When examining the mechanical structure of large trucks, it’s essential to have a clear understanding of the various elements that contribute to their durability and performance. These vehicles are built to handle challenging environments, and the core systems responsible for their mobility are designed with strength and precision in mind.

The driving mechanism that powers these trucks is an intricate network of interconnected parts, working together to ensure smooth operation on diverse terrains. From managing weight distribution to enabling consistent movement, every part of this complex system plays a critical role.

In this guide, we will explore the fundamental components that make up these systems, focusing on their design, function, and how they contribute to the overall stability and efficiency of heavy-duty vehicles. Understanding these elements is key to maintaining and optimizing the performance of your truck over time.

Ford F250 4×4 Front Axle Overview

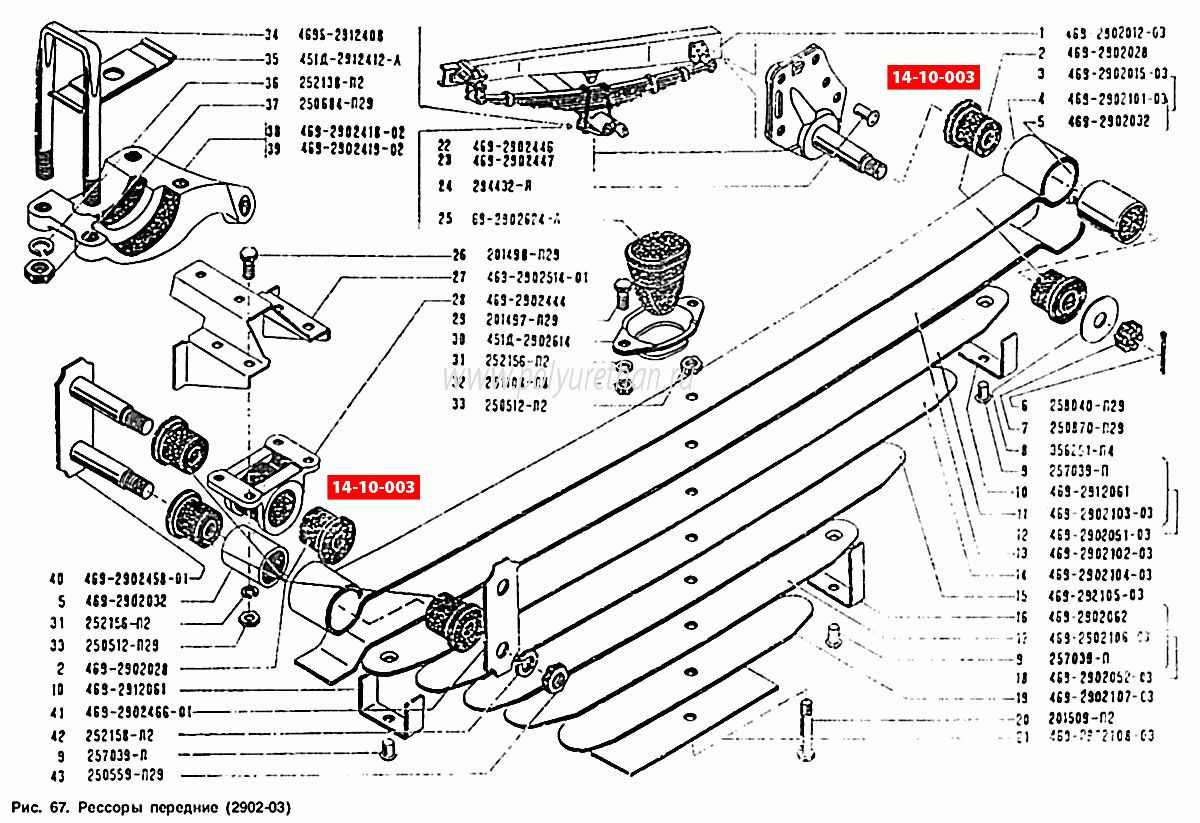

The primary system beneath the vehicle that connects the wheels to the drivetrain is a crucial component for handling rugged terrain. This mechanism allows for the transfer of power to the wheels, ensuring efficient movement and control on uneven surfaces. Built to endure heavy loads and challenging conditions, the assembly includes various elements designed to work together harmoniously for smooth and reliable operation.

Key components of this system contribute to its durability and functionality, ensuring that the vehicle maintains traction and stability. These parts work in unison to provide both power distribution and steering capabilities, adapting to a variety of driving scenarios. The robust design of this setup is critical for performance, especially when navigating tough environments.

One of the main features of this structure is its ability to distribute torque effectively, supporting the vehicle’s weight while providing consistent movement. This ensures that each part of the system functions optimally, delivering a balanced and efficient driving experience.

Main Components of the Front Axle Assembly

The assembly in question is a crucial element of vehicle suspension systems, responsible for ensuring stability and smooth performance. This system connects key structural elements and allows for proper distribution of load and torque, contributing to the overall functionality of the vehicle. Below, we’ll examine the essential components that contribute to the efficient operation of this mechanical system.

Key Elements in the System

- Steering Knuckles: These parts connect the wheel hub to the suspension, enabling precise control during steering.

- Control Arms: These components manage the movement of the wheel, maintaining alignment and providing a smooth driving experience.

- Bearings: These ensure smooth rotation of the wheel by reducing friction and supporting the load.

- Universal J

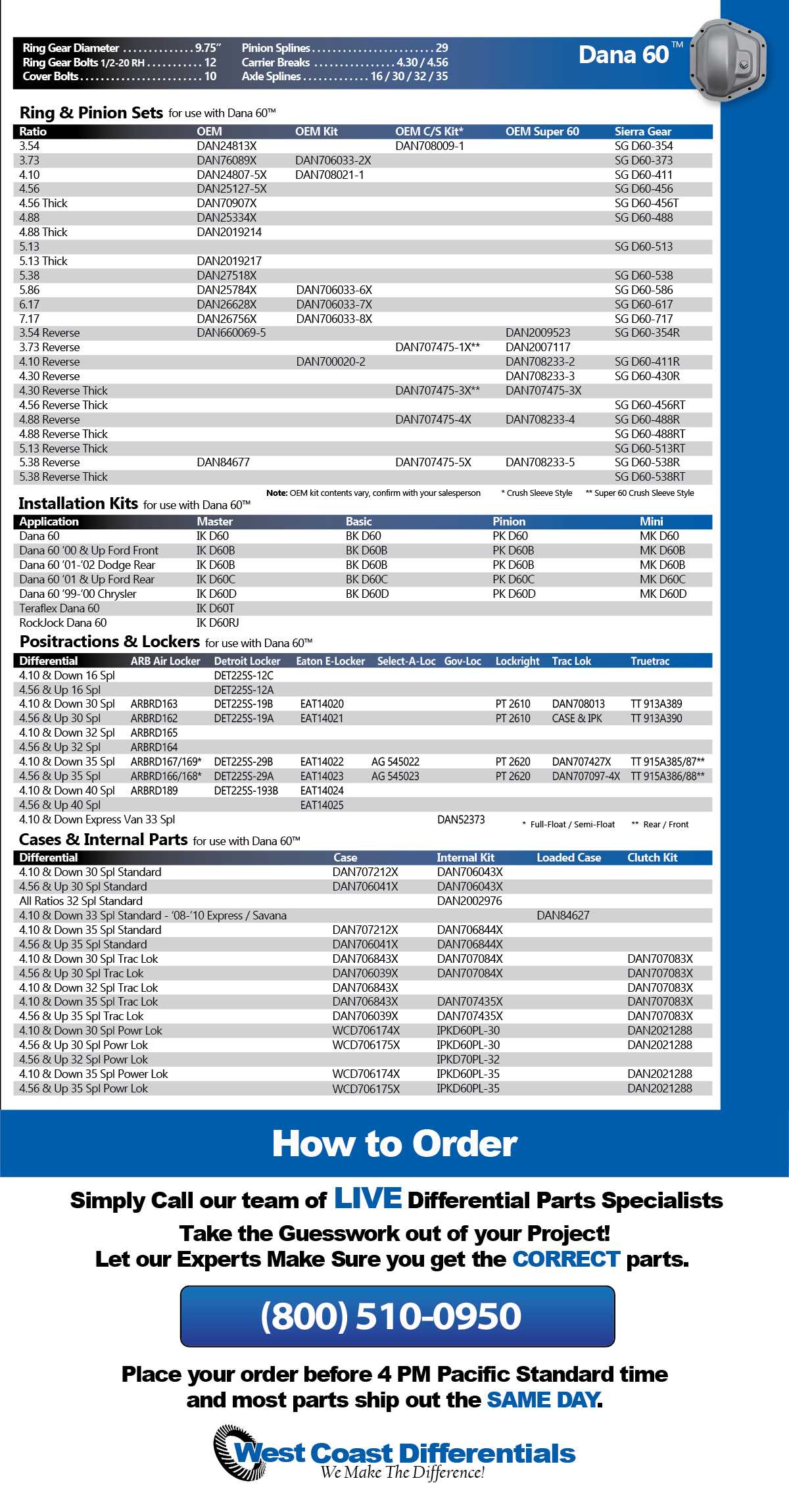

Functionality of Differential in 4×4 Systems

The differential plays a critical role in distributing power between the wheels, allowing them to rotate at different speeds. This is especially important when navigating turns, as the inner and outer wheels travel at varying distances. Without this mechanism, steering would become challenging and tire wear would increase significantly.

Main Purpose of the Differential

The key function of the differential is to balance the torque sent to the wheels. It ensures that each wheel receives the appropriate amount of power, which helps in maintaining control during various driving conditions. This system adapts to changes in road surfaces, preventing skidding and providing stability.

Key Components of the Differential

- Pinion Gear: Transfers power from the drive shaft to the differential mechanism.

- Ring Gear: Works with the pinion to adjust the speed of wheel rotation.

- Spider Gears: Allow wheels to spin independently when turning, ensuring smooth operation.

By coordinating the movement of individual wheels, the differential ensures smooth handling, which is essent

How Steering Knuckles Affect Front Axle Performance

The steering knuckle plays a pivotal role in the overall functionality of a vehicle’s suspension system. It directly influences how the wheels are positioned and how they move during steering maneuvers. Understanding how these components work together can help improve vehicle handling and ensure a smooth driving experience.

Steering and Wheel Alignment

The steering knuckle is essential in maintaining the proper alignment of the wheels. It ensures that the wheels pivot correctly, allowing for precise control of the vehicle. Poor alignment caused by worn or damaged knuckles can lead to uneven tire wear and difficulty steering, negatively impacting overall driving efficiency.

Durability and Load Bearing

In addition to its steering function, the knuckle bears a significant amount of the vehicle’s weight. This makes it crucial for maintaining the integrity of the suspension system, especially under heavy loads. A strong and well-maintained knuckle ensures long-lasting durability and better performance u

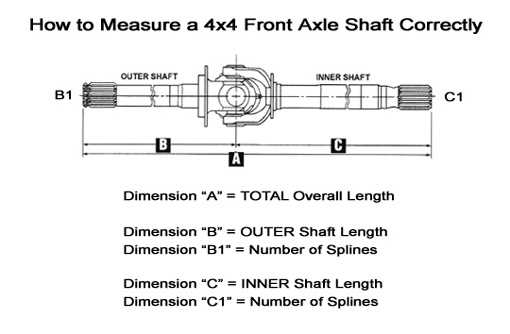

Understanding the Role of Axle Shafts

The shafts in the drivetrain serve as critical connectors between the transmission system and the wheels, ensuring that power generated by the engine is effectively transferred. These components are designed to withstand the immense forces exerted during motion, especially when the vehicle is under heavy load or challenging conditions. Without their proper function, the wheels would not receive the necessary torque to rotate efficiently.

Durability and precision are key attributes of these components. They must be constructed from high-strength materials to handle stress and prevent breakage during operation. Over time, wear can occur, and regular inspections help in identifying any issues before they become major problems.

Proper maintenance of these shafts is essential to extend the lifespan of the vehicle’s drivetrain. Regular lubrication and checking for any signs of wear or damage are crucial steps to ensure optimal performance.

Ball Joints and Their Importance in Axle Systems

Ball joints play a crucial role in the functionality and safety of vehicle suspension systems. They act as connectors between various components, allowing for smooth movement and ensuring the vehicle’s stability. These small but vital components enable the wheels to move up and down while maintaining control and alignment of the vehicle’s structure.

Functionality and Movement

Ball joints facilitate the pivoting motion between the wheel assembly and the vehicle’s framework, providing flexibility during steering and driving. They allow for the necessary range of motion to absorb shocks and bumps while maintaining the correct alignment for proper handling and comfort.

Durability and Maintenance

Regular inspection and maintenance of ball joints are essential for long-term performance. Worn-out joints can lead to uneven tire wear, reduced steering control, and potentially dangerous driving conditions. Ensuring these components are in good condition is crucial for both vehicle safety and performance.

Hub Assemblies and Their Impact on Wheel Rotation

The hub assembly plays a crucial role in the overall motion of a vehicle’s wheels. It acts as the connecting point between the wheel and the suspension system, ensuring smooth and efficient movement during driving. A properly functioning hub allows the wheel to rotate freely while maintaining the necessary stability and control for the vehicle’s performance.

Key Components of Hub Assemblies

The hub assembly is composed of several integral components, including the hub itself, bearings, and seals. These parts work together to minimize friction and wear, allowing the wheel to rotate with precision. The bearings support the wheel’s rotation while the seals protect the internal components from dirt, moisture, and debris that could impair performance.

Impact on Vehicle Handling and Safety

A well-maintained hub assembly is vital for optimal vehicle handling. Any malfunction, such as damaged bearings or worn seals, can lead to increased friction, reduced wheel rotation efficiency, and ultimately poor handling. This can result in uneven tire wear and even compromise vehicle safety, as the wheel may not respond correctly to steering inputs.

Driveshaft Connection to the Axle

The connection between the powertrain and the wheel assembly is crucial for transmitting rotational force. This linkage ensures the wheels are driven, providing necessary traction and stability. The components involved must work in unison to deliver smooth and efficient power transfer under various driving conditions.

- U-Joint: A key element, this component allows flexibility and movement between the driveshaft and the wheel assembly. It accommodates the angular motion that occurs as the suspension moves.

- Yoke: The yoke is the connecting piece that links the driveshaft to the wheel system. It is secured with bolts or pins, ensuring a tight fit for optimal power transmission.

- Flange: A flange may be used in some setups, providing a stable connection and reducing the risk of misalignment between the driveshaft and the wheel system.

- Carrier Bearings: These bearings support the driveshaft and reduce strain on the U-joints, contributing to the durability of the connection over time.

Each of these components plays a significant role in ensuring the efficient transfer of power from the drivetrain to the wheels, allowing for reliable vehicle performance.

Benefits of Locking Hubs in Off-Road Conditions

Locking hubs play a crucial role in enhancing vehicle performance during off-road adventures. These components offer significant advantages by providing better control and traction, especially in challenging terrains.

- Improved Traction: Locking hubs engage the drive system, ensuring maximum torque is distributed to the wheels, improving grip on slippery or uneven surfaces.

- Increased Fuel Efficiency: When the hubs are disengaged, the vehicle operates with less drivetrain resistance, leading to better fuel consumption on highways or non-challenging roads.

- Enhanced Durability: By engaging the hubs only when necessary, the vehicle’s drivetrain experiences less wear and tear, increasing the lifespan of various components.

- Better Control in Tough Terrain: Locking hubs help maintain consistent power delivery, ensuring smoother and more stable handling over rocks, mud, or sand.

Overall, these hubs provide versatility and adaptability, allowing the vehicle to perform optimally across different driving conditions, from highways to rugged off-road environments.

Seals and Bearings in the Axle Structure

The integrity of a vehicle’s drivetrain heavily relies on the quality and function of seals and bearings. These components work together to ensure smooth rotation, prevent debris entry, and maintain lubrication within the moving elements. Without proper seals and bearings, friction and wear can compromise the system’s efficiency and longevity.

Seals: Protection and Efficiency

Seals play a crucial role in keeping the internal mechanisms free from external contaminants while retaining lubrication. A well-designed seal ensures that no moisture, dirt, or other particles can enter sensitive areas, preventing corrosion and excessive wear on the components.

Bearings: Smooth Movement and Durability

Bearings are vital for minimizing friction between moving parts, allowing for smoother motion and reducing energy loss. High-quality bearings improve the system’s overall performance by distributing loads evenly and reducing the chances of heat build-up or mechanical failure.

Common Axle Issues and Maintenance Tips

When dealing with the vehicle’s steering and suspension system, certain challenges can arise over time. Regular use, heavy loads, and rough terrain can cause wear and tear on critical components, affecting both performance and safety. Addressing these issues promptly can prevent costly repairs and improve overall driving experience.

Common Problems

- Uneven Tire Wear: This is often caused by misalignment or worn components within the vehicle’s suspension, affecting the tires’ lifespan and traction.

- Vibration While Driving: Unusual shaking or vibrations, particularly during acceleration, may indicate issues with the steering mechanism or suspension parts.

- Difficulty Steering: If the steering becomes stiff or unresponsive, it might be a sign of damaged bushings or faulty components in the suspension system.

- Noise When Turning: Grinding or popping sounds during turns can point to damaged joints or excessive wear on the steering system.

Maintenance Tips

- Regular Inspections: Periodically check the key elements of the steering and suspension, especially in areas prone to damage from rough conditions.

- Lubrication: Ensure that moving parts are properly lubricated to minimize friction and prevent premature wear.

- Alignment Checks: Regular alignment checks will ensure that tires wear evenly and the steering remains responsive.

- Replace Worn Components: Replace worn bushings, joints, or any other components showing signs of damage to prevent further complications.

Upgrading Front Axle Parts for Better Durability

Enhancing the key components of your vehicle’s steering and suspension system can significantly improve its strength and longevity. Choosing higher-quality elements for critical mechanical structures ensures better performance under challenging conditions and minimizes wear over time.

Improving robustness is essential when operating under tough conditions, especially for heavy-duty tasks. Upgrading with advanced materials and reinforced components can greatly increase the overall lifespan of these systems.

Durability improvements also extend to the vehicle’s handling and load-carrying capacity, making it more reliable and safer for various driving conditions. Investing in quality upgrades provides peace of mind, ensuring that your vehicle remains durable even after extensive use.