When it comes to ensuring a smooth flow of water in various home settings, having a clear grasp of the essential elements that make up these devices is crucial. Knowing how each component works together helps in both maintenance and troubleshooting, ensuring that water runs efficiently and consistently without unexpected issues. Recognizing the significance of these individual elements will empower users to take better care of their systems.

Each mechanism is designed with specific features that contribute to the overall functionality. Whether it’s for controlling water pressure, regulating temperature, or managing the flow direction, each piece plays a vital role in the operation. This understanding can make it easier to address potential issues, ensuring longevity and optimal performance.

In this guide, we will take a closer look at the various elements that form the structure of such water systems, providing insights into how they are designed, assembled, and maintained. With a clearer view of how everything fits together, you will be better equipped to handle any challenges that may arise.

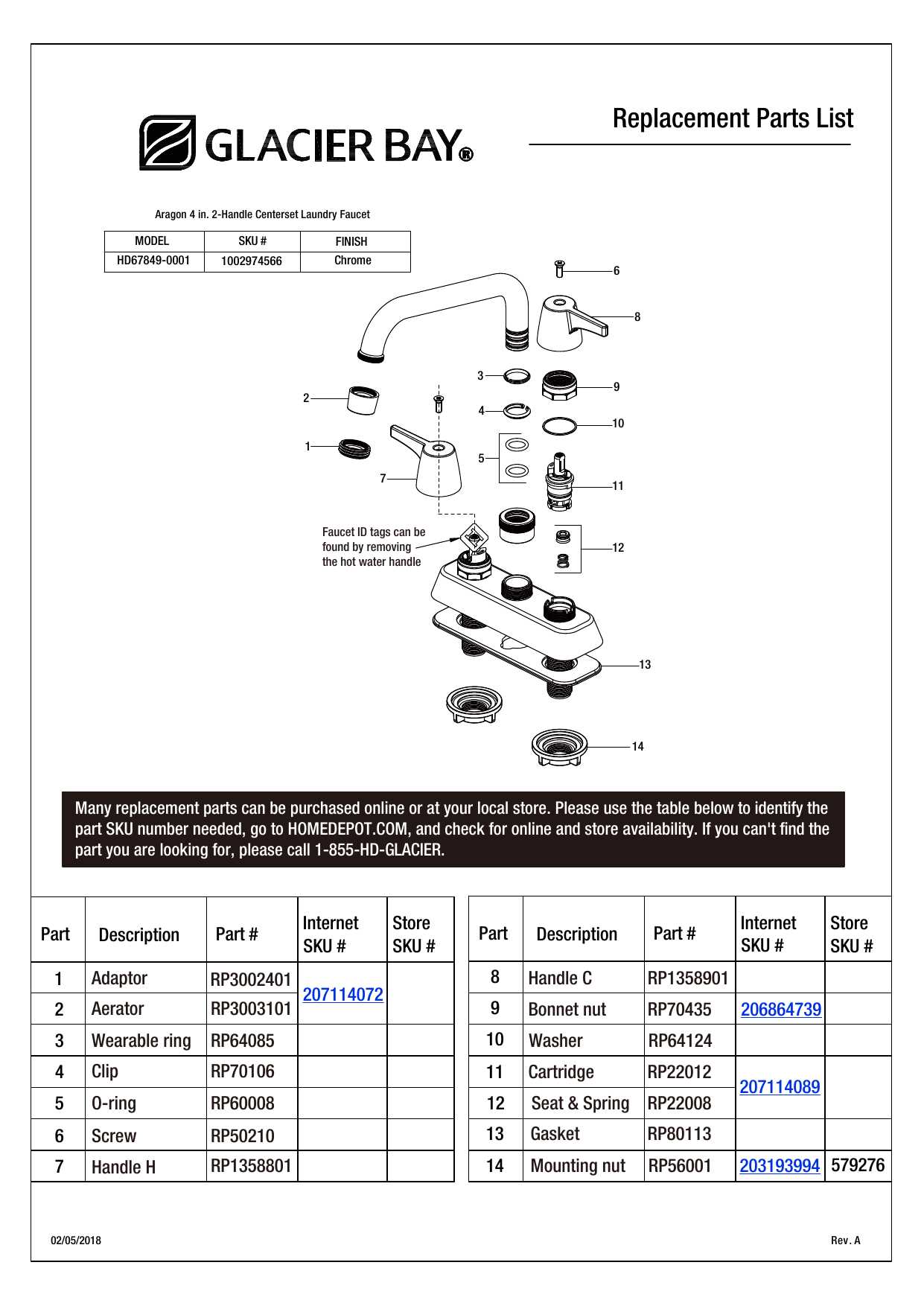

Understanding the Structure of Laundry Faucets

In modern water fixtures, each component plays a critical role in ensuring smooth and reliable operation. By gaining insights into their composition, it becomes easier to identify issues, perform repairs, and maintain long-lasting functionality.

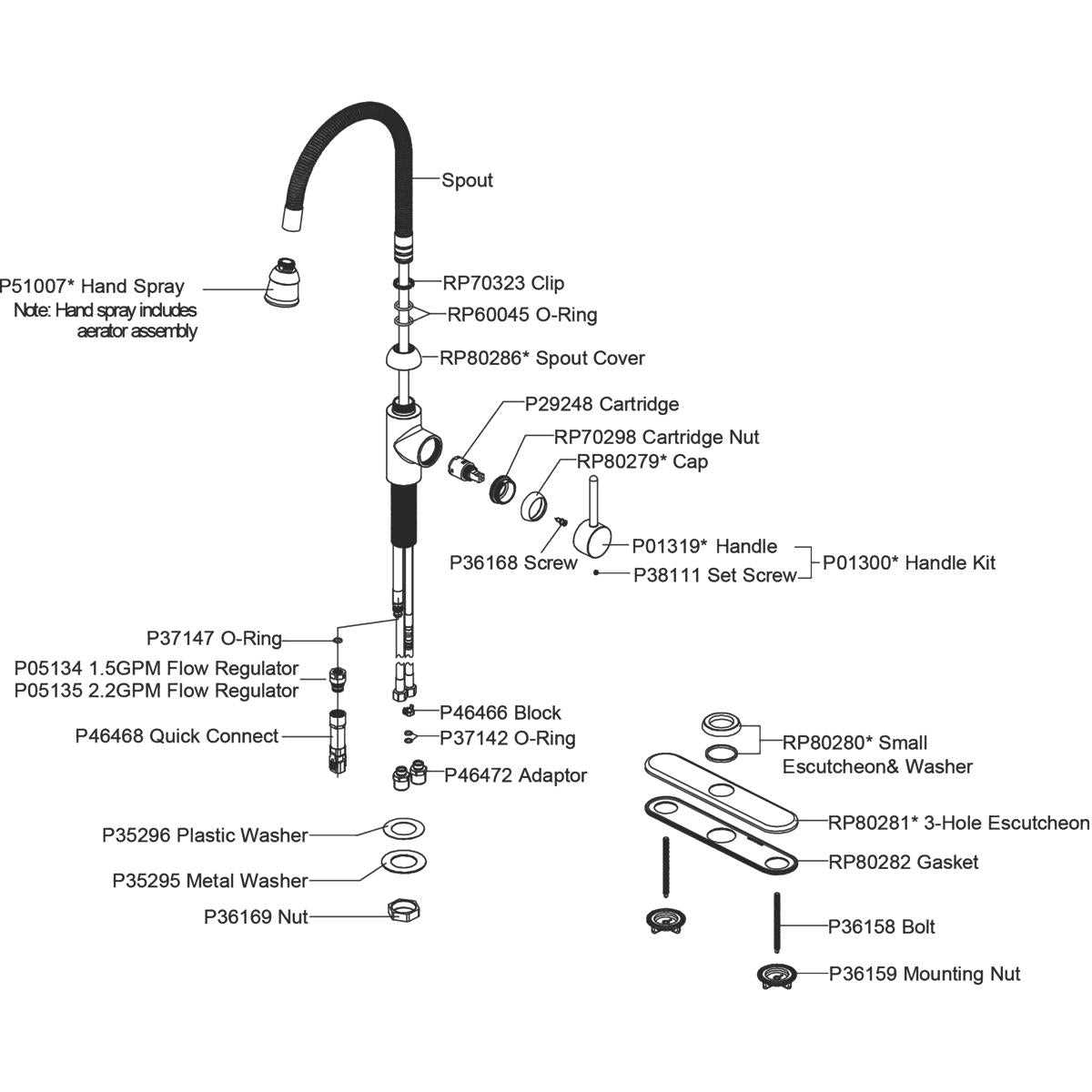

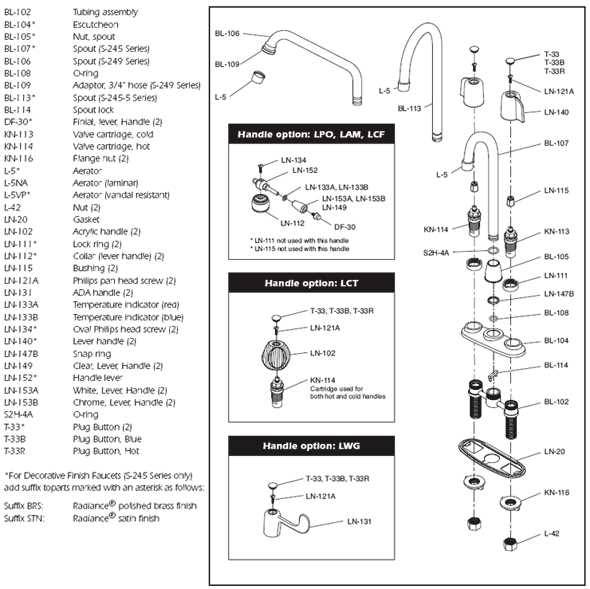

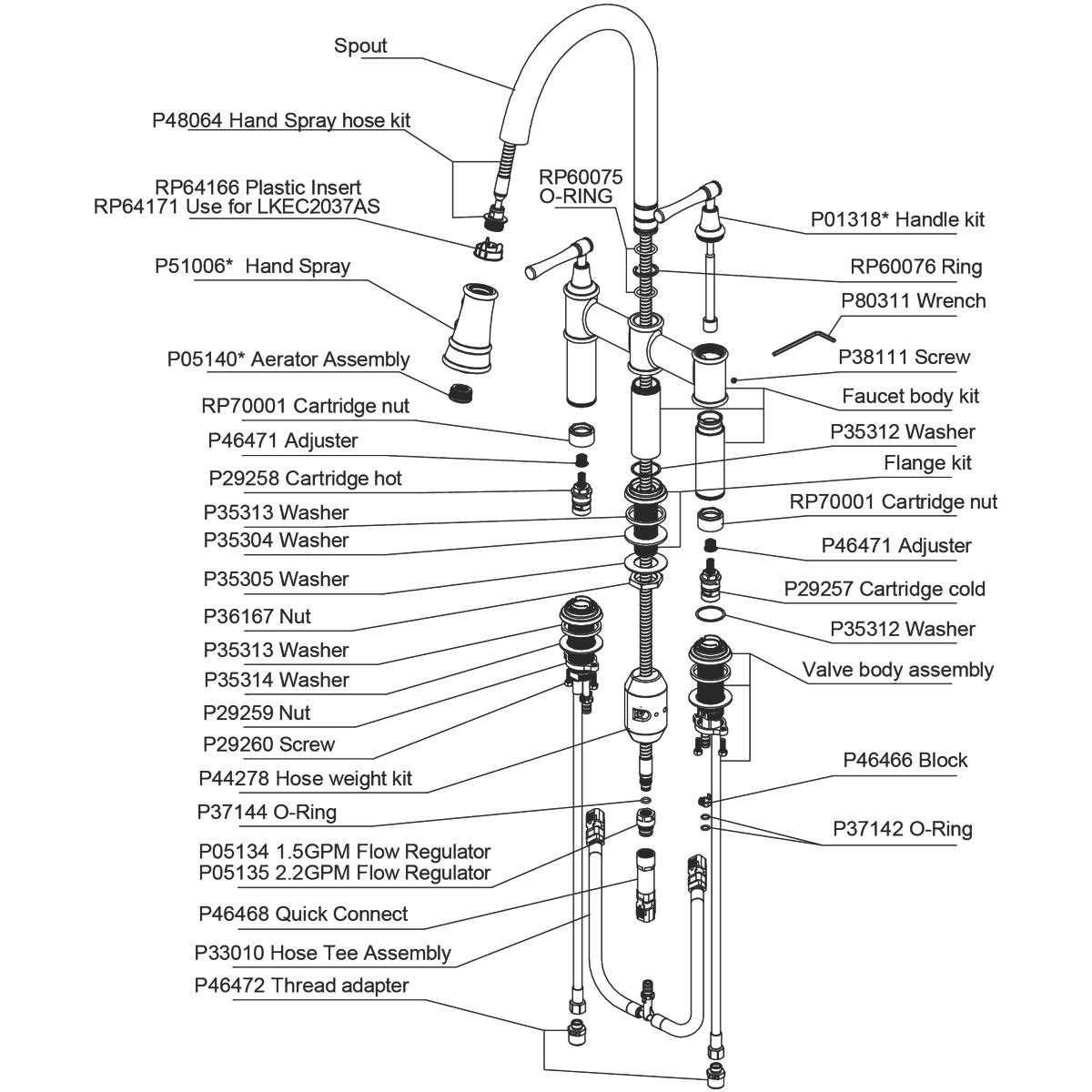

- Spout: The main channel responsible for delivering water to the desired location.

- Handles or Knobs: These are the control points that allow for adjusting the water flow and temperature.

- Cartridge: An internal mechanism that regulates water pressure and flow through the system.

- Valve: A critical section that manages the opening and closing of water channels to control supply.

- Seals and Gaskets: These small elements ensure that no water leaks occur, maintaining system efficiency.

Each element is carefully designed to work together, ensuring efficient operation and easy access for repairs or upgrades. Familiarizing oneself with these components makes it easier to troubleshoot any issues.

Key Components of a Laundry Faucet

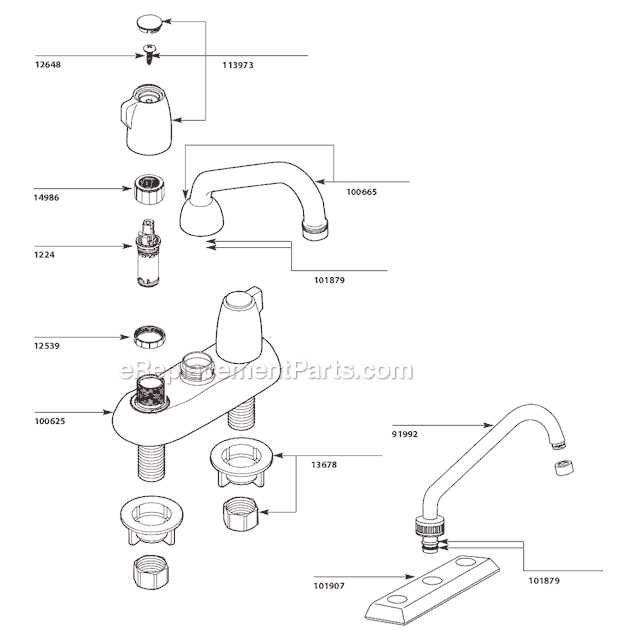

In this section, we will explore the primary elements that make up a typical water fixture used in utility areas. Understanding how each piece functions is crucial for both installation and maintenance. These essential elements ensure proper water flow, temperature control, and ease of use, contributing to the overall efficiency of the system.

Handles and Valves

The handles are responsible for controlling the flow of water. Connected to valves, they allow precise regulation of both cold and hot water. The valves inside ensure that water flow can be easily adjusted or shut off when necessary.

Spout and Aerator

The spout directs the water, providing a steady flow into the desired area. Attached to the spout is an aerator, a small device that mixes air with water to control the stream and minimize splashing. Together, they ensure smooth operation and water conservation.

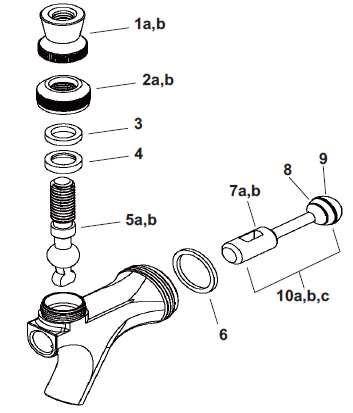

How to Identify Faucet Handle Parts

Understanding the key elements of handle mechanisms is essential for successful repairs and maintenance. By recognizing the individual components, it becomes easier to troubleshoot or replace the necessary elements when needed. These controls are often made up of several integral pieces, each contributing to the smooth operation and overall function.

Main Structural Elements

The central shaft is the core of the handle mechanism, ensuring stability and allowing proper movement. It is connected to the control mechanism, which regulates the flow. The external shell, or casing, provides grip and aesthetic value, making the operation easy and ergonomic.

Key Internal Components

Within the mechanism, the retaining nut secures the assembly in place, while a washer serves to prevent leaks and ensure a tight seal. Springs or tensioners are also common, providing the necessary force for smooth control adjustment. Recognizing these hidden parts is crucial for resolving common issues such as stiffness or irregular flow control.

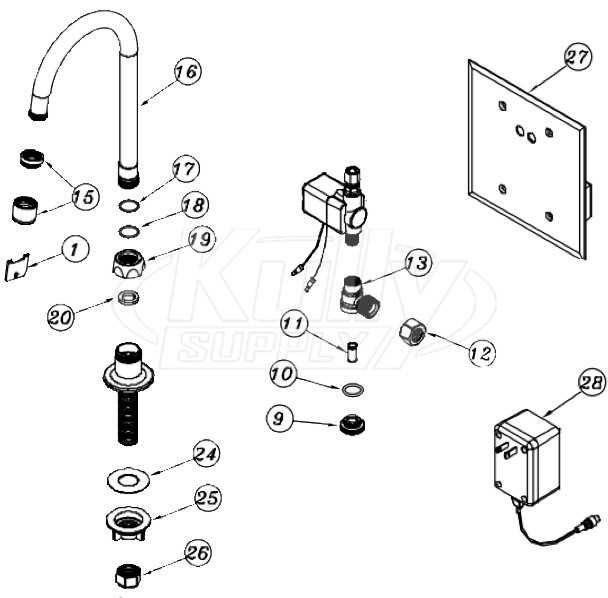

Exploring the Internal Mechanisms of Valves

Valves play a crucial role in controlling the flow of liquids or gases, ensuring that systems operate efficiently and without leaks. The internal structure of these devices is meticulously designed to regulate pressure, flow rate, and direction. Understanding the mechanisms inside helps in identifying how they achieve their functionality and what components contribute to their precise operation.

Main Components of a Valve

At the core of the mechanism are essential parts like the seat and stem. The seat acts as the surface where the valve closes, creating a tight seal to prevent unwanted flow. The stem, connected to the handle or actuator, controls the movement of the internal elements, determining whether the passage is open or closed. These parts work in harmony to control the flow with precision.

Seal Integrity and Material Choice

A critical aspect of valve function is the seal. Materials used for seals, such as rubber or metal, are carefully chosen based on the medium passing through the valve. The right material ensures that the seal

Washer and O-ring Placement Guide

Proper placement of washers and O-rings is crucial for ensuring a tight seal and preventing leaks. These small components play a significant role in maintaining effective water flow and preventing wear over time. Understanding where and how to install them can greatly extend the lifespan of your equipment and avoid common issues like dripping or inconsistent pressure.

Types of Washers and O-rings

Washers and O-rings come in various shapes and materials, each designed for specific uses. Rubber O-rings provide flexibility and are often used in areas requiring a tight seal, while metal or fiber washers are more rigid and durable for high-pressure zones. Choosing the right type for each location is essential for optimal performance.

Correct Placement Locations

Each washer and O-ring must be placed in the appropriate location to function correctly. Below is a table highlighting common placements and their recommended types:

| Component | Washer Type | O-ring Type |

|---|

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Leaking | Worn seals or cracks in the cartridge | Replace the cartridge or seals |

| Low Water Pressure | Debris buildup or faulty cartridge | Clean or replace the cartridge |

| Inconsistent Temperature | Malfunctioning temperature control | Inspect and replace the cartridge |

| Difficulty Turning | Corrosion or wear | Lubricate or replace the cartridge |

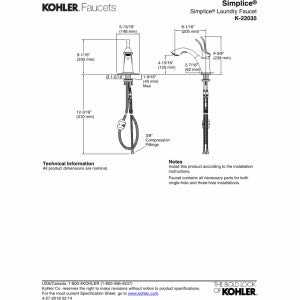

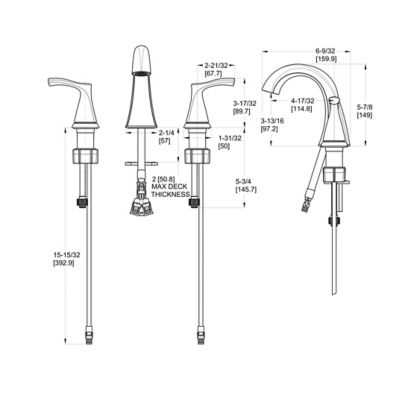

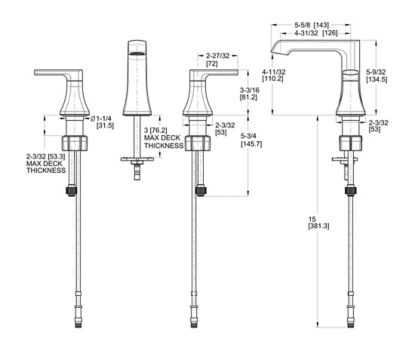

Spout Connection and Replacement Tips

Understanding the attachment and maintenance of the water outlet is essential for ensuring optimal performance and preventing leaks. This section provides guidance on how to effectively connect and replace this crucial component, enhancing both functionality and longevity.

Connection Process: When connecting the outlet, ensure that all fittings are clean and free from debris. Begin by aligning the spout with the designated connector, applying gentle pressure to secure a snug fit. It’s advisable to use thread seal tape on threaded connections to prevent water seepage.

Replacement Guidelines: If you find that the outlet is damaged or not functioning correctly, replacement may be necessary. Start by turning off the water supply to avoid any unwanted spills. Detach the old unit carefully, noting the arrangement of washers and seals. When installing the new spout, reverse the removal process, ensuring that all seals are properly positioned to prevent leaks.

Regular checks for wear and tear will help maintain the integrity of the connection. Taking proactive measures can save time and resources in the long run, ensuring a smooth and efficient operation.

Proper Installation of Laundry Faucet Aerators

Installing aerators correctly is essential for ensuring optimal water flow and reducing waste. Properly fitted aerators enhance efficiency by mixing air with water, creating a steady stream while conserving resources. This section will guide you through the steps needed to achieve a successful installation, ensuring your system operates smoothly.

Tools and Materials Needed

Before beginning, gather the necessary tools and materials. You will need a wrench, plumber’s tape, and the appropriate aerator for your specific setup. Having everything on hand will streamline the process and prevent interruptions.

Step-by-Step Installation Process

Begin by turning off the water supply to prevent any leaks during the installation. Carefully remove the existing aerator from the spout using a wrench, taking care not to damage the threads. Clean the area thoroughly to remove any debris or mineral buildup that could affect the new aerator’s performance. Wrap the threads with plumber’s tape to ensure a watertight seal. Finally, screw the new aerator onto the spout, tightening it securely with your hands. Turn the water supply back on and check for any leaks, ensuring a successful and efficient setup.

Hot and Cold Water Line Attachments

This section explores the connections responsible for directing heated and chilled water to your installation. Understanding these fittings is crucial for ensuring efficient operation and preventing leaks.

The attachments typically consist of two primary components: the hot water supply, often color-coded in red, and the cold water supply, usually marked in blue. Each connection must be securely fastened to maintain a reliable flow of water. Using the correct tools and materials when installing these lines can significantly impact the overall performance of your system.

Moreover, it is essential to consider the material compatibility between the piping and the fittings to avoid corrosion or other issues. Regular maintenance and inspections of these connections will help prolong the lifespan of your setup and ensure a consistent supply of water at the desired temperature.

Troubleshooting Leaks in Faucet Joints

Addressing issues with water seepage at connection points can be essential for maintaining an efficient plumbing system. Over time, wear and tear, combined with fluctuating temperatures, can lead to various problems that require attention. Identifying the source of the moisture is the first step towards an effective resolution.

Inspecting the Connections: Begin by examining the junctions for visible signs of dampness. Tightening any loose fittings may help eliminate minor leaks. Use an adjustable wrench to ensure a snug fit, but take care not to overtighten, as this can damage the threads.

Checking for Damaged Washers: Often, rubber washers can degrade over time. If moisture persists after tightening connections, consider disassembling the joints to inspect the washers. Replacing worn or damaged washers can significantly reduce or eliminate leaks.

Evaluating the Seals: Inspect the seals around the connections for any cracks or deterioration. If the seals are compromised, replacing them will help create a watertight barrier, preventing further issues.

Testing for Water Pressure: High water pressure can exacerbate leaks. Using a pressure gauge can help determine if adjustments are necessary. If the pressure is too high, a pressure-reducing valve may be required to maintain a balanced system.

By systematically examining these aspects, one can effectively troubleshoot and resolve leakage issues, ensuring a more reliable and efficient plumbing installation.

Maintaining and Replacing Laundry Faucet Seals

Proper upkeep and timely replacement of seals are essential for ensuring a smooth and leak-free operation of your water dispensing unit. Over time, these components can wear out due to constant exposure to water and pressure. This section provides insights on how to effectively maintain and replace these crucial elements, prolonging the lifespan of your fixture.

Routine Maintenance Tips

- Regularly inspect for signs of wear or damage.

- Clean around the sealing areas to prevent debris buildup.

- Check for leaks periodically to address any issues early.

- Ensure that connections are tightened properly to prevent movement.

Steps for Replacement

- Turn off the water supply to avoid any spills.

- Remove the handle and any decorative covers to access the internal components.

- Carefully detach the old seal, taking note of its placement.

- Install the new seal, ensuring it fits snugly in the designated area.

- Reassemble the unit, replacing any covers and handles.

- Turn the water supply back on and check for proper operation and any leaks.