In the realm of agricultural machinery, comprehending the intricate details of each vehicle is essential for optimal performance. A thorough exploration of these essential elements provides users with the necessary insights to maintain and repair their equipment effectively. Recognizing the various sections and their interconnections can lead to a more profound appreciation of functionality.

By examining the visual representations of these mechanical components, enthusiasts can delve into the specifics of assembly and disassembly. This knowledge proves invaluable for both novice and experienced operators alike, ensuring that every element is in its rightful place. A clear understanding aids in identifying potential issues before they escalate, preserving the longevity of the machine.

Ultimately, familiarity with the intricate parts enhances not only the efficiency of the vehicle but also the confidence of its user. Whether for routine maintenance or unexpected repairs, having a detailed overview at hand is an indispensable resource for anyone invested in the world of machinery.

Understanding the Ford 4600 Model

This section explores a widely recognized agricultural machine, renowned for its reliability and performance. Known for its robust construction, this model serves as a vital tool for various farming tasks, making it an essential asset for many operators.

Key Features

- Powerful engine designed for efficiency

- Durable chassis built for challenging terrains

- User-friendly controls for easy operation

- Versatile attachment options for multiple applications

Maintenance Considerations

- Regular oil changes to ensure smooth operation

- Check and replace filters to maintain engine performance

- Inspect tires and adjust pressure for optimal traction

- Keep hydraulic systems well-maintained to prevent leaks

Understanding the intricacies of this model not only aids in its maintenance but also enhances the overall efficiency of agricultural operations.

Key Components of Ford 4600

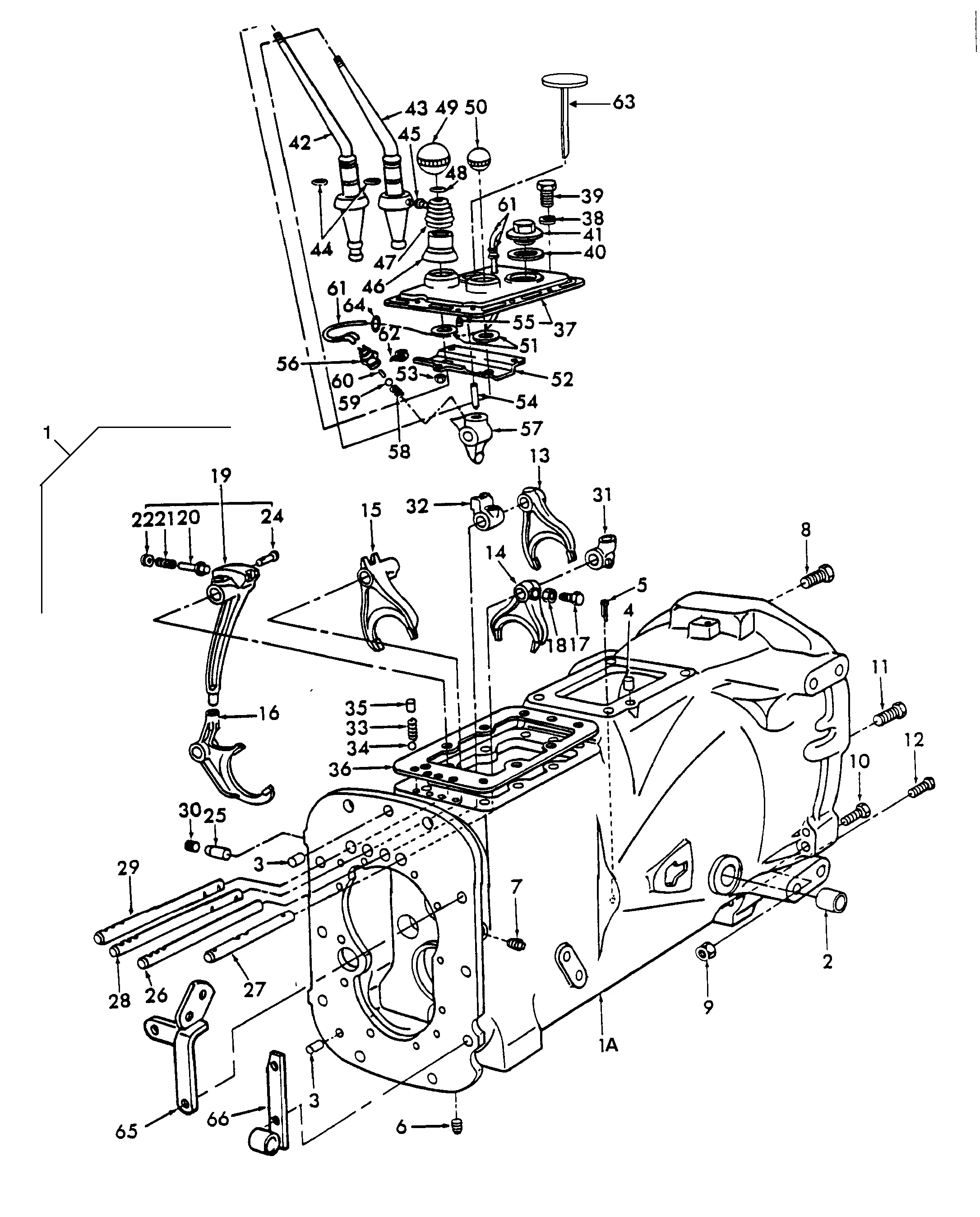

This section explores the essential elements that contribute to the functionality and performance of a specific agricultural machine. Understanding these components is crucial for maintenance and optimization of efficiency in various tasks.

Engine: The heart of the machine, providing the necessary power to drive all operations. Its reliability and performance are vital for heavy-duty applications.

Transmission: This system ensures smooth power transfer from the engine to the wheels, allowing for efficient maneuvering and operation under various conditions.

Hydraulics: An essential feature that enables the operation of attachments and implements, facilitating various agricultural tasks with precision and ease.

Chassis: The structural framework supports all components, ensuring stability and durability during operation across different terrains.

Electrical System: This network powers lights, ignition, and other electronic components, playing a critical role in the overall functionality of the equipment.

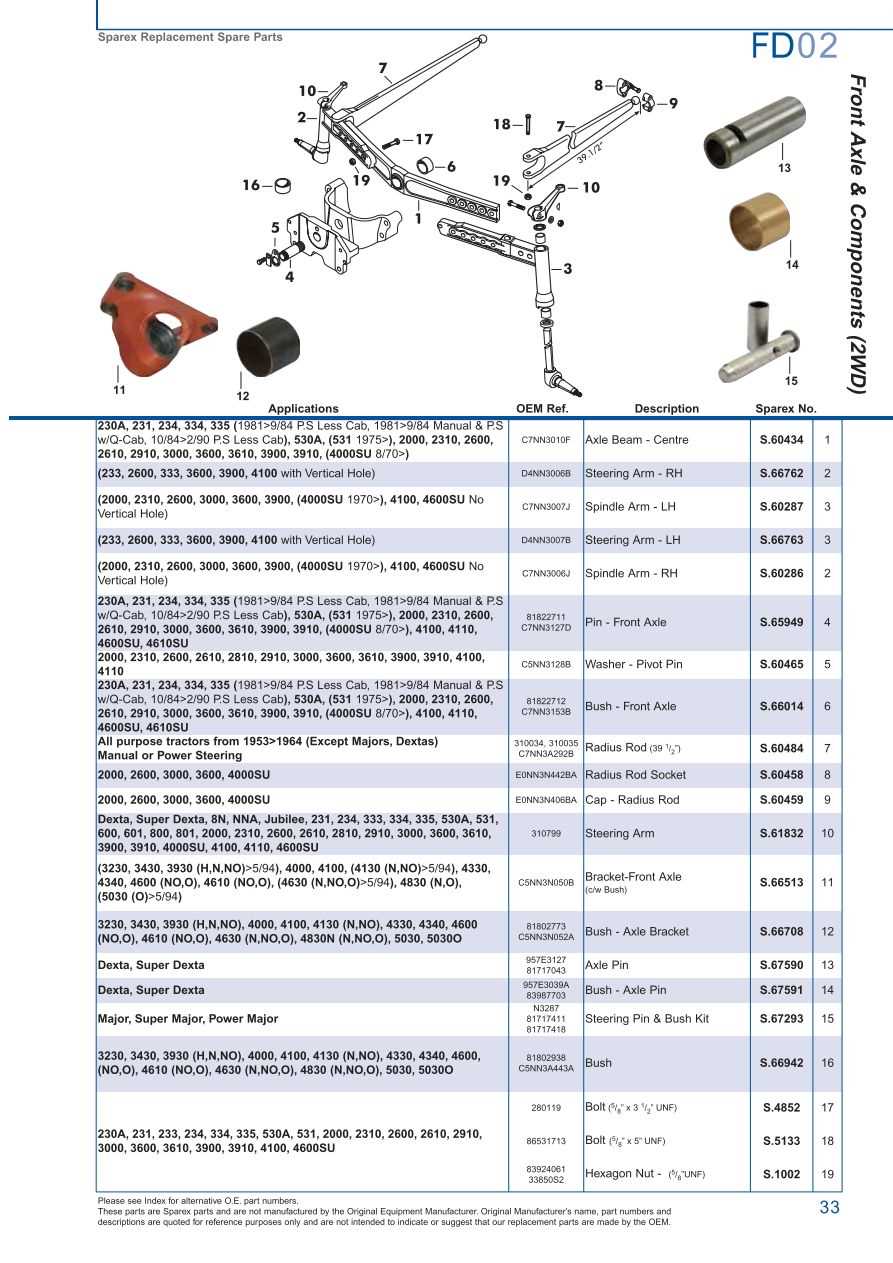

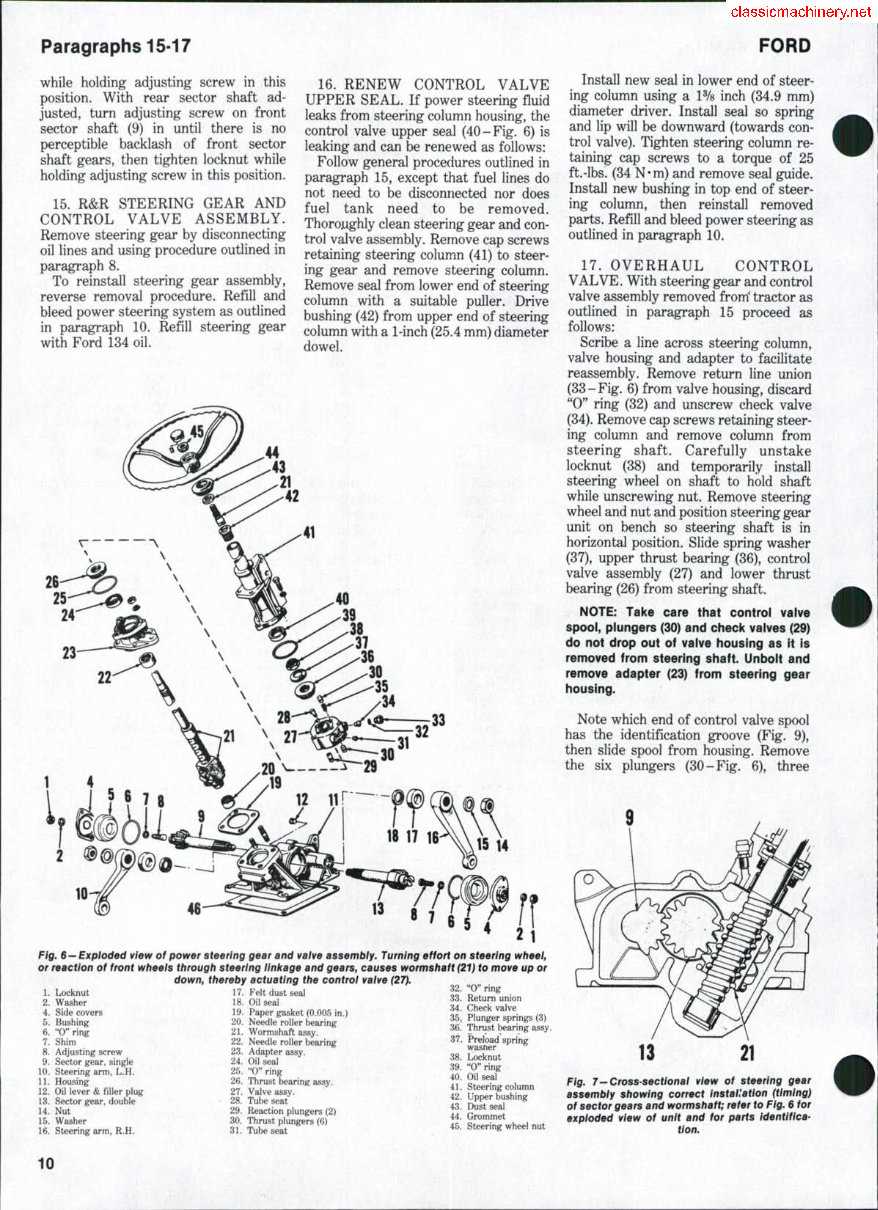

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding and maintaining machinery. They provide a clear layout of each element’s position and function, enabling users to identify what is needed for repairs or upgrades. This clarity helps in reducing errors during assembly or disassembly, ultimately saving time and resources.

Facilitating Repairs

By illustrating the relationships between different elements, these visuals aid technicians in troubleshooting issues effectively. When one knows exactly where each piece fits, it becomes easier to locate problems and implement solutions.

Enhancing Efficiency

Efficient workflow is another key advantage. With a comprehensive view of the necessary components, workers can quickly gather the required items, minimizing downtime and enhancing productivity. This leads to smoother operations overall.

| Benefits | Description |

|---|---|

| Clarity | Offers a straightforward view of component layout. |

| Accuracy | Reduces mistakes in assembly and repair processes. |

| Time-Saving | Accelerates troubleshooting and maintenance tasks. |

How to Read Parts Diagrams

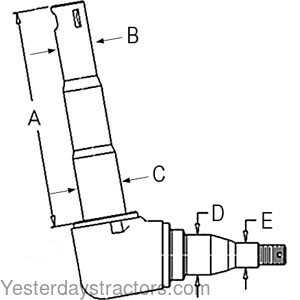

Understanding technical illustrations can greatly enhance your ability to identify components and their interrelations in machinery. By learning to interpret these visual representations, you can efficiently locate specific items and understand their roles within the overall system.

Identifying Key Elements

Begin by familiarizing yourself with the essential features of the illustration. Look for labels that denote specific components, and pay attention to numbering systems that correspond to a parts list. This foundational knowledge will make it easier to locate and differentiate various elements.

Interpreting Connections

Next, focus on how components are linked within the illustration. Arrows or lines often indicate relationships, showing how parts interact or connect with one another. Understanding these connections is crucial for grasping the overall functionality of the machinery.

Common Issues with Ford 4600

When dealing with agricultural machinery, operators often encounter a variety of challenges that can affect performance and efficiency. Understanding these prevalent problems is essential for effective maintenance and operation. By identifying common concerns, users can take proactive steps to ensure their equipment runs smoothly and lasts longer.

Engine Performance Problems

One frequent issue is related to engine performance. Symptoms may include rough idling, decreased power output, or difficulty starting. These problems can stem from various sources, such as fuel system blockages, air intake restrictions, or ignition failures. Regular checks and timely repairs can help mitigate these issues.

Hydraulic System Failures

Hydraulic system malfunctions are another common concern. Users might notice slow or unresponsive hydraulic functions, which can hinder operations significantly. This may be due to fluid leaks, worn seals, or clogged filters. Ensuring proper fluid levels and routine maintenance can help prevent such complications.

Finding Replacement Parts Easily

Locating components for machinery can often feel overwhelming, but with the right strategies, it can be a straightforward process. Understanding where to search and how to approach the task can save time and ensure you get the correct items needed for your repairs or maintenance.

Where to Look

- Online Retailers: Many websites specialize in equipment components.

- Local Dealers: Visiting nearby dealerships can provide immediate assistance.

- Salvage Yards: These locations may have used items at lower prices.

- Community Forums: Online communities can offer recommendations and tips.

Tips for Success

- Verify Compatibility: Always check that the item fits your specific model.

- Use Model Numbers: These can streamline your search and ensure accuracy.

- Keep a Record: Document previous purchases for future reference.

- Compare Prices: Look across multiple sources to find the best deals.

Aftermarket vs. OEM Parts

When it comes to maintaining or upgrading machinery, choosing the right components can significantly impact performance and longevity. Understanding the differences between various types of available options is crucial for making informed decisions that align with both budget and quality requirements.

Key Differences

- Quality: OEM components are manufactured by the original producer, ensuring compatibility and reliability, while aftermarket alternatives can vary widely in quality.

- Cost: Aftermarket options are often more affordable, but may not always match the durability of OEM selections.

- Availability: Aftermarket products might be easier to find and provide a broader range of choices.

Considerations for Selection

- Assess the specific needs of your machinery.

- Evaluate warranty and support options offered by each type.

- Consider the long-term implications of your choice on maintenance and performance.

Maintenance Tips for Longevity

Ensuring the extended lifespan of machinery requires regular attention and care. By following a few essential practices, operators can prevent common issues and maintain optimal performance. Consistent maintenance not only enhances reliability but also saves costs in the long run.

Regularly checking fluid levels is crucial. Engine oil, coolant, and hydraulic fluids should be monitored and replaced as needed to prevent wear and tear. Clean filters contribute to efficiency, so routine inspections and replacements are necessary.

Pay attention to the tires and tracks. Proper inflation and alignment help maintain traction and reduce unnecessary strain. Inspecting for any signs of damage or wear ensures safety and optimal function.

Keep the exterior clean and free from debris. Accumulated dirt can lead to overheating and mechanical failures. A clean machine also makes it easier to spot potential issues early.

Finally, follow the manufacturer’s service schedule. Regular check-ups and professional servicing ensure that all components function harmoniously, ultimately prolonging the life of the equipment.

Popular Modifications for Ford 4600

Enhancing the performance and functionality of agricultural machinery can significantly improve productivity. Many enthusiasts explore various upgrades to achieve better efficiency, power, and comfort while operating their equipment. Below are some common enhancements that operators often consider.

Engine Upgrades: Increasing horsepower and torque can be achieved through modifications such as turbocharging or installing high-performance exhaust systems. These changes can greatly enhance the machine’s capabilities.

Transmission Improvements: Upgrading the transmission allows for smoother shifting and improved overall performance. Options include installing a different gear ratio or adding a performance clutch.

Hydraulic System Enhancements: Modifying the hydraulic system can boost lifting capacity and responsiveness. Adding larger pumps or upgraded cylinders often yields significant benefits.

Comfort Features: Incorporating ergonomic seats and better cab insulation can enhance operator comfort, especially during long hours of use. These modifications lead to a more enjoyable working experience.

Tire and Wheel Changes: Switching to larger or specialized tires can improve traction and stability on various terrains, making the equipment more versatile for different tasks.

These modifications not only enhance performance but also prolong the life of the equipment, ensuring operators can tackle their tasks effectively.

Expert Recommendations on Upgrades

When it comes to enhancing machinery performance, informed decisions can lead to significant improvements. Upgrading various components can optimize efficiency, increase durability, and enhance overall functionality.

- Evaluate Performance Needs: Assess specific requirements and determine which areas need improvement.

- Prioritize Quality Components: Invest in high-quality replacements that offer better performance and longevity.

- Consult Professionals: Seek advice from experts to ensure compatibility and effectiveness of upgrades.

By following these recommendations, users can ultimately achieve a more reliable and efficient operation.

Where to Buy Quality Parts

Finding reliable components is essential for ensuring optimal performance and longevity of your machinery. With a myriad of options available, knowing where to source these items can significantly impact both efficiency and cost-effectiveness.

Online Retailers

The internet is a treasure trove for purchasing high-quality components. Numerous platforms specialize in offering a wide selection of items, often at competitive prices. Be sure to check customer reviews and ratings to gauge reliability.

Local Distributors

Visiting local suppliers can provide the advantage of immediate access to required components. Building relationships with distributors can lead to better service and potential discounts on bulk purchases.

| Source Type | Advantages | Considerations |

|---|---|---|

| Online Retailers | Wide selection, competitive pricing | Shipping times, return policies |

| Local Distributors | Immediate access, personalized service | Limited stock, potentially higher prices |

Utilizing Online Resources Effectively

In today’s digital landscape, leveraging online tools can significantly enhance your search for specific components and schematics. Knowing how to navigate these resources is essential for obtaining accurate information and optimizing your projects. This section aims to provide insights into the most effective strategies for utilizing digital platforms.

| Strategy | Description |

|---|---|

| Keyword Optimization | Use relevant keywords to narrow down your search results effectively. |

| Forum Engagement | Participate in community forums to gather insights and tips from experienced users. |

| Resource Comparison | Analyze multiple websites to find the most comprehensive and reliable information. |

| Utilize Visuals | Look for diagrams and illustrations to better understand the layout and components. |

By implementing these strategies, you can ultimately enhance your research process and make informed decisions in your projects.

Community Support and Forums

Engaging with fellow enthusiasts is essential for anyone looking to enhance their knowledge and tackle challenges related to machinery. Online platforms provide a space for users to exchange insights, share experiences, and seek assistance with repairs and upgrades.

- Find specific forums dedicated to your model.

- Participate in discussions about troubleshooting and maintenance.

- Access a wealth of shared resources and guides.

- Connect with local groups for in-person support and networking.

Utilizing these community resources can ultimately lead to more effective solutions and a deeper understanding of your equipment.