In the realm of automotive maintenance and repair, a comprehensive guide to components is essential for both enthusiasts and professionals. This invaluable resource allows for a clear visualization of various elements and their interconnections within a vehicle’s structure. By exploring these detailed illustrations, individuals can enhance their knowledge and tackle repairs with greater confidence.

The intricate nature of machinery demands precision and attention to detail. Recognizing how each segment fits into the larger framework not only aids in troubleshooting but also in optimizing performance. Familiarity with these schematics empowers users to make informed decisions when sourcing replacements or undertaking modifications.

Whether you are restoring a classic model or conducting routine maintenance on a modern machine, having access to well-organized representations of assembly layouts is crucial. These visuals serve as a roadmap, guiding users through the complexities of automotive design and ensuring a more effective approach to vehicle care.

Understanding Ford NAA Parts

Grasping the components of classic machinery is essential for maintenance and restoration. Each element plays a pivotal role in ensuring optimal functionality and longevity. This section aims to elucidate the various elements that constitute these vintage models, providing insights for enthusiasts and restorers alike.

Key Components

- Engine assembly: The heart of the machine, responsible for power generation.

- Transmission system: Facilitates movement by transferring power to the wheels.

- Hydraulic systems: Crucial for operating attachments and implements.

Maintenance Tips

- Regularly inspect components for wear and tear.

- Keep lubrication consistent to ensure smooth operation.

- Document any replacements for future reference.

History of the Ford NAA Model

This section delves into the evolution of a significant agricultural machine that emerged during the mid-20th century. Renowned for its robust performance and versatility, this model played a crucial role in transforming farming practices and enhancing productivity on various terrains. Its introduction marked a pivotal moment in agricultural machinery, combining innovative design with practical functionality.

Development and Features

The journey of this machine began in the post-war era, a time characterized by technological advancements and a growing demand for efficient farming solutions. Engineers and designers focused on creating a vehicle that could withstand rigorous use while also providing ease of operation. Key features included a powerful engine, a user-friendly interface, and adaptability to various attachments, making it a favorite among farmers.

Impact on Agriculture

This model significantly influenced agricultural practices, allowing for increased efficiency in plowing, cultivating, and transporting goods. Farmers experienced a remarkable reduction in labor intensity and time spent on tasks, which contributed to higher yields and improved economic viability. Its legacy continues, as many vintage models are still in use today, cherished for their reliability and nostalgic value.

| Year | Key Milestones |

|---|---|

| 1948 | Initial concept development |

| 1950 | Official launch of the model |

| 1960 | Introduction of enhanced features |

| 1970 | Legacy models still in operation |

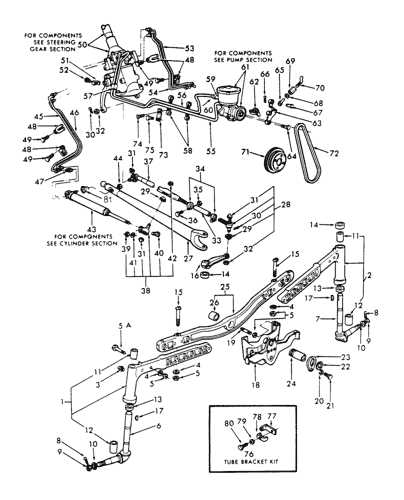

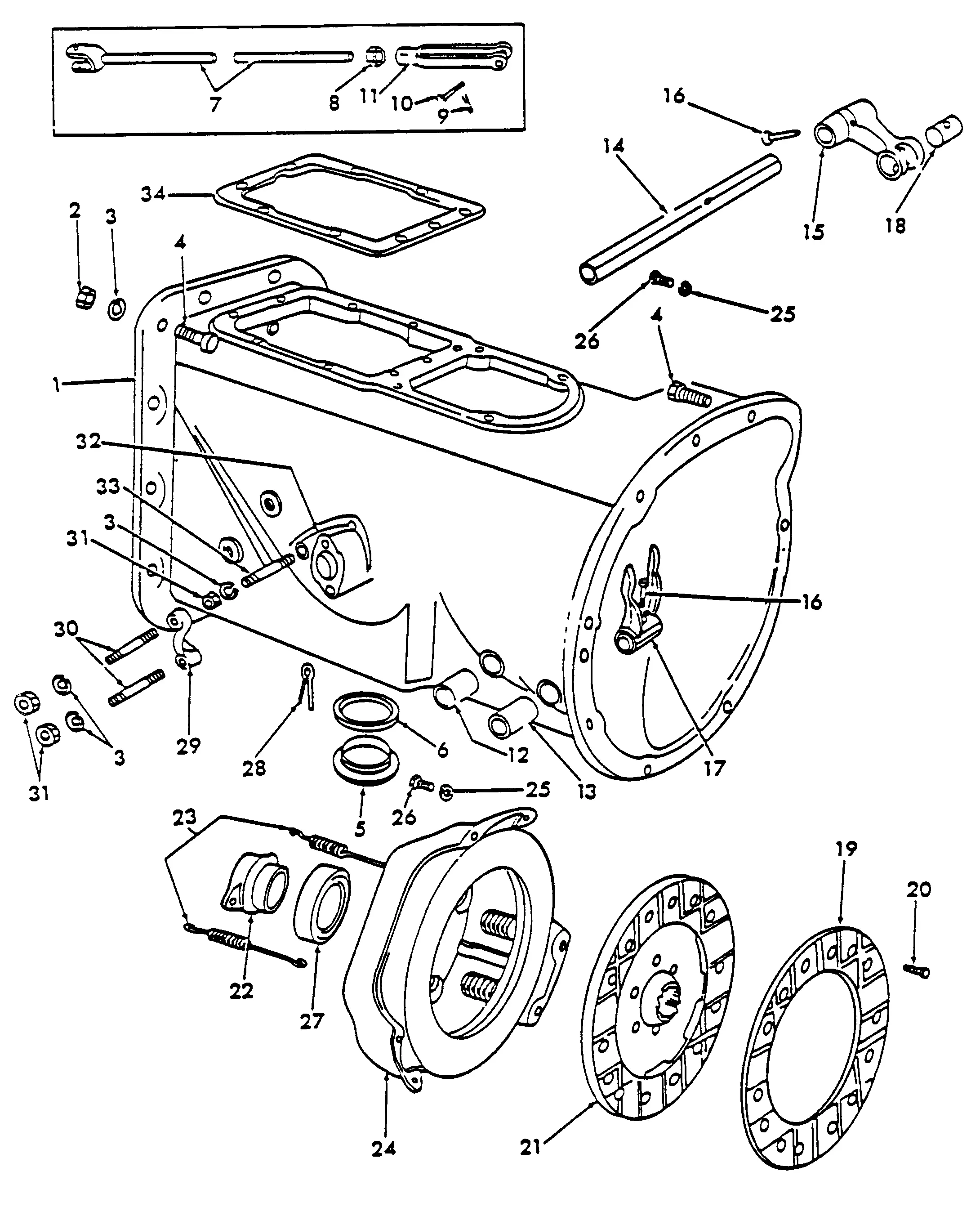

Importance of Parts Diagrams

Understanding the components of any mechanical system is essential for efficient maintenance and repair. Visual representations serve as valuable tools for both professionals and enthusiasts, facilitating easier identification and troubleshooting.

- Enhances comprehension of assembly and disassembly processes.

- Improves accuracy when ordering replacements.

- Streamlines the identification of potential issues.

Additionally, these visual aids can:

- Reduce the risk of errors during repairs.

- Provide a clear reference for maintenance schedules.

- Support training and skill development for new technicians.

Key Components of Ford NAA

This section explores the essential elements that contribute to the functionality and performance of this classic machinery. Understanding these components is crucial for maintenance and optimal operation.

- Engine: The heart of the machine, providing power and efficiency.

- Transmission: Responsible for transferring power to the wheels, allowing for smooth operation.

- Hydraulic System: Enables lifting and controlling attachments, enhancing versatility.

- Electrical System: Powers lights and starting mechanisms, ensuring reliable operation.

- Chassis: The frame that supports the entire structure, contributing to stability and strength.

Each of these components plays a vital role in the overall functionality, and understanding their interplay is essential for anyone looking to delve deeper into the workings of this equipment.

Where to Find Diagrams

Finding visual representations of components and their arrangements can be crucial for effective maintenance and repair. Various sources provide comprehensive illustrations that can aid in understanding the layout and function of specific elements. Here are some recommended avenues to explore when seeking these valuable resources.

Online Resources

The internet is a treasure trove of information. Websites dedicated to automotive enthusiasts often host a variety of schematics. Consider visiting forums and specialized blogs where users share their own collections. Additionally, manufacturer websites may offer downloadable content or interactive tools that facilitate navigation through different systems.

Print and Digital Manuals

Technical manuals, both in print and digital formats, are indispensable. Look for service guides that provide detailed visuals alongside explanations. These documents often include exploded views and assembly instructions, making them perfect for hands-on projects. Local libraries or bookstores may have a selection, while online platforms frequently offer e-books that can be purchased or rented.

Interpreting the Diagrams Effectively

Understanding technical illustrations can significantly enhance your ability to work with machinery components. These visual representations provide critical insights into how various elements interact and function within the overall system. Mastering the art of reading these illustrations not only saves time but also ensures accuracy in repairs and maintenance.

To begin, familiarize yourself with the legend and any accompanying symbols. Each icon conveys specific information about the components, such as their location, orientation, and relationship to one another. Pay close attention to the details, as even small variations can lead to significant differences in assembly or disassembly processes.

Next, consider the layout of the illustration. Typically, parts are arranged logically, often following the flow of operations or assembly sequence. This organized structure allows you to visualize the sequence in which tasks should be performed, making it easier to troubleshoot issues and streamline repairs.

Finally, practice makes perfect. The more you engage with these visual tools, the more intuitive they become. Take the time to cross-reference with your manual or other reliable sources. This approach will deepen your understanding and boost your confidence when tackling complex mechanical tasks.

Common Issues with Parts

When it comes to automotive components, several frequent challenges can arise, impacting functionality and performance. Understanding these issues is essential for maintaining optimal operation and ensuring longevity.

One prevalent problem involves compatibility between different elements, which can lead to installation difficulties or subpar performance. Additionally, wear and tear over time can result in decreased efficiency, making regular inspections crucial. Environmental factors, such as corrosion and exposure to harsh conditions, also play a significant role in the deterioration of these components.

Another concern is the quality of replacements available in the market. Inferior alternatives may not only fail to meet specifications but can also cause further damage. Staying informed about trusted sources for high-quality replacements can mitigate these risks.

Maintenance Tips for Ford NAA

Proper upkeep of your machinery is crucial for ensuring optimal performance and longevity. Regular attention to various components can prevent breakdowns and enhance efficiency. Here are some essential practices to consider for maintaining your equipment effectively.

Regular Inspections

Conduct routine checks on all critical systems. Look for signs of wear and tear, such as leaks, cracks, or unusual noises. Pay close attention to the engine, hydraulic system, and transmission. Identifying issues early can save time and resources in the long run.

Fluid Management

Ensure all fluids are at the appropriate levels and replace them as needed. This includes oil, coolant, and hydraulic fluid. Using high-quality lubricants can significantly reduce friction and improve overall performance. Regular fluid changes are essential to prevent overheating and ensure smooth operation.

Comparing Parts with Other Models

In the world of automotive components, understanding how various pieces fit and function across different models can be crucial for enthusiasts and professionals alike. This section aims to highlight the similarities and differences in components among various vehicle lineages, providing insights that can enhance maintenance and restoration efforts.

Identifying Commonalities: Many vehicles share design principles and manufacturing techniques, leading to interchangeable components. Recognizing these overlaps can save time and resources when sourcing replacements.

Examining Unique Features: While some elements may appear similar, unique characteristics can influence performance and compatibility. Delving into these specifics can prevent potential issues in installations.

Ultimately, understanding these comparisons not only broadens knowledge but also aids in making informed decisions for repairs and upgrades.

Essential Tools for Repairs

When it comes to maintaining and fixing machinery, having the right instruments at your disposal is crucial. The effectiveness of any repair job largely hinges on the quality and appropriateness of the tools used. A well-equipped workspace not only streamlines the repair process but also enhances safety and efficiency.

Basic Hand Tools

Every repair enthusiast should start with a solid set of hand tools. These typically include wrenches, screwdrivers, and pliers. Wrenches come in various sizes and types, making them indispensable for loosening or tightening nuts and bolts. Screwdrivers, available in both flat and Phillips styles, are essential for handling screws, while pliers are perfect for gripping, twisting, and cutting wire or other materials.

Power Tools for Efficiency

In addition to hand tools, incorporating power tools into your toolkit can significantly increase your efficiency. Drills and impact drivers are particularly useful for quickly creating holes or driving fasteners. Using power tools not only speeds up the repair process but also reduces physical strain, allowing for more complex tasks to be completed with ease.

Upgrading Ford NAA Components

Enhancing the performance and efficiency of vintage machinery can significantly improve their functionality and longevity. This section explores the various avenues for upgrading critical components, ensuring a smoother operation and greater reliability in everyday tasks.

When considering enhancements, focus on the following key areas:

- Engine Performance

- Transmission Efficiency

- Hydraulic Systems

- Electrical Components

Each area offers unique opportunities for improvement:

- Engine Performance: Upgrading to a modern carburetor or fuel injection system can enhance fuel efficiency and increase horsepower.

- Transmission Efficiency: Consider replacing worn gears or adding a higher-quality oil to ensure smoother shifting and better overall performance.

- Hydraulic Systems: Upgrading hoses and fittings can improve responsiveness and reduce leakage, enhancing lifting capabilities.

- Electrical Components: Modernizing the electrical system with a more efficient alternator and better wiring can prevent issues related to power supply.

By focusing on these areas, owners can achieve significant improvements in both performance and reliability, breathing new life into their machinery while ensuring it remains effective for years to come.

Resources for Enthusiasts and Owners

This section aims to provide a wealth of information and tools for those passionate about their vehicles. Whether you’re a seasoned collector or a new owner, having access to reliable resources can enhance your experience and facilitate maintenance and restoration projects.

Online Communities

Joining online forums and social media groups dedicated to automotive enthusiasts allows for knowledge sharing and networking. Members often share tips, tricks, and advice on everything from restoration techniques to troubleshooting common issues.

Technical Manuals and Guides

Accessing comprehensive manuals and instructional guides is crucial for understanding your vehicle’s intricacies. Many resources are available online, offering detailed information on maintenance schedules, repair processes, and upgrade options.