Water flow systems in homes have evolved significantly over the years, and the intricate design of their mechanisms plays a crucial role in ensuring a smooth and efficient operation. By familiarizing yourself with the key elements of these systems, you can better understand how they work and maintain them effectively when needed.

In this article, we will explore the inner workings of common fixtures used in household water systems. We will highlight how different elements contribute to functionality and address common concerns regarding upkeep and repairs. Whether you’re troubleshooting or simply curious, gaining insight into the various components will empower you to make informed decisions.

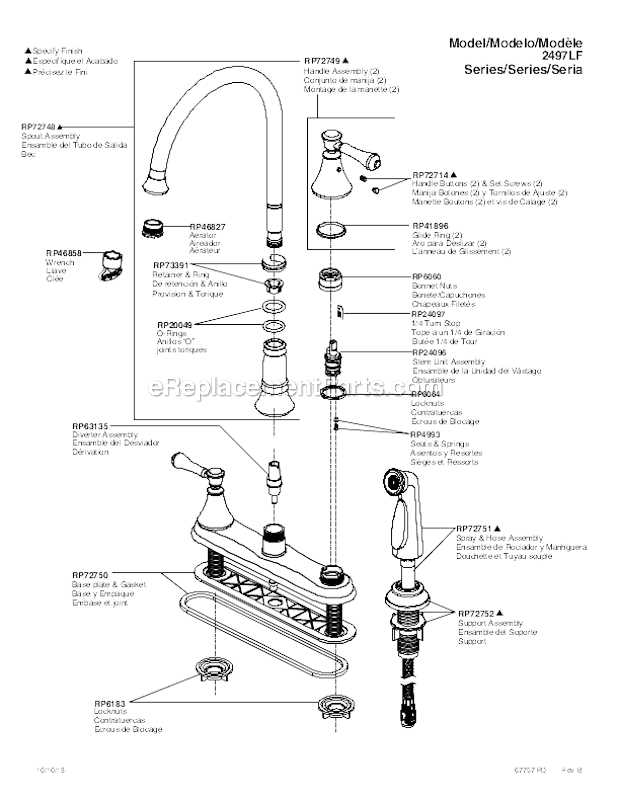

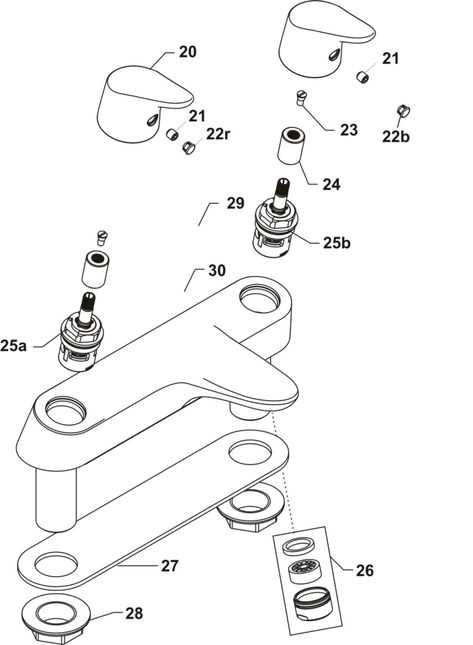

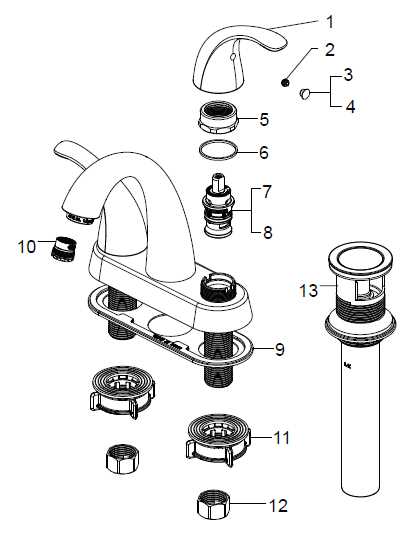

Delta Bathroom Sink Faucet Parts Diagram

Understanding the assembly of a common household fixture involves recognizing the various components that work together to control water flow and temperature. Each piece serves a specific role, ensuring proper functionality and longevity of the system.

- Handles – These allow the adjustment of water flow and temperature by turning or lifting them.

- Spout – Directs the flow of water into the basin.

- Cartridge – The internal mechanism that mixes hot and cold water and controls the output pressure.

- Valve Body – Connects to the water supply and directs the flow based on handle movement.

- Escutcheon – The decorative plate that covers the holes in the countertop or sink surface.

- O-rings and Seals – Prevent leaks and ensure a tight connection between components.

- Aerator – Fitted at the tip of the spout

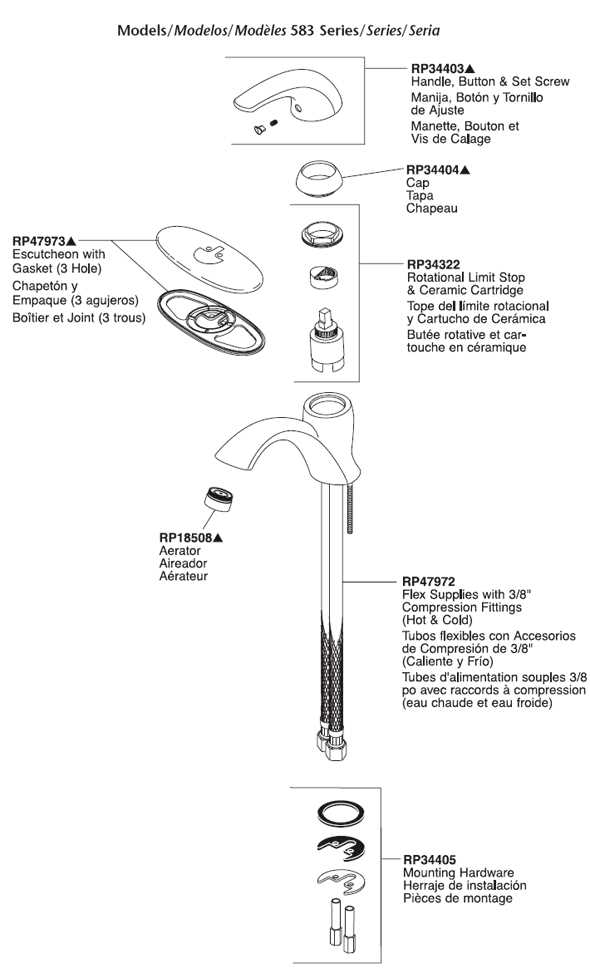

Understanding the Anatomy of Delta Faucets

To fully grasp how a typical water dispenser operates, it’s important to explore the internal structure and how each component contributes to its function. Knowing these elements will aid in both the installation and troubleshooting of the system.

Key Components of a Water Dispenser

These systems are composed of several integral pieces that work together to control water flow and temperature. Below are the most crucial elements you should be familiar with:

- Handle: The control mechanism that regulates water pressure and temperature by moving a valve.

- Spout: The outlet through which water is directed into the basin.

- Cartridge: A critical internal mechanism that mixes hot and cold water, allowing for temperature adjustment.

- Supply Lines: Pipes that deliver hot and cold water from the source to the system.

- Common Components Found in Delta Sink Faucets

The design of most fixtures used for water control relies on several key elements that ensure smooth operation and durability. These essential components are designed to regulate the flow of liquid, prevent leaks, and offer ease of use. Understanding the structure of these elements can help in maintenance or repair, ensuring long-lasting performance.

Handle mechanisms are one of the primary elements, allowing users to adjust the temperature and volume of the flow. The internal cartridge plays a crucial role in this process, as it responds to the movements of the handle to control the mix of hot and cold streams.

Another vital part is the spout, which directs the flow into the desired location. Attached beneath the spout is often an aerator, a small device designed to mix air with water to create a smooth, non-splashing stream while also conserving water.

To ensure no leakage occurs, seals and g

How Delta Faucet Cartridges Work

The core mechanism behind these devices is designed to control the flow and temperature of water efficiently. Inside the system, the key component regulates the mixture of hot and cold streams, ensuring a balanced output. This allows for precise adjustments while maintaining a consistent water flow.

Cartridges are engineered with internal seals that manage water pressure and prevent leaks. They are crucial for smooth operation, as the system relies on these seals to block or open specific pathways. By moving the handle, the user adjusts the position of the internal elements, controlling how much hot or cold water is mixed.

The design also incorporates wear-resistant materials, which help the internal components maintain performance over time. This ensures a long-lasting, reliable experience, even with frequent usage. The simplicity of the internal structure allows for easy replacement when needed, further enhancing the durability of the system.

Exploring the Functions of Faucet Handles

Handles play a crucial role in controlling the flow of water and adjusting temperature. Their design and functionality directly affect user experience, providing ease and precision in daily use. Understanding how these components operate can help in selecting the right option for various settings.

- Flow Control: Handles regulate how much water is released, offering either a steady stream or a reduced flow depending on the user’s preference.

- Temperature Adjustment: By turning the handle in different directions, users can mix hot and cold water to achieve the desired temperature.

- Ergonomics: Handle designs are tailored for comfort and ease of use, ensuring smooth operation with minimal effort.

- Durability: Well-constructed handles are built to last, providing long-term reliability through daily operation.

The choice of handles can impact not only functionality but also the overall aesthetic of the fixture, blending form

Replacing O-Rings in Delta Faucets

O-rings play a crucial role in ensuring a leak-free operation of various plumbing fixtures. Over time, these rubber seals can wear out, leading to drips and leaks that not only waste water but can also damage surrounding surfaces. Replacing these seals is a straightforward process that can save both water and repair costs.

Here’s a simple guide to help you through the replacement procedure:

- Gather the Necessary Tools:

- Wrench

- Screwdriver

- Replacement O-rings

- Plumber’s grease

- Shut Off the Water Supply:

Locate the water shut-off valves and turn them off to prevent any leaks during the repair.

- Disassemble the Fixture:

Using the screwdriver and wrench, carefully remove the components to access the worn O-rings.

- Remove Old O-Rings:

Gently take out the old seals from their grooves. Take care not to scratch any surfaces while doing this.

- Install New O-Rings:

Apply a thin layer of plumber’s grease to the new seals before placing them into their respective grooves. This will ensure a smooth operation and extend the life of the seals.

- Reassemble the Fixture:

Carefully reattach all components, ensuring that everything is securely fastened.

- Turn the Water Supply Back On:

Once everything is back in place, turn the water supply on and check for leaks.

Regular maintenance of these rubber components is key to prolonging the life of your plumbing fixtures. By following these simple steps, you can effectively eliminate leaks and ensure optimal performance.

The Role of Aerators in Delta Faucets

Aerators play a crucial role in enhancing the performance and efficiency of various plumbing fixtures. These devices are designed to mix air with water, resulting in a smoother flow while conserving water. By integrating an aerator, homeowners can enjoy a more comfortable experience during daily tasks while also promoting sustainability.

Improving Water Efficiency

One of the primary benefits of incorporating an aerator is the significant reduction in water consumption. These devices limit the flow rate without sacrificing pressure, allowing users to perform tasks effectively while using less water. This not only helps in lowering utility bills but also contributes to environmental conservation by minimizing waste.

Enhancing User Experience

In addition to efficiency, aerators improve the overall user experience. By softening the water stream, they help prevent splashing and provide a more gentle feel. The incorporation of air creates a fuller stream, enhancing the sensation of volume and pressure without increasing the actual water usage. This combination of comfort and efficiency makes aerators an essential component in modern plumbing.

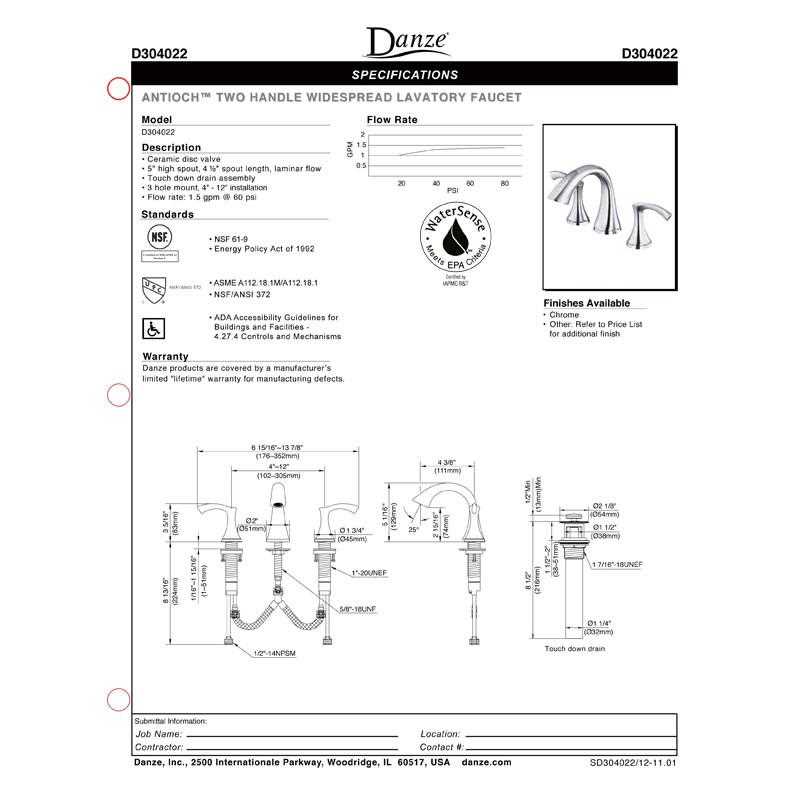

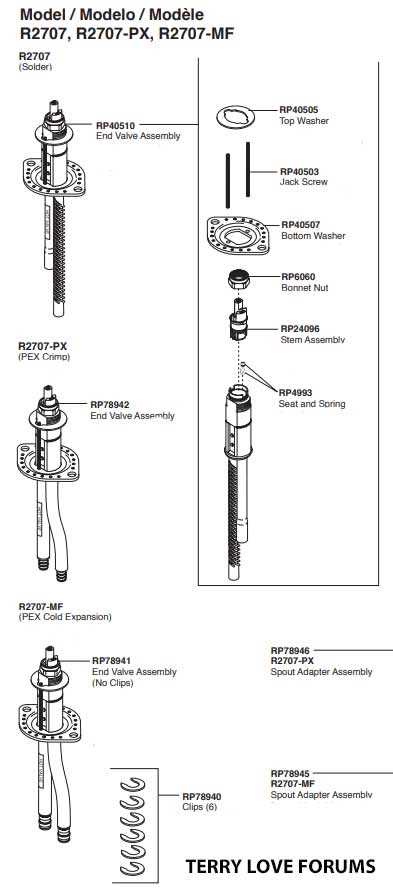

Identifying Washer Types in Delta Faucets

Understanding the various types of washers utilized in plumbing fixtures is essential for effective maintenance and repair. Washers play a crucial role in ensuring a tight seal, preventing leaks and ensuring smooth operation. Identifying the correct type can significantly enhance the longevity and efficiency of your fixture.

Different types of washers are designed for specific applications, each offering unique benefits. Here’s a breakdown of some common washer types and their characteristics:

Washer Type Material Application Rubber Washer Rubber Commonly used in compression fittings. Flat Washer Metal Used for providing a larger surface area to distribute load. O-Ring Rubber/Neoprene Ideal for creating airtight seals in cylindrical fittings. Composite Washer Various materials Used in high-pressure applications for enhanced durability. By recognizing these types, you can make informed decisions when replacing or repairing components. Ensuring you have the correct washer type is vital for optimal performance and longevity of the fixture.

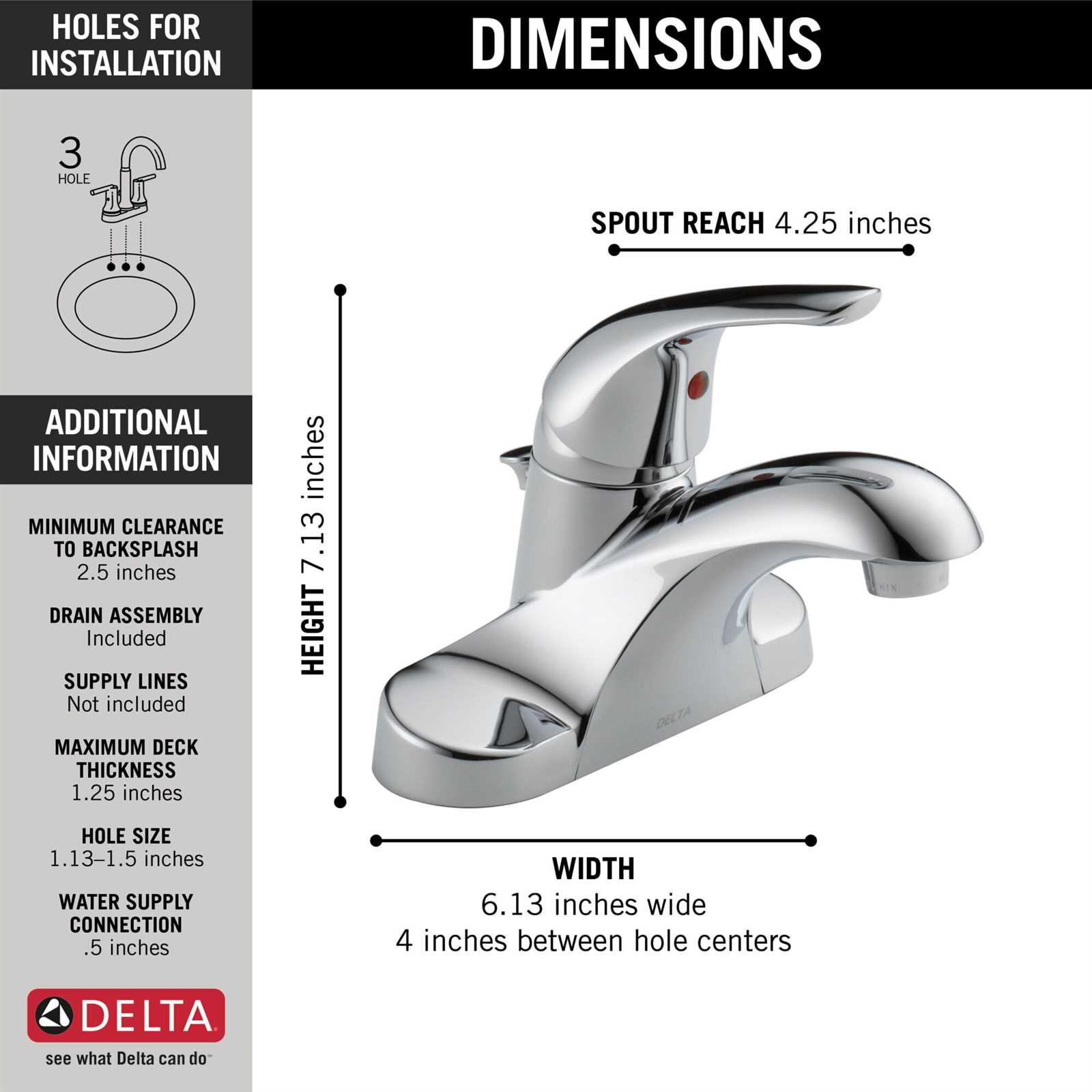

How to Replace Delta Faucet Valves

Replacing the internal components of a tap is essential for maintaining its functionality and preventing leaks. Over time, these components may wear out, leading to issues such as dripping or inconsistent water flow. This guide provides a step-by-step approach to efficiently replace the valves in your fixture, ensuring it operates smoothly.

Before you begin the replacement process, gather the necessary tools and materials:

Tools Materials Adjustable wrench Replacement valves Screwdriver Plumber’s grease Towel Sealing tape Start by turning off the water supply to the unit. This prevents any unexpected leaks during the replacement process. After shutting off the supply, open the tap to release any remaining water pressure.

Next, remove the handle by locating the screw that holds it in place. Use a screwdriver to unscrew it, then gently lift the handle off. This will expose the internal mechanisms.

Once the handle is removed, use the adjustable wrench to unscrew the retaining nut that secures the valve. Carefully take out the old valve, making note of how it is positioned for easy reinstallation of the new part.

Install the new valve by reversing the removal process. Ensure it is positioned correctly and securely fastened with the retaining nut. Apply plumber’s grease to the threads for a smooth operation.

After replacing the valve, reattach the handle and secure it with the screw. Finally, turn the water supply back on and check for any leaks. Test the operation of the fixture to ensure everything is functioning as expected.

Delta Sink Faucet Stem and Seat Explained

The stem and seat assembly is a crucial component in a water delivery mechanism, playing a significant role in regulating the flow and pressure of liquid. Understanding its functionality and structure can help in troubleshooting issues and ensuring optimal performance. This section delves into the intricacies of the stem and seat, highlighting their importance and how they interact with other components.

Functionality of the Stem

The stem acts as a control device within the system, allowing users to adjust the water flow as desired. When the handle is turned, the stem moves up or down, either opening or closing the passageway. This mechanism ensures precise control over the water supply, making it essential for any liquid dispensing setup.

Understanding the Seat

The seat serves as a sealing surface that works in conjunction with the stem. When the stem is in the closed position, it presses against the seat, creating a watertight seal that prevents leakage. Any wear or damage to this sealing surface can lead to leaks, making regular inspection important for maintenance.

Component Description Stem Controls the flow of liquid; moves to open or close the passage. Seat Sealing surface that prevents leakage when the stem is closed. Handle Allows user to operate the stem; directly linked to the stem’s movement. Mounting Assembl

The mounting assembly is a crucial component in securing a fixture to a surface, ensuring stability and proper function. This assembly typically consists of several elements that work together to facilitate a seamless installation process. Understanding these components is essential for effective setup and maintenance.

Component Description Mounting Bracket A metal or plastic support that anchors the fixture to the countertop. Mounting Screws Fasteners that hold the bracket in place, securing the fixture firmly. Rubber Washer Provides a watertight seal to prevent leaks between the fixture and the surface. Lock Nut A nut that secures the assembly in position, preventing movement after installation. Spacer A component that ensures proper alignment and distance between the fixture and the mounting surface. Each of these components plays a vital role in the overall performance of the assembly, contributing to the durability and functionality of the fixture. Proper installation and understanding of these elements can lead to an efficient and long-lasting setup.