The inner workings of a water dispensing device can seem intricate, yet with the right overview, it becomes easy to grasp. Whether you’re curious about the mechanical aspects or simply want to familiarize yourself with how everything fits together, gaining insight into these elements will help you appreciate how water is delivered smoothly and efficiently.

In this guide, we’ll explore the key elements that ensure proper functionality and flow. Each piece plays a vital role in managing water distribution and ensuring both durability and ease of use. By breaking down these sections, you’ll be able to better understand their purpose and how they contribute to overall operation.

Let’s dive into the details and uncover how various components work in harmony to maintain steady and controlled water output.

Understanding a Bathroom Sink Faucet Diagram

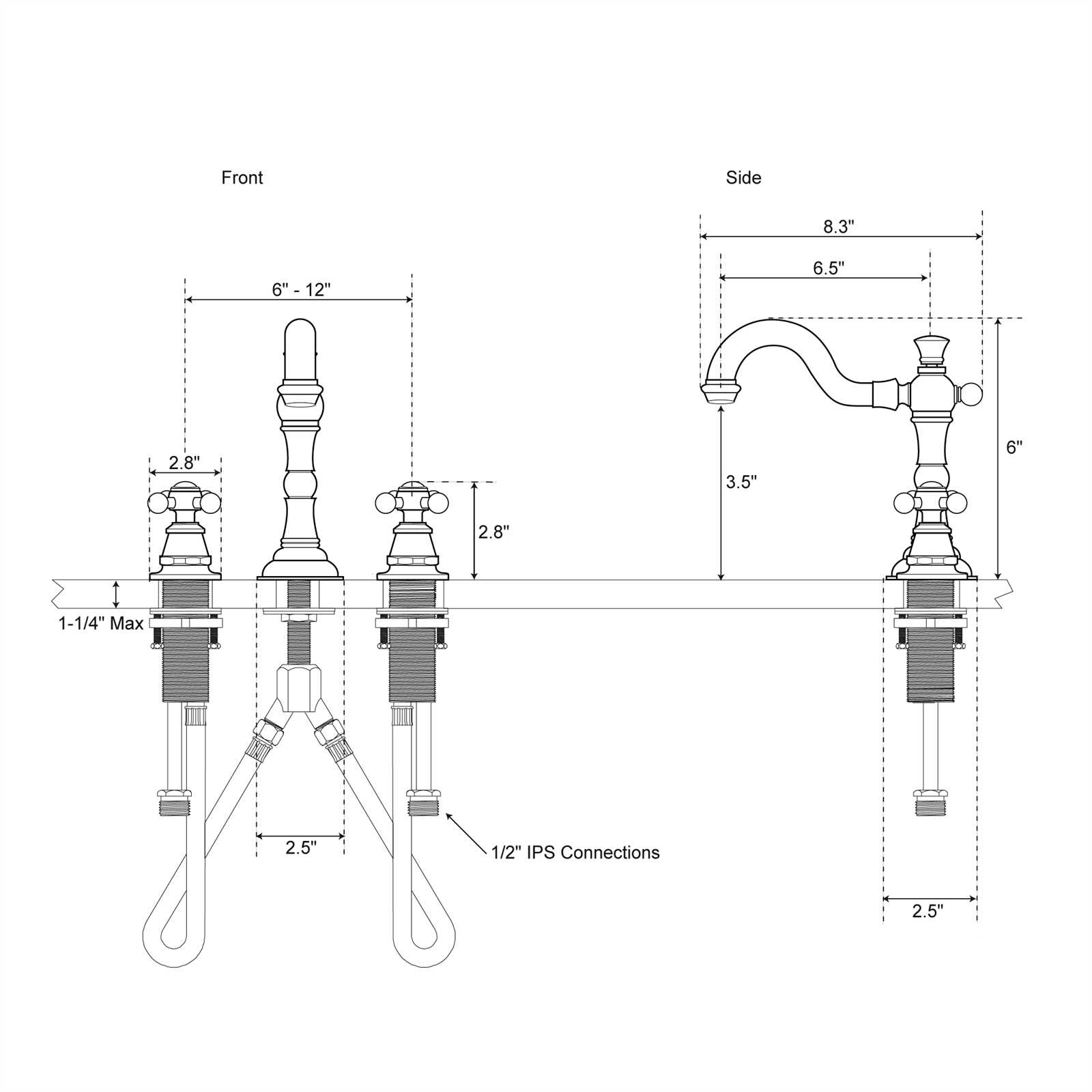

When it comes to the mechanics of water flow and control in your home, the structure under the tap is more intricate than it seems at first glance. It’s essential to get familiar with the key mechanisms and how they operate together to ensure a smooth flow of water and proper function.

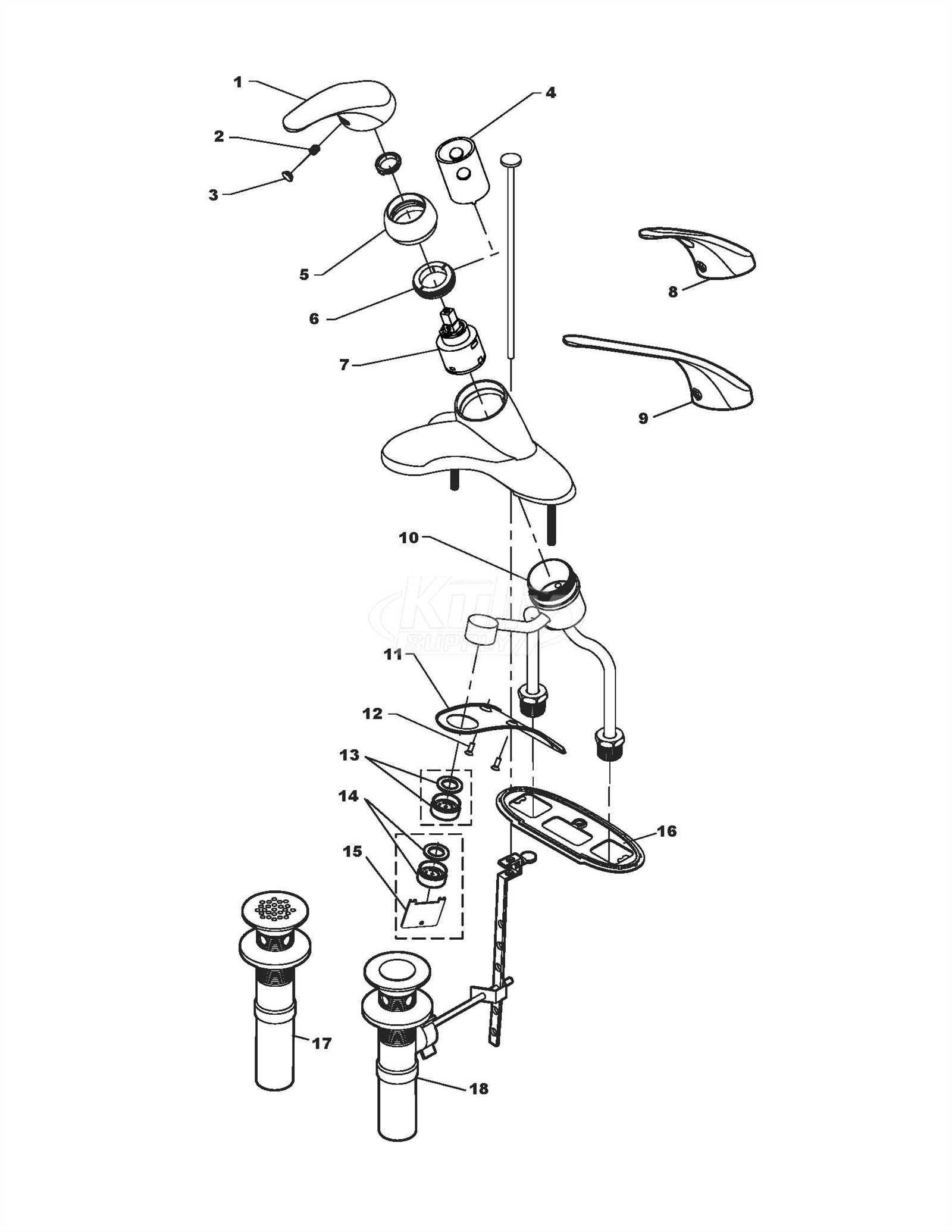

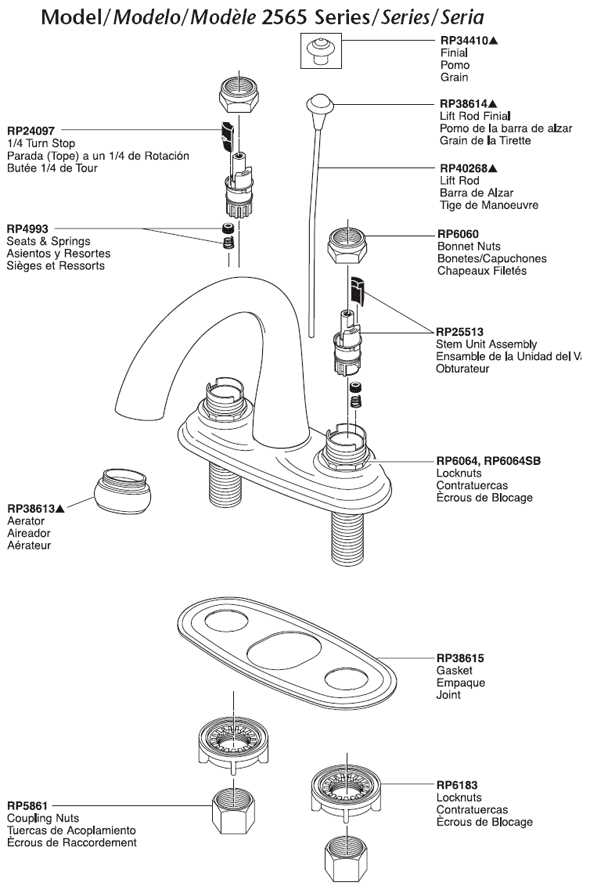

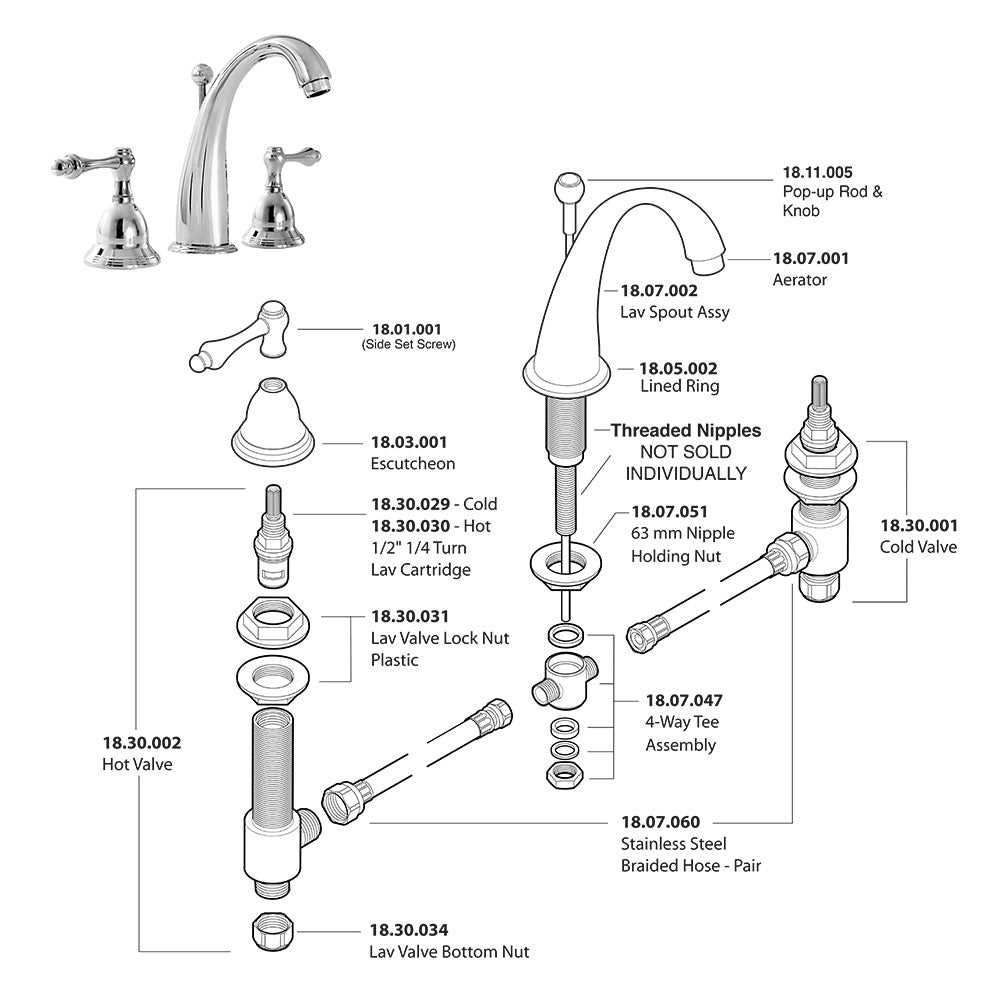

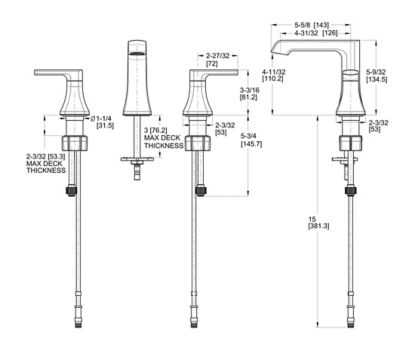

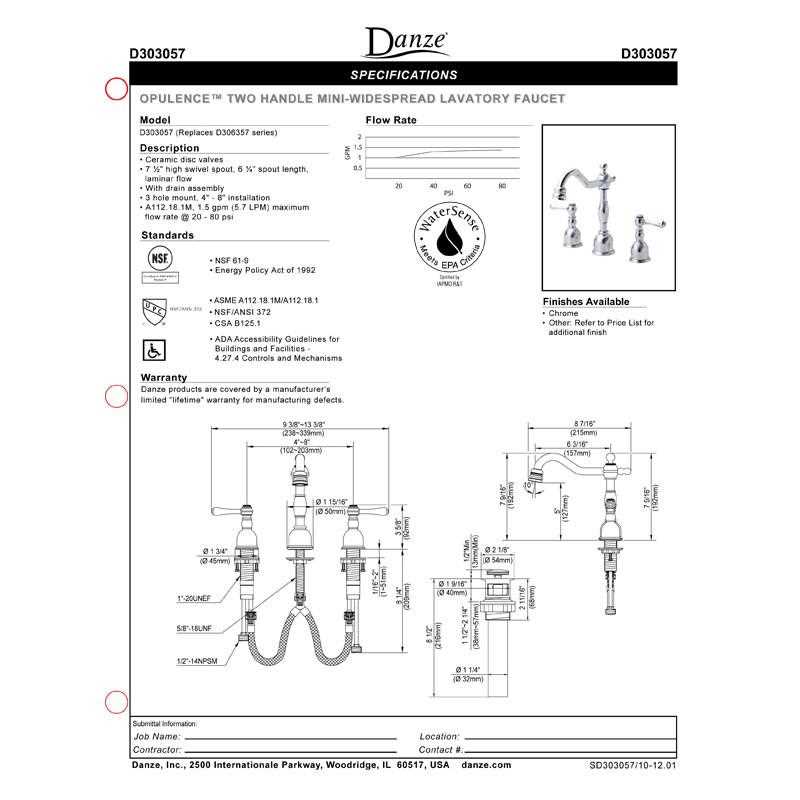

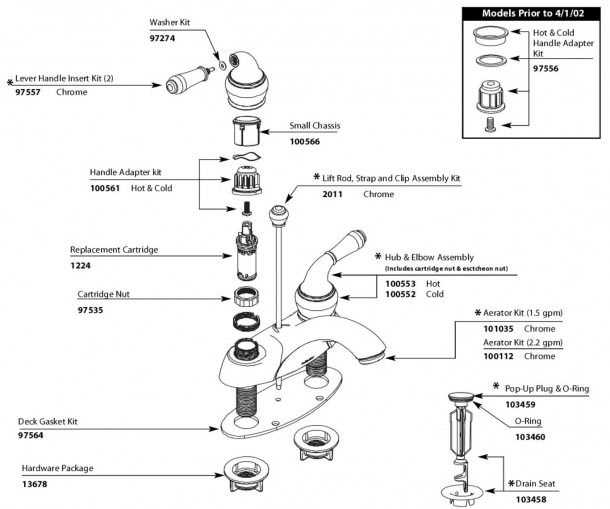

The main elements in the water dispensing mechanism include several interconnected parts that work to regulate water pressure, temperature, and direction. These components are strategically placed and designed to ensure both functionality and efficiency. Below is a simplified breakdown of the key components that help with water management:

| Component | Function | ||

|---|---|---|---|

| Control Handle | Used to adjust the flow and temperature of the water. | ||

| Water Supply Lines | These channels deliver both hot and cold water to the tap. |

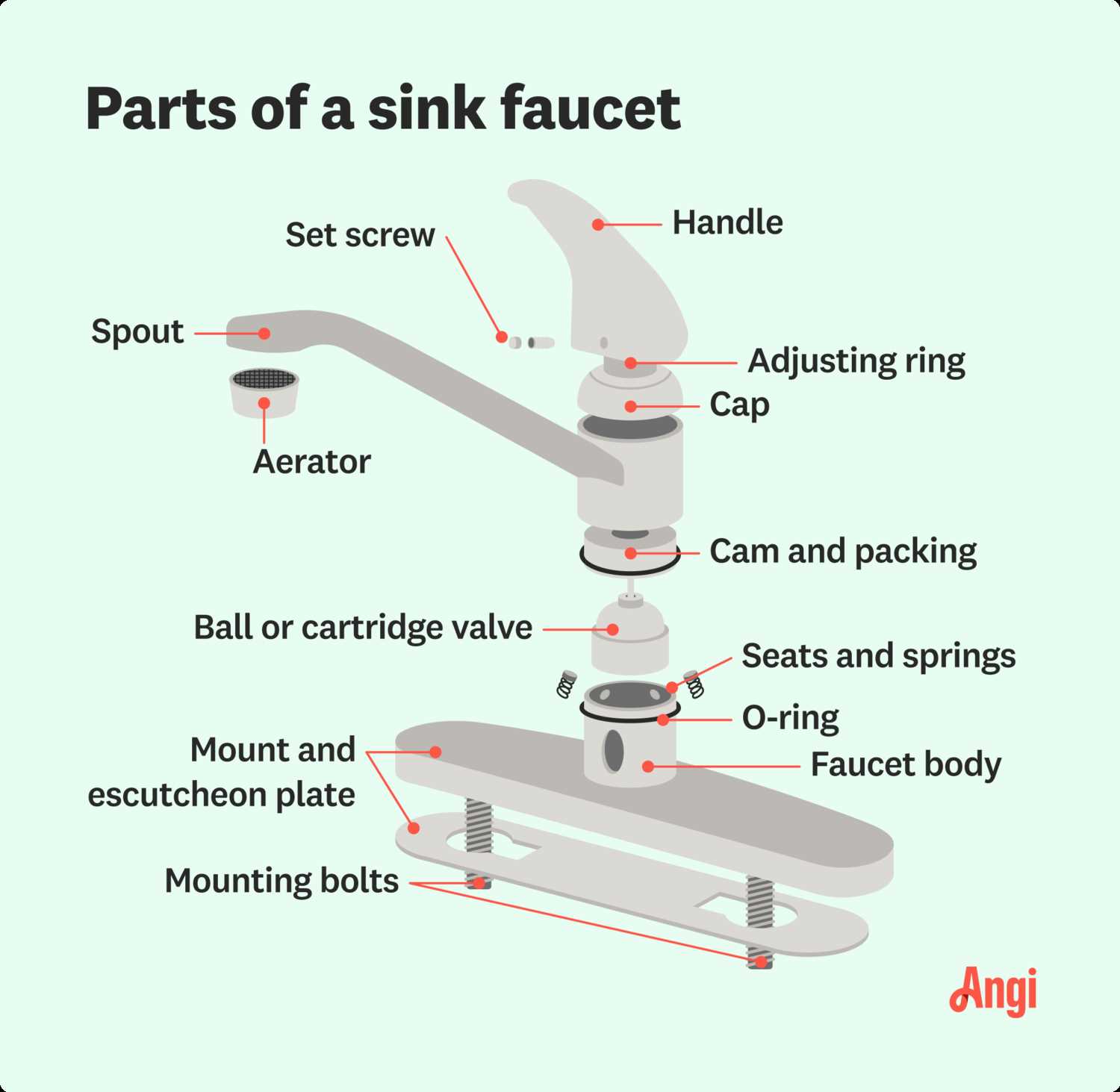

| Type | Features | Pros | Cons |

|---|---|---|---|

| Compression | Simple mechanism with rubber washers | Inexpensive and easy to replace | Can wear out quickly |

| Ball | Contains a ball that controls flow | Durable and easy to operate | Can be complex to repair |

| Cartridge | Uses a cylindrical cartridge for flow control | Highly efficient and adjustable | May require specific replacement parts |

| Disc | Features ceramic discs for durability | Long-lasting and smooth operation | Higher initial cost |

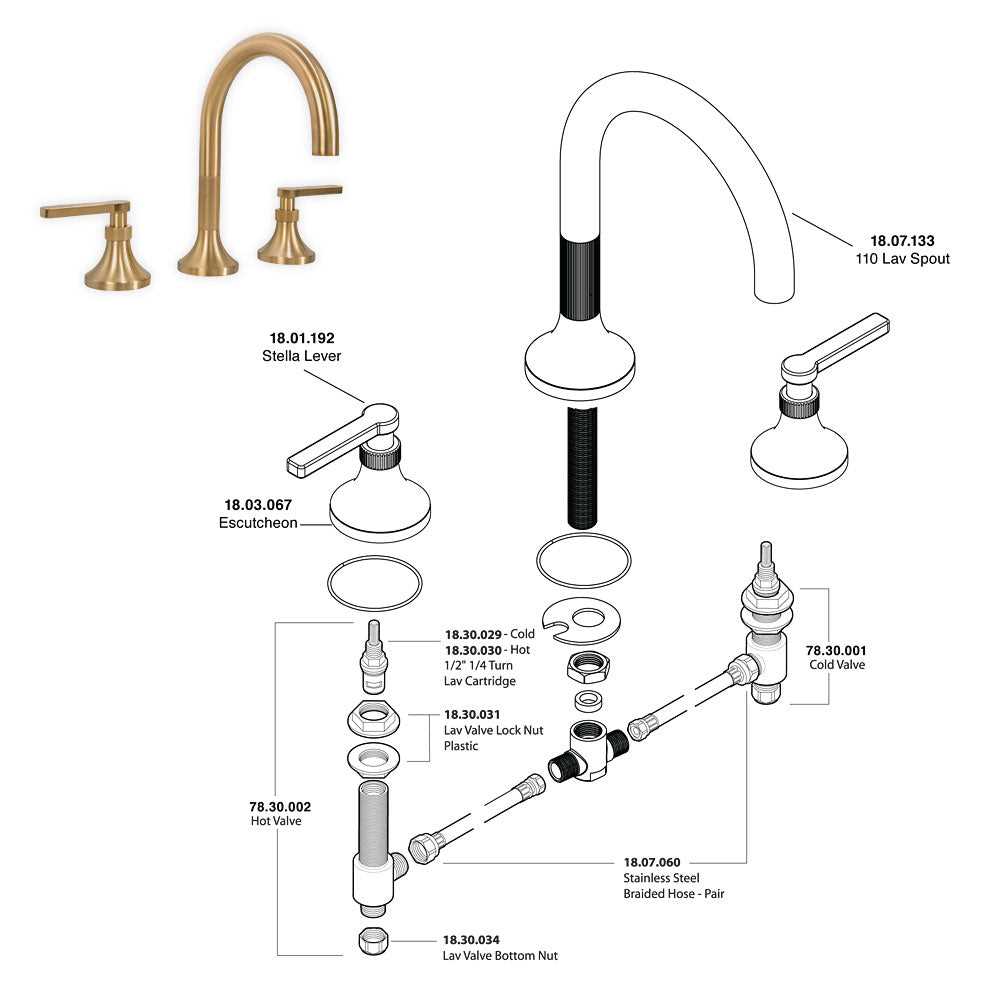

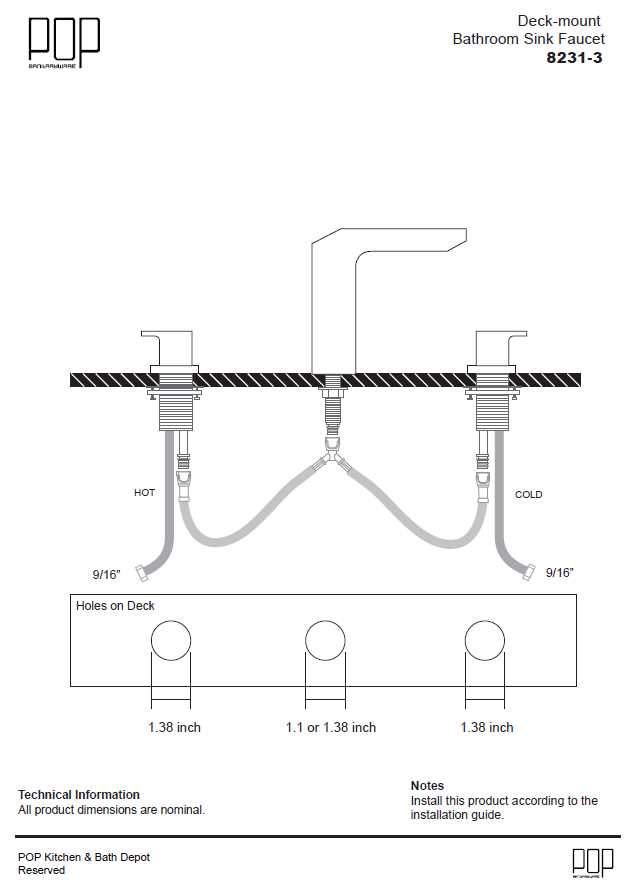

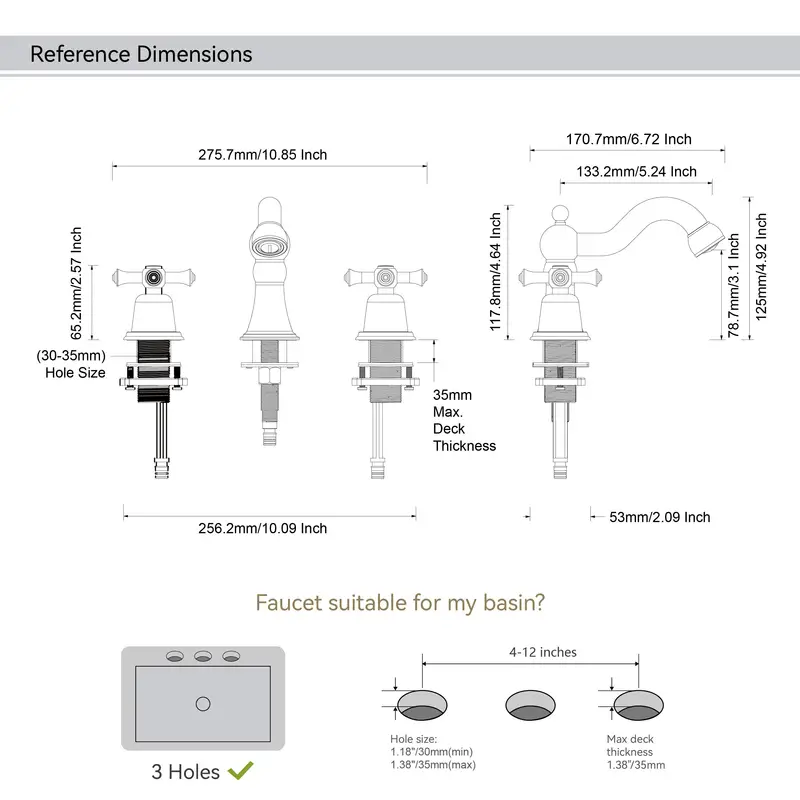

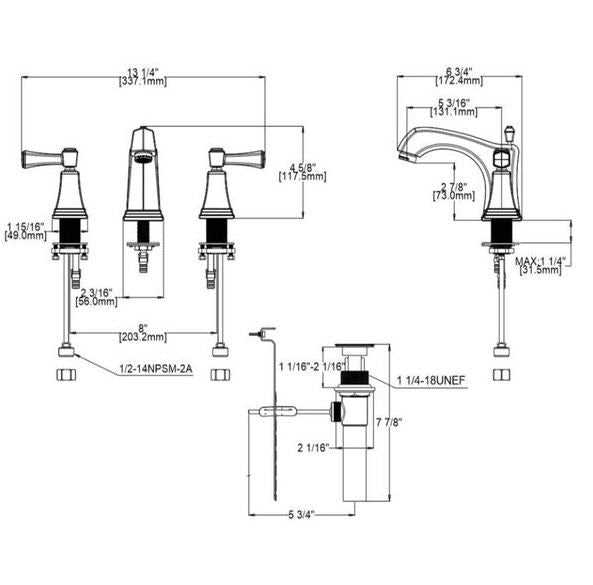

Connection Points of Water Supply Lines

Understanding the connection points for water supply lines is crucial for effective plumbing systems. These points serve as the interfaces where water enters and exits the system, ensuring a steady flow to fixtures. Proper installation and maintenance at these locations are essential for preventing leaks and ensuring optimal performance.

Key Connection Types

- Shut-off Valves: These are critical for controlling the flow of water and are typically located near the entry points.

- Flexible Supply Lines: These lines connect shut-off valves to the main fixture, allowing for adjustments and easier installations.

- Rigid Pipes: Used for longer runs, these pipes provide a stable and reliable connection to the water source.

Installation Considerations

- Ensure compatibility between different types of fittings to avoid leaks.

- Use appropriate sealing materials to create watertight connections.

- Regularly check and maintain connection points to prevent potential issues.

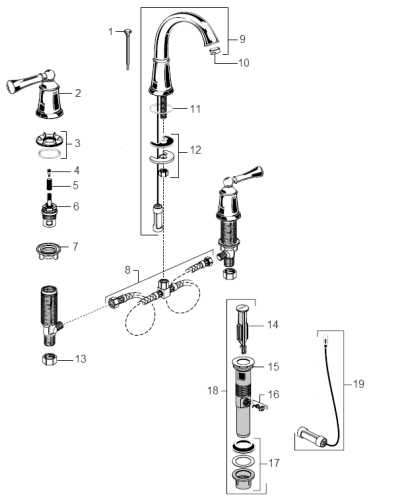

The Purpose of the Valve and Seal

The valve and seal are essential components that contribute to the efficient operation of any water flow system. Their primary function revolves around regulating the movement of liquid, ensuring that it flows smoothly and without leakage. These elements work in tandem to create a reliable barrier, controlling the release and containment of water within the system.

Valves serve as control points, enabling users to adjust the flow rate according to their needs. This control is crucial, as it allows for variations in water pressure and volume, enhancing user experience. The seal, on the other hand, acts as a protective layer that prevents unwanted leakage. By maintaining a tight fit, it ensures that water remains contained, thereby preventing wastage and potential damage from leaks.

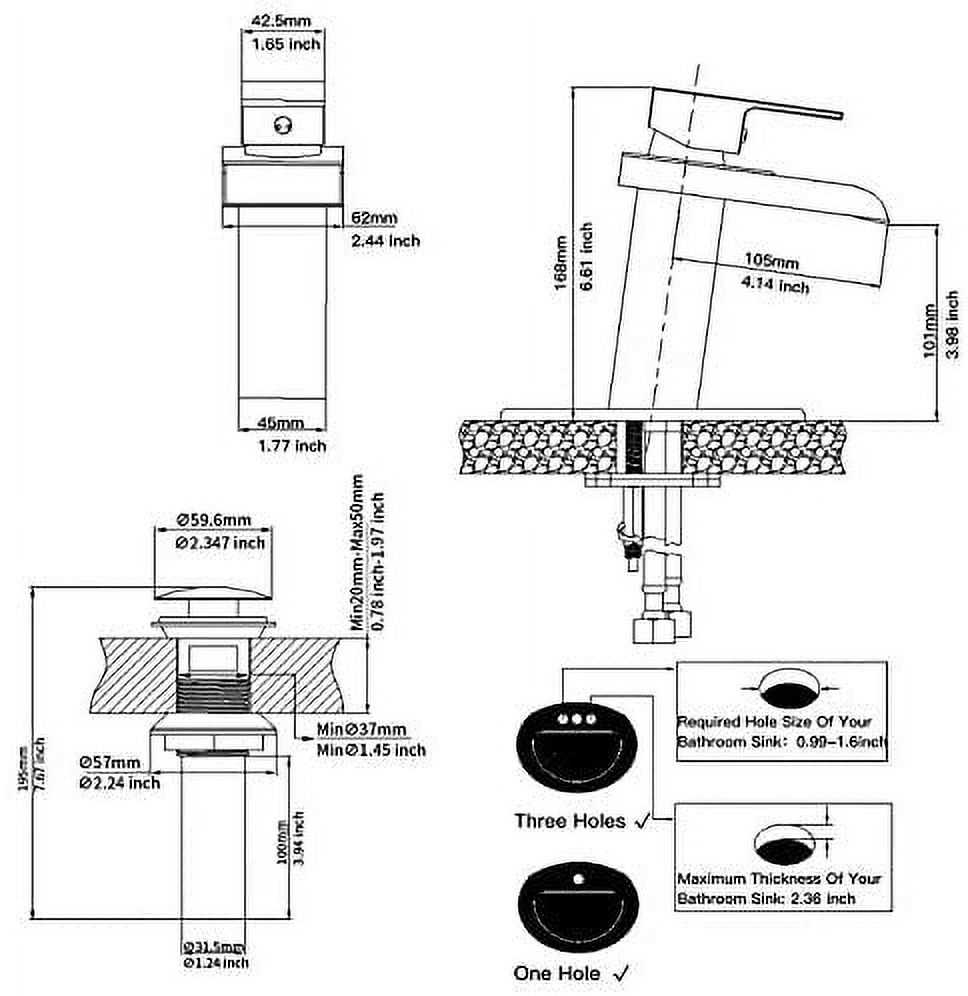

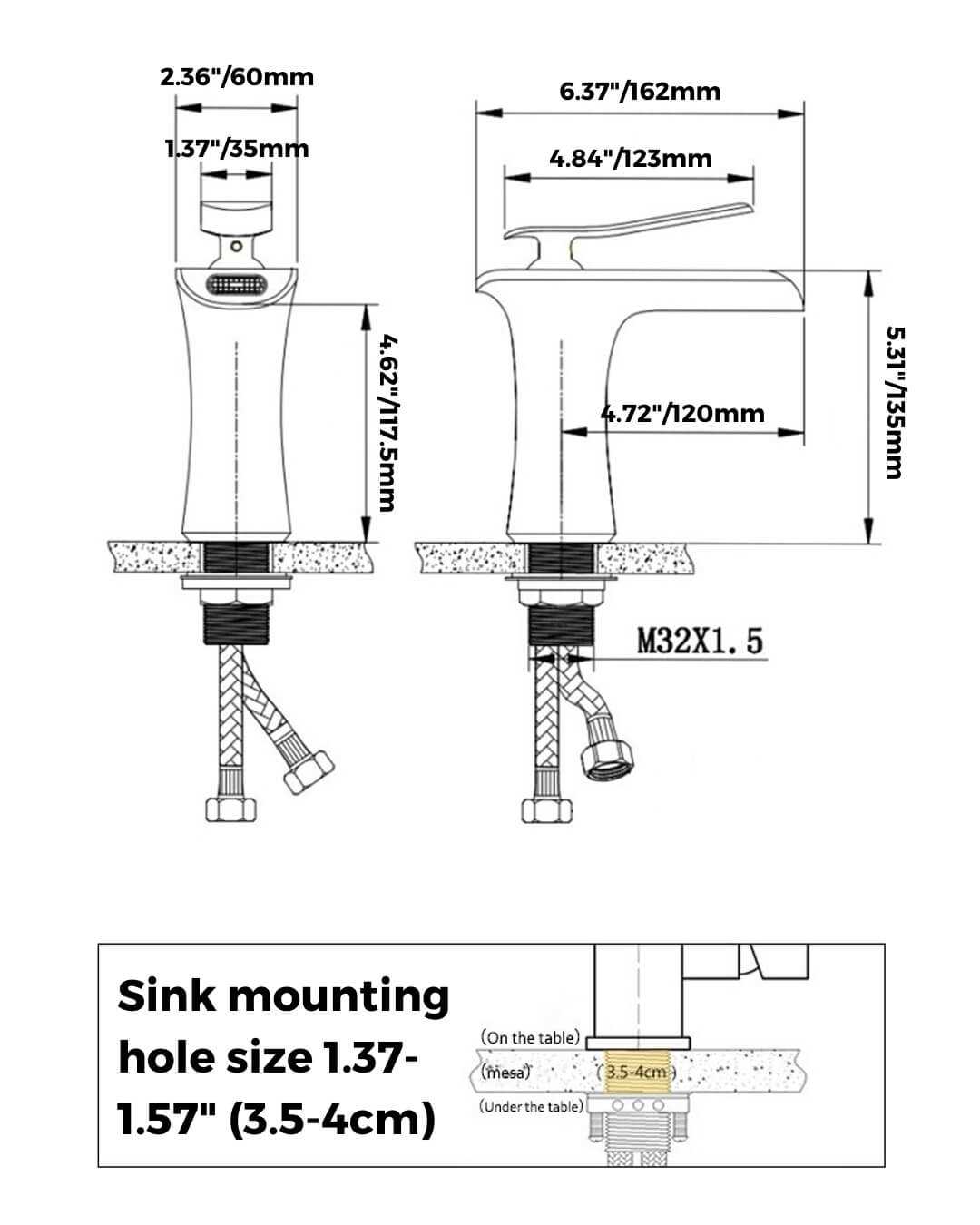

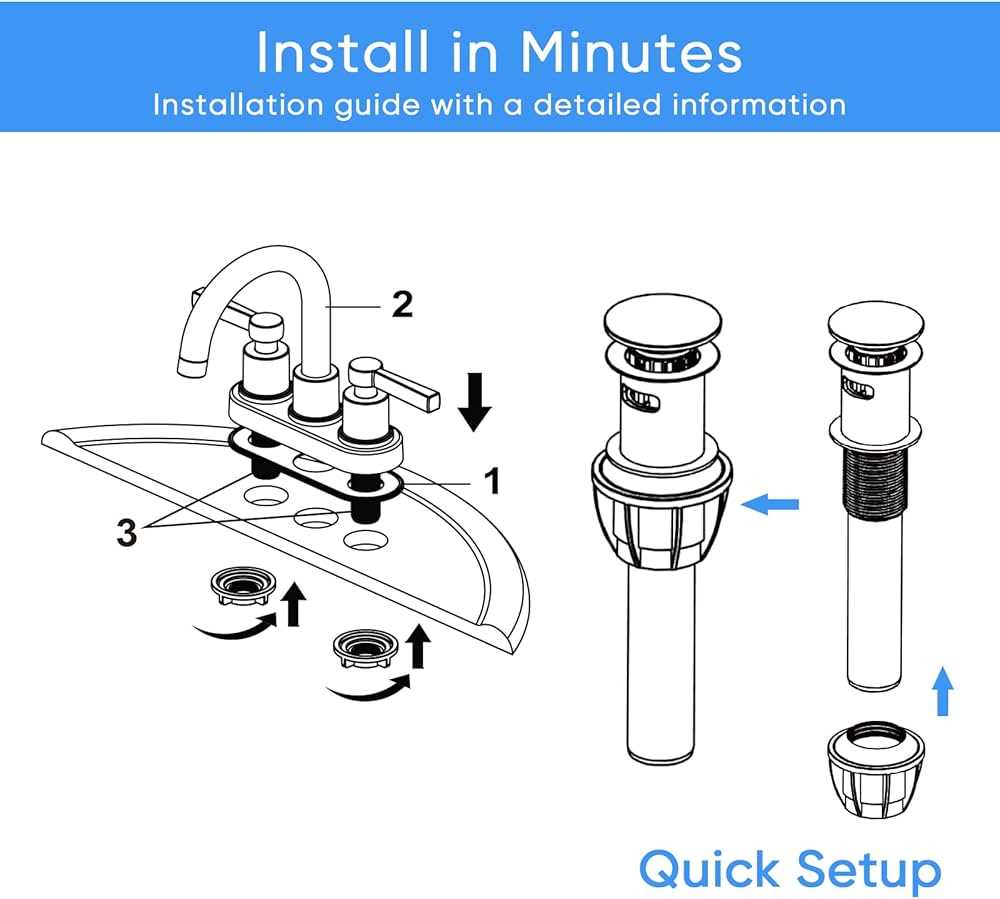

How the Faucet Base Is Secured

The foundation of a water delivery system is essential for ensuring stability and functionality. Proper installation methods prevent leaks and ensure that the fixture remains firmly in place during use.

There are several techniques employed to secure the base effectively:

- Mounting Hardware: Specialized screws or bolts are utilized to attach the foundation to the countertop.

- Rubber Washers: These provide a cushioning effect, helping to create a watertight seal and prevent movement.

- Plumber’s Putty: A flexible substance is often applied to enhance sealing between surfaces, minimizing the risk of leaks.

When installing, it’s crucial to follow the manufacturer’s guidelines to ensure proper alignment and secure fastening. Regular maintenance checks can help identify any issues that may arise over time.

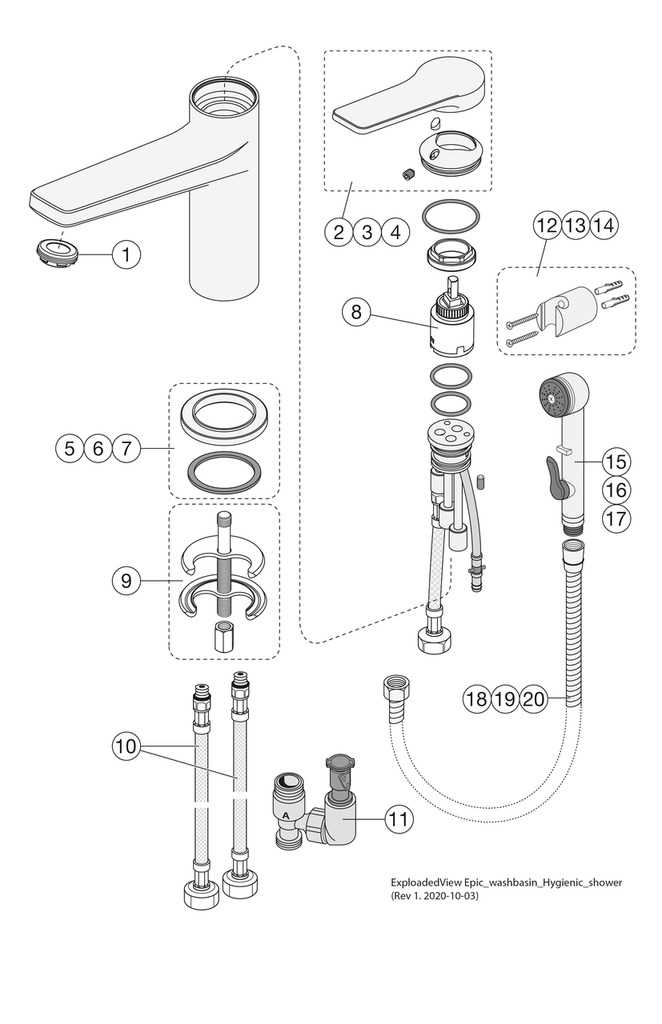

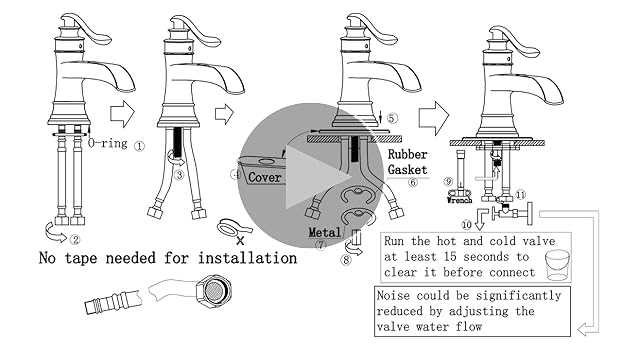

Replacing Washers and O-Rings

When dealing with leaks or drips in your fixture, replacing certain components can be an effective solution. This process often involves swapping out worn or damaged seals and rings, which can restore proper function and prevent water wastage. Understanding how to perform this task can save both time and resources.

Before starting the replacement process, gather the necessary tools and materials. Here’s a brief overview of the essential items you will need:

| Tool/Material | Description |

|---|---|

| Wrench | A tool for loosening and tightening nuts and bolts. |

| Screwdriver | Used to remove screws from the fixture. |

| Replacement washers | New seals to replace the old, worn-out ones. |

| O-rings | Rubber rings that create a watertight seal. |

| Plumber’s grease | Lubricant to ensure a smooth installation of new components. |

Begin by turning off the water supply and draining any residual water. Next, carefully disassemble the fixture to access the seals and rings. Remove the old components, taking care to note their placement for easy reassembly. Install the new washers and O-rings, applying a small amount of plumber’s grease to ensure a snug fit. Finally, reassemble the fixture and restore the water supply, checking for any leaks before concluding the process.

Tools Required for Faucet Maintenance

To ensure the longevity and proper functioning of your plumbing fixtures, having the right equipment on hand is essential. A well-prepared toolkit can make routine upkeep and repairs more manageable, preventing potential leaks and other issues from developing over time.

Essential Equipment

Basic tools such as adjustable wrenches, screwdrivers, and pliers are crucial for carrying out maintenance tasks effectively. These instruments allow for easy tightening, loosening, and adjustment of components, ensuring a secure and leak-free installation.

Additional Helpful Items

In addition to the basic toolkit, having a utility knife and plumber’s tape can enhance your repair capabilities. The utility knife is useful for cutting through various materials, while plumber’s tape aids in sealing threaded connections, minimizing the risk of leaks.