When exploring the intricacies of a vehicle’s drivetrain, it is crucial to familiarize oneself with the essential mechanical elements responsible for handling and control. These components are vital in ensuring that the vehicle operates smoothly, with precise steering and stability. The system responsible for distributing power to the wheels, as well as supporting the load of the vehicle, is made up of various interconnected pieces that work together seamlessly.

Each element in this system is meticulously designed to perform a specific function, contributing to the overall performance and safety of the vehicle. From the initial connection to the road surface to the complex systems of motion and rotation, understanding these key components helps in maintaining optimal functionality. Knowing how these elements interact is fundamental for any vehicle enthusiast or technician seeking to diagnose, maintain, or upgrade their system effectively.

Exploring these components requires a clear understanding of their arrangement and how they contribute to the vehicle’s overall structure. Each piece plays a unique role, from providing support to ensuring proper alignment. By delving into these intricate systems, one can gain a deeper appreciation for the engineering that makes modern vehicles reliable and efficient.

Essential Components of the Ford F350 Front Axle

When it comes to the mechanical structure that supports a vehicle’s weight and facilitates smooth movement, several key elements are involved. These components play an integral role in maintaining balance, traction, and stability, allowing the vehicle to perform optimally under various conditions. Understanding these elements is crucial for ensuring the reliability and durability of the system responsible for distributing power to the wheels. Each part has a specific function that contributes to overall performance and longevity.

Suspension assembly is a vital part of this system, providing the necessary flexibility for handling bumps and uneven surfaces. It is designed to absorb shocks while keeping the wheels aligned with the rest of the structure. Another significant element is the steering knuckle, which connects the suspension and steering components, enabling precise control during turns and maneuvers.

Additionally, the bearing housing is essential for supporting rotating components, ensuring smooth movement while minimizing friction. The tie rod and pitman arm are also crucial in linking the steering system to the wheels, allowing for direct feedback and responsive handling. Each of these elements contributes to the overall efficiency and safety of the vehicle.

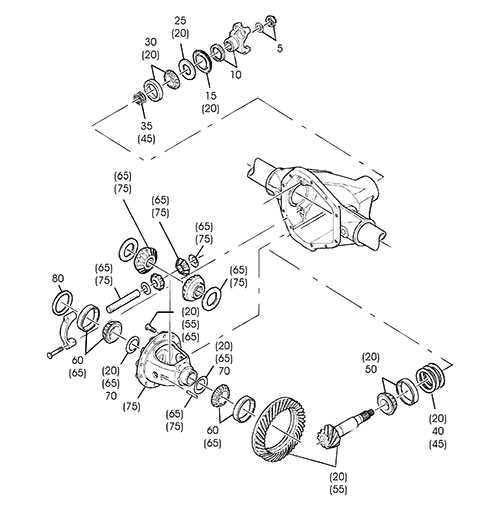

Understanding the Ford F350 Axle Assembly

The assembly of the wheel support system in heavy-duty vehicles is crucial for ensuring reliable performance and durability. The system consists of various components that interact to provide stability and efficient power transmission to the wheels. Proper knowledge of these elements and their roles is essential for anyone involved in maintenance or repair tasks.

Main Elements of the Wheel Support System

- Housing: This encases the internal mechanisms and keeps them secure.

- Spindle: Connects to the wheel and provides support during movement.

- Bearings: Enable smooth rotation of the wheels by minimizing friction.

- Seals: Prevent dirt and moisture from entering sensitive parts.

- U-joints: Allow flexibility in the drive shaft while maintaining power transmission.

Functionality and Importance

Each of these components works in harmony to ensure the vehicle maintains proper balance under heavy loads. The system distributes the weight evenly and helps in managing the stresses that come with demanding tasks. Over time, wear and tear can affect the system’s efficiency, so regular inspections and maintenance are essential to prolong the lifespan of the vehicle.

Key Parts of the F350 Front Suspension

The suspension system is a critical element in maintaining vehicle stability and handling. It is responsible for providing a smooth ride by absorbing shocks and distributing the vehicle’s weight evenly. In the context of heavy-duty trucks, this system must withstand high stresses and offer durability under challenging conditions. Key components work together to ensure proper alignment, steering, and control, all of which are vital for safe and efficient operation.

Key Components

One of the primary elements is the steering knuckle, which connects the wheel to the suspension and allows for turning motion. This component is essential for steering precision and the smooth rotation of the wheels. Another critical part is the control arm, which links the vehicle’s frame to the suspension system, providing stability and controlling the up-and-down movement of the wheels. These arms are often paired with bushings to minimize wear and reduce noise during operation.

Shock Absorbers and Springs

Shock absorbers are another key part of the system, responsible for dampening the impact of rough surfaces and preventing excessive bouncing. They play a crucial role in maintaining comfort while driving. Coupled with coil springs or leaf springs, they ensure the vehicle remains level, even when carrying heavy loads. Together, these components provide a balanced and controlled ride, ensuring the safety and performance of the vehicle.

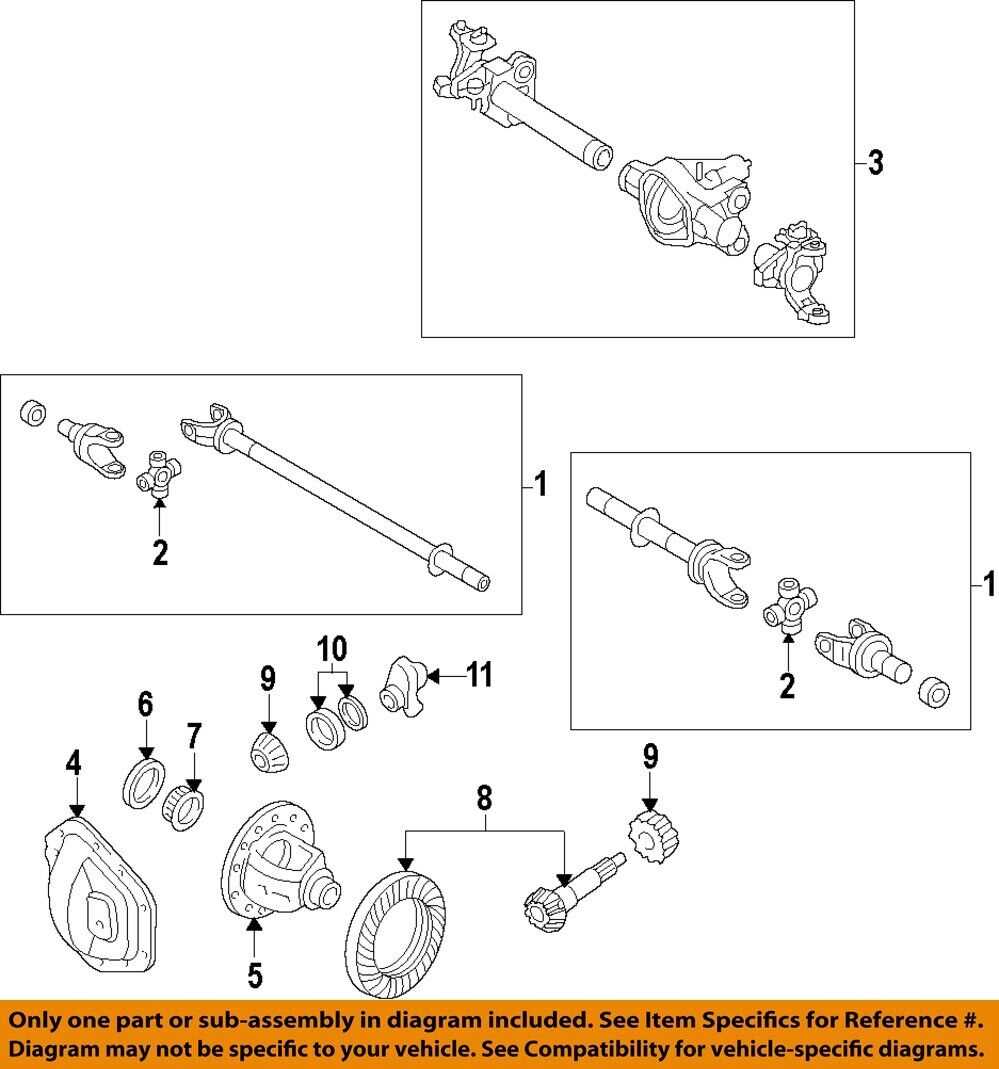

How to Identify Ford F350 Axle Components

Recognizing the key elements of a vehicle’s suspension and steering mechanism is crucial for any enthusiast or technician. Understanding the various components that make up this system helps in both maintenance and troubleshooting. When dealing with a heavy-duty truck, it is important to identify these key elements correctly to ensure proper functionality and safety.

Step 1: Start by examining the central housing, which is responsible for connecting the wheel hubs and transmitting power from the transmission to the wheels. It serves as the core structure for holding other components in place.

Step 2: Pay attention to the brake assemblies attached to the housing, typically including rotors, pads, and calipers, which are vital for stopping the vehicle effectively. These components can be recognized by their round shape and heavy construction.

Step 3: Look for the steering knuckles, which are the pivot points for the wheels. They are usually located between the suspension system and the wheel hubs, providing the ability to turn the wheels while ensuring stability.

Step 4: Identify the shock absorbers and springs, which are designed to absorb shocks from the road, reducing wear on the vehicle and improving overall ride comfort.

Step 5: Finally, check for the drive shafts that connect the differential to the wheel hubs. These are responsible for transmitting rotational power from the engine to the wheels, often visible running parallel to the vehicle’s main structure.

Step-by-Step Ford F350 Axle Disassembly

Disassembling the wheel assembly can be a complex task, but with careful planning and the right tools, you can ensure a smooth process. The goal is to separate the key components of the suspension system while maintaining the integrity of each part for reassembly. In this guide, we will walk you through the essential steps required to disassemble the suspension assembly of your vehicle, ensuring a thorough understanding of the procedure.

Preparation and Tools

Before starting, gather all necessary tools and safety equipment. You will need a variety of wrenches, sockets, and possibly a hydraulic jack or lift to elevate the vehicle. Ensure that you have a clean workspace to keep the components organized. Make sure the vehicle is securely lifted and positioned to prevent any accidents during the process.

Disassembly Procedure

Begin by loosening the bolts securing the wheel to the suspension. Once the wheels are removed, focus on the main assembly securing the driveshaft and related components. It is crucial to carefully note the placement of each piece, as misplacement during reassembly can lead to issues. Gently remove any bolts connecting the suspension components, starting from the outermost parts and working inward. Take special care when handling heavy components to avoid damage or injury.

After disassembling the primary components, inspect all parts for wear or damage. If necessary, order replacements in advance to avoid delays in reassembly. This step will also allow you to clean and lubricate the components for better performance in the future. Reassembling everything correctly will ensure optimal function when you put the vehicle back in operation.

Common Issues with Front Axle Parts

When it comes to the key components that ensure smooth and safe vehicle handling, certain elements are prone to wear and tear. Over time, these vital mechanisms can develop issues that compromise performance and lead to costly repairs. Identifying these problems early can help prevent more serious damage, ensuring a smoother ride and prolonging the lifespan of the vehicle.

Worn Bearings and Bushings

One of the most common challenges is the deterioration of the bearings and bushings that support the wheel assemblies. These components are crucial for maintaining stability and reducing vibrations. As they wear out, you may experience an uneven ride or hear unusual noises coming from the wheel area. Excessive play or movement in these areas can also lead to misalignment, affecting handling and steering precision.

Damage to Joints and Shafts

Another frequent issue involves the joints and shafts that connect the wheels to the rest of the suspension system. These elements can suffer from fatigue, resulting in squeaks, grinding sounds, or a loss of smooth steering ability. Additionally, if a shaft becomes bent or misaligned, it can cause significant wear on surrounding components, leading to more extensive damage.

| Component | Common Issue | Potential Consequence |

|---|---|---|

| Bearings | Worn or damaged | Vibrations, steering instability |

| Bushings | Cracked or degraded | Unsteady handling, noise |

| Joints | Excessive wear or damage | Grinding sounds, loss of responsiveness |

| Shafts | Bent or misaligned | Premature wear on other components, reduced performance |

Maintenance Tips for the F350 Axle

Regular upkeep of the vehicle’s suspension system is essential to ensure optimal performance and longevity. Proper maintenance can prevent unnecessary wear and tear on key components, leading to smoother operation and improved safety on the road. Understanding how to maintain these critical elements will help avoid costly repairs and keep your vehicle in top condition for years to come.

Routine Inspections

Conducting regular inspections of the vehicle’s suspension setup is key to catching potential issues early. Look for signs of wear, such as unusual noises or vibrations when driving. Additionally, inspect for any fluid leaks, cracks, or damage that may indicate a problem with the system’s integrity. It’s important to address any abnormalities as soon as they are noticed to avoid more extensive damage over time.

Lubrication and Cleaning

Keeping the suspension components properly lubricated is crucial for preventing friction that can lead to premature wear. Regularly apply the appropriate lubricant to the necessary components as recommended by the manufacturer. Additionally, clean any dirt or debris that accumulates around the suspension system, as excessive buildup can hinder movement and cause damage. Maintenance in these areas helps maintain smooth functionality and extends the lifespan of the system.

Upgrading Your F350 Front Axle System

Enhancing the suspension and steering system of your heavy-duty vehicle can significantly improve its performance, stability, and overall driving experience. Whether you’re looking to boost off-road capabilities or enhance handling during daily use, upgrading these essential components can make a noticeable difference. This guide will explore the key aspects of improving your vehicle’s steering mechanisms and suspension assemblies for a more robust and efficient ride.

Key Considerations for System Enhancement

Before diving into the specific upgrades, it’s important to assess your driving needs and the type of terrain you frequently navigate. Upgrading your suspension system may require balancing the durability of individual components with the comfort and control you desire. Investing in higher-quality materials and advanced designs will help ensure that your vehicle can handle challenging conditions, whether you are hauling heavy loads or driving over rough landscapes.

Essential Components for a Successful Upgrade

Several elements play a crucial role in optimizing the performance of your vehicle’s suspension and steering mechanisms. From reinforced housings to enhanced steering arms, each component contributes to a more stable and resilient system. Choosing parts that are both durable and suitable for your specific use case will result in a noticeable improvement in vehicle handling and longevity.

| Component | Description | Benefits of Upgrading |

|---|---|---|

| Steering Stabilizers | Reduces steering wheel wobble and improves handling stability. | Enhanced control, smoother ride, reduced steering fatigue. |

| Leaf Springs | Reinforced springs that support heavy loads and provide better suspension. | Increased weight capacity, improved durability, better shock absorption. |

| Ball Joints | Connects the suspension components to the steering assembly, allowing for movement. | Improved steering precision, reduced wear on other components. |

| Control Arms | Metal arms that allow for smooth movement of the suspension system. | Increased strength, enhanced steering response. |

By focusing on these key components and considering the unique demands of your driving environment, you can make informed decisions when upgrading your vehicle’s steering and suspension system. This will lead to improved handling, safety, and overall performance across a range of driving conditions.

Tools Required for Front Axle Repair

When working on the suspension system of a heavy-duty vehicle, having the right tools is essential for ensuring a successful repair. Whether you’re replacing worn components or performing a complete rebuild, the correct equipment will make the task smoother and safer. Below is a list of tools you will need to get the job done efficiently.

- Hydraulic Jack and Jack Stands: These are critical for safely lifting the vehicle off the ground and securing it while you work on the suspension system.

- Socket Set: A complete set of sockets, including deep sockets, is essential for removing bolts of various sizes. You’ll need both standard and metric sizes for different fasteners.

- Torque Wrench: To ensure all fasteners are tightened to the manufacturer’s specifications, a torque wrench is necessary. This tool prevents over-tightening and ensures safety.

- Pry Bar: A pry bar will help with separating stubborn components, such as bushings and bearings, that may be stuck together after years of use.

- Ball Joint Press: This tool is designed for removing and installing ball joints. It helps avoid damaging the components during the process.

- Impact Wrench: An electric or pneumatic impact wrench can significantly speed up the removal of larger bolts and fasteners.

- Hammer and Mallet: A hammer is useful for gently tapping components into place, while a rubber mallet can be used to avoid damaging delicate parts.

- Seal Puller: For removing seals and bearings, a seal puller is a handy tool that ensures you don’t damage the housing or other components.

- Snap Ring Pliers: Snap rings often secure various components. Having a pair of snap ring pliers will make their removal and installation much easier.

- Measuring Tape: Accurate measurements are important for checking alignment and ensuring that replacement components are the correct size.

Having these tools readily available will make the repair process much more manageable, saving both time and effort. It’s always a good idea to double-check your toolbox before starting the job to ensure nothing is missing or broken.

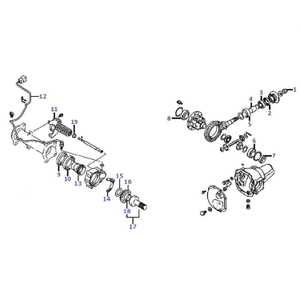

F350 Front Axle Parts Diagram Overview

This section provides an overview of the essential components that contribute to the functionality of the vehicle’s front suspension system. These elements work together to ensure stability, steering precision, and load distribution, which are crucial for both performance and safety. Understanding how each part interacts can help in maintenance, troubleshooting, and enhancing overall vehicle durability.

Key Components of the Suspension System

The assembly includes critical elements such as the central hub, suspension beams, and steering mechanisms. These components allow for the distribution of forces encountered during driving, ensuring smooth operation on various terrains. Additionally, support brackets and linkages maintain alignment and reduce wear on moving parts.

Maintenance Considerations

Regular inspection of these crucial parts is vital for preventing excessive wear and tear. Components like bearings, bushings, and seals play key roles in absorbing shocks and preventing damage to other elements. Neglecting these checks can lead to misalignment, reduced handling capabilities, and compromised safety.

Where to Find Replacement Axle Parts

When it comes to restoring or upgrading the key components that support the movement and stability of your vehicle, locating the right replacements is essential. Whether you are dealing with worn-out or damaged components, finding high-quality alternatives can ensure your vehicle operates smoothly and safely. In this section, we’ll explore various reliable sources where you can acquire the necessary components to get your vehicle back in shape.

Authorized Dealers and Manufacturers

One of the most dependable options is to purchase directly from the original equipment manufacturers (OEM). These suppliers provide components that are specifically designed for your vehicle model, ensuring compatibility and performance. While OEM options can be more expensive, they are often built to last and come with manufacturer warranties. It is worth checking with local dealerships or their online platforms to see if they stock the parts you need.

Aftermarket Suppliers

If you are looking for more affordable alternatives, aftermarket suppliers offer a wide variety of options. These parts, while not from the original manufacturer, are often produced by third-party companies and can be just as reliable. It is important to check reviews and specifications before making a purchase to ensure that the quality meets your expectations. Many online marketplaces and specialized stores focus on providing aftermarket components for a range of vehicles.

| Source | Advantages | Disadvantages |

|---|---|---|

| OEM Dealers | Guaranteed compatibility, often comes with warranty | Higher cost |

| Aftermarket Suppliers | More affordable, a variety of options | May vary in quality, less guaranteed compatibility |

| Online Marketplaces | Convenient, competitive prices | Risk of counterfeit items, requires careful selection |