In modern agricultural systems, various equipment plays a crucial role in ensuring the efficiency and productivity of day-to-day operations. One of the most significant elements in these machines involves mechanisms that manage power transfer to external implements. Whether it’s for driving additional tools or enhancing operational capabilities, understanding these essential systems can make a substantial difference in maintaining and repairing equipment.

Over time, the components responsible for the transfer of mechanical energy may require maintenance or replacement. Familiarizing yourself with how these systems are constructed and the roles different parts play is vital for smooth operation. Detailed illustrations and breakdowns of individual components allow for easier identification and replacement, ultimately extending the lifespan of the equipment.

Overview of Ford 5000 PTO System

The power transfer mechanism of this agricultural machine is designed to deliver reliable energy distribution for various attachments. It operates through a complex setup that ensures seamless connection between the engine and external equipment. This system allows the machine to perform multiple tasks, from powering implements to driving auxiliary tools, enhancing its overall functionality on the field.

Key Components and Functionality

At the core of this mechanism lies a transmission unit that regulates the flow of energy from the engine to the equipment. The system is built with precision to handle a range of attachments, providing the necessary torque and power. Its operation depends on various controls that engage and disengage the flow, ensuring safety and efficiency during use.

Durability and Maintenance

Regular upkeep of the system is crucial for maintaining its longevity. Ensuring that all components are well-lubricated and free of wear helps prevent breakdowns. Proper inspection of the connections and gears will help identify any potential issues before they become major problems,

Main Components of the Power Take-Off System

The power transmission mechanism is a crucial part of agricultural machinery, responsible for transferring energy from the engine to various equipment attachments. This system is designed to ensure efficient and reliable operation, allowing the machine to drive different tools without interruptions.

- Clutch Assembly: Acts as the engagement point, allowing the operator to control the transmission of power between the engine and the connected equipment.

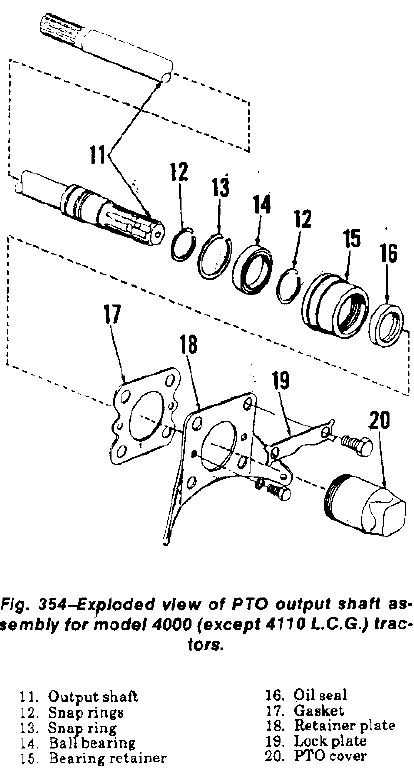

- Output Shaft: This rotating component transfers the engine’s energy to external attachments, powering them for effective performance.

- Drive Gears: These gears work together to adjust the power output, ensuring that the correct speed and torque are delivered to the connected equipment.

- Safety Shield: A protective element that covers the rotating parts, reducing the risk of injury during operation.

- Control Lever: Provides manual control over the engagement and disengagement of the power transfer mechanism, ensuring the system only runs when needed.

Understanding the PTO Shaft Functionality

The mechanism of transferring rotational power from the engine to other equipment plays a crucial role in agricultural machinery. This system allows the primary engine to operate tools that would otherwise require separate motors, ensuring efficient energy use.

The shaft is at the heart of this power transfer, linking the vehicle’s engine to external attachments. To understand its operation, it’s essential to recognize how this connection works and the components involved.

- Input and Output Transfer: The shaft sends power from the engine, allowing equipment like mowers or harvesters to perform various tasks.

- Rotational Energy: As the engine spins, this motion is transferred through the shaft, which connects to the implement, providing the necessary force to operate machinery.

- Attachment Point: The secure connection at both ends ensures stable energy transfer, preventing slippage and maximizing efficiency.

By understanding these key principles, operators can maximize equipment performance, reducing the need for additional power sources.

Power Take-Off Clutch Assembly Details

The clutch mechanism responsible for driving auxiliary equipment is a vital part of agricultural machinery, ensuring a smooth and efficient transfer of energy to external implements. Understanding the internal structure of this component is essential for maintaining optimal performance and ensuring longevity of the system. The assembly is composed of several key elements that work together to engage and disengage the power flow seamlessly.

Main Components: The core of the clutch system includes multiple interconnected parts, each playing a specific role. These components ensure that the energy transmission process happens without causing damage or strain to the equipment. Attention to detail in the arrangement of these parts guarantees reliability in demanding conditions.

Maintenance and Adjustment: Regular maintenance of the clutch system, including proper lubrication and adjustments, is crucial. Ensuring that all parts are aligned and functioning correctly can prevent premature wear and extend the service life of the machinery. Detailed inspection of the assembly should be carried out periodically to avoid potential issues.

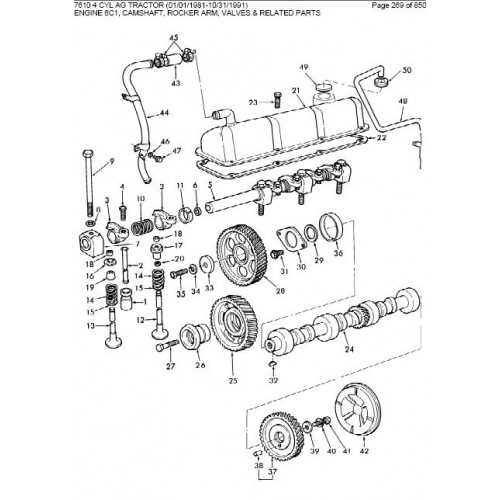

How to Identify PTO Gear Types

Understanding the different gear types is essential when working with power transmission systems in agricultural and industrial machinery. Each gear type has distinct features that determine how torque is transferred, and recognizing these characteristics can help in proper equipment maintenance and repair.

Helical Gears

Helical gears are designed with teeth that are cut at an angle to the gear’s face. This angled design allows for smoother and quieter operation compared to other gear types. They can handle more load due to the gradual engagement of the gear teeth, which reduces shock loads and wear. However, they are also more complex to manufacture.

Straight Cut Gears

Straight cut gears, also known as spur gears, have teeth that are aligned parallel to the axis of rotation. These gears are typically louder and generate more noise during operation, but they offer simplicity in design and are easier to produce. They are most effective for low-speed applications where noise is not a concern.

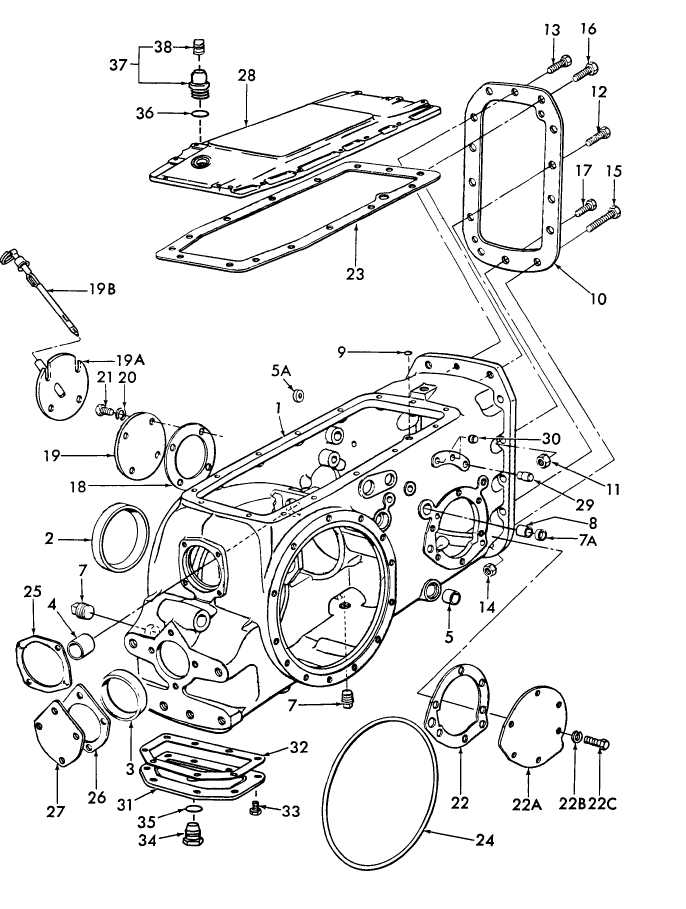

PTO Housing Parts and Maintenance

The housing unit of the power take-off mechanism plays a crucial role in the efficient functioning of agricultural machinery. Understanding its components and the necessary upkeep can significantly enhance performance and longevity. Regular inspection and maintenance are essential to ensure that all elements work seamlessly together, minimizing the risk of mechanical failure.

Key components of the housing unit include bearings, seals, and connectors, each serving a specific purpose in the overall operation. Proper maintenance of these elements involves periodic checks, lubrication, and timely replacements when necessary. Below is a summary of essential components and their functions:

| Component | Function |

|---|---|

| Bearings | Support rotational movement and reduce friction. |

| Seals | Prevent fluid leakage and protect internal parts from contaminants. |

| Connectors | Ensure secure attachments between the housing and other machinery components. |

By paying attention to these components and adhering to a regular maintenance schedule, operators can ensure that their machinery remains in optimal condition, reducing downtime and improving productivity.

Common PTO Problems and Solutions

The power take-off system is an essential component in agricultural machinery, enabling the transfer of mechanical energy to various attachments. However, like any mechanical system, it can encounter issues that may hinder performance. Understanding common challenges can help operators troubleshoot and maintain their equipment effectively.

Frequent Issues and Their Causes

One of the most prevalent problems is the inability to engage the drive. This can result from a faulty clutch mechanism or misalignment within the assembly. Additionally, abnormal noises during operation may indicate wear on internal components or insufficient lubrication. Operators should regularly inspect these elements to prevent further damage.

Effective Solutions

To address engagement issues, first check the alignment and condition of the clutch components. Adjust or replace as necessary to restore functionality. For noise-related concerns, conduct a thorough inspection of the gears and bearings, applying appropriate lubricants to minimize friction. Regular maintenance and prompt repairs are crucial in prolonging the life of the system.

Inspecting PTO Bearings and Seals

Regular examination of bearings and seals within machinery is essential for optimal performance and longevity. These components play a critical role in ensuring smooth operation and preventing fluid leaks, which can lead to significant damage. Proper maintenance and timely inspection can help identify issues before they escalate, ultimately saving time and resources.

Visual Inspection

Begin with a thorough visual assessment of the bearings and seals. Look for signs of wear, such as cracks, deformation, or discoloration. Any accumulation of grease or oil may indicate a failure in sealing, while unusual noise during operation could signal that the bearings are not functioning properly. Observing these signs early can prevent costly repairs.

Functional Testing

In addition to visual checks, functional testing is vital. Rotate the machinery to listen for any irregular sounds and assess the movement of the bearings. If there is excessive play or resistance, it may indicate that replacement is necessary. Ensuring that seals are properly seated and intact will further help in maintaining the integrity of the system.

Replacement Options for Worn PTO Parts

When it comes to addressing the deterioration of crucial components in your agricultural machinery, selecting the right alternatives is essential for maintaining performance and efficiency. As these elements wear down over time, various solutions can be considered to ensure the machinery operates smoothly and effectively.

Aftermarket Components: Many manufacturers offer aftermarket options that provide a cost-effective solution. These components often meet or exceed the original specifications and can be a great choice for those looking to save on maintenance costs without sacrificing quality.

OEM Parts: For those who prefer original equipment manufacturer items, investing in OEM replacements ensures compatibility and reliability. While these may come at a higher price, they are designed specifically for the machinery, ensuring optimal performance.

Rebuilt Units: Another viable option is opting for rebuilt units. These components have been restored to meet original standards and can provide a reliable alternative to brand-new parts at a lower cost.

Consultation with Professionals: It is often beneficial to consult with professionals who specialize in agricultural machinery. Their expertise can guide you in selecting the best alternatives suited for your specific model and usage requirements.

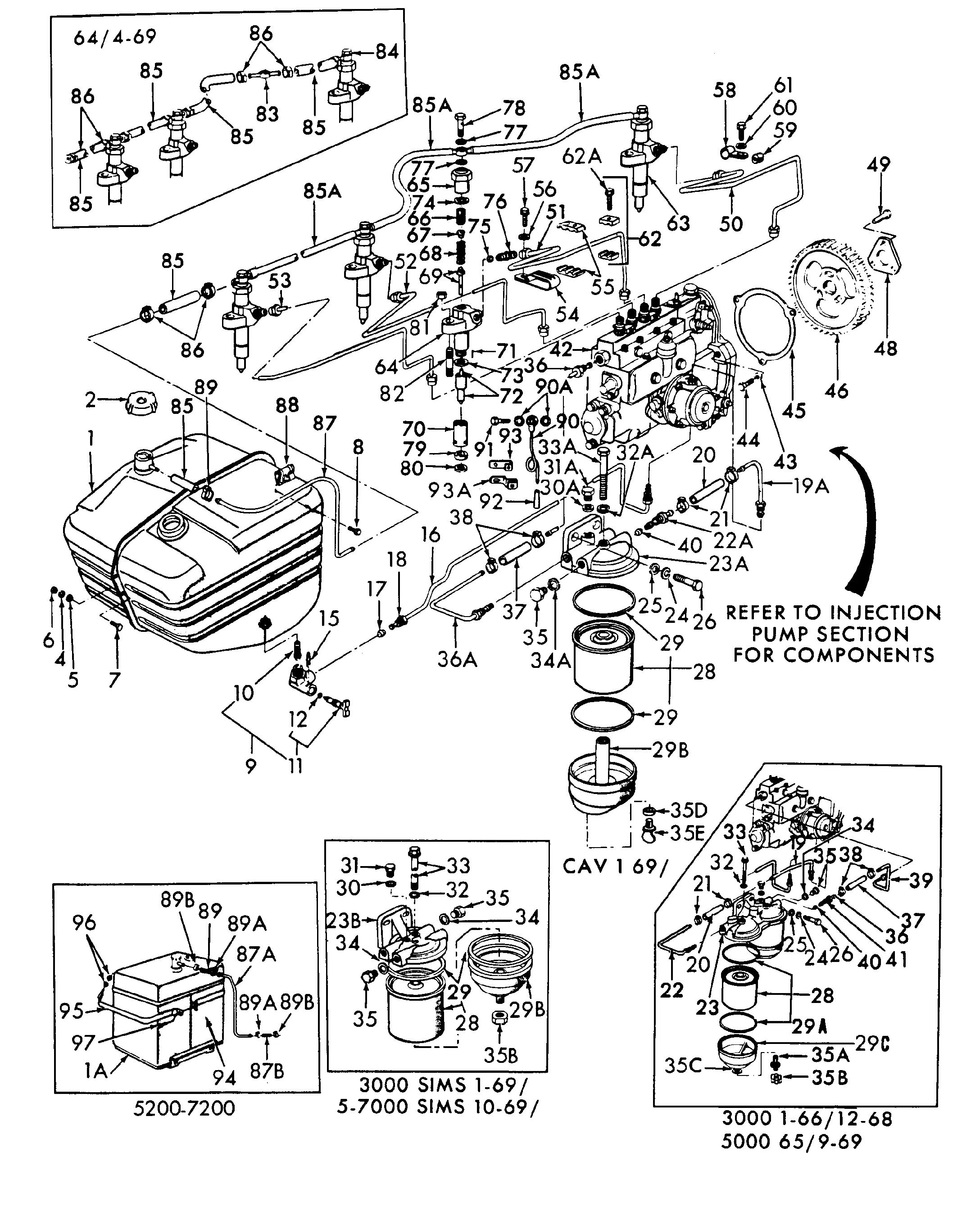

Step-by-Step Guide to PTO Diagram Reading

Understanding the schematic representation of machinery components is essential for effective operation and maintenance. This guide will simplify the process of interpreting visual representations, ensuring you can navigate through the essential elements with confidence. By following these steps, you will gain a clearer comprehension of how different parts interact within a system.

Key Elements to Identify

Before diving into the specifics, it’s crucial to familiarize yourself with the fundamental components you will encounter. Here are some key elements to look for:

| Component | Description |

|---|---|

| Input Shaft | The part that receives power from the engine. |

| Gearbox | Modifies the power output to the required speed and torque. |

| Output Shaft | Transmits power to the attached implements. |

| Clutch | Engages or disengages power flow as needed. |

Steps for Effective Reading

To efficiently interpret the schematic, follow these systematic steps:

- Start from the power source and trace the flow of energy through the various components.

- Identify the connections between elements and note any control mechanisms that may regulate their functions.

- Pay attention to any symbols or notations that indicate specific operational details or safety measures.

- Cross-reference the schematic with the machinery manual for additional context and clarification.

Best Practices for PTO Installation

Proper installation of power take-off systems is essential for ensuring optimal performance and safety. Adhering to best practices during this process can significantly enhance the functionality of your equipment while minimizing potential issues.

Preparation Steps

- Review the manufacturer’s guidelines thoroughly to understand specific requirements and recommendations.

- Gather all necessary tools and components before beginning the installation to streamline the process.

- Inspect the area for any debris or obstacles that might interfere with the installation.

Installation Guidelines

- Align the system components accurately to avoid misalignment issues during operation.

- Secure all connections firmly, ensuring there is no risk of disconnection while in use.

- Test the system at low speeds initially to confirm that everything is functioning correctly before full operation.