In the world of heavy-duty vehicles, knowledge of essential components is crucial for maintenance and repair. An intricate network of mechanisms ensures that these robust machines operate smoothly and efficiently. Familiarity with these elements not only enhances performance but also extends the lifespan of the vehicle.

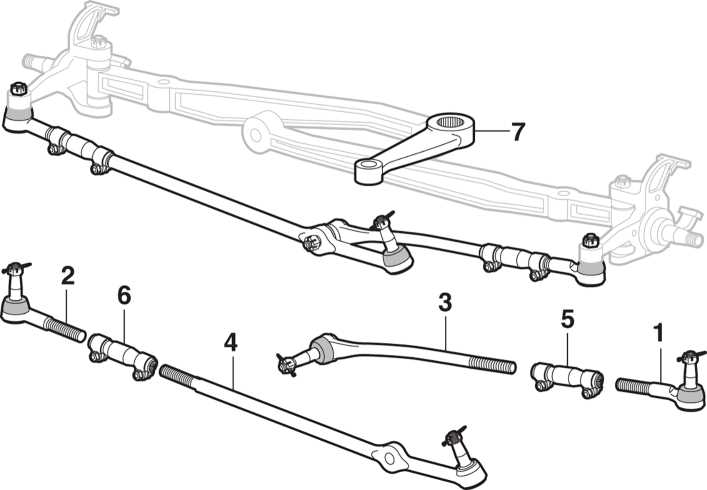

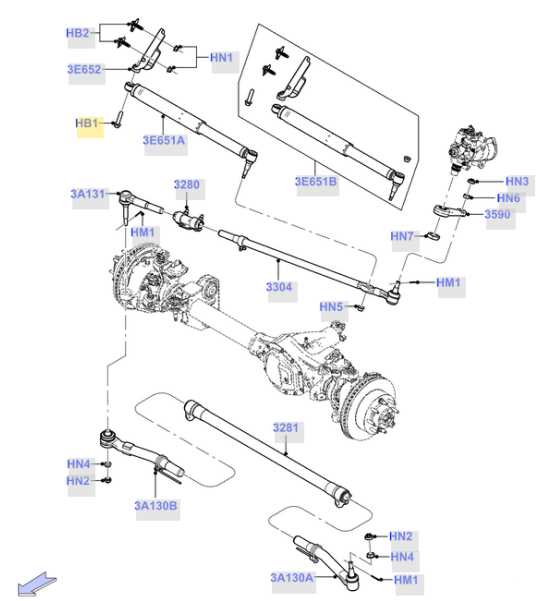

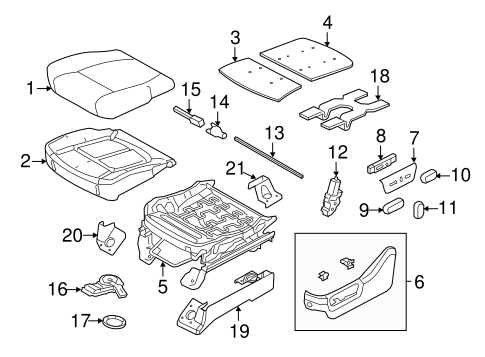

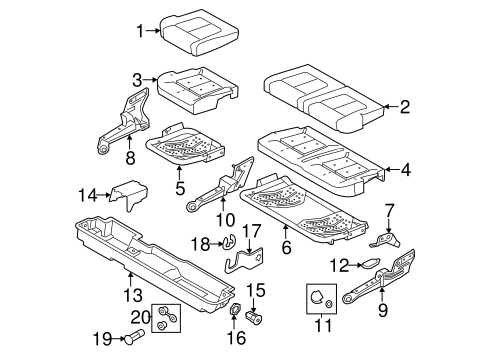

Visual representations of these components can be invaluable for technicians and enthusiasts alike. They provide clarity on how various sections interconnect and function together. A well-organized illustration aids in identifying specific pieces, facilitating easier troubleshooting and replacement processes.

By delving into the specifics of a certain model, one can uncover valuable insights into its design and engineering. Understanding the layout of crucial components helps in grasping their roles and significance within the overall structure of the vehicle. This knowledge is particularly beneficial for those involved in repairs or upgrades, as it allows for informed decision-making and efficient execution of tasks.

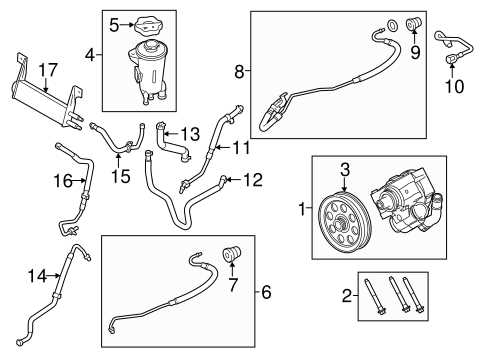

Overview of 2014 Ford F250 Front End

This section provides a comprehensive understanding of the essential components located at the front section of a heavy-duty pickup truck model, focusing on their functions and interrelations. These elements are crucial for maintaining vehicle stability, ensuring safety, and enhancing performance on various terrains.

The primary components include:

- Chassis: The main structure that supports various other elements and influences the vehicle’s handling.

- Suspension System: This system absorbs shocks from the road, contributing to a smoother ride.

- Steering Mechanism: Responsible for directing the vehicle, allowing for precise maneuvering.

- Braking System: Essential for stopping power, ensuring safety during operation.

- Lighting Fixtures: These improve visibility and enhance safety during night driving and adverse weather conditions.

Understanding these components not only aids in maintenance but also enhances the overall driving experience by providing insight into how they work together to support the vehicle’s functionality.

- Regular inspection of the suspension can prevent wear and ensure optimal performance.

- Maintaining the steering system is crucial for safe navigation and control.

- Proper upkeep of the braking system enhances safety and responsiveness.

By familiarizing oneself with these vital aspects, owners can make informed decisions regarding maintenance and upgrades, leading to improved longevity and performance of their vehicle.

Key Components of the Front End

The assembly at the forefront of a vehicle plays a crucial role in both functionality and safety. Understanding its main elements helps in maintaining optimal performance and enhancing longevity.

Main Elements

- Chassis

- Suspension System

- Steering Mechanism

- Braking System

- Cooling Components

Importance of Each Component

- Chassis: Provides structural support and stability.

- Suspension System: Ensures smooth handling and comfort during travel.

- Steering Mechanism: Facilitates precise control and maneuverability.

- Braking System: Vital for safety, allowing for effective stopping power.

- Cooling Components: Prevents overheating, maintaining engine efficiency.

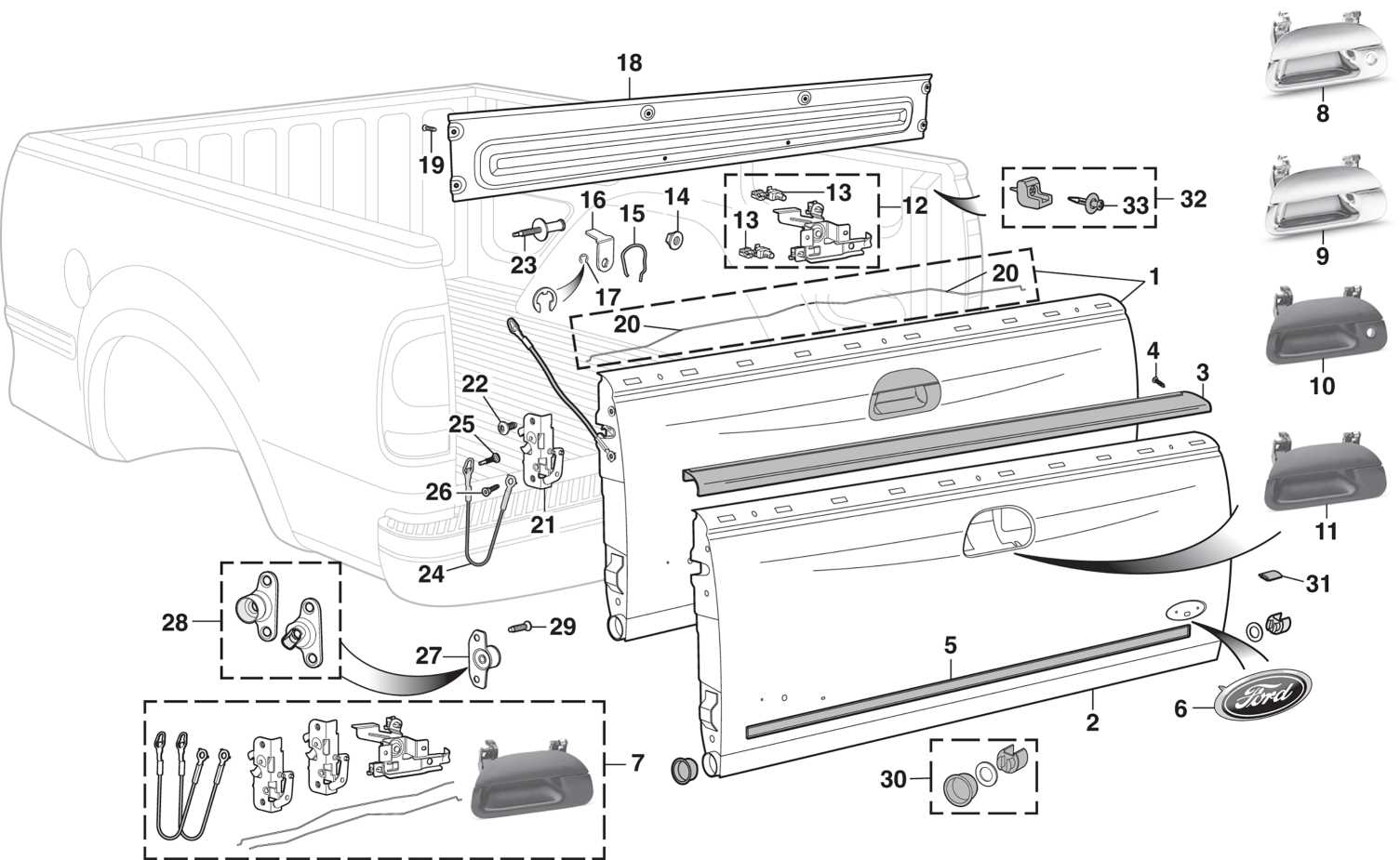

Importance of a Proper Diagram

A clear and accurate illustration of components plays a crucial role in understanding the assembly and functionality of any mechanical system. Without a well-structured representation, diagnosing issues and performing repairs can become a daunting task. This clarity not only aids technicians but also empowers vehicle owners to engage more confidently with maintenance processes.

Enhanced Understanding

Having a detailed visual guide allows for easier comprehension of how various elements interact within the system. When individuals can see the layout and connections, it fosters a deeper grasp of the mechanics at play. This understanding is vital for effective troubleshooting and ensuring that each piece functions as intended.

Efficient Repairs

With the right schematic, repair tasks become significantly more efficient. Technicians can quickly locate specific components and follow the correct procedures for removal or replacement. This efficiency not only saves time but also reduces the likelihood of errors, leading to a more reliable and safe vehicle performance.

In summary, a well-crafted visual reference is indispensable for anyone involved in vehicle maintenance. It bridges the gap between theory and practice, making the complex world of automotive repair more accessible and manageable.

Common Issues with Front End Components

The assembly at the front of a vehicle is critical for steering and stability. Various elements work together to ensure smooth operation, but they can experience wear and tear over time. Understanding typical problems associated with these components can help in maintaining optimal performance and safety.

Common Problems

- Worn Bushings: Rubber bushings can degrade, leading to increased play in the suspension system.

- Ball Joint Failure: These joints can wear out, causing knocking sounds and poor handling.

- Steering Linkage Issues: Loose or damaged linkages can result in unresponsive steering and alignment problems.

- Shock Absorber Degradation: Old or leaking shocks may compromise ride quality and stability.

Symptoms to Watch For

- Excessive vibration or shaking during driving.

- Uneven tire wear, indicating misalignment.

- Difficulty steering or a feeling of looseness in the wheel.

- Unusual noises when turning or going over bumps.

Regular inspections and prompt replacements of compromised components can prevent further damage and enhance driving safety.

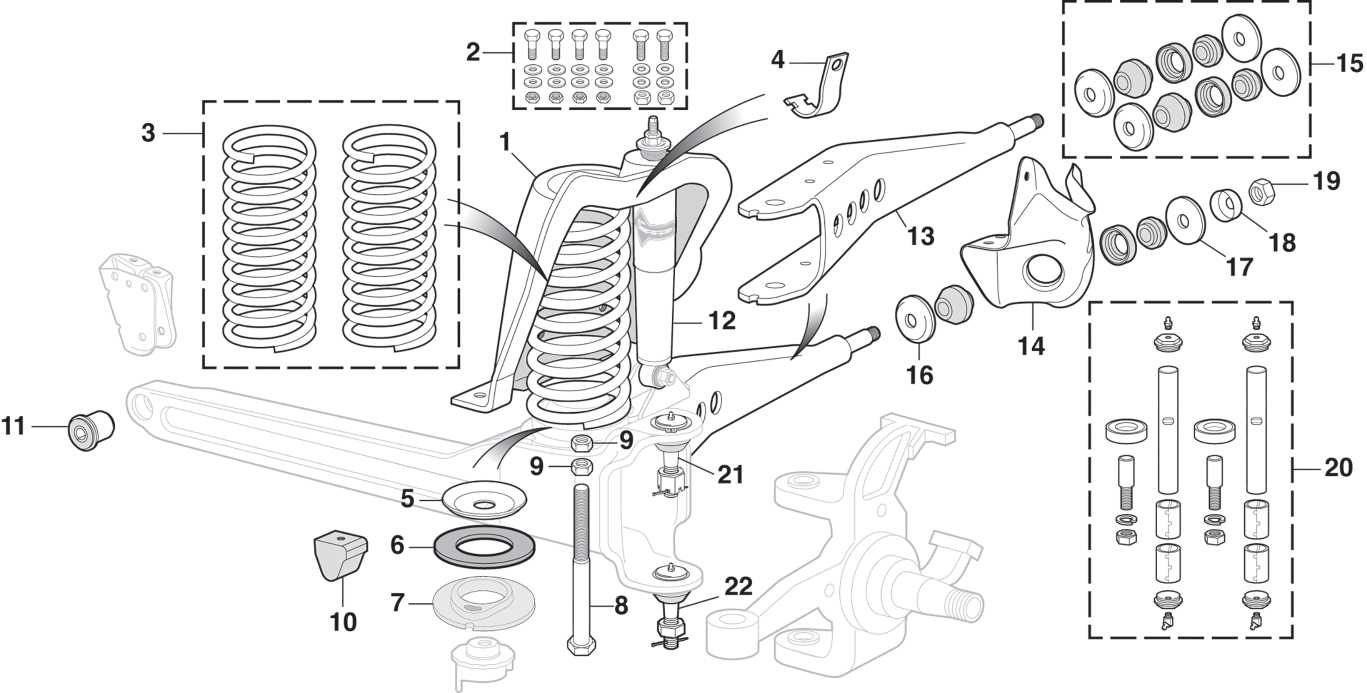

Understanding Suspension Systems in Trucks

The suspension system plays a crucial role in the overall performance and comfort of a vehicle. It connects the vehicle’s body to its wheels, ensuring a smooth ride while maintaining stability and control. A well-designed suspension allows for better handling, enhanced load-carrying capabilities, and improved traction on various terrains.

Key Components of Suspension Systems

| Component | Function |

|---|---|

| Shock Absorbers | Reduce bounce and stabilize the vehicle by controlling the rate of spring compression and extension. |

| Springs | Support the weight of the vehicle and absorb road impacts, enhancing ride quality. |

| Control Arms | Connect the vehicle’s chassis to the wheels, allowing for controlled movement and alignment. |

| Sway Bars | Minimize body roll during turns, improving handling and stability. |

Types of Suspension Systems

There are various types of suspension configurations designed to cater to different vehicle needs and driving conditions. Each type offers unique advantages and is suited for specific applications.

| Type | Description |

|---|---|

| Leaf Spring | Commonly used in trucks, providing excellent load-bearing capacity and durability. |

| Coil Spring | Offers a smoother ride, often found in passenger vehicles and light trucks. |

| Air Suspension | Utilizes air-filled bags for adjustable ride height and enhanced comfort, ideal for towing and heavy loads. |

Choosing Quality Replacement Parts

When it comes to maintaining a vehicle, selecting high-grade components is crucial for ensuring longevity and optimal performance. Quality replacements not only enhance the overall functionality but also contribute to the safety and reliability of the vehicle. Investing in superior alternatives can save money and time in the long run.

Research is vital when evaluating options. Look for reputable brands that are known for durability and performance. Additionally, consider reviews from other customers, as their experiences can provide valuable insights into the quality of the products.

Compatibility is another essential factor. Always verify that the components are designed to fit your specific model. This ensures seamless integration and reduces the risk of future issues. Moreover, checking for warranties can offer peace of mind, as they often indicate the manufacturer’s confidence in their product.

Ultimately, taking the time to delve into your choices will yield the best results, ensuring that your vehicle remains in excellent condition for years to come.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for efficient maintenance and repair. These visuals serve as a roadmap, guiding you through the assembly and functionality of various elements. By mastering the interpretation of these illustrations, you can enhance your skills and ensure accurate repairs.

Key Elements to Identify

- Labels: These often indicate the names or functions of each component.

- Numbers: Reference numbers may correlate with a parts list, helping you find specific items.

- Connections: Lines and arrows typically illustrate how components interact or are linked.

Steps to Decode the Illustration

- Familiarize yourself with the layout, noting how parts are grouped.

- Cross-reference labels and numbers with the accompanying parts list.

- Pay attention to connection lines to understand the flow and assembly.

- Take notes for any components that require further investigation.

Maintenance Tips for Front End Components

Regular upkeep of crucial components is essential for ensuring vehicle safety and performance. Implementing effective maintenance practices can significantly enhance longevity and reliability.

1. Routine Inspections: Schedule frequent checks to identify wear and tear. Look for any unusual noises or handling issues that may indicate problems.

2. Lubrication: Apply appropriate lubricants to joints and bushings to reduce friction and prevent premature wear. Ensure that all moving parts are adequately serviced.

3. Alignment Checks: Maintaining correct alignment is vital for optimal handling and tire longevity. Regularly inspect and adjust as needed to prevent uneven tire wear.

4. Tire Maintenance: Monitor tire pressure and tread depth consistently. Properly inflated and well-maintained tires contribute to better steering and stability.

5. Component Replacement: Be proactive about replacing any damaged or worn components. Delaying repairs can lead to more extensive damage and higher costs in the long run.

By following these tips, you can ensure your vehicle remains safe and performs at its best.

Signs of Front End Wear and Tear

Recognizing the symptoms of deterioration in vehicle suspension and steering components is crucial for maintaining safety and performance. Various indicators can reveal underlying issues that, if left unchecked, may lead to more significant problems or even accidents.

Common Indicators

- Unusual Noises: Clunking, popping, or grinding sounds when turning or going over bumps often signal problems.

- Vibrations: Excessive shaking in the steering wheel can indicate misalignment or worn components.

- Pulling to One Side: If the vehicle drifts left or right without steering input, it may point to uneven wear or misalignment.

- Tire Wear Patterns: Uneven tire wear can suggest issues with suspension parts or alignment.

- Loose Steering: A lack of responsiveness or a feeling of slack in the steering wheel indicates potential wear.

What to Do Next

If you notice any of these signs, it’s advisable to have your vehicle inspected by a qualified mechanic. Early diagnosis can save time and money while ensuring your safety on the road.

Tools Needed for Front End Repairs

Undertaking repairs on the vehicle’s forward assembly requires a specific set of instruments to ensure efficiency and effectiveness. Proper tools not only simplify the process but also enhance safety during the task. Below is a guide to essential equipment that will aid in performing various maintenance and repair operations.

Essential Hand Tools

- Socket Set: Various sizes to accommodate different fasteners.

- Wrenches: Both standard and adjustable to tackle various bolt types.

- Torque Wrench: For applying precise torque to fasteners.

- Screwdrivers: A range of flathead and Phillips for different screws.

- Pliers: Needle-nose and standard for gripping and bending.

Specialized Equipment

- Jack and Jack Stands: To safely lift the vehicle for access.

- Ball Joint Separator: Useful for disconnecting ball joints without damage.

- Alignment Tools: For ensuring proper wheel alignment after repairs.

- Shop Manual: A reference for specifications and procedures.

Having the right tools on hand not only streamlines the repair process but also minimizes the risk of damaging components or injuring oneself. Investing in quality equipment is crucial for achieving reliable results and maintaining vehicle performance.

Cost Estimates for Replacement Parts

When considering the financial aspects of restoring vehicle components, it’s crucial to evaluate potential expenses associated with various replacement items. Understanding these costs can help in planning budgets effectively and ensuring that repairs are conducted without financial strain.

New Components: Prices for brand-new replacements often range from moderate to high, depending on the specific item and brand quality. On average, expect to invest anywhere from $100 to $1,000 for a single component.

Used or Refurbished Items: Opting for second-hand or refurbished options can be a cost-effective alternative. These parts might be available for $50 to $500, but it’s essential to assess their condition carefully to avoid future issues.

Labor Costs: Don’t overlook the expense of professional installation, which can add significantly to the overall cost. Labor fees typically range from $75 to $150 per hour, depending on the complexity of the repair.

Ultimately, budgeting wisely for these expenses will ensure a smoother repair process and a more reliable vehicle once the work is completed.

DIY vs. Professional Repairs

When it comes to maintaining and fixing vehicles, individuals often face the decision between tackling the task themselves or hiring a skilled technician. Each approach has its own set of advantages and challenges that can impact the overall outcome.

Choosing to do repairs on your own can be rewarding. Here are some benefits:

- Cost Savings: Handling repairs yourself can significantly reduce labor costs.

- Learning Experience: DIY work allows you to gain valuable knowledge about your vehicle.

- Flexibility: You can work at your own pace and schedule.

However, there are also challenges to consider:

- Time-Consuming: Repairs can take longer without professional experience.

- Skill Limitations: Lack of expertise may lead to mistakes or incomplete fixes.

- Tools Required: Some tasks may necessitate specialized equipment that can be expensive.

On the other hand, hiring a professional offers its own set of benefits:

- Expertise: Professionals have the training and experience to handle complex issues efficiently.

- Warranty Protection: Many shops provide warranties on their work, giving you peace of mind.

- Time Efficiency: Professionals can often complete repairs faster due to their experience and tools.

Despite these advantages, there are drawbacks to consider:

- Higher Costs: Professional services can be more expensive than DIY repairs.

- Lack of Control: You may have limited insight into the repair process and outcomes.

- Dependency: Relying on others can be inconvenient, especially during busy times.

Ultimately, the choice between DIY repairs and professional assistance depends on individual circumstances, including skills, budget, and the specific nature of the repairs needed.

Resources for Further Information

This section aims to provide a variety of sources for those seeking more knowledge about specific components and their arrangements within vehicles. Exploring these resources can enhance understanding and facilitate informed decision-making for maintenance and repairs.

Online Resources

- Automotive forums and communities

- Manufacturer websites for technical specifications

- Online repair manuals and guides

Books and Publications

- Automotive repair textbooks

- Specialized magazines focused on vehicle maintenance

- Guides from industry experts