In the realm of small machinery, a comprehensive grasp of the various elements that comprise these powerful systems is essential. Each component plays a vital role in the overall functionality, and recognizing how they interact can significantly enhance maintenance and repair efforts. Knowledge of these intricate systems empowers users to troubleshoot effectively and optimize performance.

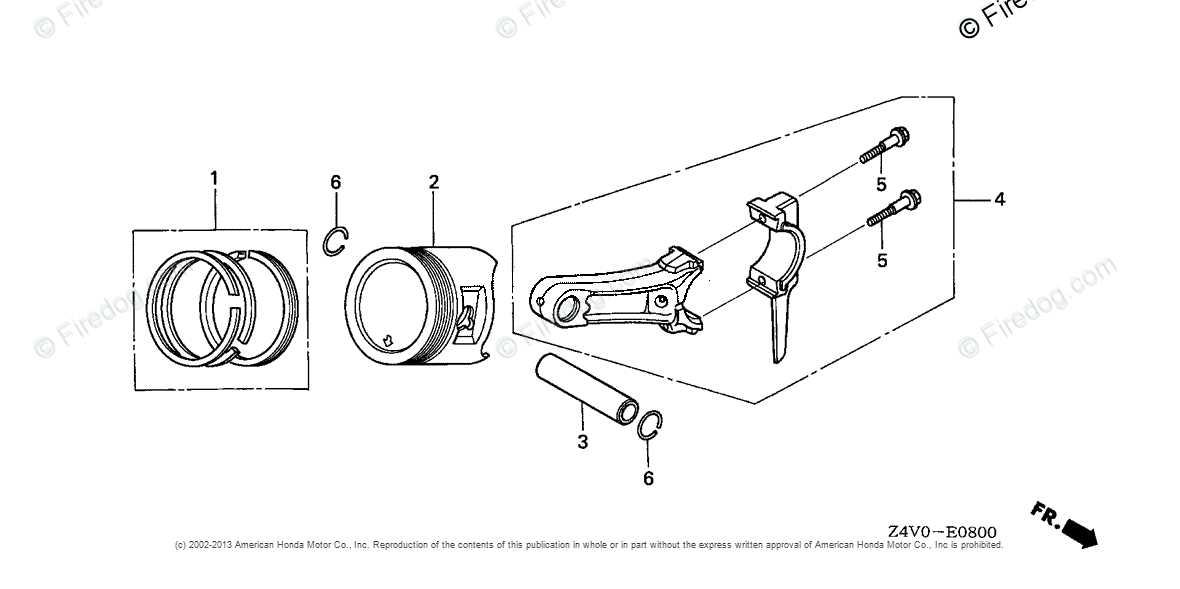

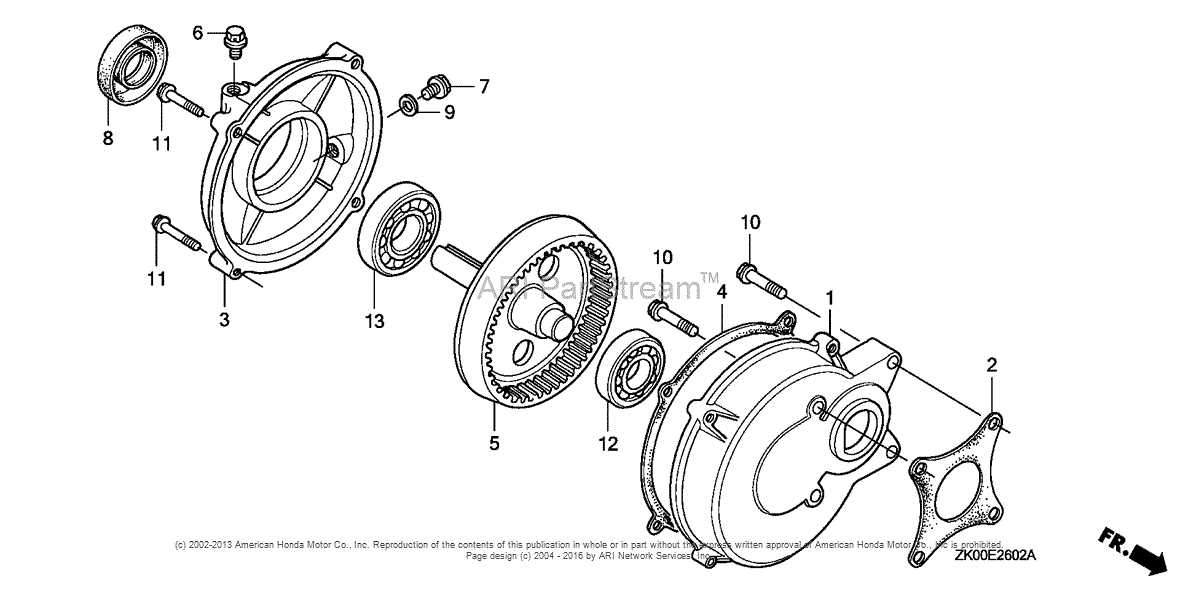

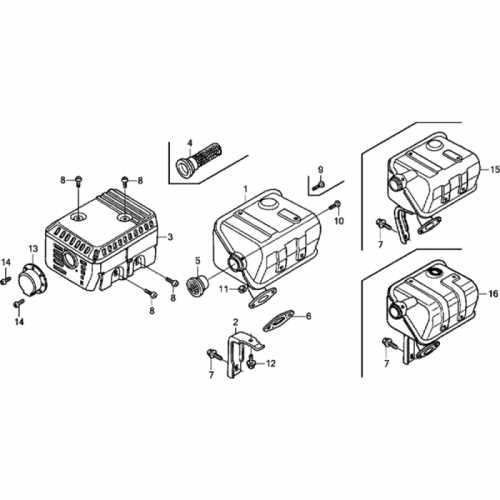

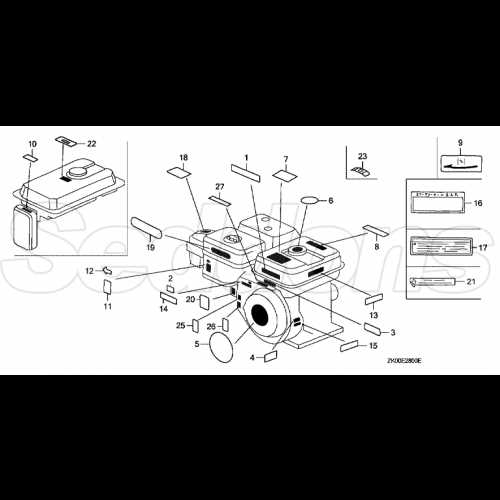

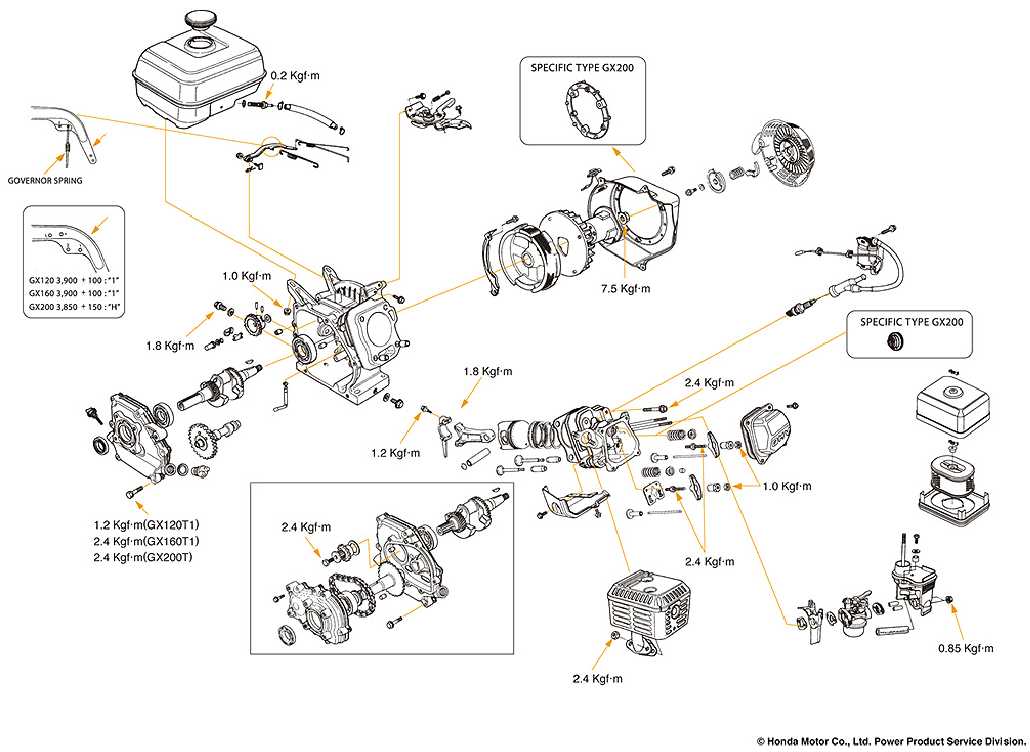

Visual representations of these mechanisms serve as invaluable resources, allowing enthusiasts and professionals alike to familiarize themselves with the structure and organization of crucial parts. By delving into detailed illustrations, one can identify each element’s specific function and position within the assembly. This understanding is not only beneficial for repairs but also aids in the selection of compatible replacements when necessary.

As you explore this topic, you will uncover the intricacies involved in the design and assembly of these compact power units. Gaining insight into the layout of these systems not only enhances your technical expertise but also fosters a deeper appreciation for the engineering behind everyday machinery. Whether you are a seasoned technician or a curious hobbyist, this knowledge is foundational to your success in maintaining and enhancing the performance of your equipment.

Understanding the Honda GX200 Engine

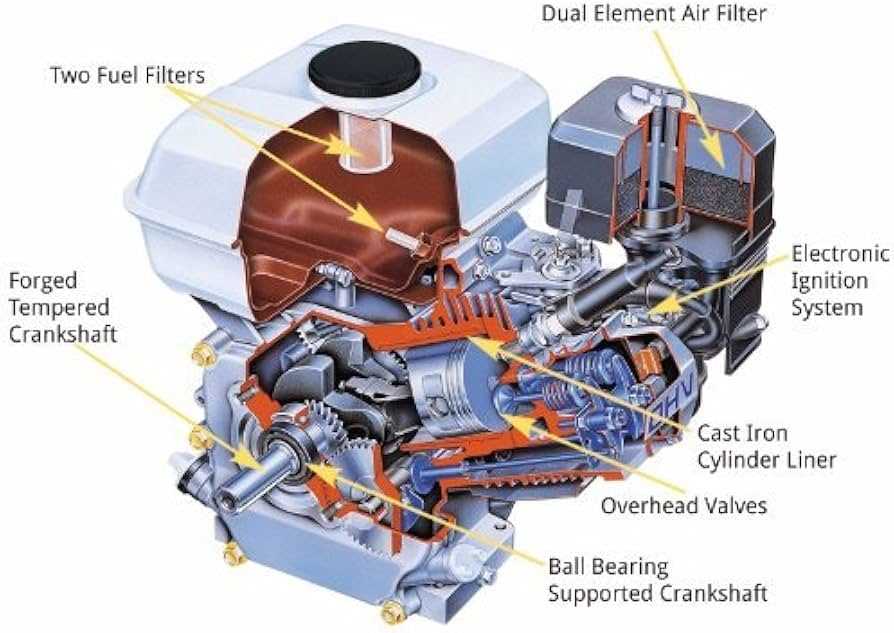

This section explores the intricacies of a popular power unit widely used in various applications. It highlights the design, functionality, and components that contribute to its reliability and efficiency. By examining these elements, users can gain a deeper insight into the machine’s performance and maintenance requirements.

| Component | Description |

|---|---|

| Cylinder | The chamber where combustion occurs, providing power to the system. |

| Piston | A moving part that transfers energy from combustion to mechanical movement. |

| Crankshaft | Converts linear motion of the piston into rotational motion. |

| Carburetor | Mixes fuel and air for optimal combustion. |

| Ignition System | Responsible for initiating the combustion process. |

Key Features of GX200 Engine

This section highlights the essential characteristics of a widely used power unit, known for its reliability and efficiency. It combines advanced technology with robust construction, making it suitable for various applications.

One significant aspect is its remarkable fuel efficiency, allowing extended operation without frequent refueling. Additionally, the compact design ensures easy installation and integration into different machinery.

Durability is another hallmark, as the unit is built to withstand harsh conditions, thereby reducing maintenance needs. Furthermore, the straightforward design facilitates effortless repairs and part replacements.

Finally, the versatility of this power source is noteworthy, as it can be utilized in a range of equipment, from generators to pressure washers, catering to diverse user requirements.

Importance of Engine Parts Diagrams

Understanding the layout and function of various components in a machine is essential for maintenance and repair. Visual representations provide clarity, enabling users to identify and troubleshoot issues effectively. These illustrations serve as valuable resources for both novices and experienced technicians alike.

Benefits of Visual Representations

- Enhanced Understanding: Visual aids simplify complex mechanisms, making it easier to grasp how different elements interact.

- Efficient Troubleshooting: Quick identification of faulty components allows for faster repairs, reducing downtime.

- Accurate Reassembly: Following a visual guide ensures that all pieces are correctly positioned during reassembly, preventing future malfunctions.

Applications in Maintenance

- Servicing machinery: Knowing where each element fits aids in performing routine maintenance.

- Replacement planning: Helps in ordering the correct components for replacements.

- Training and education: New users can learn more effectively with visual guides at their disposal.

In conclusion, visual representations are indispensable tools that facilitate better comprehension, efficient repairs, and effective learning, ensuring the longevity and performance of machines.

Overview of Common GX200 Components

Understanding the key elements of small power units can greatly enhance maintenance and repair efforts. Each component plays a crucial role in ensuring optimal performance, reliability, and longevity. Familiarity with these vital parts allows for more informed decisions during servicing.

Fuel System: This includes the tank, carburetor, and fuel lines, which work together to deliver the necessary mixture for combustion.

Ignition System: Comprising the spark plug and ignition coil, this system is responsible for creating the spark that initiates the fuel combustion process.

Cooling Mechanism: Typically featuring a flywheel and cooling fins, this component ensures the unit operates within safe temperature limits, preventing overheating.

Lubrication System: Essential for reducing friction, this system includes oil passages and a pump that circulates lubricant throughout the machinery.

Mechanical Assembly: The crankshaft, piston, and connecting rod form the heart of the unit, converting fuel energy into mechanical power efficiently.

By delving into each of these components, users can achieve a deeper understanding of functionality and enhance the overall operation of their machinery.

How to Read Engine Diagrams

Understanding technical illustrations is essential for anyone involved in machinery maintenance or repair. These visuals serve as a guide to the various components and their interconnections, helping users to troubleshoot issues effectively. Familiarity with these representations can streamline the repair process and enhance overall comprehension of the system.

Identifying Components

Each element within the illustration is typically labeled with specific identifiers. Familiarize yourself with these labels to understand what each part is. Pay attention to the symbols and color coding, as they often indicate functionality or significance. This knowledge will enable you to pinpoint areas that require attention.

Interpreting Relationships

Beyond identifying individual components, it’s crucial to comprehend how they interact with one another. Look for lines or arrows that denote connections, indicating how energy or fluids flow through the system. Understanding these relationships can aid in diagnosing problems and ensuring that repairs are made in the correct order.

Maintenance Tips for GX200 Parts

Regular upkeep is essential for ensuring the longevity and optimal performance of your machinery. By implementing systematic care practices, you can prevent common issues and maintain efficiency. This section outlines effective strategies for maintaining various components of your unit.

| Component | Maintenance Tip |

|---|---|

| Air Filter | Clean or replace the filter regularly to prevent dirt and debris from obstructing airflow. |

| Spark Plug | Inspect and replace the spark plug as needed to ensure reliable ignition and smooth operation. |

| Fuel System | Use fresh fuel and check for leaks. Clean the fuel filter periodically to maintain fuel flow. |

| Oil | Change the oil regularly to keep the lubrication system effective and prevent wear. |

| Cooling System | Ensure the cooling fins are clean and free of debris to prevent overheating. |

Following these guidelines can significantly enhance the reliability and efficiency of your equipment. Regular attention to these elements will not only extend their lifespan but also improve overall functionality.

Identifying Replacement Parts for GX200

When it comes to maintaining small power units, recognizing the components that may need to be substituted is crucial for optimal performance. Understanding the structure and function of each individual element allows for timely replacements, ensuring longevity and efficiency. This guide aims to simplify the process of identifying essential components that may require attention.

Start by consulting the specific model documentation, which typically includes comprehensive information about each element’s role. Additionally, visual aids can be invaluable; they provide a clear representation of where each component is situated within the unit. Familiarizing yourself with the terminology and classifications used in manuals can significantly enhance your understanding.

When searching for substitutes, consider factors such as compatibility, quality, and reliability. It is advisable to source components from reputable suppliers who offer detailed descriptions and specifications. This ensures that the replacements meet the necessary standards for performance and safety.

Regular inspections are beneficial in identifying wear and tear, allowing for preemptive measures before failures occur. Keeping a checklist of the most commonly replaced elements can also streamline the maintenance process, making it easier to track condition and order replacements as needed.

Tools Needed for Engine Repairs

Effective maintenance and restoration of mechanical systems require specific instruments to ensure precision and efficiency. These essential tools not only facilitate the disassembly and reassembly of components but also aid in diagnosing issues accurately. A well-equipped workshop is crucial for anyone looking to tackle repairs successfully.

Start with basic hand tools such as wrenches, screwdrivers, and pliers, which are vital for loosening and tightening various fasteners. Additionally, a socket set can provide the leverage needed for stubborn bolts. For more intricate tasks, specialty tools like torque wrenches and feeler gauges allow for precise adjustments and measurements.

Safety equipment is equally important; goggles and gloves protect against potential hazards during repairs. Investing in a quality workbench and proper lighting also enhances the working environment, making the repair process smoother and more efficient.

Common Issues with GX200 Engines

When it comes to small power units, various challenges can arise, impacting performance and reliability. Understanding these frequent problems can help users diagnose issues effectively and ensure optimal functioning.

Frequent Performance Problems

One of the most common challenges faced is difficulty in starting. This can be attributed to fuel-related issues, such as contamination or incorrect mixture ratios. Additionally, irregular operation may occur due to clogged air filters or faulty spark plugs, leading to inefficient combustion.

Maintenance and Wear Issues

Over time, components may wear down, leading to reduced efficiency and potential failure. Regular maintenance is crucial to address issues such as oil leakage or overheating, which can severely affect performance and longevity.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Difficulty Starting | Unit fails to start or starts intermittently | Check fuel quality, clean filters |

| Inefficient Operation | Stalling or irregular running | Inspect spark plug, clean carburetor |

| Oil Leakage | Visible oil spots, low oil level | Replace gaskets, tighten seals |

| Overheating | Unit runs hot, performance drops | Check cooling fins, replace faulty components |

Where to Find OEM Parts Online

Locating authentic components for your machinery can be a straightforward task if you know where to look. The internet offers a variety of platforms that specialize in providing original equipment items, ensuring quality and compatibility for your needs.

Popular Online Retailers

- Amazon – A wide selection with user reviews.

- eBay – New and used options from various sellers.

- Official manufacturer websites – Direct source for genuine components.

Specialty Websites

- PartsTree – Focused on outdoor equipment.

- Repair Clinic – Helpful resources for troubleshooting.

- eReplacementParts – Extensive catalog of original items.

Utilizing these resources can significantly enhance your chances of finding the ideal components you require, maintaining the integrity and performance of your machinery.