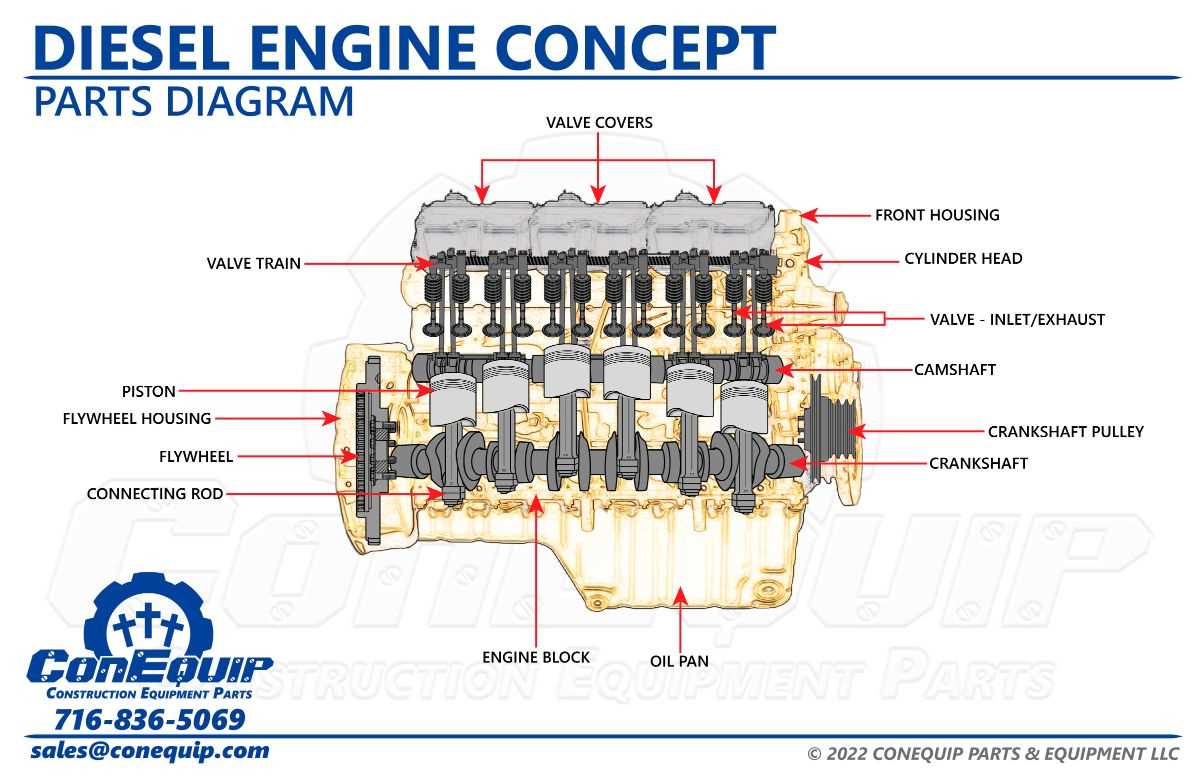

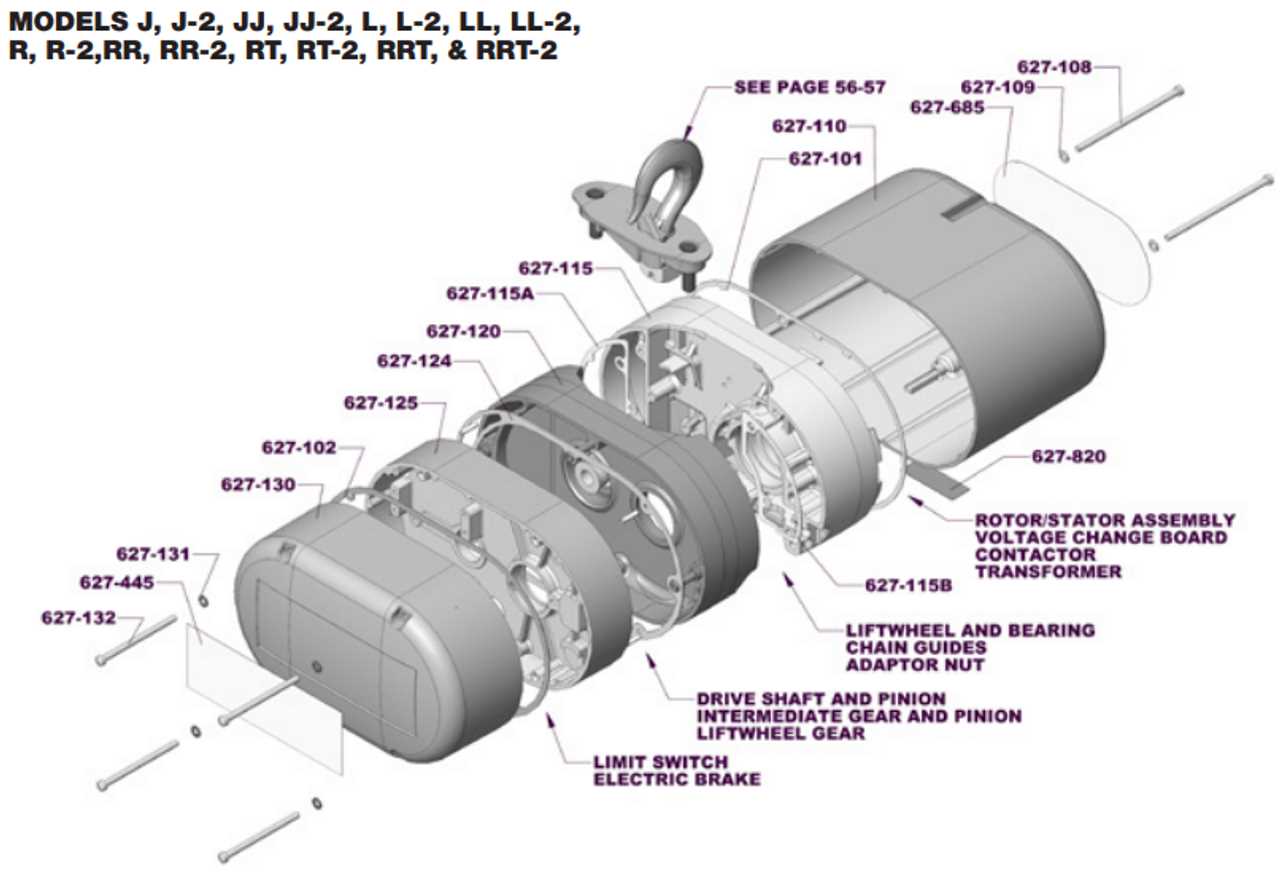

In mechanical systems, various elements work together to perform essential tasks. Each component has a specific function and contributes to the overall performance of the setup. This section provides an overview of the key structures and how they fit together, offering insight into the overall configuration.

As we delve deeper, you will learn how these elements interconnect and the role each one plays in the operation. By exploring the arrangement and positioning of these vital structures, it becomes easier to grasp their significance in ensuring the efficient functioning of the machinery.

The following details will guide you through the layout and interaction of various components, giving a clearer picture of how everything works in unison. This information will be especially helpful when maintaining, repairing, or assembling mechanical systems.

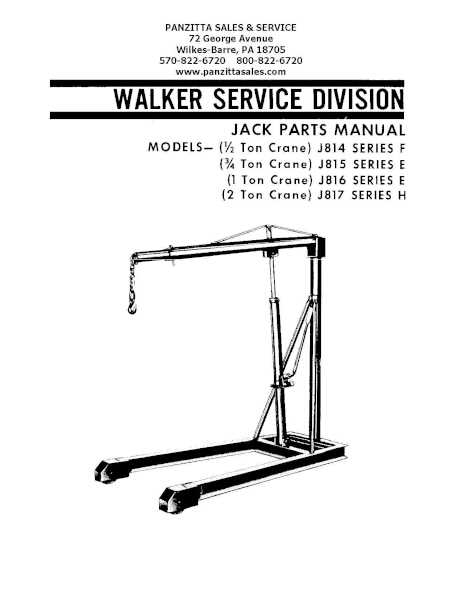

Understanding Engine Hoist Components

When working with heavy machinery, it’s essential to be familiar with the various elements that make lifting equipment function effectively. Each individual piece plays a crucial role in ensuring the overall system operates smoothly and safely. By understanding how these components interact, you can enhance your equipment’s performance and ensure its longevity.

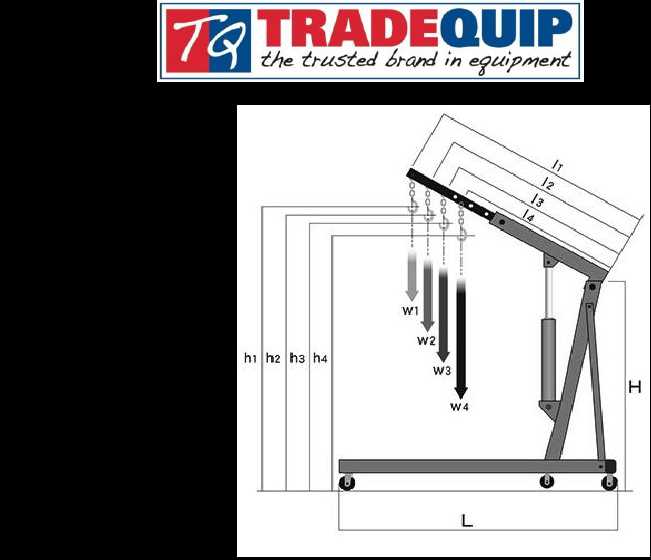

Main Structural Elements

The framework of lifting devices consists of several robust sections designed to bear significant loads. These parts must be strong enough to support the object being elevated while maintaining stability. Reinforced metals and durable joints form the core of the system, ensuring the weight is distributed evenly.

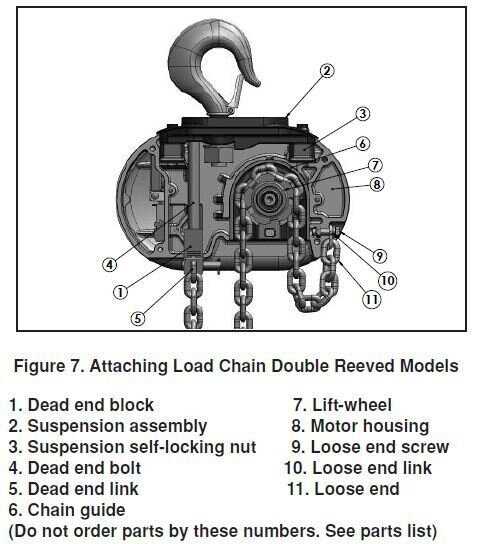

Operational Mechanisms

Various mechanisms are responsible for controlling the movement of the load. These include systems

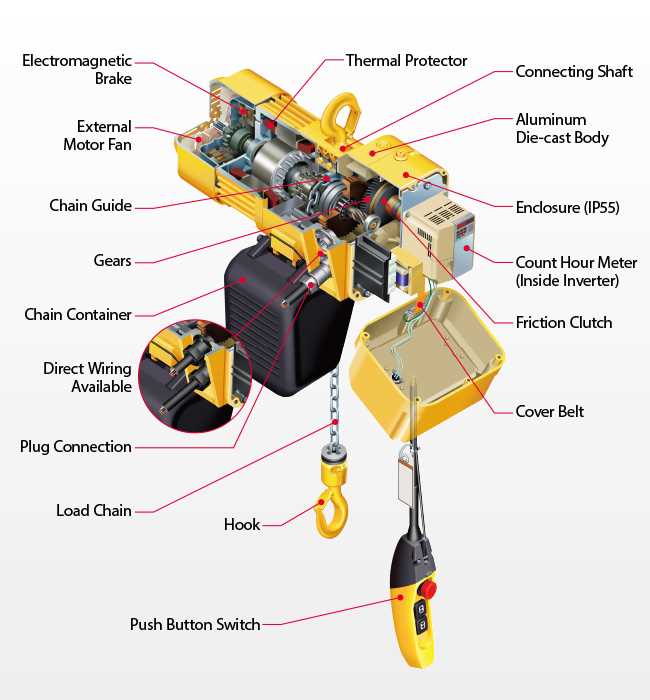

Key Functions of Hoist Parts

The equipment used to lift and move heavy objects relies on a series of crucial components working together. Each element plays a significant role in ensuring the system operates smoothly and safely, from supporting the weight to controlling the movement. Understanding the role of each component helps ensure efficient usage and maintenance.

| Component | Primary Function | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lifting Mechanism | Responsible for raising and lowering loads, providing the necessary force to lift heavy materials. | ||||||||||||||||||

| Frame | Offers structural support, ensuring stability and balance while in use. | ||||||||||||||||||

| Chains or Cables | Transfer force and connect the lifting mechanism to the load, ensuring secure handling. | ||||||||||||||||||

| Wheel Type | Material | Weight Capacity | Ideal Surface |

|---|---|---|---|

| Rubber | Rubber | Up to 500 lbs | Hard floors |

| Polyurethane | Polyurethane | Up to 800 lbs | Concrete and asphalt |

| Plastic | Plastic | Up to 300 lbs | Indoor use |

| Metal | Steel | Up to 1000 lbs | Rough surfaces |

In summary, caster wheels play a crucial role in enhancing the mobility of various equipment, providing the flexibility needed to operate efficiently. Selecting the right type of wheel based on the specific needs can greatly impact operational effectiveness.

Maintaining Safety with Proper Hook Use

Ensuring safety during lifting operations is paramount. Proper use of attachments plays a critical role in preventing accidents and ensuring the security of loads. Adhering to guidelines and best practices will help minimize risks associated with lifting tasks.

Here are key considerations for using attachments safely:

- Inspection: Regularly check attachments for signs of wear, damage, or deformation. Ensure they are free from cracks or other imperfections.

- Weight Limits: Always adhere to the manufacturer’s specified weight capacity. Never exceed the recommended limits to avoid potential failures.

- Compatibility: Ensure that the attachment is compatible with the lifting device. Using mismatched components can lead to dangerous situations.

- Proper Attachment: Always securely attach the load before lifting. Use appropriate methods to ensure that the load remains stable during the lift.

- Load Balance: Make sure the load is evenly balanced to prevent tipping or swinging during movement.

By following these guidelines, operators can significantly reduce the risk of accidents and enhance overall safety during lifting operations.

Assessing Hoist Frame Durability

Evaluating the resilience of lifting structures is crucial for ensuring operational safety and longevity. A thorough examination of the framework can prevent potential failures and enhance overall performance. Understanding the factors that contribute to structural integrity allows for informed maintenance and operational decisions.

Key aspects to consider when assessing structural durability include:

- Material Quality: The type of materials used in construction significantly influences strength and lifespan.

- Design Features: Specific design elements can enhance stability and load-bearing capacity.

- Environmental Factors: Conditions such as humidity, temperature fluctuations, and exposure to chemicals may affect durability.

Regular inspection and maintenance routines are essential to uphold the integrity of lifting frameworks. Consider implementing the following practices:

- Conduct visual inspections for signs of wear, corrosion, or deformation.

- Utilize non-destructive testing methods to evaluate internal conditions.

- Maintain a detailed log of inspections and repairs to track performance over time.

By prioritizing the assessment of structural durability, operators can enhance safety measures and optimize the lifespan of lifting equipment.

Choosing the Right Hoist for Heavy Engines

Selecting the appropriate lifting device for substantial machinery requires careful consideration. Various factors influence the decision-making process, ensuring that the chosen apparatus can handle the task efficiently and safely.

When determining the best option, consider the following aspects:

- Weight Capacity: Assess the total weight of the machinery to ensure the selected model can support it without strain.

- Height Requirements: Evaluate the lifting height needed to access the desired areas effectively.

- Material and Build Quality: Choose a device made from durable materials to withstand frequent use and heavy loads.

- Mobility: Consider whether a stationary or portable option best suits your workspace, allowing for flexibility in operations.

- Ease of Use: Look for features that simplify the lifting process, such as ergonomic handles or user-friendly controls.

By analyzing these criteria, you can ensure that your lifting equipment will meet your needs and enhance your productivity while prioritizing safety and efficiency.