomes possible to understand how well the mechanism operates and where improvements can be made.

- Power Output: One of the primary indicators, this metric reflects how much work the system can perform over a specific period.

- Efficiency: This parameter determines how effectively energy is converted into useful work, minimizing waste and maximizing productivity.

- Responsiveness: